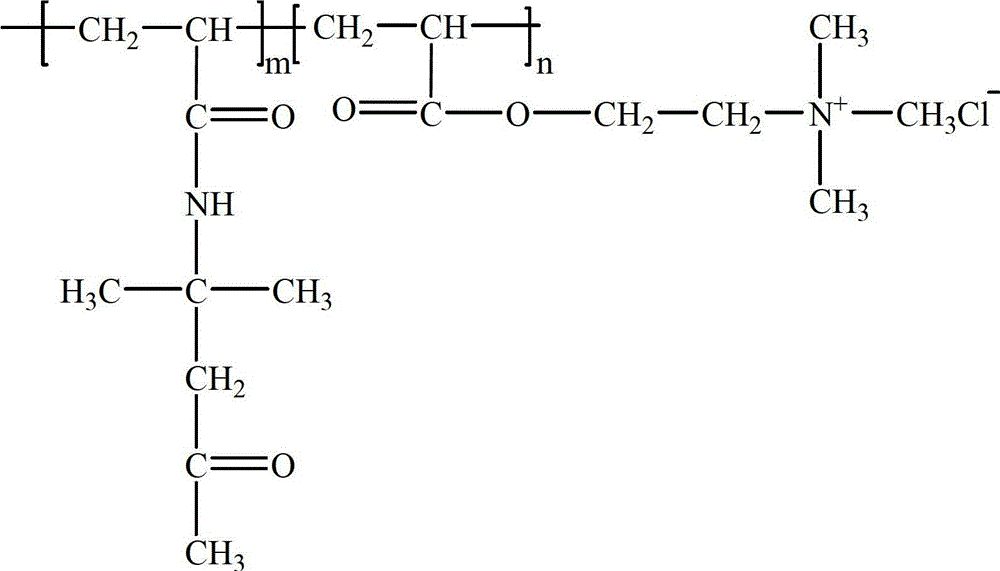

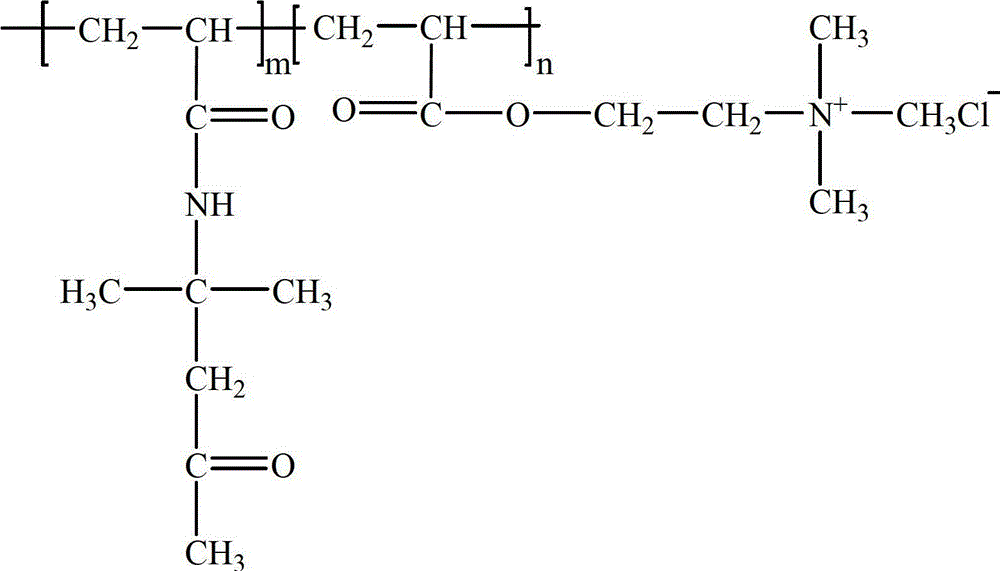

A kind of diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer and preparation method thereof

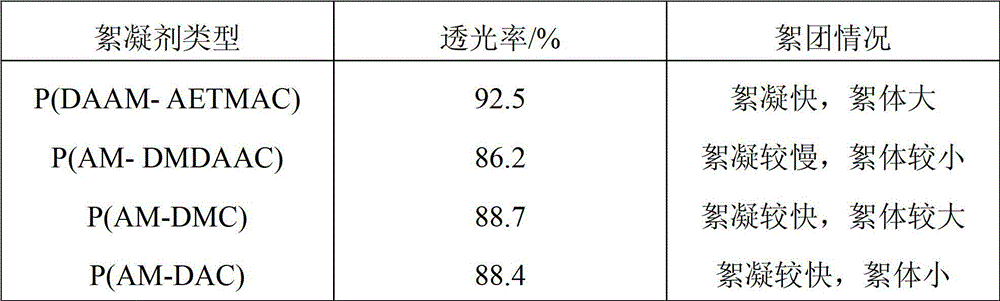

A technology of acryloyloxyethyltrimethylammonium chloride and diacetone acrylamide is applied in the field of diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer and preparation thereof, and can solve the residual cost , flocculant toxicity and other problems, to achieve the effect of less side reactions, short process cycle and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A preparation method of diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer, comprising the following steps:

[0046] (1) Dissolve 3g of reaction monomer diacetone acrylamide in 20mL of distilled water, stir until completely dissolved to make diacetone acrylamide solution; weigh 0.1g potassium persulfate and 0.05g sodium bisulfite, add diacetone acrylamide solution, N 2 Deoxygenation, stirring at 40°C until fully mixed to obtain a diacetone acrylamide solution containing an initiator;

[0047] (2) Under nitrogen gas, weigh 15 g of acryloyloxyethyltrimethylammonium chloride with a mass fraction of 60% (mass ratio of acryloyloxyethyltrimethylammonium chloride: diacetone acrylamide = 3 : 1), add dropwise at a rate of 4 drops / min into the diacetone acrylamide solution containing the initiator, after dropping for 1.5h, continue the reaction at 30°C for 7h to obtain diacetoneacrylamide-acryloyloxyethyl The crude product solution of trimethylammonium ch...

Embodiment 2

[0050] A preparation method of diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer, comprising the following steps:

[0051] (1) Dissolve 5g of reaction monomer diacetone acrylamide in 35mL of distilled water, stir until completely dissolved to make diacetone acrylamide solution; weigh 0.16g of potassium persulfate and 0.08g of sodium bisulfite, add diacetone acrylamide solution, N 2 Deoxygenation, stirring at 40°C until fully mixed to obtain a diacetone acrylamide solution containing an initiator;

[0052] (2) Weigh 33.3 g of acryloyloxyethyltrimethylammonium chloride with a mass fraction of 60%: mass ratio of diacetone acrylamide = 4:1), add 4 drops / Add it dropwise into the diacetone acrylamide solution containing the initiator at a speed of 1 minute, and then continue to react at 45°C for 5 hours after dropping for 1 hour to obtain diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer Crude solution;

[0053] (3) At 80°C, the ob...

Embodiment 3

[0055] A preparation method of diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer, comprising the following steps:

[0056] (1) Dissolve 6g of reaction monomer diacetone acrylamide in 50mL of distilled water, stir until completely dissolved to make diacetone acrylamide solution; weigh 0.12g of potassium persulfate and 0.06g of sodium bisulfite, add diacetone acrylamide solution, N 2 Deoxygenation, stirring at 40°C until fully mixed to obtain a diacetone acrylamide solution containing an initiator;

[0057] (2) Weigh 20 g of acryloyloxyethyltrimethylammonium chloride with a mass fraction of 60%, and add it dropwise to the diacetone acrylamide solution containing the initiator at a rate of 4 drops / min. After 1.5 hours of dropping , and continue to react at 50° C. for 4 hours to obtain a crude product solution of diacetone acrylamide-acryloyloxyethyltrimethylammonium chloride copolymer;

[0058] (3) At 80°C, the obtained crude copolymer was subjected to S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com