A kind of rice bran plant protein formaldehyde remover and preparation method thereof

A formaldehyde remover and plant protein technology, applied in the field of rice bran plant protein formaldehyde remover and its preparation, to achieve the effects of increasing removal rate and removal rate, high viscosity, and extending shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

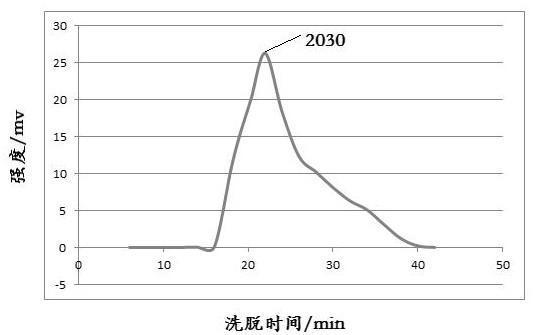

Image

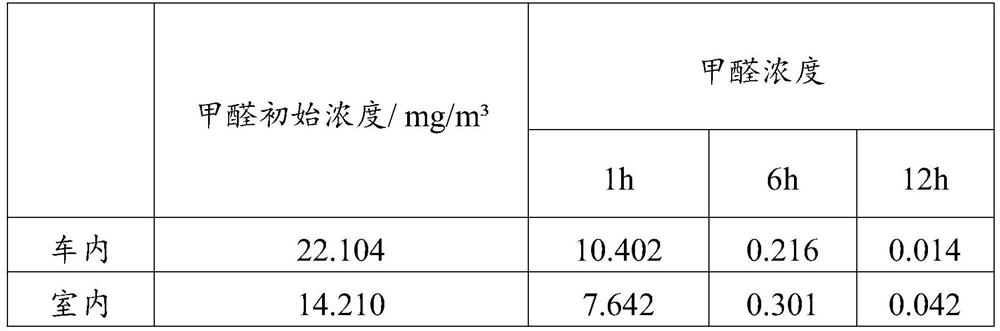

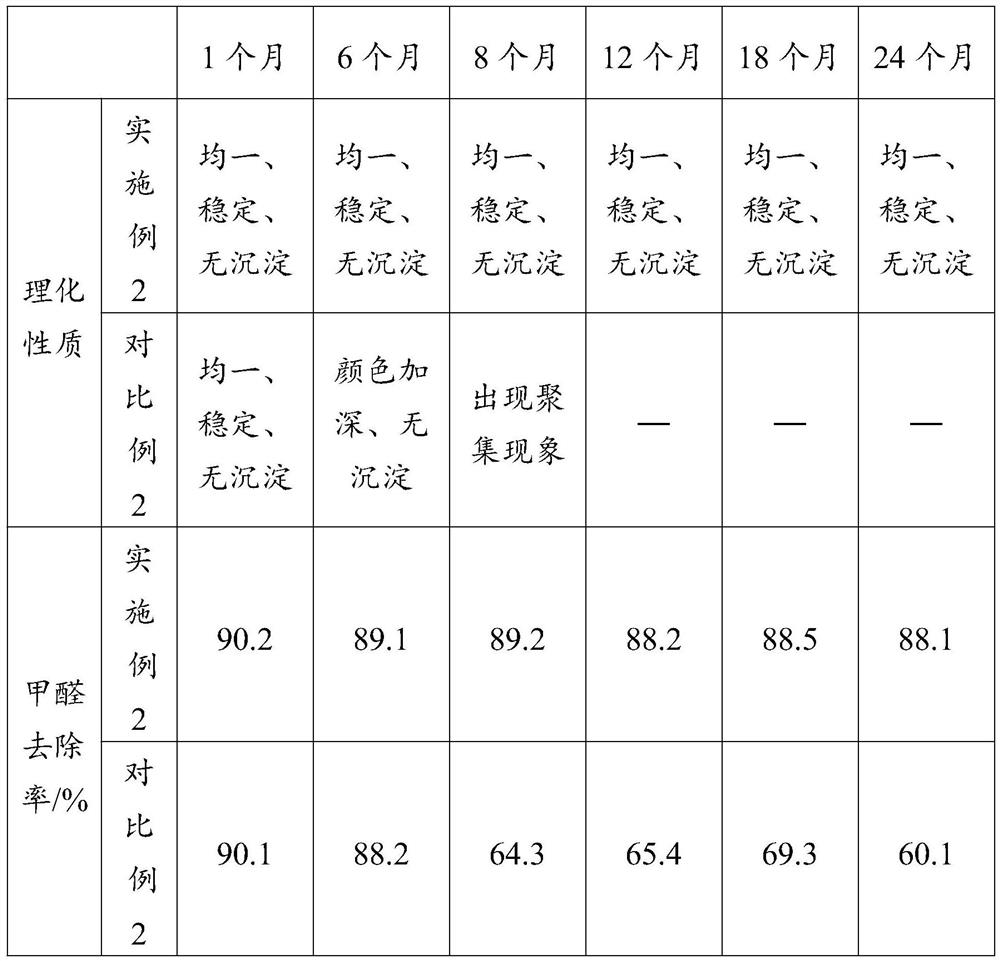

Examples

Embodiment 1

[0040] In the early stage of R&D, the R&D personnel screened different hydrolysis systems (hydrochloric acid, acetic acid, sodium hydroxide, potassium hydroxide, alkaline protease B8360, acid protease B8410, papain G8430) based on amino content as an indicator, and finally screened out ammonia water-pineapple Protease system, and optimize it to obtain the most suitable process for preparing rice bran vegetable protein liquid:

[0041] 1) Add 1.0kg of rice bran protein powder to 3kg of purified water and ultrasonically swell at 50°C for 24h;

[0042] 2) Add 0.2kg of ethylenediaminetetraacetic acid, continue ultrasonication for 30min, and then filter with a filter membrane with a pore size of 2 microns;

[0043] 3) Put the filter cake in 5kg of deionized water, add 0.01kg of sodium dodecylsulfonate, stir and dissolve evenly, then add ammonia solution to adjust the pH to 7.5-8.2, control the temperature to 60-65°C and stir for 1-2h Alkaline treatment solution;

[0044] 4) Add p...

Embodiment 1-A

[0049] Compared with Example 1, the difference is that the pH in step 3) is adjusted by sodium hydroxide to be 8.0, that is, sodium hydroxide is used to replace the ammonia solution, and the rest are exactly the same as in Example 1.

Embodiment 1-B

[0051] Compared with the examples, the difference is that sodium hydroxide is used to adjust the step 3) without adding ammonia solution to carry out the preliminary treatment of alkali, directly adopting potassium dihydrogen phosphate to adjust the pH to 7.0-7.5, and then adding bromelain 0.06-0.08kg to control Enzymolysis was carried out until the temperature was 50-55°C for 5-6 hours; the rest were exactly the same as in Example 1.

[0052] Table 1 is the detection result of the amino group content of the rice bran vegetable protein liquid prepared by embodiment 1 and its embodiment 1-A, 1-B:

[0053] Table 1 Detection results of rice bran protein amino group content

[0054] source Amino content / %wt Example 1 4.20 Example 1-A 1.21 Example 1-B 2.02

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com