High adhesive force dipping-adhesive manufacturing process

A manufacturing process and high adhesion technology, applied in the direction of adhesives, epoxy glue, adhesive types, etc., to achieve the effects of high cross-linking density, good corrosion resistance, and large internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

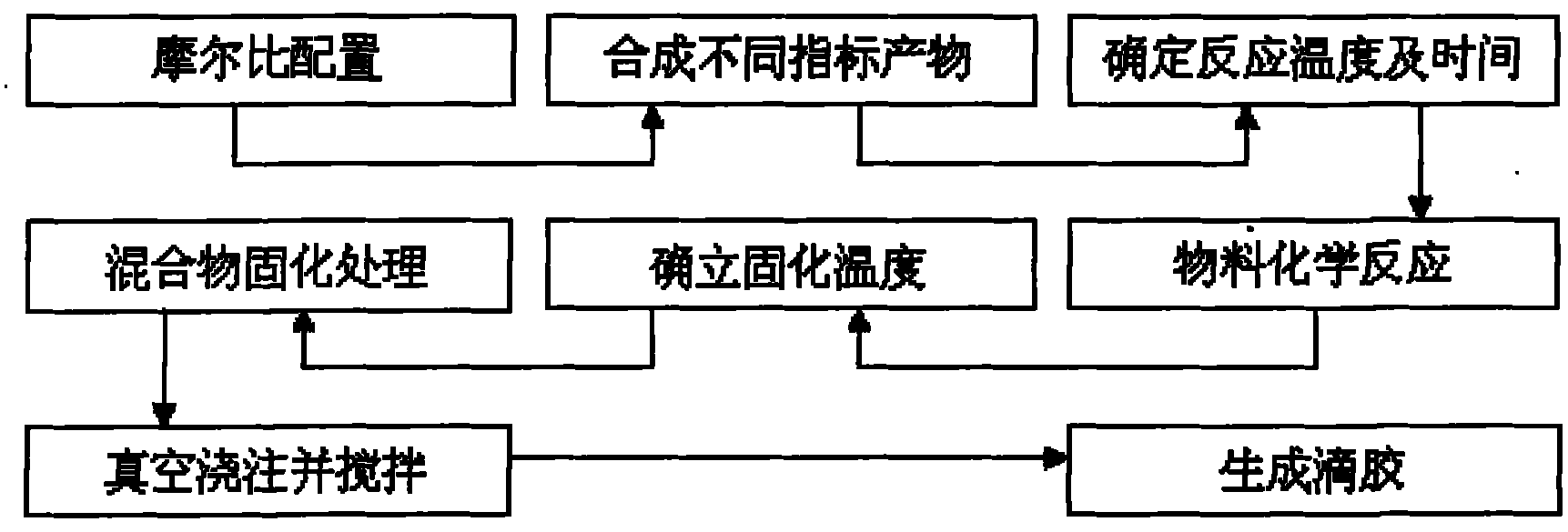

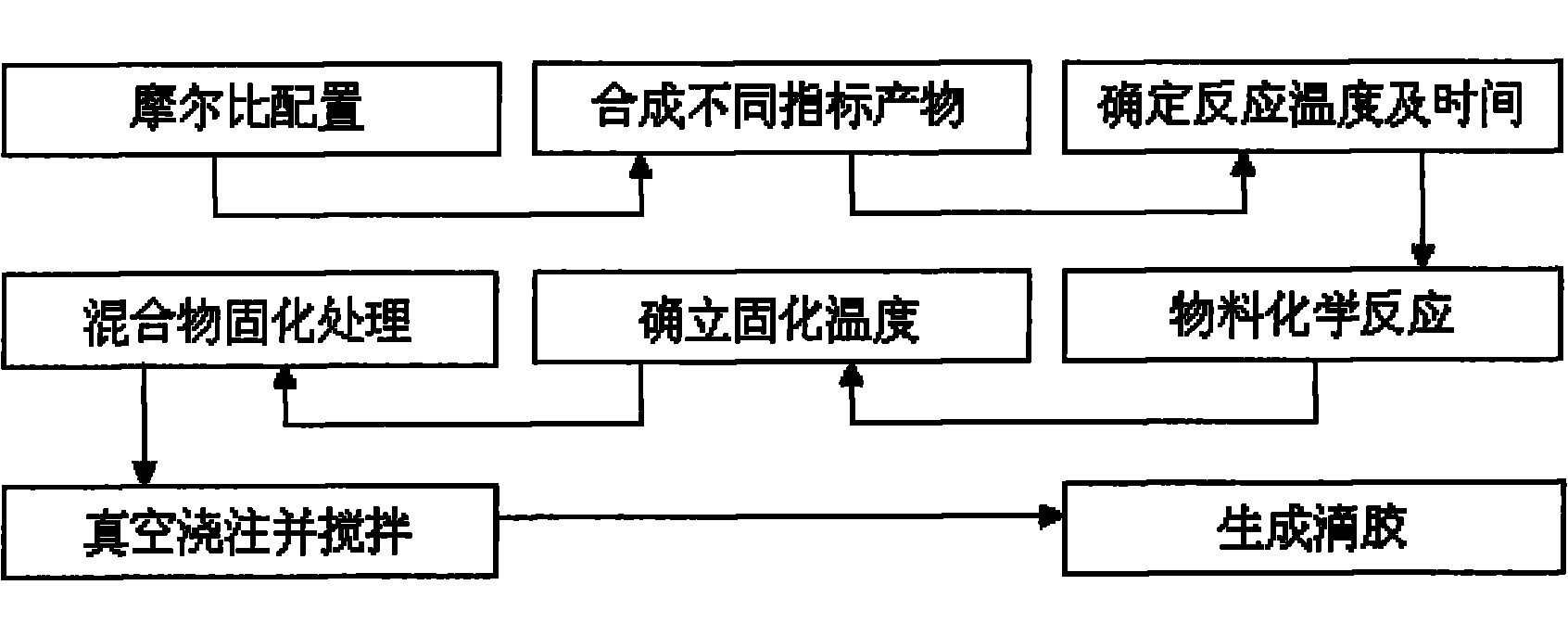

[0017] see figure 1 , a high-adhesion epoxy manufacturing process, the manufacturing process includes the following steps:

[0018] (1) The molar ratio configuration of the reaction substances: according to the ratio of different amine values, viscosities and solid contents, the products with different indexes are synthesized;

[0019] (2) Establishment of reaction temperature and reaction time: control the reaction time and temperature according to the index; determine the sufficient reaction of the material chemical infrastructure;

[0020] (3) Establishment of curing temperature: after the reactants have reacted, perform curing treatment to obtain a mixture with a balanced viscosity and solid content;

[0021] (4) Vacuum casting process: Stir the mixture repeatedly and put it into a vacuum box to reduce the air gap and air bubbles in the casting product to obtain the finished product.

[0022] The step (2) also includes the following steps: after the reaction of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com