Sulfonate lycine type hydrophobic associated polymer and preparation method thereof

A technology of hydrophobic association and betaine, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems that the heat and salt resistance of hydrophobic association polymers needs to be improved, and achieve enhanced oil recovery, Broad market prospects, improve the effect of viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh acrylamide (10g) and acrylic acid (2.5g), add distilled water and stir evenly, and adjust the pH value to 7; then add 3-(methacrylamidopropyldimethylamino)propanesulfonate (0.1g), N -Phenylethyl-N-dodecylmethacrylamide (0.1g) and sodium lauryl sulfate (0.3g), then add a certain amount of distilled water to make the total mass of the solution reach 50g, stir until the solution is clear; Nitrogen for 15 minutes to remove dissolved oxygen in water; add initiator v50 (0.1-0.2 wt% of the total mass of the monomer), place it under a photoinitiator, and react for 3 hours.

Embodiment 2

[0031] Weigh acrylamide (10g), acrylic acid (2.5g), add distilled water and stir evenly, adjust the pH value to 7; add 3-(methacrylamidopropyldimethylamino)propanesulfonic acid (0.1g), N-benzyl Base-N-dodecylmethacrylamide (0.1g) and sodium lauryl sulfate (0.3g), then add a certain amount of distilled water to make the solution quality reach 50g, stir until the solution is clear; Nitrogen gas for 15 minutes, Remove the dissolved oxygen in the water; add initiator v50 (0.1-0.2wt% of the total mass of the monomer), place it under a photoinitiator, and react for 3h.

[0032] 2. Structural characterization of sulfonate betaine-type hydrophobic association polymers

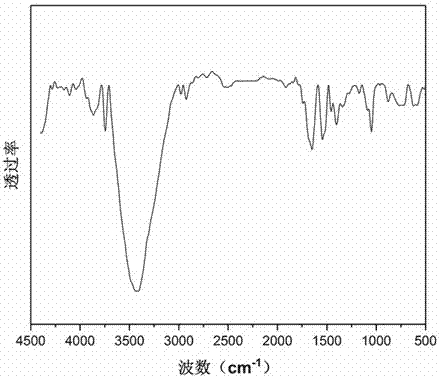

[0033] figure 1 It is the infrared spectrogram of the polymer synthesized in Example 1.

[0034] As you can see from the picture: 3408cm -1 The characteristic absorption peak of primary amide N-H stretching vibration is at 2981cm -1 and 2897cm -1 The characteristic absorption peaks of methylene antisymmetric stret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com