Polyether-ether-ketone wear resistant composite material, preparation method and application thereof in mechanical polishing retaining rings

A technology of polyether ether ketone and composite materials, which is applied to the application and preparation of mechanical polishing retaining rings, in the field of polyether ether ketone wear-resistant composite materials, can solve the problems of unsatisfactory wear resistance and achieve dispersibility and interfacial phase Good capacitance, uniform transfer film formation, and the effect of reducing roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

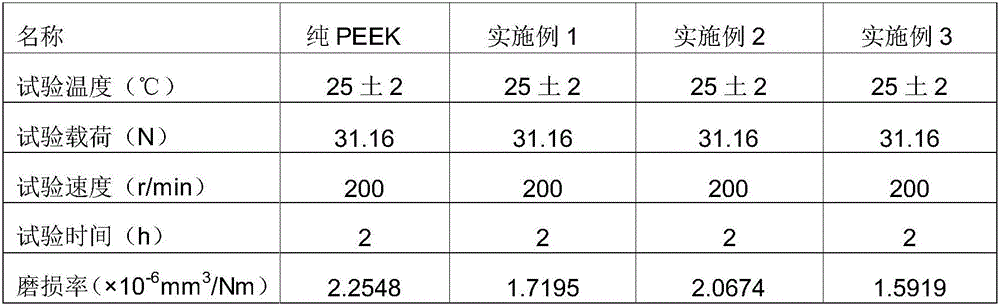

Embodiment 1

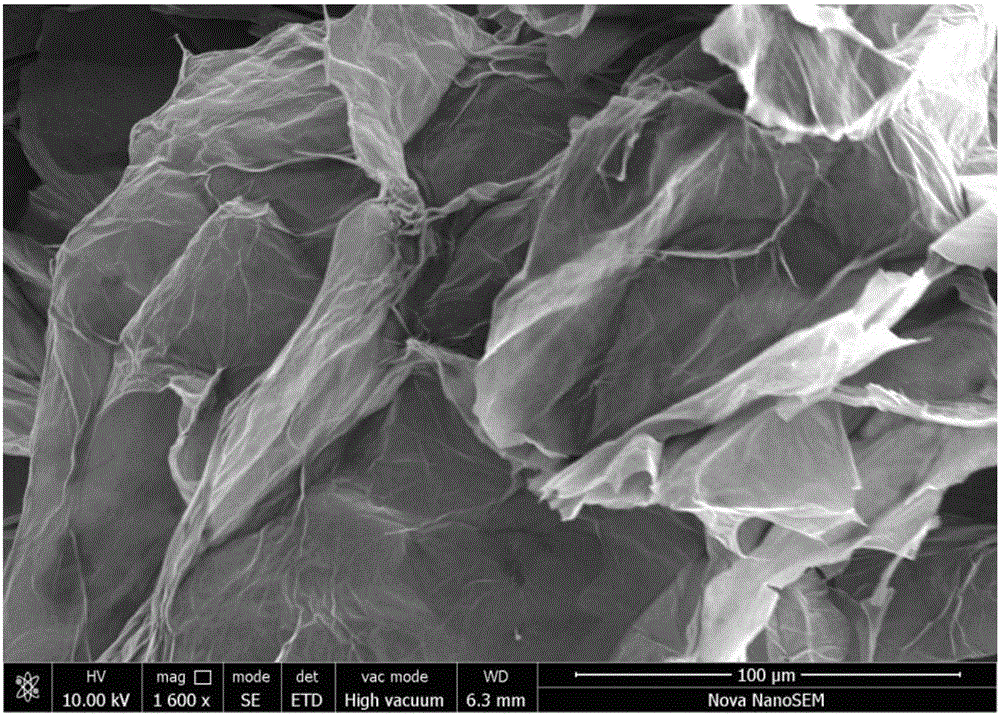

[0025] First, graphene oxide was prepared by the improved hummers method, the specific process is as follows:

[0026] Pre-oxidation: Add 2.5g of potassium persulfate and 2.5g of phosphorus pentoxide to 12mL of concentrated sulfuric acid (98% mass fraction), stir and heat to 80°C to dissolve, then add 3g of graphite powder and continue to stir and react at 80°C 6h. After the reaction is complete, cool down to room temperature, add 0.5L of deionized water, filter with suction, wash with absolute ethanol until neutral, and dry at 65°C for 8 hours to obtain pre-oxidized graphite.

[0027] Oxidation: Add the above-mentioned pre-oxidized graphite to 80 mL of ice-bathed concentrated sulfuric acid (98% by mass), slowly add 8 g of potassium permanganate, and control the temperature at 5°C. After the addition, the temperature was raised to 35° C. for 3 h, and 150 mL of deionized water was slowly added. After stirring for 0.5 h, 500 mL of deionized water and 10 mL of hydrogen peroxide ...

Embodiment 2

[0033] The graphene oxide preparation process and steps in the present embodiment adopt the improved hummers method in the embodiment 1 to prepare the graphene oxide process;

[0034] Surface modification treatment: Add 0.30g graphene oxide to 45mL absolute ethanol solution, stir ultrasonically for 30min, add 1.5mL silane coupling agent KH550 dropwise to the above solution, react at 75°C for 10h, filter, wash and bake Dry to obtain 0.34 g of graphene oxide modified by a coupling agent.

[0035]Disperse 0.25g of graphene oxide modified by coupling agent in 10mL of absolute ethanol solvent, the concentration is 0.25g / 10mL, ultrasonically disperse for 0.5h;

[0036] Disperse 49.75 g of graphene oxide and polyether ether ketone (brand: 550UPF; manufacturer: Changchun Jida Special Plastic Engineering Research Co., Ltd.) powder modified by the coupling agent after ultrasonic dispersion in 500 mL ethanol solution, and after ultrasonic dispersion for 30 min After 20 minutes of mechan...

Embodiment 3

[0039] The graphene oxide preparation process and steps in this example adopt the improved hummers method in Example 1 to prepare graphene oxide process.

[0040] Surface modification treatment: Add 0.60g graphene oxide to 90mL absolute ethanol solution, stir ultrasonically for 30min, add 3.0mL silane coupling agent KH550 dropwise to the above solution, react at 75°C for 10h, filter, wash and bake Dry to obtain 0.68 g of graphene oxide modified by a coupling agent.

[0041] Take 0.50 g of graphene oxide modified by coupling agent and disperse it in 10 mL of absolute ethanol solvent, the concentration is 0.50 / 10 mL, and ultrasonically disperse for 0.5 h;

[0042] Disperse 49.50 g of graphene oxide and polyether ether ketone (grade: 550UPF; manufacturer: Changchun Jida Special Plastic Engineering Research Co., Ltd.) powder modified by the coupling agent after ultrasonic dispersion in 500 mL ethanol solution, and after ultrasonic dispersion for 30 min After 30 minutes of mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com