Polylactic acid antibacterial thin film and preparation method thereof

A polylactic acid and film technology, applied in the field of polylactic acid antibacterial film and its preparation, can solve problems such as barrier performance and antibacterial performance defects, and achieve the effects of improving barrier performance, easy surface effect and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A kind of preparation method of polylactic acid antibacterial film that the embodiment of the present invention provides, comprises the following steps:

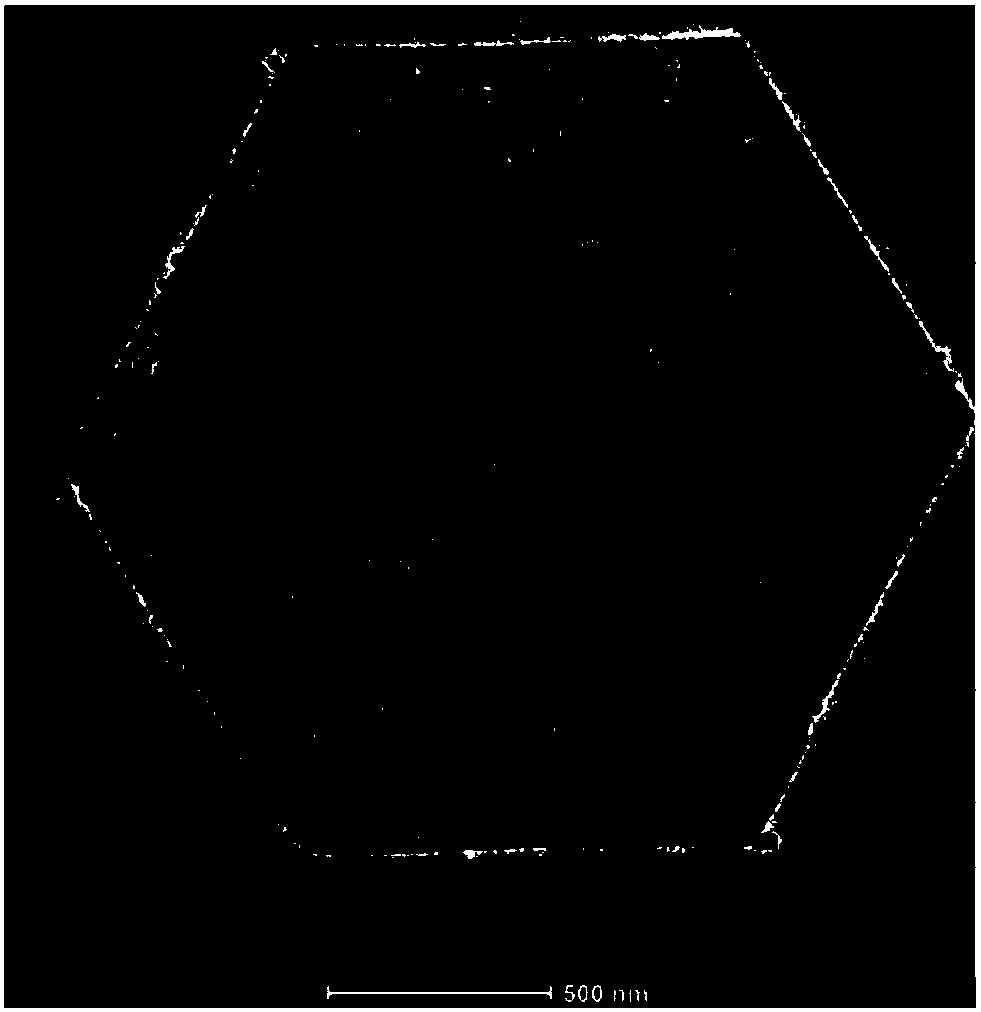

[0025] S1, acid-treating the nano-layered clay to obtain acid-activated layered clay;

[0026] S2, dispersing the acid-activated layered clay in water, adding an aqueous solution of tannic acid, and after adsorption, adding an iron salt solution to obtain a reaction solution, and reacting the reaction solution for 0.8 to 1.5 minutes to obtain a modified layered clay;

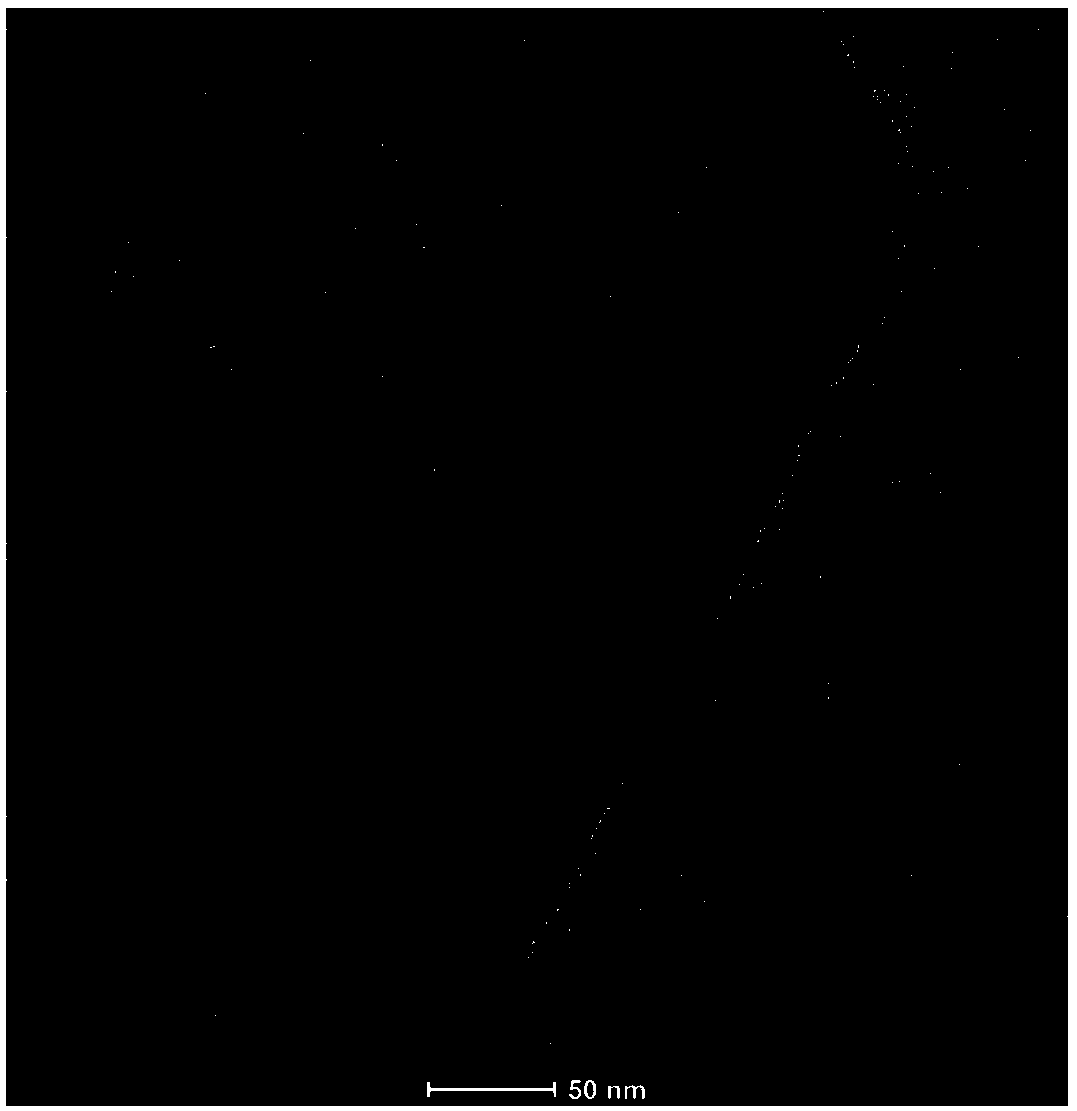

[0027] S3, adding glutathione dropwise to the silver nitrate solution to obtain a nano-silver precursor;

[0028] S4, dispersing the modified layered clay in water, adding the nano-silver precursor under ice bath conditions, stirring and reacting, filtering and drying to obtain nano-silver loaded modified layered clay;

[0029] S5, mixing the nano-silver loaded modified layered clay and polylactic acid to form a film.

[0030] Further, in a preferred ...

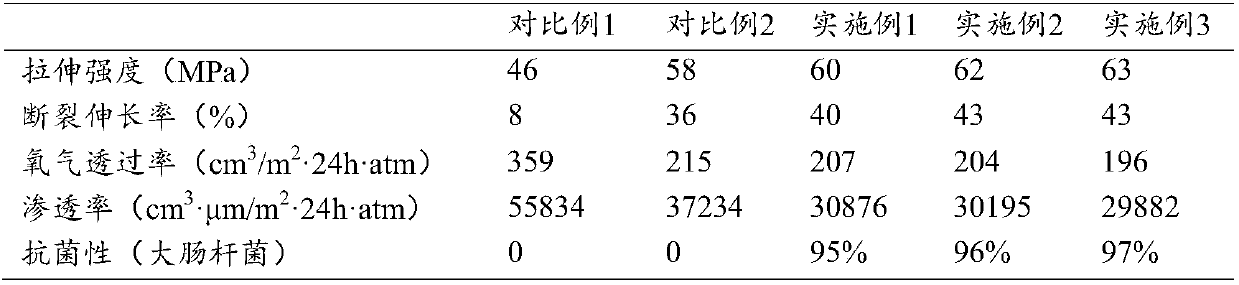

Embodiment 1

[0048] An antibacterial polylactic acid film provided in this embodiment is prepared according to the following steps.

[0049] (1) Weigh 0.18 mol of magnesium chloride, 0.08 mol of aluminum chloride and 0.385 mol of urea and dissolve them in deionized water, then sonicate for 30 minutes, transfer to an autoclave, and then put them in a muffle furnace at 160°C for 6 hours , after the reaction, filter and wash to obtain LDHs powder.

[0050] (2) Disperse 0.3g of LDHs in 50ml of deionized water, sonicate for 30min, add 5ml of 0.01M HCl and react at 60°C for 2.5h. After the reaction, wash by centrifugation and freeze-dry to obtain acid-activated LDHs.

[0051] (3) Prepare TA aqueous solution and FeCl with a concentration of 24mM respectively 3 aqueous solution.

[0052] (4) Add 0.06g of acid-activated LDHs into 50ml of deionized water, sonicate for 45min, then add 0.5ml of TA aqueous solution (0.02gTA), after fully adsorbed, add 0.2ml of FeCl 3 Aqueous solution (0.0008g FeCl ...

Embodiment 2

[0058] An antibacterial polylactic acid film provided in this embodiment is prepared according to the following steps.

[0059] (1) Weigh 0.18 mol of magnesium chloride, 0.08 mol of aluminum chloride and 0.385 mol of urea and dissolve them in deionized water, then sonicate for 30 minutes, transfer to a high-pressure reactor, and first heat up to 120 ℃ at 4 ℃ / min for 3 hours , and then heated at 1°C / min to 160°C for 4h to obtain LDHs powder.

[0060] (2) Disperse 0.3g of LDHs in 50ml of deionized water, sonicate for 30min, add 5ml of 0.01M HCl and react at 60°C for 2.5h. After the reaction, wash by centrifugation and freeze-dry to obtain acid-activated LDHs.

[0061] (3) Prepare TA aqueous solution and FeCl with a concentration of 24mM respectively 3 aqueous solution.

[0062] (4) Add 0.06g of acid-activated LDHs into 50ml of deionized water, sonicate for 45min, then add 0.5ml of TA aqueous solution (0.02gTA), after fully adsorbed, add 0.2ml of FeCl 3 Aqueous solution (0.000...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com