Method for preparing polycarbonate by copolymerizing carbon dioxide and alpha-pinene derivatives

A technology of polycarbonate and carbon dioxide, applied in the field of preparation of new polycarbonate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of α-epoxy pinane

[0036] The sodium carbonate of equimolar, chloroform, the α-pinene that mass percent concentration is 93% are added in the reactor, and the peracetic acid that the mass percent concentration of equimolar concentration is 30% is added dropwise while stirring, wherein reaction The temperature is 30°C, the reaction time is 1.5 hours, the product is extracted once with chloroform after adding water, the solution is alternately washed with saturated sodium chloride and saturated sodium thiosulfate solution to neutrality, dried over anhydrous sodium sulfate, and reduced Pressure distillation collected fractions at 75°C and 2.0KPa to obtain the product α-epoxypinane.

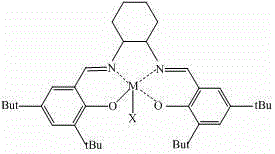

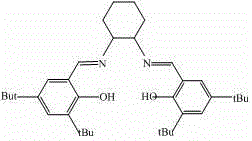

[0037] 2. The main catalyst is the tetradentate Schiff base metal complex SalenCr Ⅲ The preparation of Cl, the structure of the catalyst is shown in formula III:

[0038]

[0039] I

[0040] In the formula: M is Cr 3+ ; X is Cl -1 ;

[0041] The preparation method of t...

Embodiment 2

[0051] 1. Preparation of α-epoxy pinane

[0052] Add equimolar sodium carbonate, chloroform, mass percent concentration of 93% α-pinene into the reactor, add dropwise equimolar mass percent concentration of 35% peracetic acid while stirring, wherein the reaction The temperature was 35°C, and the reaction time was 3.0 hours. After adding water, the product was extracted three times with chloroform, and the solution was alternately washed with saturated sodium chloride and saturated sodium thiosulfate solution to neutrality, dried over anhydrous sodium sulfate, and reduced Pressure distillation collected fractions at 77°C and 2.0KPa to obtain the product α-epoxypinane.

[0053] 2. The main catalyst is the tetradentate Schiff base metal complex SalenCr Ⅲ The preparation of Cl, the structure of this catalyst is shown in formula I:

[0054]

[0055] I

[0056] In the formula: M is Cr 3+ ; X is Cl -1 ;

[0057] Ligand preparation

[0058] Add (R,R)-1,2-cyclohexanediamine...

Embodiment 3

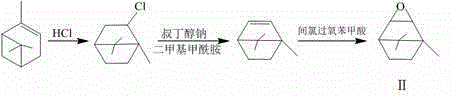

[0066] 1. Preparation of epoxybornene

[0067] Add 5g of α-pinene into the reactor, feed dry hydrogen chloride gas at -10°C, and stop the aeration after the liquid in the reactor is completely converted into a solid, to obtain a solid crude product, add dimethylformamide and tert-butyl Sodium alkoxide until the solid crude product is completely dissolved, and the reaction is stopped after stirring at 80°C for 2 hours. After the product is washed with distilled water to neutrality, the product is extracted with petroleum ether after adding water, and the extract is dried over anhydrous sodium sulfate, and evaporated under normal pressure. Remove the solvent to obtain crystalline norbornene, add the dissolved solution into the reactor according to the ratio of 1.0g norbornene dissolved in 15ml dichloromethane solvent, and add the dichloromethane solution of m-chloroperoxybenzoic acid dropwise while stirring at a constant temperature of 20°C ( 1g m-chloroperoxybenzoic acid is dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com