Wear-resistant and temperature-resistant artificial turf and preparation method thereof

A technology of artificial turf and artificial grass, which is applied in the manufacture of rayon, conjugated synthetic polymer rayon, textiles and papermaking, etc. It can solve the problems of grass fiber shedding, poor temperature resistance, poor wear resistance, etc., and achieve interface Effects of enhanced force, improved temperature resistance, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

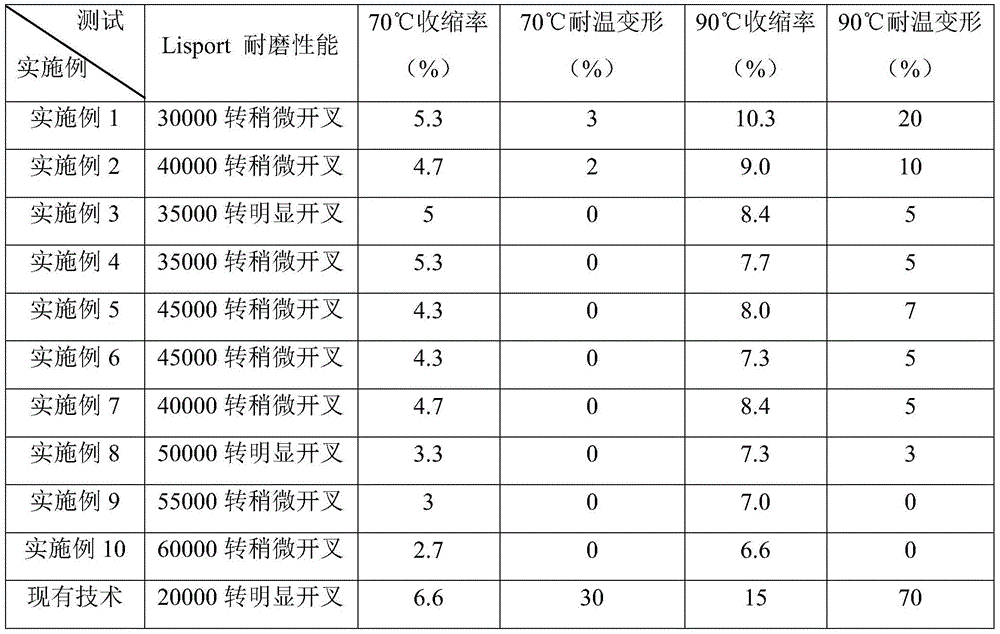

Examples

Embodiment 1

[0031] Wear-resistant and temperature-resistant masterbatch formula: LLDPE (melt index 10g / 10min) 50Kg

[0032] Superfine calcium carbonate (2500 mesh) 50Kg

[0033] After mixing the powder in the high-speed mixer for 5 minutes, put it into the feeding barrel of the twin-screw extruder. The screw extruder is plasticized, extruded, and granulated. The set temperature of the extruder is 160°C, and the screw speed is 40r / min. .

[0034] Wear-resistant and temperature-resistant artificial grass fiber formula: LLDPE (melt index 2g / 10min) 58Kg

[0035] Thermoplastic elastomer DF740 20Kg

[0036] Wear-resistant and temperature-resistant masterbatch 10Kg

[0037] Anti-aging agent 10104Kg

[0038] Masterbatch 8Kg

[0039] After mixing evenly, the artificial grass fiber with wear-resistant and temperature-resistant masterbatch is obtained after blending extrusion, traction, drafting, and heat setting treatment. The temperature of the oven is 100° C., and the heat setting shrinkage...

Embodiment 2

[0042] Wear-resistant and temperature-resistant masterbatch formula: LLDPE (melt index 10g / 10min) 50Kg

[0043] Superfine calcium carbonate (2500 mesh) 50Kg

[0044] After mixing the powder in the high-speed mixer for 5 minutes, put it into the feeding barrel of the twin-screw extruder. The screw extruder is plasticized, extruded, and granulated. The set temperature of the extruder is 160°C, and the screw speed is 40r / min. .

[0045] Wear-resistant and temperature-resistant artificial grass fiber formula: LLDPE (melt index 2g / 10min) 48Kg

[0046] Thermoplastic elastomer DF740 20Kg

[0047] Wear-resistant and temperature-resistant masterbatch 20Kg

[0048] Anti-aging agent 10104Kg

[0049] Masterbatch 8Kg

[0050] After mixing evenly, the artificial grass fiber with wear-resistant and temperature-resistant masterbatch is obtained after blending extrusion, traction, drafting, and heat setting treatment. The temperature of the oven was 100° C., and the heat setting shrinkag...

Embodiment 3

[0053] Wear-resistant and temperature-resistant masterbatch formula: LLDPE (melt index 10g / 10min) 50Kg

[0054] Superfine calcium carbonate (2500 mesh) 50Kg

[0055] After mixing the powder in the high-speed mixer for 5 minutes, put it into the feeding barrel of the twin-screw extruder. The screw extruder is plasticized, extruded, and granulated. The set temperature of the extruder is 160°C, and the screw speed is 40r / min. .

[0056] Wear-resistant and temperature-resistant artificial grass fiber formula: LLDPE (melt index 2g / 10min) 38Kg

[0057] Thermoplastic elastomer DF740 20Kg

[0058] Wear-resistant and temperature-resistant masterbatch 30Kg

[0059] Anti-aging agent 10104Kg

[0060] Masterbatch 8Kg

[0061] After mixing evenly, the artificial grass fiber with wear-resistant and temperature-resistant masterbatch is obtained after blending extrusion, traction, drafting, and heat setting treatment. The temperature of the oven was 100° C., and the heat setting shrinkag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com