Preparation method of organosilicon modified polyacrylate pressure-sensitive adhesive and obtained pressure-sensitive adhesive

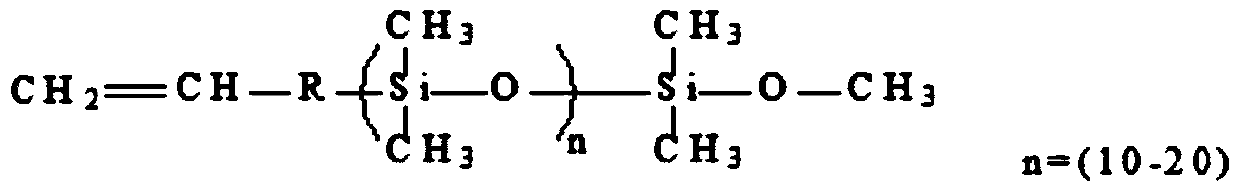

A technology of polyacrylate and butyl acrylate, which is used in the preparation of silicone-modified polyacrylate pressure-sensitive adhesives and silicone-modified polyacrylate pressure-sensitive adhesives, can solve the problems of complex process, low addition amount, and high addition amount. Many other problems, to achieve the effect of improving polymerization efficiency, good adhesion, and reducing residual glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

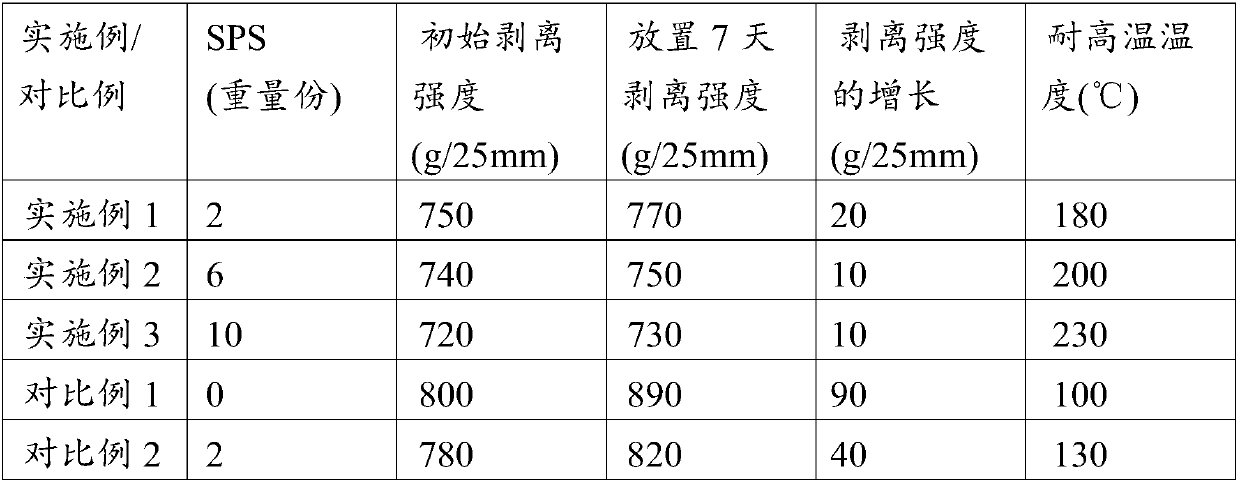

Embodiment 1

[0025] (1) Prepare 2g SPS, 19g 2-ethylhexyl acrylate, 19g butyl acrylate, 5.5g methyl methacrylate, 2.5g hydroxypropyl acrylate, 2g acrylic acid, 0.2g dibenzoyl peroxide, 49.8 g ethyl acetate;

[0026] (2) Add SPS, 2-ethylhexyl acrylate, butyl acrylate, hydroxypropyl acrylate, acrylic acid and three-quarters of dibenzoyl peroxide into the monomer mixing kettle, and stir while feeding, Obtain mixed material A;

[0027] (3) Add one-third of the ethyl acetate into the reaction kettle, while stirring and raising the temperature to 82° C., then dropwise add the mixed material A to the reaction kettle, and finish dropping after 4 hours;

[0028] (4) Add methyl methacrylate into the reaction kettle, stir for 2 minutes, then add the remaining dibenzoyl peroxide and one-sixth of ethyl acetate, and react at a constant temperature of 82° C. for 2 hours;

[0029] (5) Lower the temperature of the reaction kettle to 40° C., add the remaining ethyl acetate, and discharge after stirring for...

Embodiment 2

[0031] (1) Prepare 6g SPS, 17g 2-ethylhexyl acrylate, 17g butyl acrylate, 5.5g methyl methacrylate, 2.5g hydroxypropyl acrylate, 2g acrylic acid, 0.5g dibenzoyl peroxide, 49.5 g ethyl acetate;

[0032] (2) Add SPS, 2-ethylhexyl acrylate, butyl acrylate, hydroxypropyl acrylate, acrylic acid and three-quarters of dibenzoyl peroxide into the monomer mixing kettle, and stir while feeding, Obtain mixed material A;

[0033] (3) Add one-third of the ethyl acetate into the reaction kettle, while stirring and raising the temperature to 82° C., then dropwise add the mixed material A to the reaction kettle, and finish dropping after 4 hours;

[0034] (4) Add methyl methacrylate into the reaction kettle, stir for 2 minutes, then add the remaining dibenzoyl peroxide and one-sixth of ethyl acetate, and react at a constant temperature of 82° C. for 2 hours;

[0035] (5) Lower the temperature of the reaction kettle to 40° C., add the remaining ethyl acetate, and discharge after stirring for...

Embodiment 3

[0037] (1) Prepare 10g SPS, 15g-2-ethylhexyl acrylate, 15g butyl acrylate, 5.5g methyl methacrylate, 2.5g hydroxypropyl acrylate, 2g acrylic acid, 0.8g dibenzoyl peroxide, 49.2 g ethyl acetate;

[0038] (2) Add SPS, 2-ethylhexyl acrylate, butyl acrylate, hydroxypropyl acrylate, acrylic acid and three-quarters of dibenzoyl peroxide into the monomer mixing kettle, and stir while feeding, Obtain mixed material A;

[0039] (3) Add one-third of the ethyl acetate into the reaction kettle, while stirring and raising the temperature to 82° C., then dropwise add the mixed material A to the reaction kettle, and finish dropping after 4 hours;

[0040] (4) Add methyl methacrylate into the reaction kettle, stir for 2 minutes, then add the remaining dibenzoyl peroxide and one-sixth of ethyl acetate, and react at a constant temperature of 82° C. for 2 hours;

[0041] (5) Lower the temperature of the reaction kettle to 40° C., add the remaining ethyl acetate, and discharge after stirring fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com