Supramolecular polymer based on multiple intermolecular acting forces and preparation method thereof

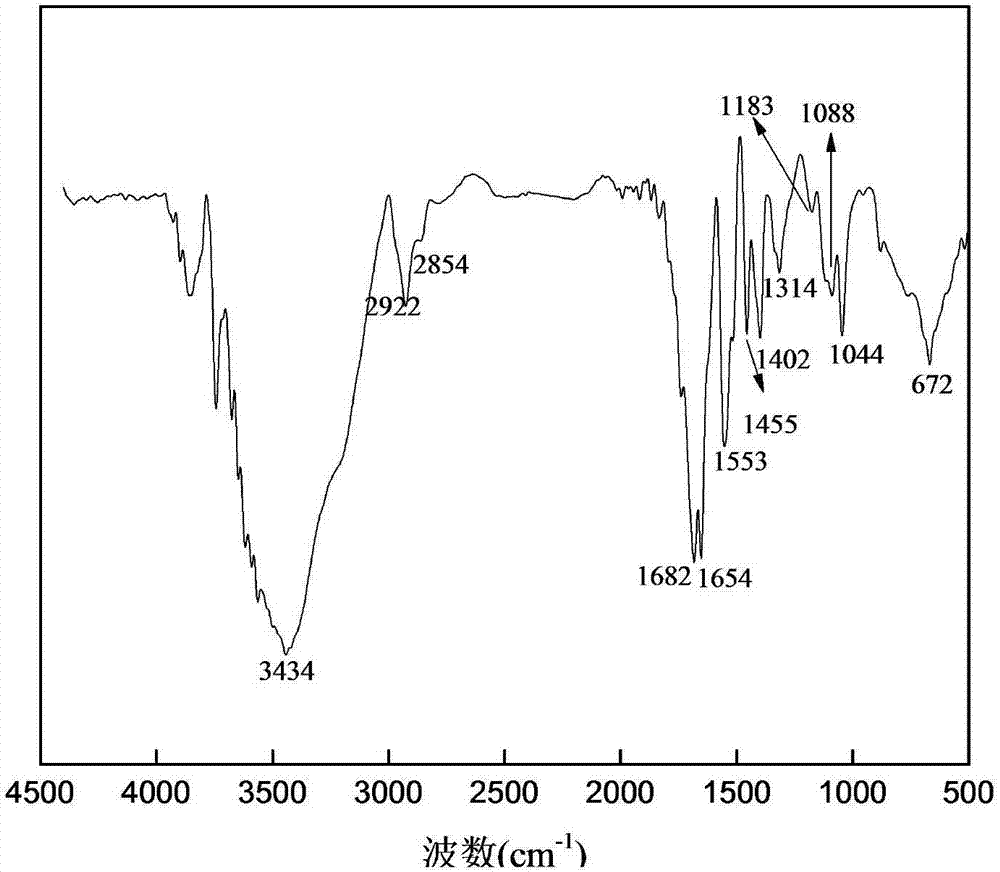

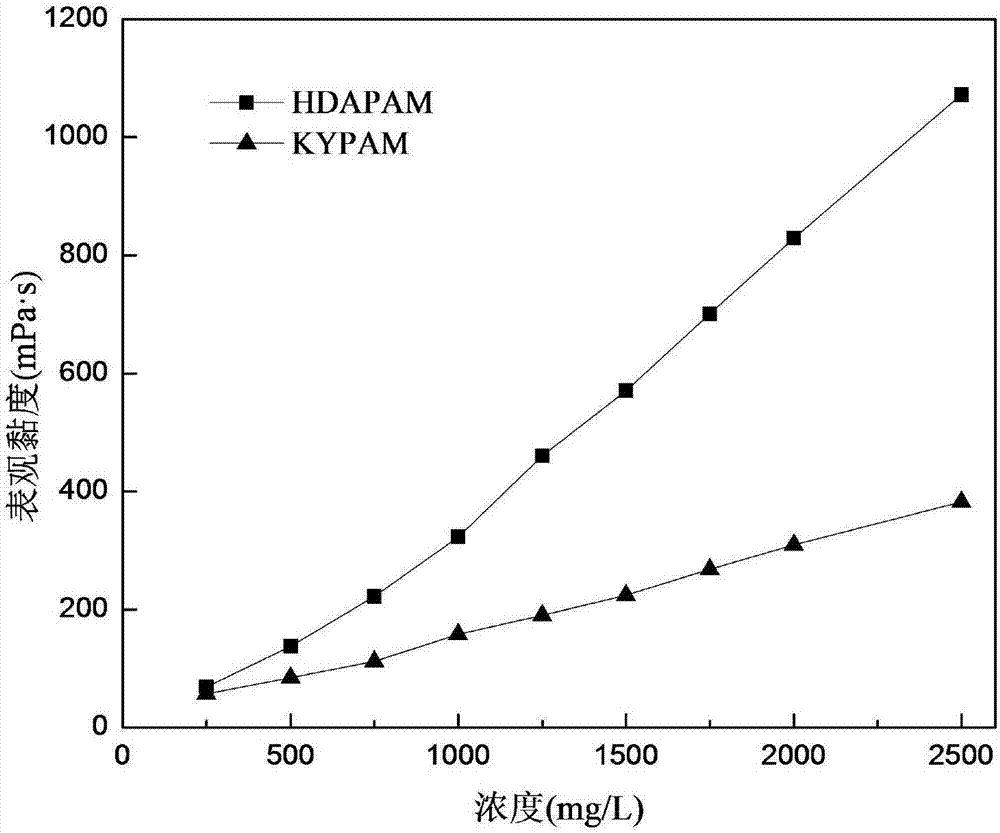

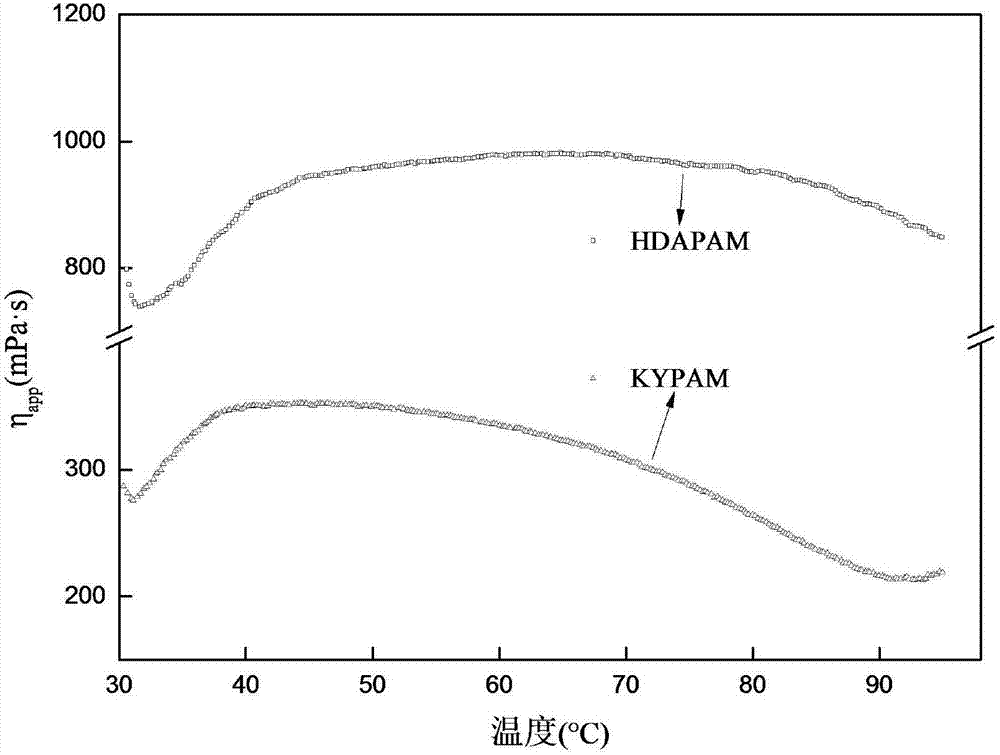

A supramolecular polymer, intermolecular force technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor temperature resistance, salt resistance and shear recovery, and achieve increased water solubility, improved Temperature resistance, the effect of increasing molecular rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a supramolecular polymer based on multiple intermolecular forces, comprising the steps of:

[0038] (1) Add acrylamide, acrylic acid, maleic anhydride modified β-cyclodextrin and methacryloyl chloride modified alkylphenol polyoxyethylene ether in deionized water to control the total amount of each reaction monomer in the reaction liquid system. The mass percentage is 20%, of which, 13% of acrylamide, 6% of acrylic acid, 0.4% of maleic anhydride modified β-cyclodextrin, 0.6% of methacryloyl chloride modified alkylphenol polyoxyethylene ether, stir well and use Sodium hydroxide adjusts the pH value of the system to 6, and stirs until the solution is clear and transparent;

[0039] (2) Nitrogen gas was passed through the solution obtained in step (1) for 30 minutes to remove oxygen, a redox initiation system composed of persulfate and sodium bisulfite was added, and then the temperature was raised to 30-50°C for 4-7 hours to obtain a polymer Colloid...

Embodiment 2

[0042] A method for preparing a supramolecular polymer based on multiple intermolecular forces, comprising the steps of:

[0043] (1) Add acrylamide, acrylic acid, maleic anhydride modified β-cyclodextrin and methacryloyl chloride modified alkylphenol polyoxyethylene ether in deionized water to control the total amount of each reaction monomer in the reaction liquid system. The mass percentage is 20%, of which, 16.7% of acrylamide, 3% of acrylic acid, 0.1% of maleic anhydride modified β-cyclodextrin, 0.2% of methacryloyl chloride modified alkylphenol polyoxyethylene ether, stir well and use The sodium hydroxide solution adjusts the pH value of the system to 7, and stirs until the solution is clear and transparent;

[0044] (2) In the solution that step (1) obtains, pass nitrogen gas 30min deoxygenation, add the oxidation-reduction initiation system that persulfate and sodium bisulfite form, add-on is 0.1% of total monomer mass, persulfate and sodium bisulfite The molar ratio ...

Embodiment 3

[0047] A method for preparing a supramolecular polymer based on multiple intermolecular forces, comprising the steps of:

[0048] (1) Add acrylamide, acrylic acid, maleic anhydride modified β-cyclodextrin and methacryloyl chloride modified alkylphenol polyoxyethylene ether in deionized water to control the total amount of each reaction monomer in the reaction liquid system. The mass percentage is 20%, of which, 15% of acrylamide, 4% of acrylic acid, 0.4% of maleic anhydride modified β-cyclodextrin, 0.6% of methacryloyl chloride modified alkylphenol polyoxyethylene ether, stir well and use Strong sodium oxide solution adjusts the pH value of the system to 7-8, and stirs until the solution is clear and transparent;

[0049] (2) In the solution that step (1) obtains, pass nitrogen gas 30min deoxygenation, add the redox initiation system that persulfate and sodium bisulfite form, the addition is 0.5% of total monomer mass, persulfate and sodium bisulfite The molar ratio of sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com