A kind of preparation technology of chitosan oligosaccharide grafted cellulose fiber

A cellulose fiber and preparation process technology, applied in plant fiber, fiber treatment, biochemical fiber treatment, etc., can solve the problems of fiber mutual bonding, product adhesion, danger and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

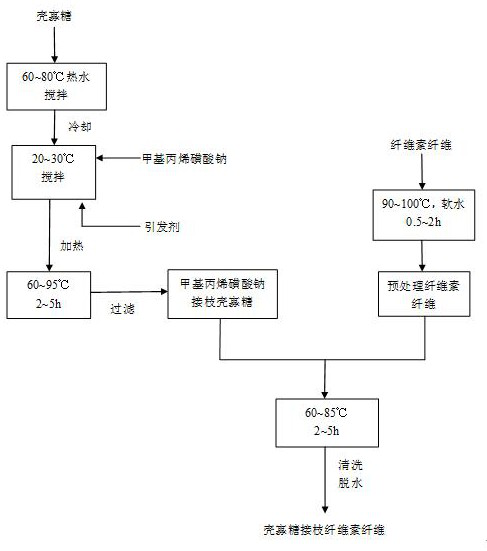

Image

Examples

Embodiment 1

[0034] A, sodium methacryl sulfonate—preparation of chitosan oligosaccharide

[0035] In the pretreatment tank a, weigh a certain amount of chitosan oligosaccharide, add hot water in proportion (it can speed up the dissolution of chitosan oligosaccharide), prepare a chitosan oligosaccharide solution with a mass concentration of 10-30%, and cool to room temperature; Weigh a certain amount of sodium methyl propylene sulfonate, the amount is 0.65-1.45 times the mass of chitosan oligosaccharide, add it to the chitosan oligosaccharide solution, the stirring speed is 150-300 rpm, and obtain a uniform solution after dissolving; gradually increase the temperature , the heating rate is 1-8°C / min, when the solution temperature reaches 60-95°C, add potassium persulfate in proportion, the dosage is 2-12% of the mass of chitosan oligosaccharide and sodium methacrylate; 95°C, the stirring rate is 150-300 rpm, and the reaction is 2-5h. After the reaction is completed, the solution is filter...

Embodiment 2

[0041] A, sodium methacryl sulfonate—preparation of chitosan oligosaccharide

[0042] In the pretreatment tank a, weigh a certain amount of chitosan oligosaccharide, add hot water in proportion (it can speed up the dissolution of chitosan oligosaccharide), and prepare a chitosan oligosaccharide solution with a mass concentration of 10%, and cool it to room temperature; A certain amount of sodium methacrylate, the amount of which is 0.65 times the mass of chitosan oligosaccharide, is added to the chitosan oligosaccharide solution, the stirring speed is 150 rpm, and a uniform solution is obtained after dissolution; the temperature is gradually raised, and the heating rate is 1 °C / min, when the temperature of the solution reaches 60-95°C, add potassium persulfate in proportion, the dosage is 2% of the quality of oligochitosan and sodium methacrylate; , Reaction 2h. After the reaction is completed, the solution is filtered through a filter cloth, and the finally obtained solutio...

Embodiment 3

[0048] A, sodium methacryl sulfonate—preparation of chitosan oligosaccharide

[0049] In the pretreatment tank a, weigh a certain amount of chitosan oligosaccharide, add hot water in proportion (it can speed up the dissolution of chitosan oligosaccharide), and prepare a chitosan oligosaccharide solution with a mass concentration of 30%, and cool it to room temperature; A certain amount of sodium methacryl sulfonate, the dosage is 1.45 times of the quality of oligochitosaccharide, added to the oligochitosaccharide solution, the stirring speed is 300 rpm, and a uniform solution is obtained after dissolution; the temperature is gradually raised, and the heating rate is 8°C / min, when the temperature of the solution reaches 60-95°C, add potassium persulfate in proportion, the dosage is 12% of the quality of oligochitosan and sodium methacryl sulfonate; keep warm at 60-95°C, and stir at 300 rpm , Reaction 5h. After the reaction is completed, the solution is filtered through a filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com