Glass fiber-reinforced polypropylene resin composition formula and preparation method

A technology of polypropylene resin and glass fiber, which is applied in the formulation and preparation of plastic materials, can solve the problems of high cost and limitations, and achieve the effects of high impact performance, improved impact strength, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

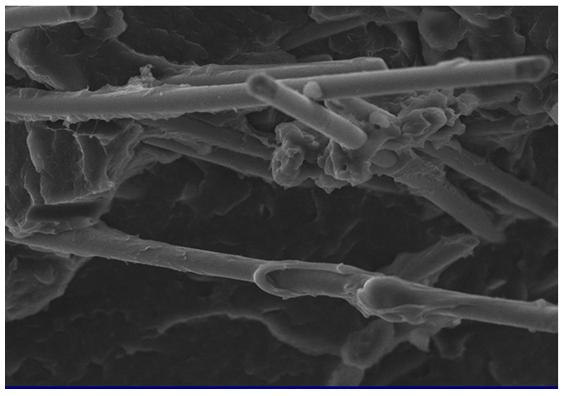

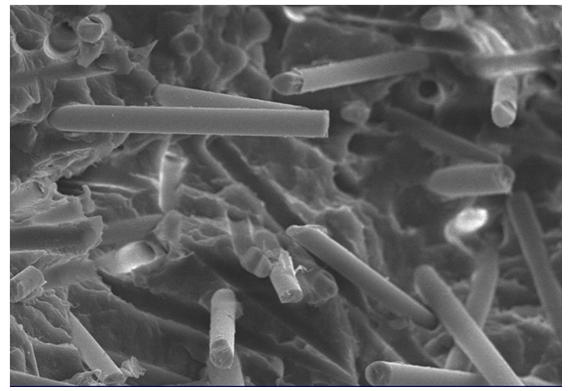

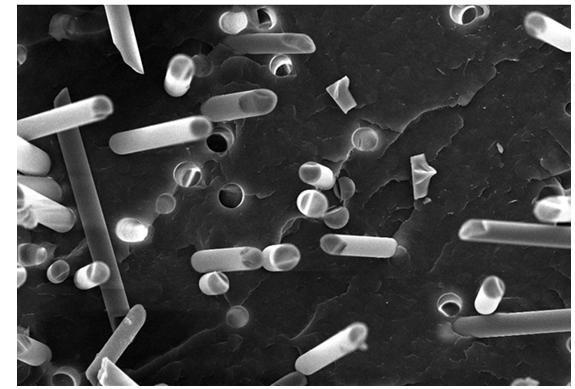

Image

Examples

Embodiment 1

[0023] Embodiment 1 of the present invention: Calculated in parts by weight, 0.1 part of dicumyl peroxide (crosslinking agent is diacyl peroxide, sulfonyl peroxide, dihydrocarbon peroxydicarbonate, peroxy ester) , percarbonate esters, peroxyketals, dihydrocarbon peroxides, alkyl hydroperoxides, ketone peroxides or peracids, or a mixture of any two or more, the implementation of the present invention The example uses dicumyl peroxide as an example) and 0.5 parts of antioxidant 1010 are dispersed in 5 parts of phthalic acid type unsaturated polyester (the unsaturated resin used can be phthalic acid type unsaturated polyester ester, isophthalic acid type unsaturated polyester, bisphenol A type unsaturated polyester and vinyl ester type unsaturated polyester) to form solution A; solution A and 60 parts of homopolypropylene particles (The melt index of homopolypropylene at ASTMD1238, 230°C is 15g / min, and its tensile strength is greater than 20MPa) Mixed in a high-speed mixer for 3...

Embodiment 2

[0024] Embodiment 2 of the present invention: Calculated in parts by weight, disperse 0.01 part of di-tert-butyl peroxide and 0.1 part of antioxidant 1010 in 1 part of isophthalic acid type unsaturated polyester to form solution A; A and 50 parts of block copolymerized polypropylene particles (the melt index of block copolymerized polypropylene at ASTMD1238, 230°C is 1g / min, and its tensile strength is greater than 20MPa) were placed in a high mixer and mixed for 2 minutes to obtain a mixed material B; then the mixed material B is added to the hopper of a twin-screw extruder with a screw diameter of 40 mm, and 50 parts of alkali-free glass fibers with a diameter of 2 μm are added during the extrusion process (glass fibers are treated with a coupling agent to obtain continuous alkali-free glass fiber), the temperature of the screw inlet and outlet sections of the twin-screw extruder is 210°C, the temperature of the middle section is 230°C, and the screw speed is 320rpm. After th...

Embodiment 3

[0025] Embodiment 3 of the present invention: Calculated in parts by weight, a mixture of 0.2 parts of tert-butyl peroxyisopropyl carbonate and cyclohexanone peroxide and 1 part of antioxidant 1010 are dispersed in 10 parts of bisphenol A type unsaturated In polyester, solution A is formed; solution A is mixed with 45 parts of homopolypropylene particles and 45 parts of block copolymerized polypropylene particles (the melt index of homopolypropylene and block copolymerized polypropylene particles is equal to ASTMD1238, 230 °C is 30g / min, and its tensile strength is greater than 20MPa) placed in a high mixer and mixed for 3 minutes to obtain the mixed material B; Add 5 parts of alkali-free glass fibers with a diameter of 13 μm (the glass fibers are treated with a coupling agent to obtain continuous alkali-free glass fibers). 230°C, the screw speed is 320rpm, the extruded material is water-cooled and pelletized to obtain pellets C; the pellets C are added to the injection moldin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com