Soybean protein-calcium carbonate nano-adhesive as well as preparation method and application thereof

A technology of soybean protein and calcium carbonate is applied in the preparation of protein adhesives, animal glue or gelatin, adhesives, etc., to achieve the effects of reducing dosage and cost, saving petroleum resources, and prolonging use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

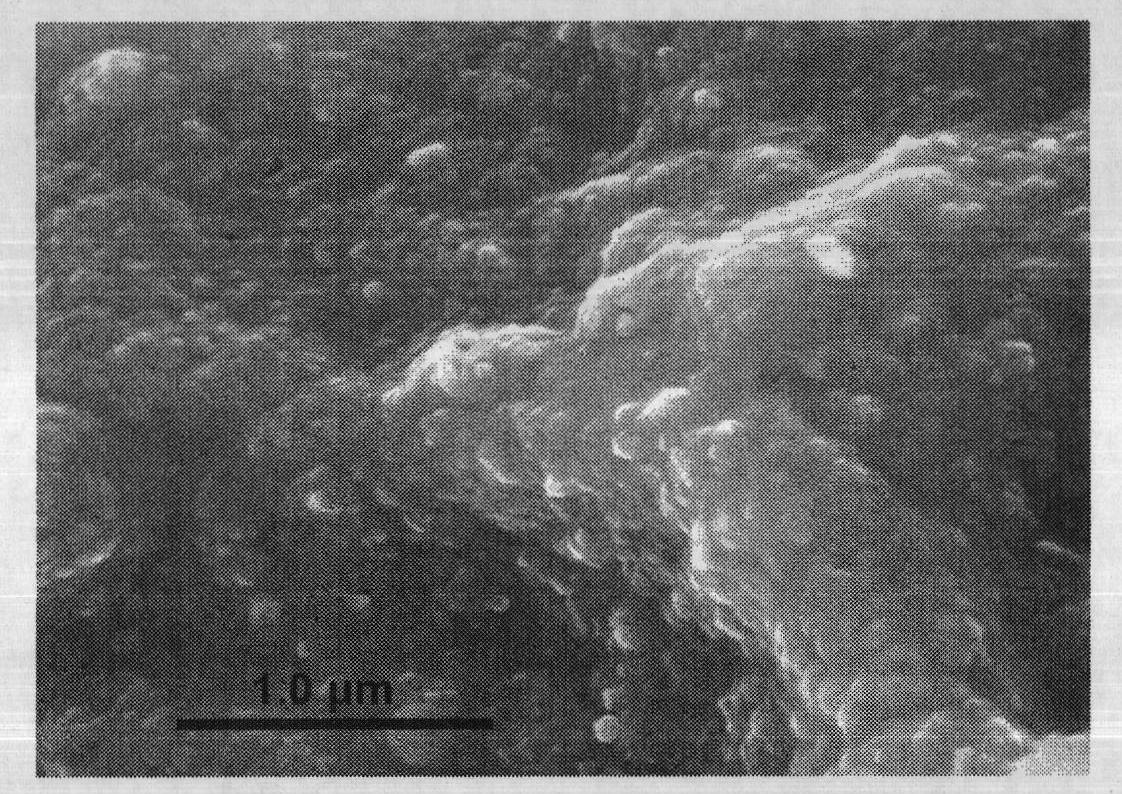

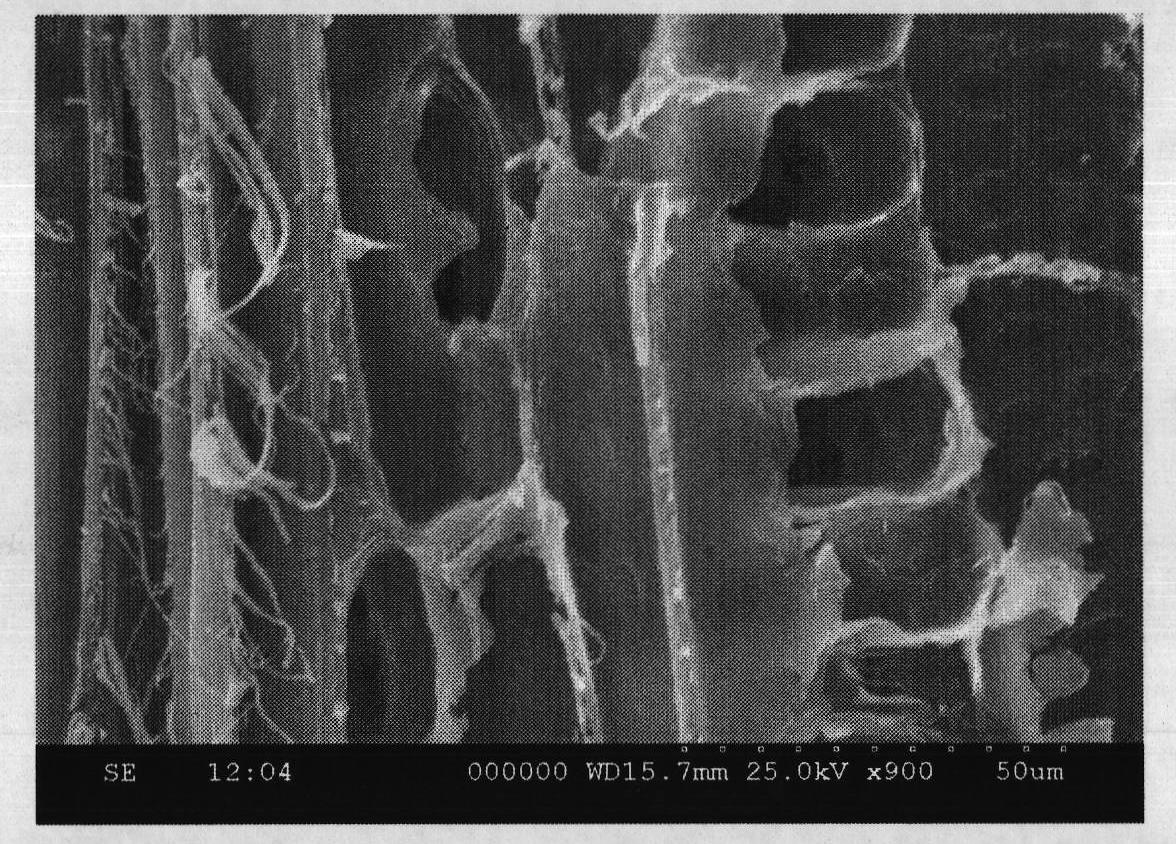

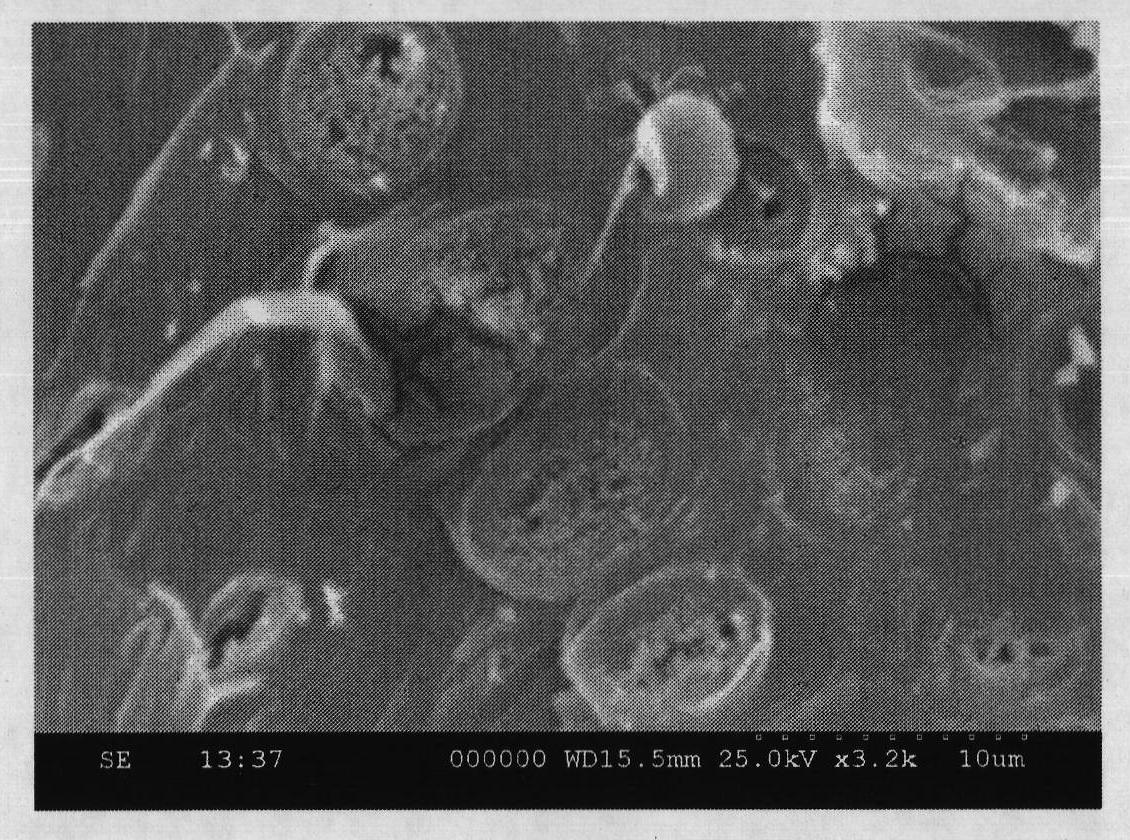

Image

Examples

Embodiment 1

[0033] Add soybean protein isolate to water to swell (soybean protein isolate content is 11%), slowly raise the temperature to 60°C, stir and react for 3 hours to obtain soybean protein suspension, and pass through a high-pressure homogenizer at 10KPa to obtain milky pure soybean protein adhesive agent.

Embodiment 2

[0035] Soybean protein isolate was placed in a tetrafluoroethylene vessel and added to water to swell (soybean protein isolate content was 11%). After slowly heating up to 60°C, 0.05mol / L calcium hydroxide aqueous solution was added to make the pH of the system 9. After 2 hours, Add 0.2 mol / L sodium potassium carbonate to the dissolved protein solution, the molar ratio of the added sodium potassium carbonate and calcium hydroxide is 1:1, stop the reaction after stirring and reacting at 60°C for 3 hours, and obtain soybean protein-calcium carbonate suspension Liquid, under 10KPa through a high-pressure homogenizer to obtain emulsion adhesive.

Embodiment 3

[0037] Put the concentrated soybean protein in a glass vessel and add water to swell (concentrated soybean protein content is 15%), slowly heat up to 80°C, add 0.1mol / L calcium hydroxide saturated solution to make the pH of the system 10, after 1.5 hours In the protein solution of dissolving, add 0.09mol / L potassium bicarbonate, the mol ratio of potassium bicarbonate and calcium hydroxide is 1: 2, stops reaction after stirring reaction at 80 ℃ for 6 hours, obtains soybean protein-calcium carbonate suspension, The emulsion adhesive was obtained through a high-pressure homogenizer at 25KPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com