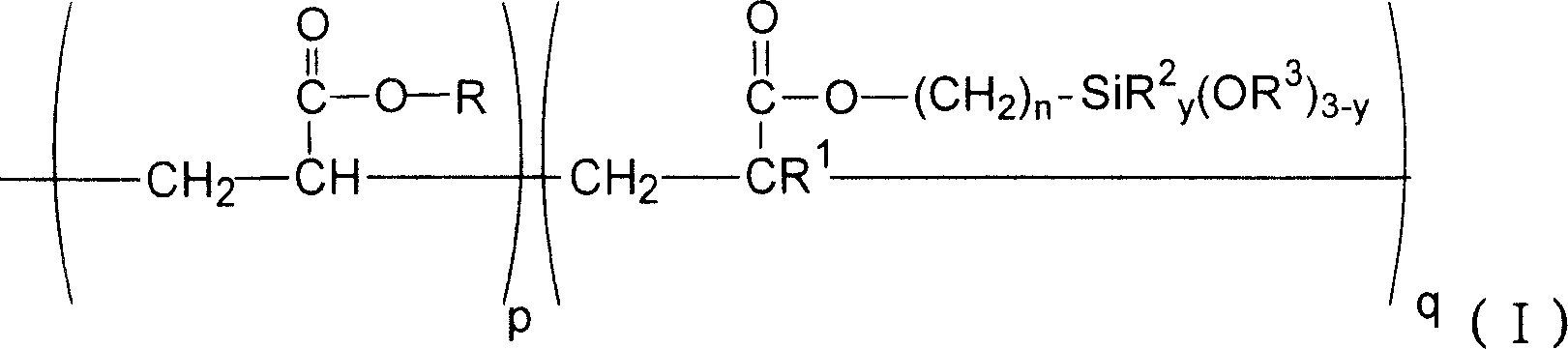

Acryloxyalkoxysilicane modified acrylic acid ester polymerization emulsion and its preparation method and application

A technology of acryloyloxyalkoxysilane and acrylate, which is applied in the field of acrylate copolymer emulsion, can solve problems such as complex process, and achieve the effects of high reactivity, improved weather resistance, and no influence on reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

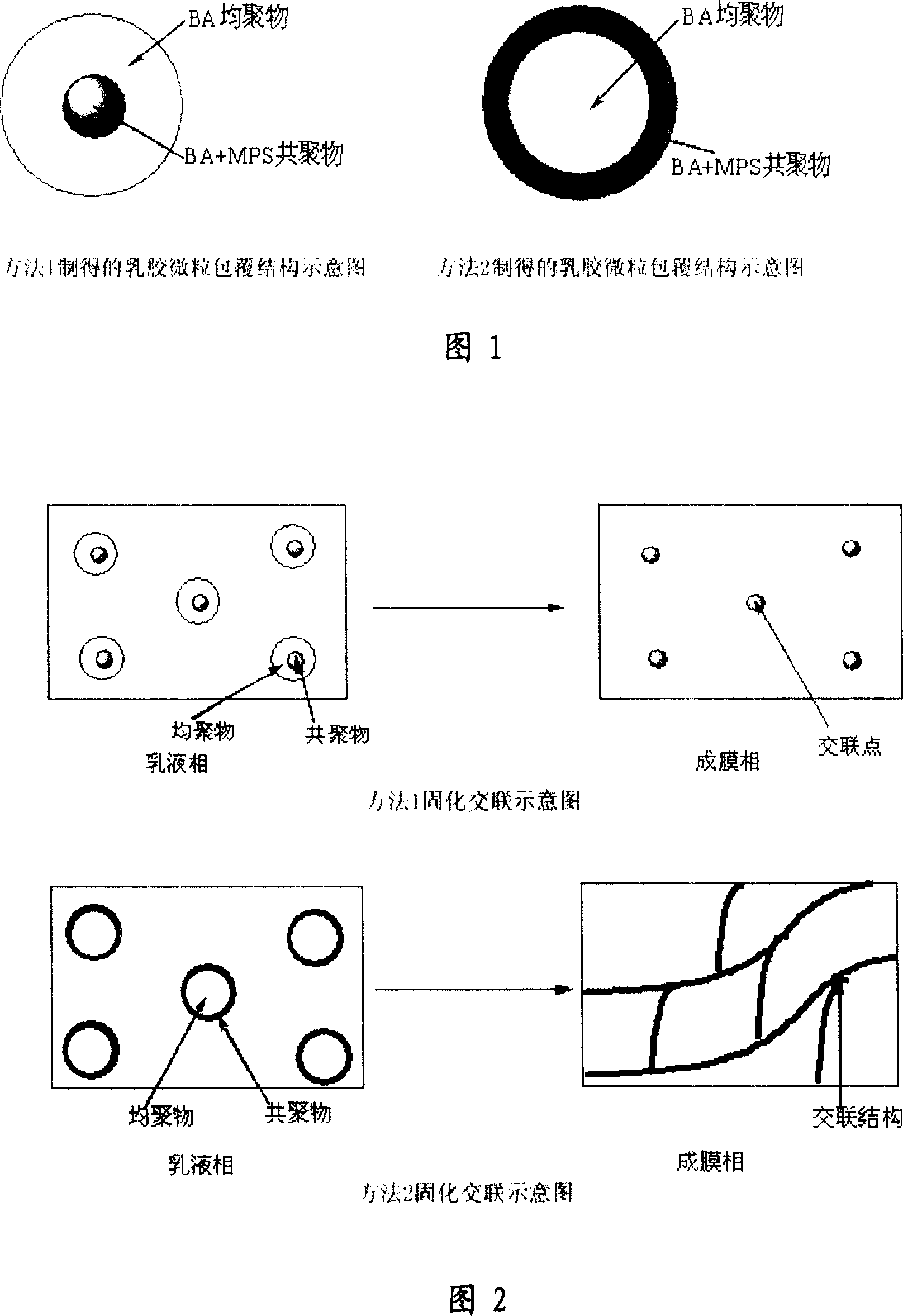

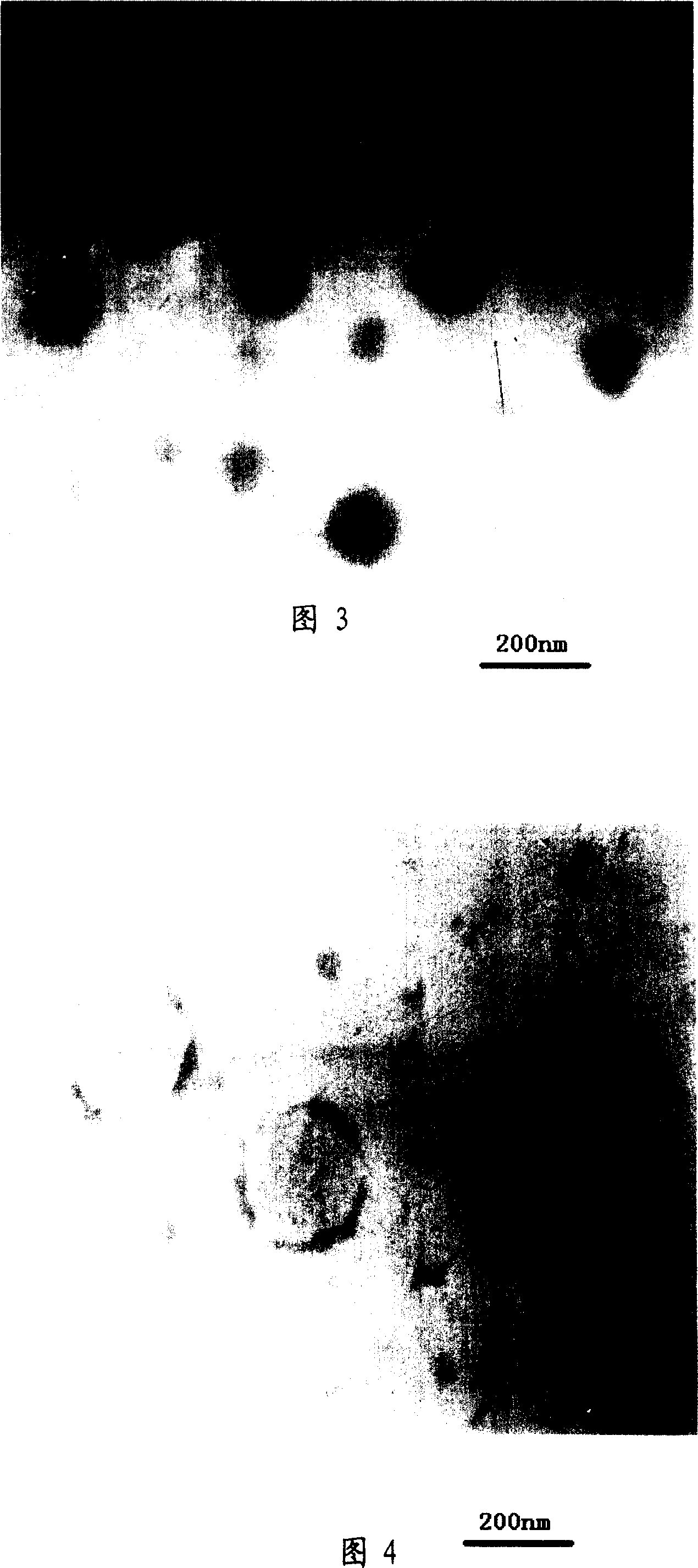

[0085] Example 1: Binary system: The monomer composition is butyl acrylate and γ-methacryloxypropyltrimethoxysilane (MPS). The formula of the emulsion is as follows:

[0086] serial number

[0087] Mix 39.60g of butyl acrylate, 1.98g of γ-methacryloxypropyltrimethoxysilane (MPS), 0.90g of emulsifier sodium lauryl sulfate, 84.00g of water, and 0.04g of dodecyl mercaptan. And buffer (NaH with pH 6.8 2 PO 4 Aqueous solution) 1.00g is added to a reactor equipped with heater, thermometer, feeding tube, reflux condenser, stirred at 480 rpm at room temperature for 20 minutes, then heated to 60°C, 0.10g initiator is added, and the temperature is raised to 75°C, During the reaction, the pH value was maintained at 7 and adjusted with 0.1 mol / L NaOH aqueous solution or HCl aqueous solution. After 6 hours of reaction, it was cooled to room temperature and filtered, and the pH value was adjusted to 8 with ammonia water. The monomer conversion rate reaches 95%. The solid content of t...

Embodiment 2

[0088] Example 2: Binary system: The monomer composition is butyl acrylate and γ-methacryloxypropyltrimethoxysilane (MPS). The formula of the emulsion is as follows:

[0089] serial number

[0090] Combine 39.60 g of butyl acrylate, 0.90 g of sodium lauryl sulfate as emulsifier, 84.00 g of water, 0.05 g of dodecyl mercaptan and buffer (NaH with a pH of 6.80) 2 PO 4 Aqueous solution) 1.01g is added to a reactor equipped with a heater, thermometer, feeding tube, reflux condenser, stirred at room temperature for 20 minutes, stirring speed at 480rpm, and then heated to 60°C, add 0.08g of initiator potassium persulfate, and set the temperature Raise to 75°C and react for 2 hours, when the conversion rate of monomer A reaches 70%, control the stirring speed at 380rpm, add 1.98g of acryloxyalkoxysilane B into the system at one time, during the reaction process Maintain pH at 7, adjust with 0.1 mol / L NaOH aqueous solution or HCl aqueous solution, after reacting for 2 hours, coo...

Embodiment 3

[0091] Example 3 (for electron microscopy observation): Binary system: The monomer composition is butyl acrylate and γ-methacryloxypropyltrimethoxysilane.

[0092] In order to increase the contrast of the binary components in the electron micrographs, the content of γ-methacryloxypropyltrimethoxysilane was increased to 10% by weight of the total amount of reactive monomers (BA+MPS). The formula of the emulsion is as follows:

[0093] serial number

[0094] 37.40g of butyl acrylate, 4.18g of γ-methacryloxypropyltrimethoxysilane (MPS), 1.00g of emulsifier sodium lauryl sulfate, 84.00g of water, and 0.02g of dodecyl mercaptan And buffer (NaH with pH 6.8 2 PO 4 Aqueous solution) 1.00g was added to the above-mentioned reaction kettle, stirred at 480rpm at room temperature for 20 minutes, then heated to 60°C, 0.09g of initiator was added, the temperature was raised to 75°C, and the pH value was maintained at 7 during the reaction, with 0.1 Adjust the mol / L NaOH aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com