High-barrier property toughening polylactic acid film and preparation method thereof

A high-barrier, polylactic acid technology, applied in flexible coverings, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of polylactic acid gas barrier properties, slow crystallization rate, hindering applications, etc., to achieve extended Effects of gas permeation path, improvement of barrier properties, and improvement of compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a high barrier toughened polylactic acid film, which is prepared according to the following steps:

[0048] Weigh 0.18 mol of magnesium chloride, 0.08 mol of aluminum chloride and 0.285 mol of urea and dissolve them in deionized water, then sonicate for 30 minutes, transfer them to a high-pressure reactor, and then put them in a muffle furnace at 180°C for 18 hours, and the reaction is over Afterwards, filter and wash to obtain LDHs powder.

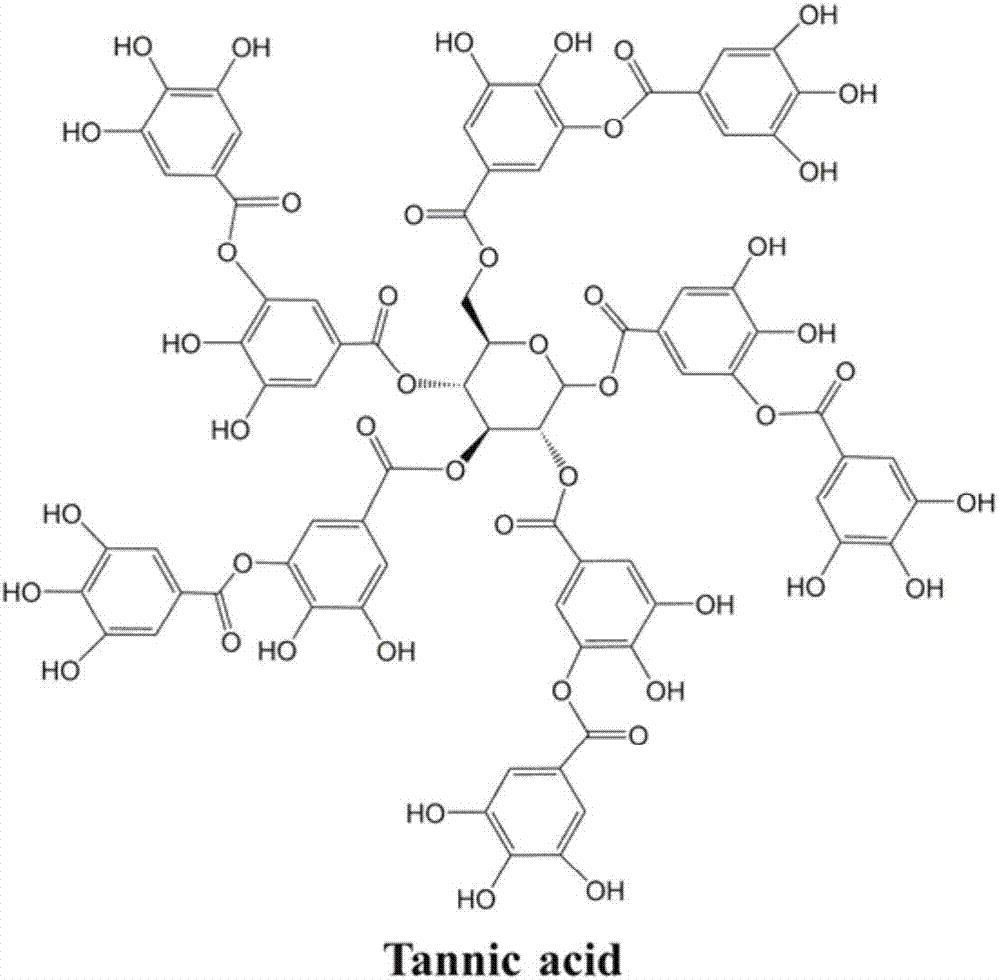

[0049] Prepare 24mM TA aqueous solution and FeCl respectively 3 aqueous solution.

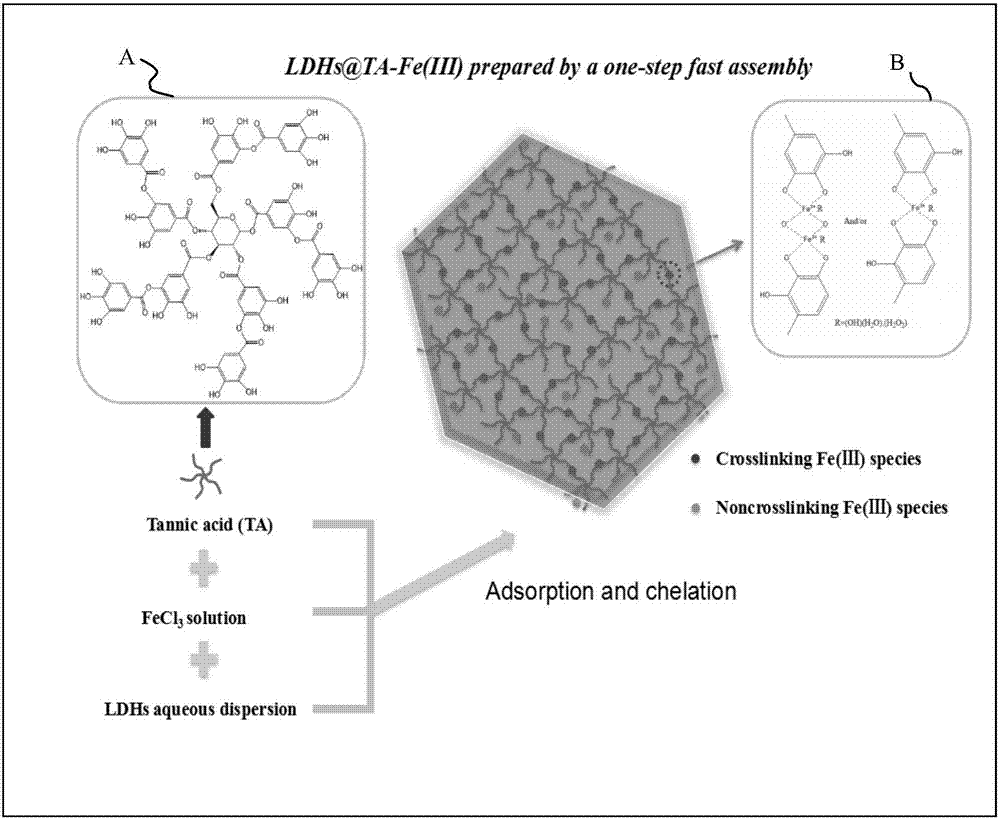

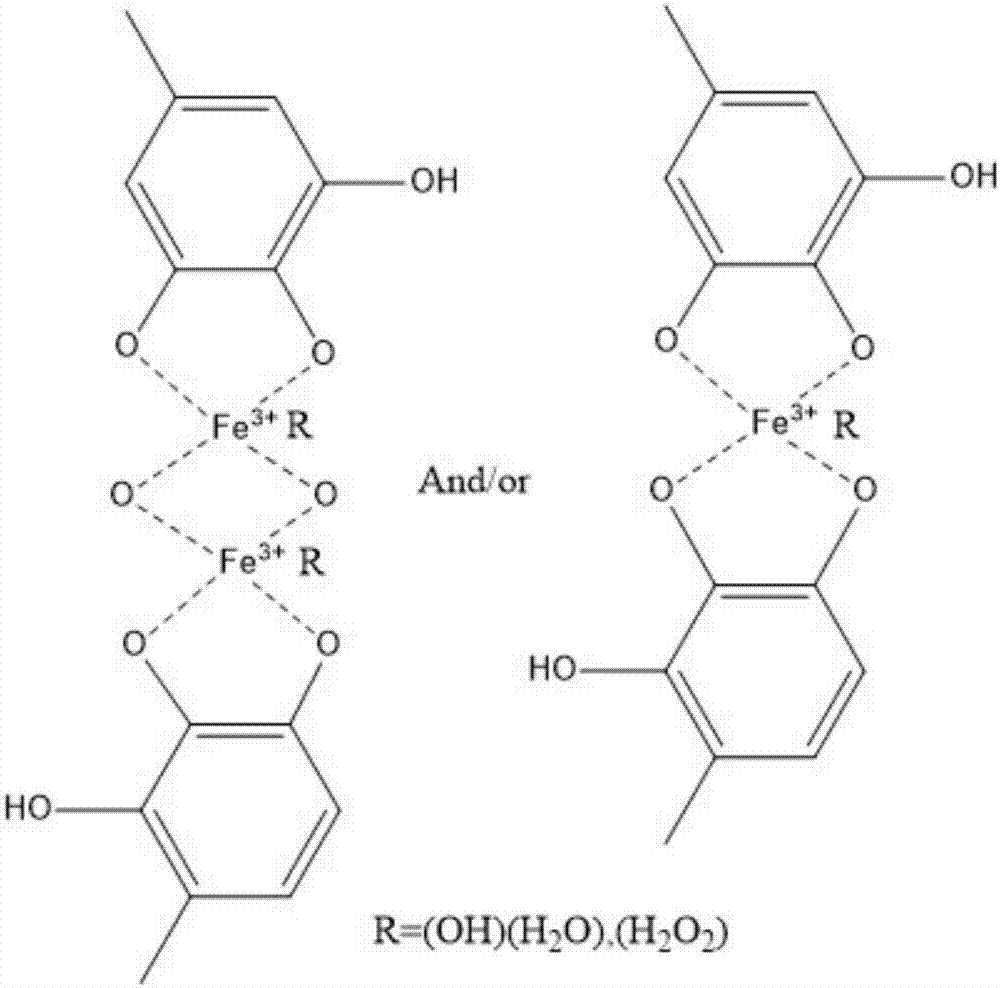

[0050] Weigh 0.05g of LDHs into 50ml of deionized water, sonicate for 45min, then add 0.5ml of TA aqueous solution, after fully adsorbed, then add 0.2ml of FeCl 3 The reaction solution was obtained from an aqueous solution, and after the reaction solution was rapidly reacted at room temperature for 1 min, it was filtered, centrifuged, washed, and freeze-dried to obtain LDHs@TA-Fe(Ⅲ) powder.

[0051] Disperse 0.042g of LDH...

Embodiment 2

[0054] This embodiment provides a high barrier toughened polylactic acid film, which is prepared according to the following steps:

[0055] Weigh 0.18 mol of magnesium chloride, 0.08 mol of zinc chloride, 0.13 mol of cerium chloride and 0.4095 mol of urea and dissolve them in deionized water, then sonicate for 20 minutes, transfer them to an autoclave, and then put them into a muffler at 120°C React in the furnace for 36 hours. After the reaction, filter and wash to obtain LDHs powder.

[0056] Prepare TA aqueous solution and FeCl with a concentration of 20mM respectively 3 aqueous solution.

[0057] Weigh 0.05g of LDHs into 50ml of deionized water, sonicate for 45min, then add TA aqueous solution (the concentration of TA in the reaction solution is 0.1g / L), after fully adsorbed, add FeCl 3 Aqueous solution (FeCl 3 The concentration in the reaction solution is 0.02g / L) to obtain a reaction solution, and after the reaction solution reacts rapidly at room temperature for 0.8m...

Embodiment 3

[0061] This embodiment provides a high barrier toughened polylactic acid film, which is prepared according to the following steps:

[0062] Weigh 0.2 mol of nickel chloride, 0.2 mol of zinc chloride, 0.1 mol of lanthanum chloride and 0.55 mol of urea and dissolve them in deionized water, then sonicate for 30 minutes, transfer them to an autoclave, and then put them in a 180°C React in a muffle furnace for 18 hours. After the reaction, filter and wash to obtain LDHs powder.

[0063] Prepare 25mM TA aqueous solution and FeCl respectively 3 aqueous solution.

[0064] Weigh 0.05g of LDHs into 50ml of deionized water, sonicate for 50min, then add TA aqueous solution (the concentration of TA in the reaction solution is 1g / L), after fully adsorbed, add FeCl 3 Aqueous solution (FeCl 3 The concentration in the reaction solution is 1 g / L) to obtain a reaction solution, and after the reaction solution reacts rapidly at room temperature for 1.5 min, it is filtered, centrifuged, washed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com