Polymer with surface activity function and preparation method and application thereof

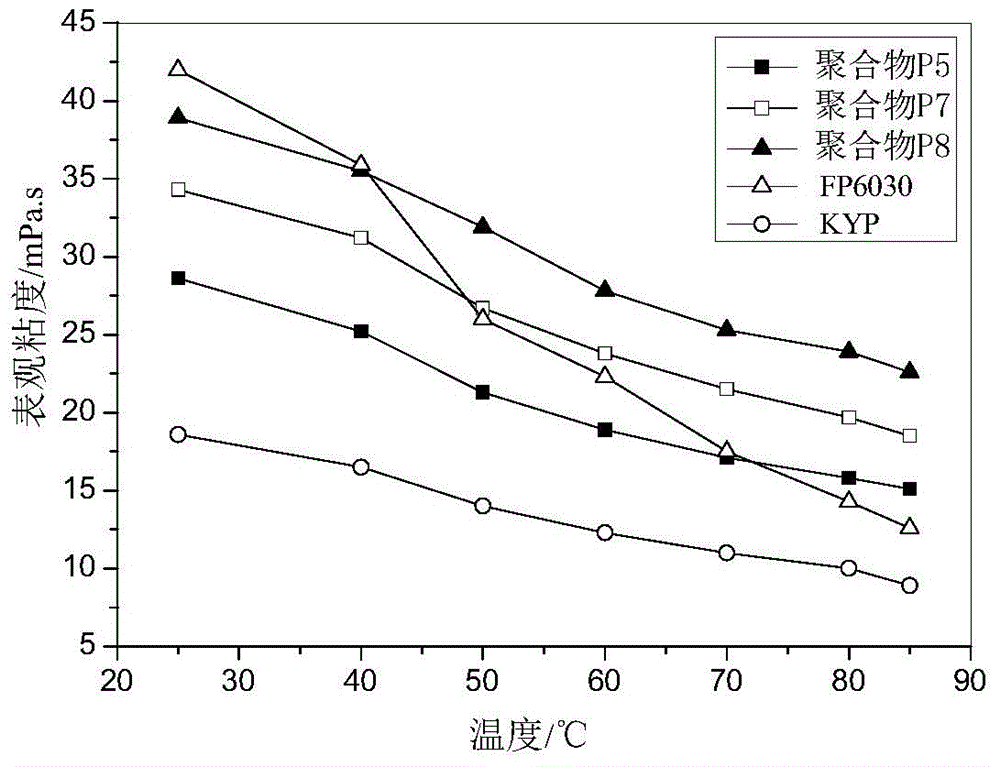

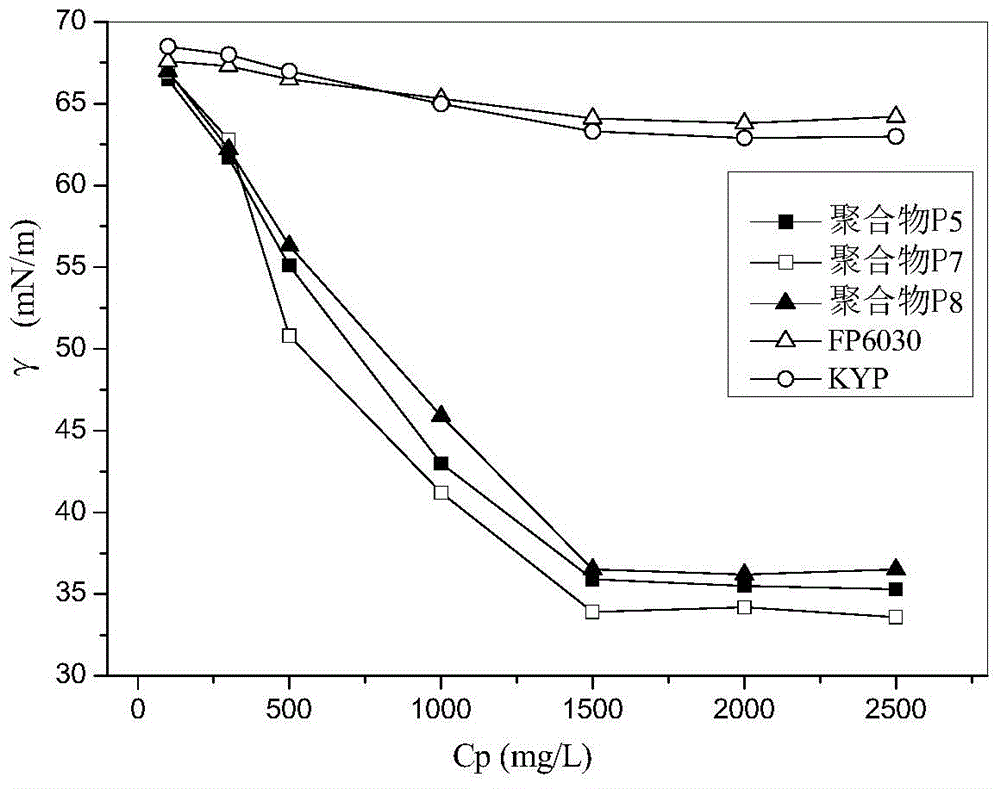

A surface active, polymer technology, applied in the polymer field, to solve the problem of poor temperature resistance and salt resistance, good resistance to cationic precipitation, and improve oil recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

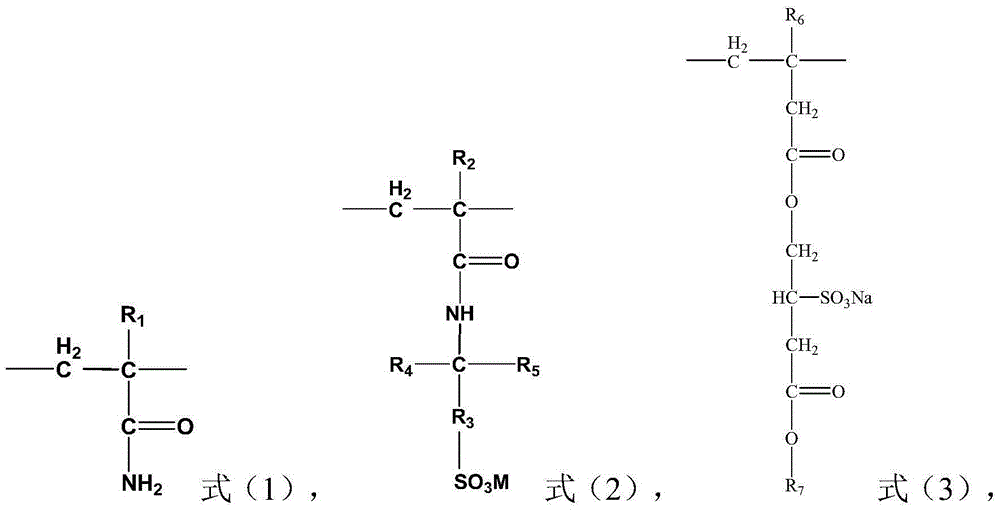

[0041] In a second aspect, the present invention provides a method for preparing a polymer with surface-active functions, the method comprising: in the presence of an initiator and water as a solvent, monomer D, monomer E and monomer F are Solution polymerization, wherein, the monomer D is a monomer having a structure shown in formula (4), the monomer E is a monomer having a structure shown in formula (5), and the monomer F is a monomer having a structure shown in formula (5) (6) The monomer of the shown structure, wherein, the amount of monomer D, monomer E and monomer F makes the content of structural unit A in the prepared polymer be 45-89% by weight, and the content of structural unit B is The content is 10-40% by weight, the content of structural unit C is 1-15% by weight, and the viscosity-average molecular weight of the prepared polymer is 5 million-20 million; the structural unit A has the formula (1) The structural unit of structure, described structural unit B is the...

Embodiment 1

[0078] This example is used to illustrate the polymer with surface active function of the present invention and its preparation method.

[0079] Adopt aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 0.375g as the structure monomer MAS-1 shown in formula (14) (Dandong Jinhai Fine Chemical Co., Ltd.) as water-soluble surface active monomer, 33.375g Acrylamide, 3.75g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomers and distilled water, the total content of monomers is 15% by weight, fully stirred into the polymerization reaction bottle The solution turned into a transparent solution. Then add 50 mg of auxiliary urea, 75 mg of disodium edetate, 1 mL of ammonia water and 10 mg of isopropanol, and at the same time adjust the pH value of the system to 6 with sodium hydroxide, and feed high-purity nitrogen with a volume concentration of 99.99% for 30 minutes. Oxy...

Embodiment 2

[0083]This example is used to illustrate the polymer with surface active function of the present invention and its preparation method.

[0084] Adopt the aqueous solution polymerization method, in the adiabatic polymerization reactor that has surface thermocouple, add 5g such as structural monomer MAS-1 (Dandong Jinhai Fine Chemical Co., Ltd.) shown in formula (14) as water-soluble surface active monomer, 25g propylene Amide, 20 g of 2-acrylamido-2-methylpropanesulfonic acid and distilled water, based on the total content of monomers and distilled water, the total content of monomers is 20% by weight, fully stirred into the solution in the polymerization reaction bottle turned into a clear solution. Then add 50 mg of auxiliary agent urea, 75 mg of disodium edetate, and 1 mL of ammonia water, and at the same time adjust the pH value of the system to 7 with sodium hydroxide, and pass high-purity nitrogen gas with a volume concentration of 99.99% for 30 minutes to remove the nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com