Ultra-light energy-storing gypsum board and preparation method thereof

A gypsum board and energy storage technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of many air bubbles, reducing the weight of gypsum board, and affecting long-term performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

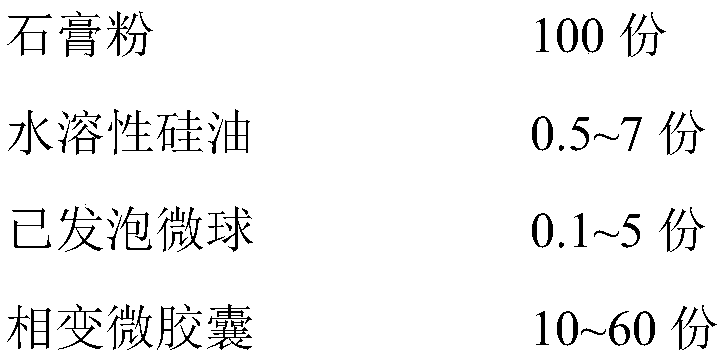

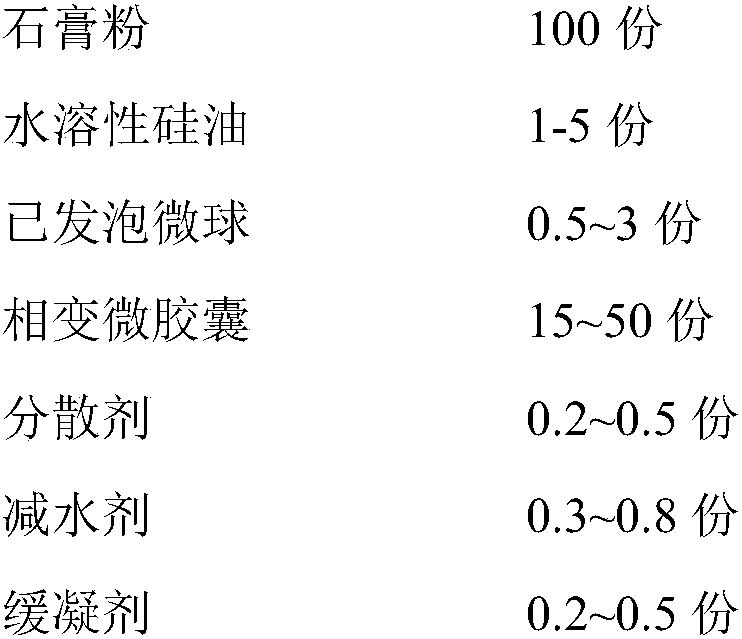

Method used

Image

Examples

Embodiment 1

[0091] Preparation of Phase Change Microcapsules

[0092] water box:

[0093]

[0094] Oil phase:

[0095]

[0096]

[0097] Preparation:

[0098]Add the water phase to the oil phase at 40°C, stir the reaction at 800rpm for 40 minutes, and continue to stir at this temperature for 2 hours, then filter with suction, collect the solids, wash with water, and put them in a vacuum oven at 50°C After drying for 20 hours, the phase change microcapsules can be obtained.

Embodiment 2

[0100] water box:

[0101]

[0102] Oil phase:

[0103]

[0104] Preparation:

[0105] Add the water phase to the oil phase at 40°C, stir the reaction at 3500rpm for 40 minutes, maintain stirring at 60°C for 9 hours, then filter with suction, collect the solids, wash with water, and dry in a vacuum oven at 50°C for 24 hours, the phase change microcapsules can be obtained.

Embodiment 3

[0107] water box:

[0108]

[0109] Oil phase:

[0110]

[0111] Preparation:

[0112] Add the water phase to the oil phase at 40°C, stir the reaction at 8000rpm for 40 minutes, maintain stirring at 90°C for 15 hours, then filter with suction, collect the solids, wash with water, and dry in a vacuum oven at 50°C for 20 hours, the phase change microcapsules can be obtained.

[0113] The composition and properties of the phase change microcapsules of each embodiment are shown in Table 1.

[0114] Table 1 Composition and properties of phase change microcapsules

[0115]

[0116]

[0117] From the particle size and distribution results of the phase change microcapsules in Table 1, it can be found that the particle size distribution of each phase change microcapsule is uniform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com