193nm photoresist containing silicon coupling agent and its filming resin

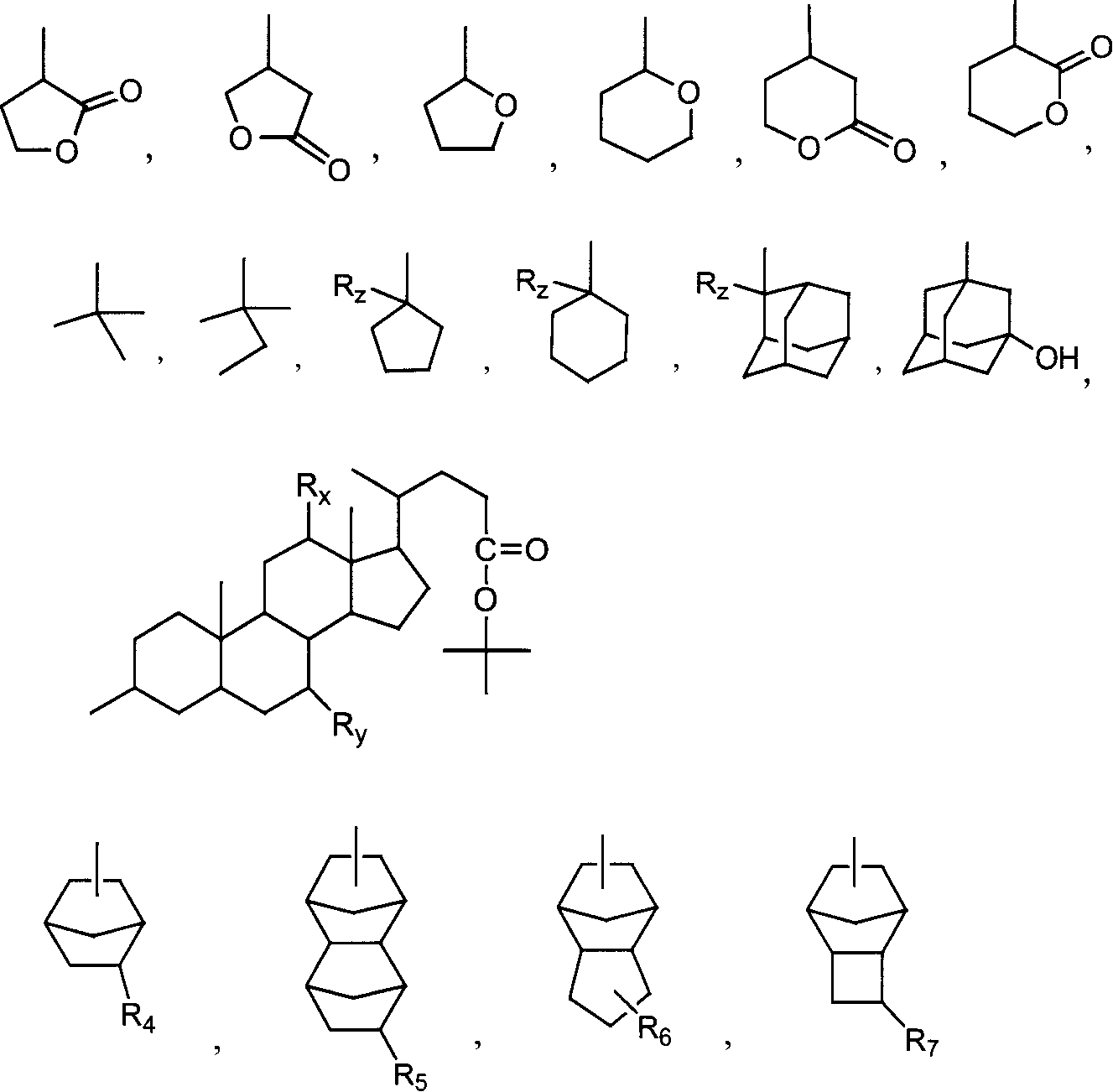

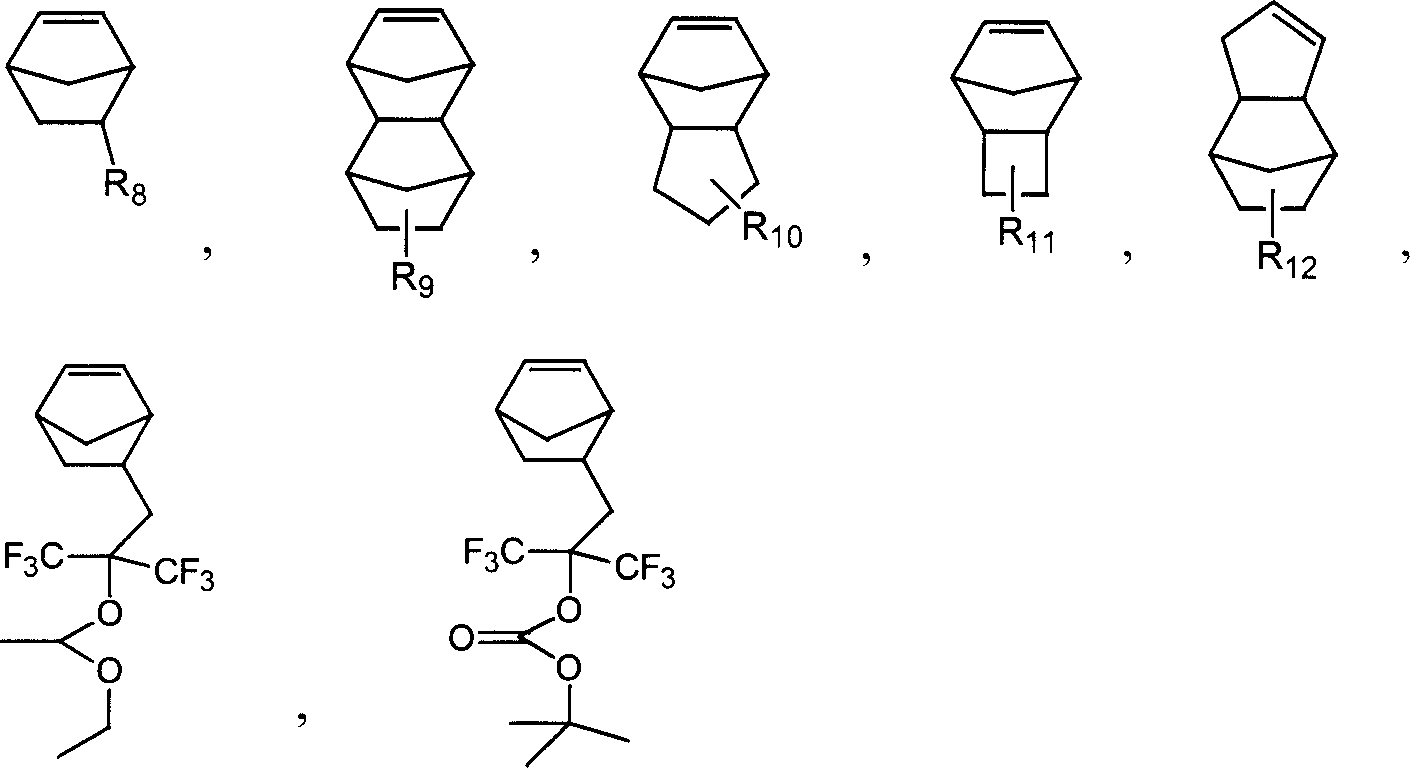

A technology of film-forming resin and silicon coupling agent, which is applied in the field of deep ultraviolet positive chemically amplified photoresist composition, and can solve problems such as failure to expose properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

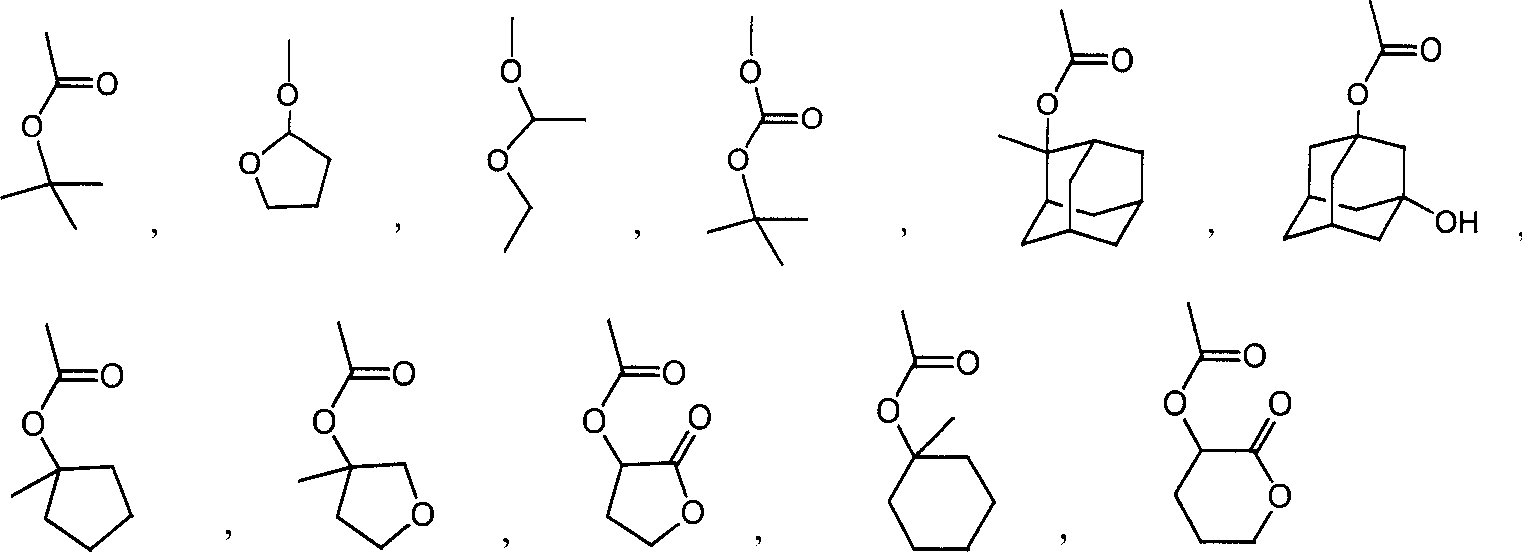

[0239] A silicon-containing coupling agent-containing copolymer film-forming resin is prepared from the following comonomers and their contents under the condition of the existence of a free radical initiator, through heating and copolymerization. The chemical formula of the copolymer film-forming resin (not expressing the sequence structure) is as follows:

[0240]

[0241] Tert-Butyl 5-norbornene-2-carboxylate 24.0 grams;

[0242] Maleic anhydride (fresh steamed) 7.5g;

[0243] 22.4 grams of 5-norbornene-2-hydroxyethyl carboxylate;

[0244] 25.8 grams of 1-methylcyclopentyl methacrylate;

[0245] Propyl dimethoxybutyl silyl methacrylate 7.0 grams.

[0246] The preparation method is: in a 1000ml three-necked flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 24.0g of 5-norbornene-2-carboxylate tert-butyl ester, Malay Acid anhydride (fresh steamed) 7.5 g, 5-norbornene-2-hydroxyethyl carboxylate 22.4 g, ...

Embodiment 2

[0248] A silicon-containing coupling agent-containing copolymer film-forming resin is prepared from the following comonomers and their contents under the condition of the existence of a free radical initiator, through heating and copolymerization. The chemical formula of the copolymer film-forming resin (not expressing the sequence structure) is as follows:

[0249]

[0250] Tert-Butyl 5-norbornene-2-carboxylate 38.2 g;

[0251] Maleic anhydride (fresh steamed) 9.8g;

[0252] 32.6 grams of 1-methylcyclohexyl methacrylate;

[0253] Methylene bis(ethyldimethoxyhydroxysilane) methacrylate 7.6 g.

[0254] The preparation method is: in a 1000ml three-necked flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 38.2 g of tert-butyl 5-norbornene-2-carboxylate, Malay Acid anhydride (fresh steamed) 9.8g, methacrylic acid-1-methylcyclohexyl 32.6g, methacrylic acid methylenebis(ethyldimethoxyhydroxysilane) 7.6g, tetr...

Embodiment 3

[0256] A silicon-containing coupling agent-containing copolymer film-forming resin is prepared from the following comonomers and their contents under the condition of the existence of a free radical initiator, through heating and copolymerization. The chemical formula of the copolymer film-forming resin (not expressing the sequence structure) is as follows:

[0257]

[0258] Tert-Butyl 5-norbornene-2-carboxylate 28.7 g;

[0259] 5-Norbornene-2,3-acid anhydride (Nadic Anhydride) 20.3 grams;

[0260] 28.4 grams of tert-butyl methacrylate;

[0261] Propyl tributoxy silane methacrylate 8.7 grams.

[0262] The preparation method is: in a 1000ml three-necked flask equipped with an electric stirrer, condenser, thermometer, temperature controller, heating mantle and nitrogen inlet, add 28.7 g of 5-norbornene-2-carboxylate tert-butyl ester, 5- Norbornene-2,3-acid anhydride (Nadic Anhydride) (fresh steamed) 20.3 g, tert-butyl methacrylate 28.4 g, propyl tributoxysilane methacrylate 8.7 g,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com