Binding material for bituminous concrete base-surfaces and preparation method thereof

A technology of asphalt concrete and bonding materials, which is applied in the field of asphalt concrete, can solve problems such as bonding failure, and achieve the effects of simple application and operation, high bonding strength, and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

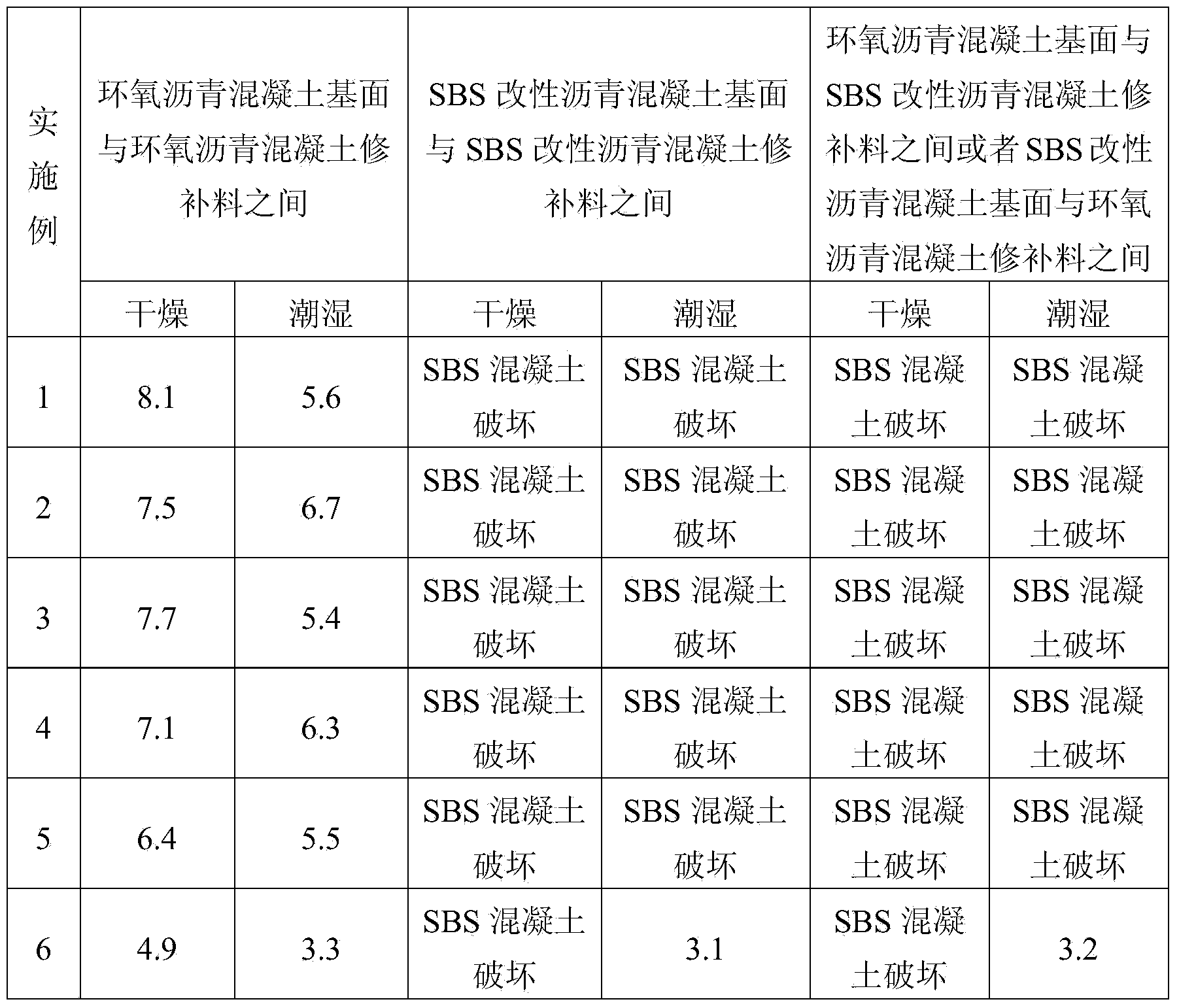

Examples

preparation example Construction

[0045] The above-mentioned preparation method for the bonding material of the asphalt concrete base surface specifically comprises the following steps:

[0046] The preparation method of matrix component comprises the following steps:

[0047] The matrix component is calculated in parts by weight and consists of the following raw materials: 10-80 parts of asphalt, 14-65 parts of synthetic resin, 2-20 parts of diluent, 1.5-5 parts of solubilizer, and the sum of the raw materials of the matrix component is 100 copies;

[0048] (1) First put the asphalt into the container, then add the diluent while stirring, and stir evenly;

[0049] (2) Add a solubilizer, seal it for 1.5 hours under stirring, and finally add synthetic resin and stir evenly;

[0050] The preparation method of hardening component comprises the following steps:

[0051] The hardening component consists of the following raw materials in parts by weight: 80-99 parts of amine curing agent, 1-20 parts of penetratin...

Embodiment 1

[0064] This embodiment provides a kind of bonding material for the base surface of asphalt concrete, which is composed of a matrix component and a hardening component, and the mass ratio of the matrix component and the hardening component is 100:60;

[0065] The matrix component is calculated in parts by weight and consists of the following raw materials:

[0066] 10 parts of coal tar pitch, 65 parts of E51 epoxy resin, 20 parts of turpentine, 5 parts of polysulfide rubber;

[0067] Among them: the average relative molecular mass of polysulfide rubber is 1000-2000, and the pH value is 6-8; the four-component content of coal tar pitch satisfies (asphaltene + colloid) / total amount of asphalt ≤ 0.46, and asphaltene / total amount of asphalt ≤0.09.

[0068] The hardening component is calculated in parts by weight and consists of the following raw materials:

[0069] 99 parts of anthracenyl alcohol amine curing agent, 1 part of a mixture of glycerin, acetone, and gasoline;

[...

Embodiment 2

[0082] This embodiment provides a kind of bonding material for asphalt concrete base surface, is made up of matrix component and hardening component, and the mass ratio of matrix component and hardening component is 100:50;

[0083] The matrix component is calculated in parts by weight and consists of the following raw materials:

[0084] 20 parts of straight run asphalt, 58.5 parts of a mixture of toluene diisocyanate and rosin resin with a mass ratio of 7:3, 20 parts of a mixture of turpentine oil and gasoline with a mass ratio of 4:1, and 1.5 parts of polysulfide rubber;

[0085] Among them: the average relative molecular mass of polysulfide rubber is 1000-2000, and the pH value is 6-8; the four-component content of straight-run asphalt meets (asphaltene + colloid) / total asphalt ≤ 0.46, and asphaltene / total asphalt ≤0.09.

[0086] The hardening component is calculated in parts by weight and consists of the following raw materials:

[0087] 95 parts of anthracenyl alcohol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com