A kind of synthetic method of graphene reverse osmosis composite membrane

A technology of graphene compounding and synthesis method, which is applied in the field of materials, can solve problems such as not being seen, and achieve the effects of low cost, high degree of dispersion, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

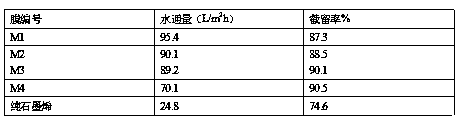

Examples

Embodiment 1

[0030] (1) In a flask, add graphene containing chloride (4.0 g), triethylamine (10 mL) and water (200 mL), and react with ultrasound. Aqueous ammonia (20 mL) was added and heated to reflux for 1 hour. Pour it into 300 mL of water, add dilute hydrochloric acid dropwise to adjust the pH to around 7. Filter, wash, and dry at 80°C for 10 hours. 3.7 g of amino-based graphene was obtained. The specific surface area of amine-based graphene is 680 square meters per gram.

[0031] (2) In a flask, add amine-based graphene (1.0 g), add acryloyl chloride (12 g) and acetonitrile (30 mL). After ultrasonic dispersion for 1 hour, triethylamine was added and stirred for 3 hours. Heat to reflux for 3 hours. Filter, discard the filtrate, the solid powder is the intermediate, and wash with acetonitrile. Add acetonitrile (30 mL), acrylamide (4 g), and ammonium persulfate (0.4 g) to the intermediate. Heat at 80°C and stir for 12 hours. Adjust the concentration of the reaction system, and ...

Embodiment 2

[0033] (1) In a flask, add graphene containing chloride (1.00 g), sodium carbonate (0.80 g) and acetonitrile (20 mL), and react with ultrasound. Ethylenediamine (2 mL) was added and heated to reflux for 5 hours. Pour it into 30 mL of water, add dilute hydrochloric acid dropwise to adjust the pH to about 7. Filter, wash, and dry at 80°C for 10 hours. 0.94 g of amino-based graphene was obtained. The specific surface area of amine-based graphene is 700 square meters per gram.

[0034] (2) In a flask, add amine-based graphene (0.8 g), add 3-butenoyl chloride (18 g) and acetonitrile (30 mL). After ultrasonic dispersion for 1 hour, triethylamine was added and stirred for 3 hours. Heat to reflux for 3 hours. Filter, discard the filtrate, the solid powder is the intermediate, add acetonitrile to wash. Acetonitrile (30 mL), ethyl acrylate (24 g) and azobisisobutyronitrile (1.4 g) were added to the intermediate. Heat to reflux for 17 hours. Adjust the concentration of the reac...

Embodiment 3

[0036] (1) In the flask, add graphene containing chloride (1.00 g), triethylamine (1 mL) and acetonitrile (20 mL), and react with ultrasound. Add 1,3-propanediamine (4 mL), and heat to reflux for 10 hours. Pour it into 30 mL of water, add dilute hydrochloric acid dropwise to adjust the pH to about 7. Filter, wash, and dry by heating at 80°C for 12 hours. 0.85 g of amino-based graphene was obtained. The specific surface area of amine-based graphene is 740 square meters per gram.

[0037] (2) In a flask, add amine-based graphene (0.80 g), add cinnamoyl chloride (16 g) and acetonitrile (30 mL). After ultrasonic dispersion for 1 hour, triethylamine was added and stirred for 3 hours. Heat to reflux for 3 hours. Filter, discard the filtrate, the solid powder is the intermediate, add acetonitrile to wash. Acetonitrile (30 mL), 2-methyl methacrylate (20 g) and benzoyl peroxide (0.8 g) were then added to the intermediate. Heat at 100°C and stir for 10 hours. Adjust the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com