Patents

Literature

43results about How to "Improve pull-out force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

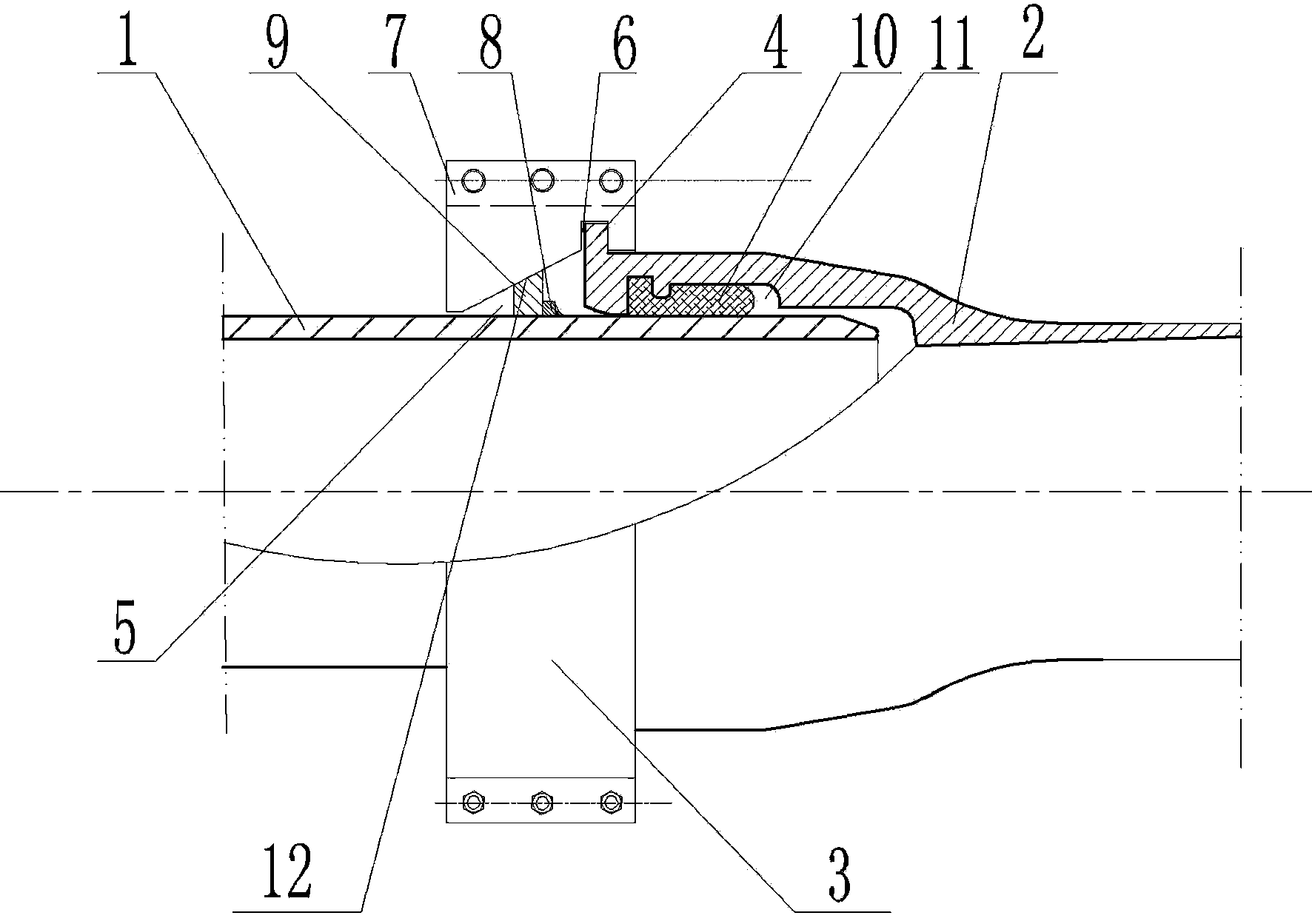

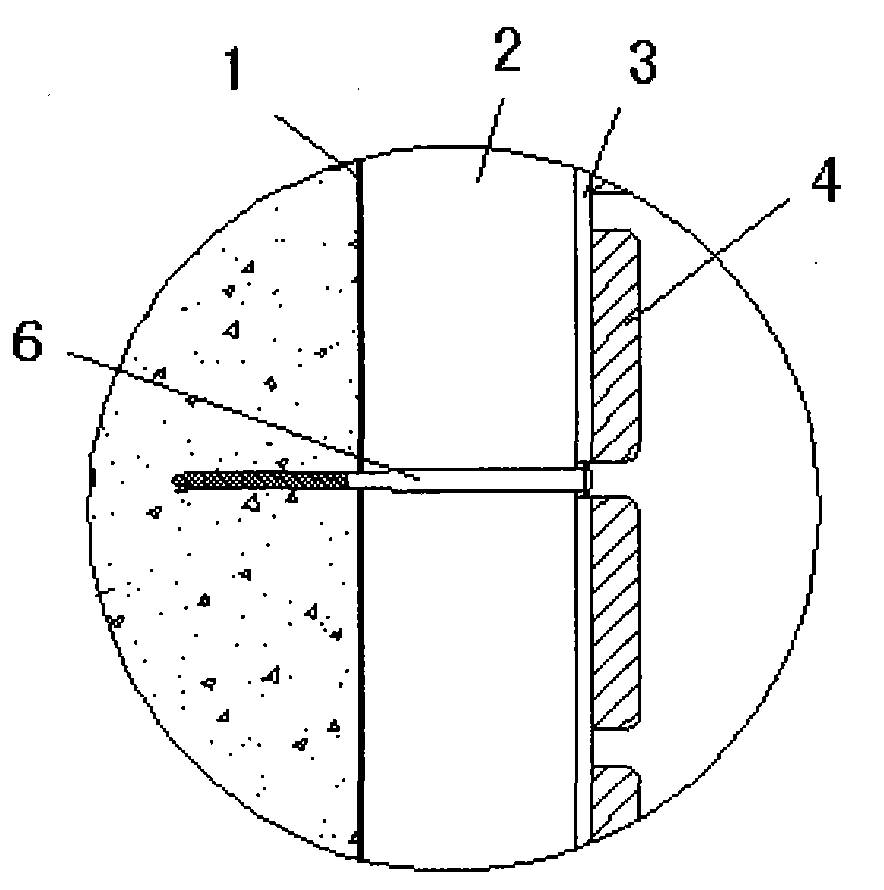

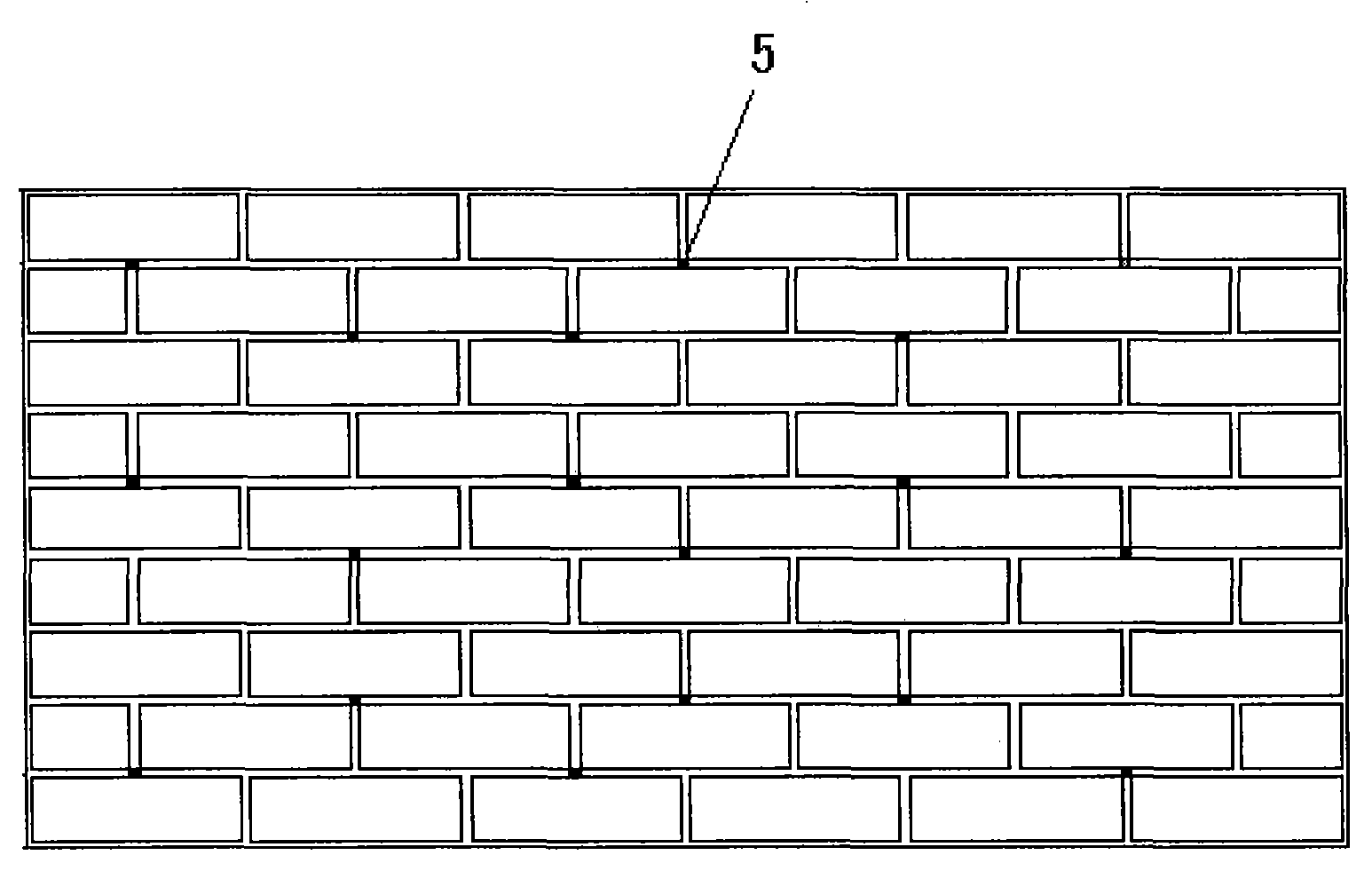

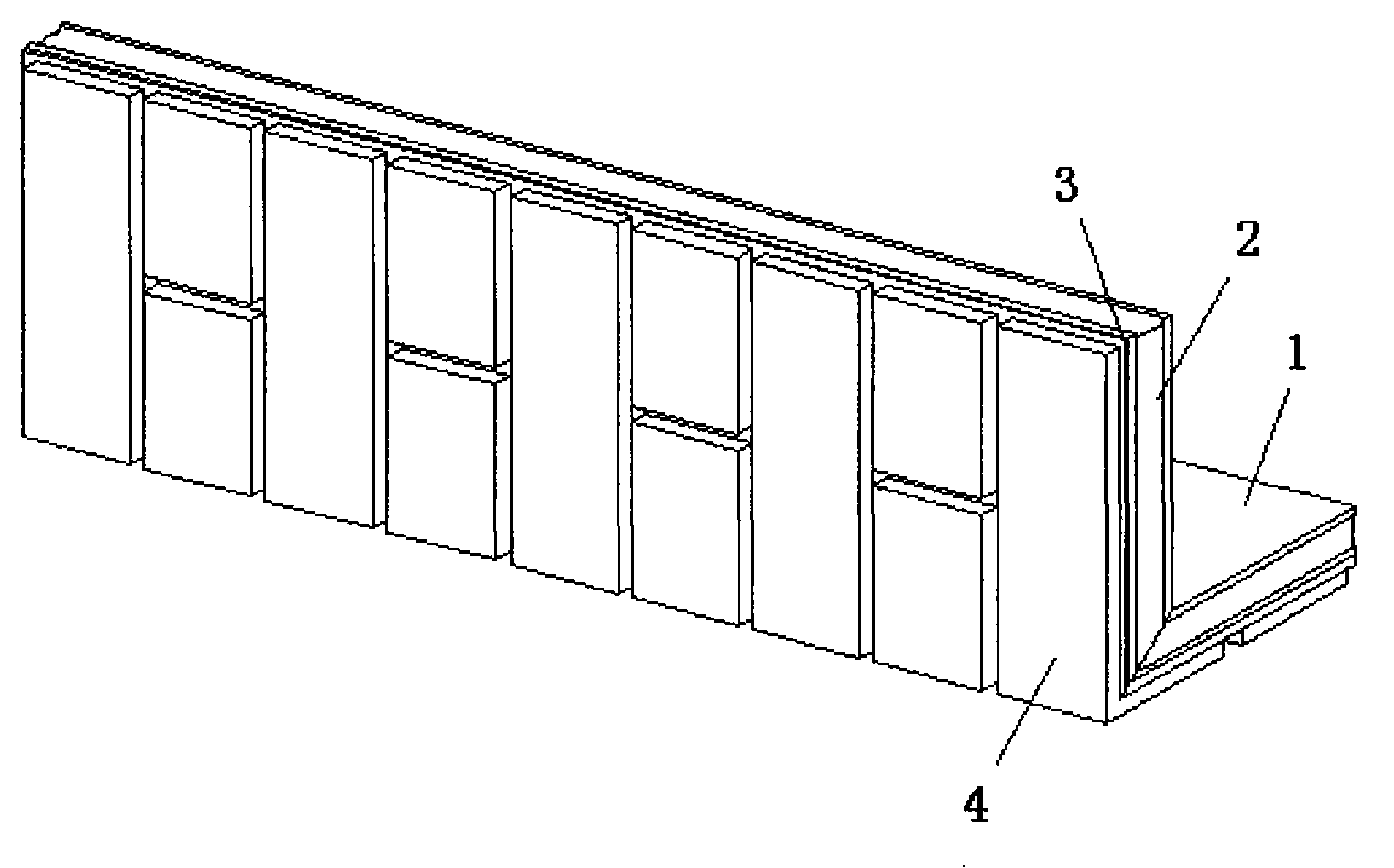

External wall heat-preserving decoration wall and its construction process

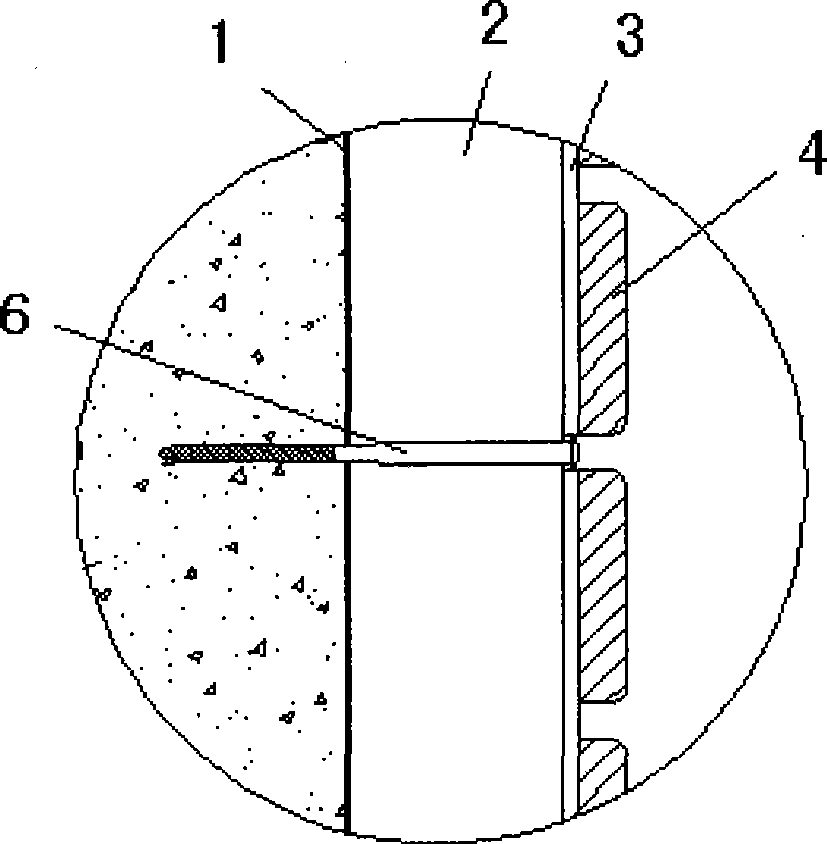

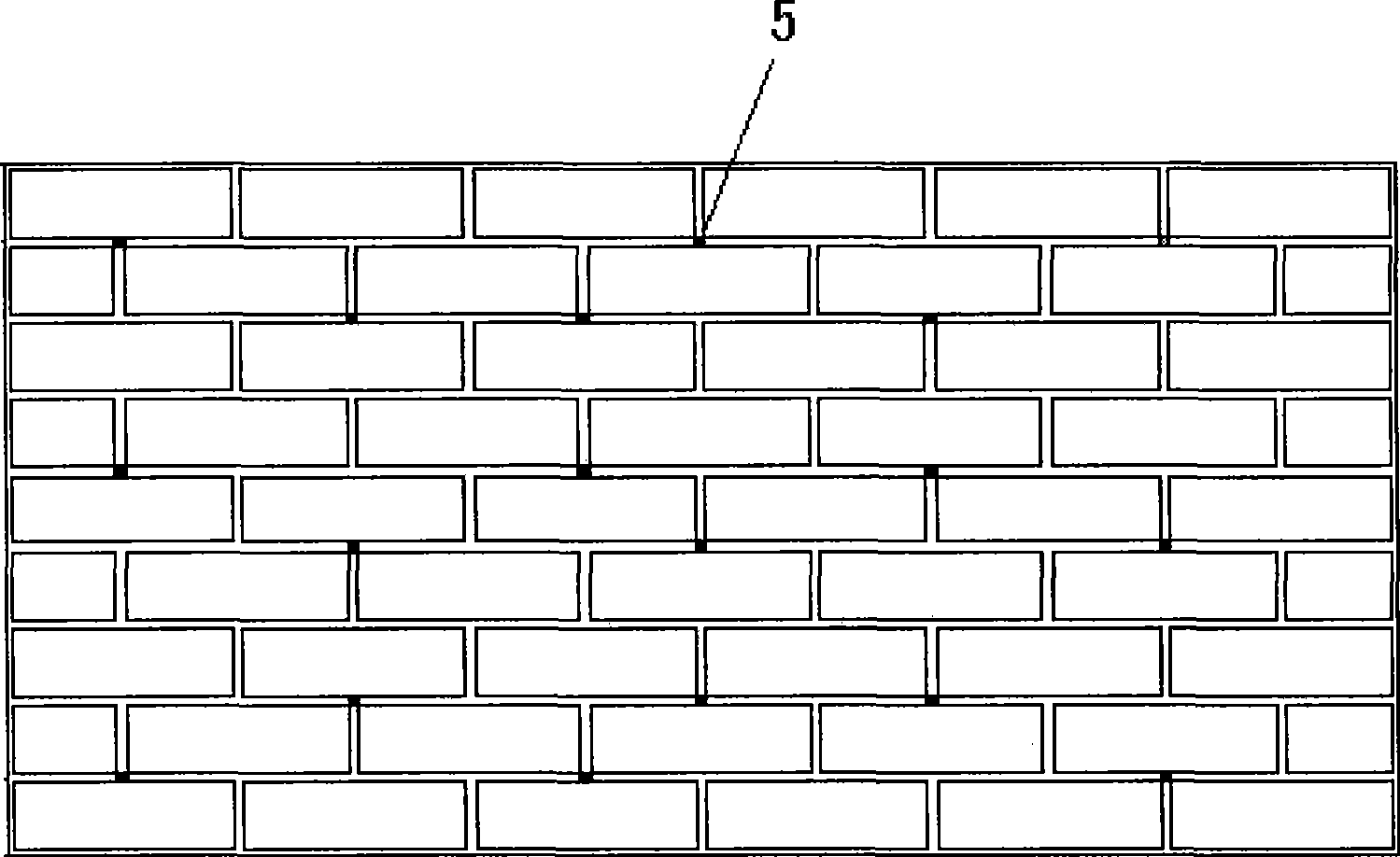

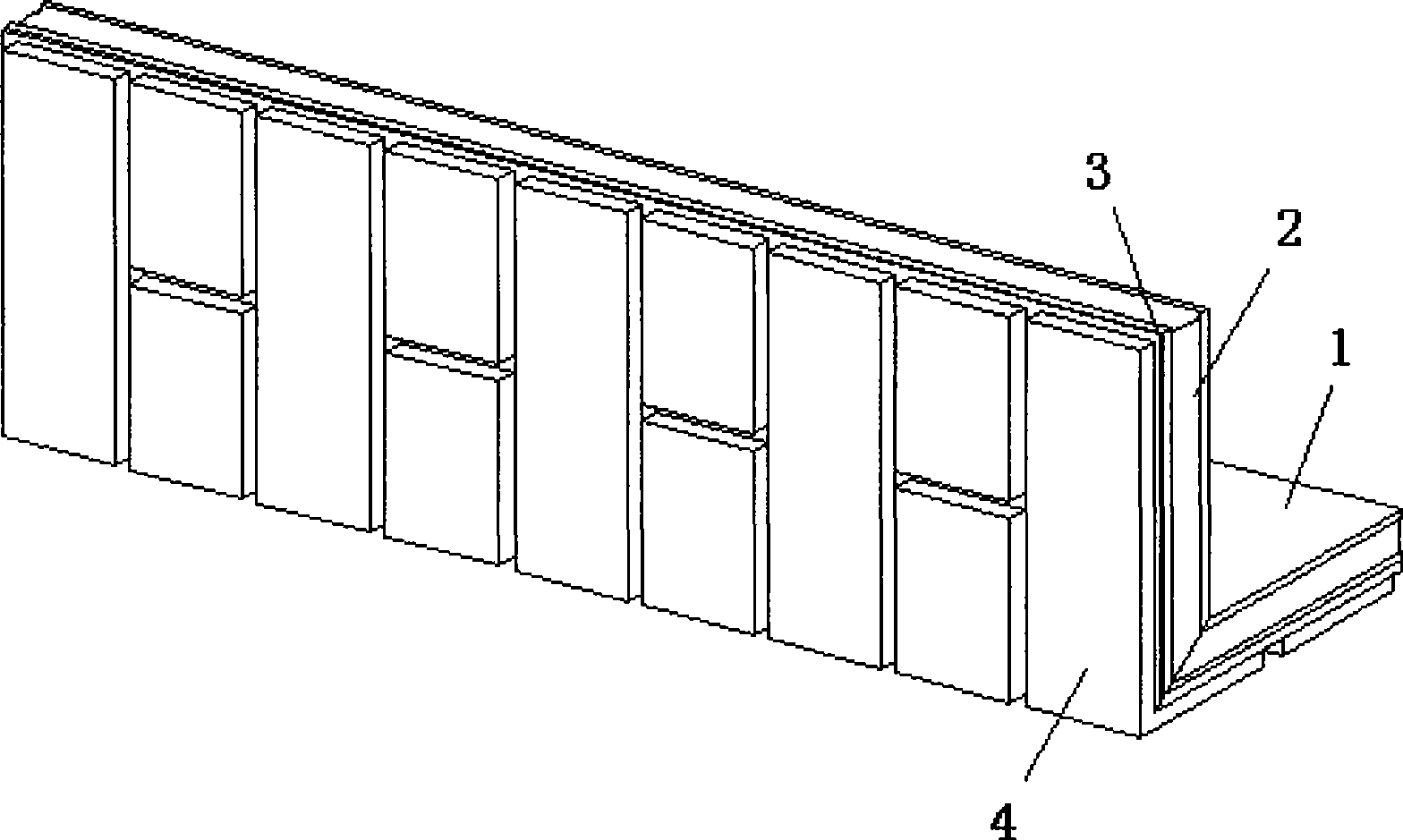

The invention relates to an insulated decorating wall for an external wall and a construction technology thereof, which is characterized in that the insulated decorating wall comprises a plurality of insulated decorating plates which are spliced and fixed on the base wall surface of the external wall, each insulated decorating wall comprises a moisture-proof film layer, an insulating layer is bonded on the upper surface of the moisture-proof film layer, and a finishing coat is bonded on the upper surface of the insulating layer through a bonding layer; the finishing coat is formed by splicing a plurality of face bricks, marks of positions for anchoring are arranged at the brick work joints of the face bricks, circulation grooves for injecting adhesive are oppositely arranged on the insulating layer at the joint of adjacent insulated decorating walls correspondingly, and injection ports and pressure relief ports can be arranged to be communicated with the circulation grooves. As basic sections of the insulated decorating plates are manufactured in advanced and can be assembled directly on site, or only need partial cutting at the most, without sticking the face bricks onto the wall on site, the time is greatly saved and the danger of aloft work is avoided, moreover, all-weather working conditions can be adapted.

Owner:李建中

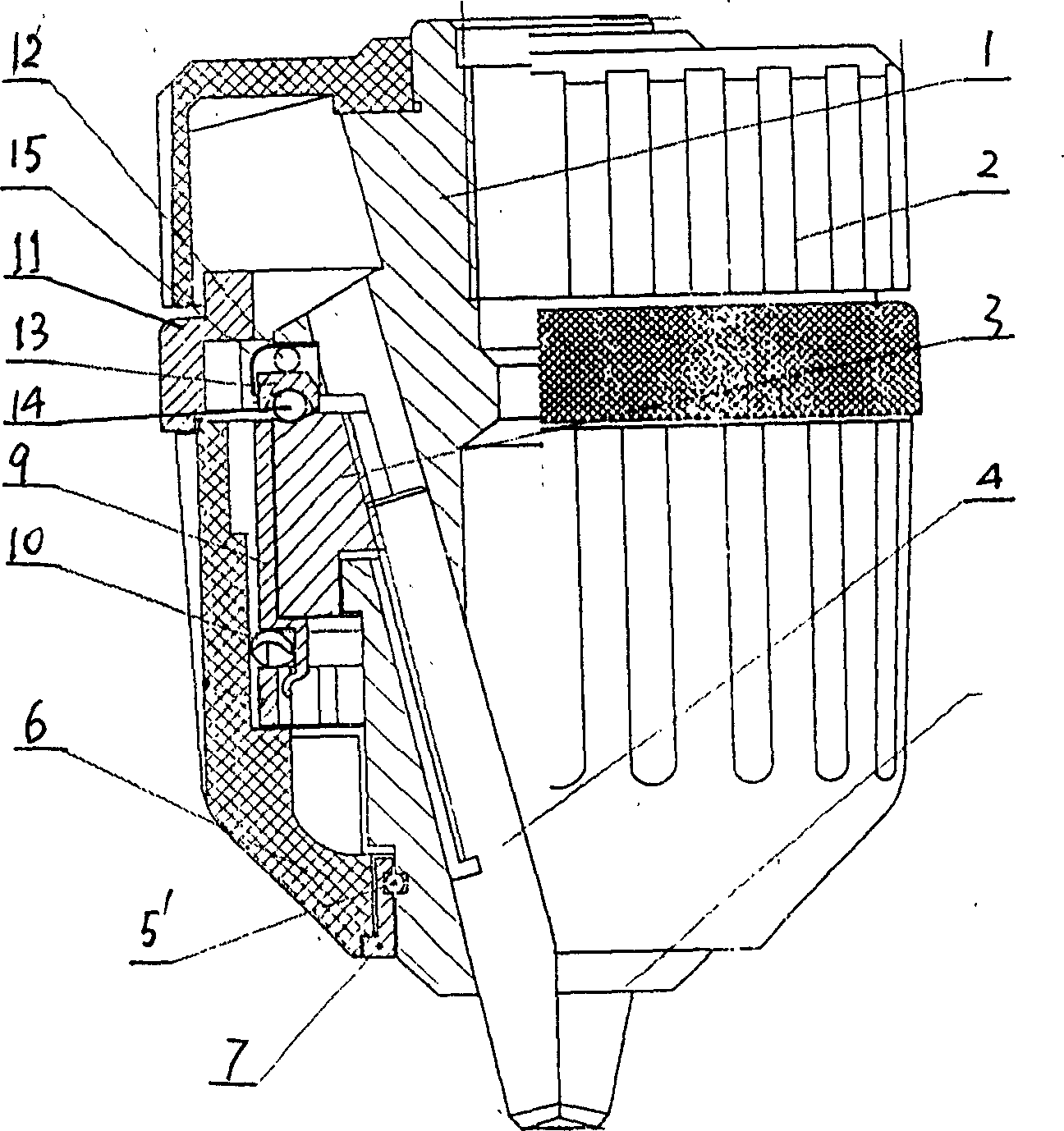

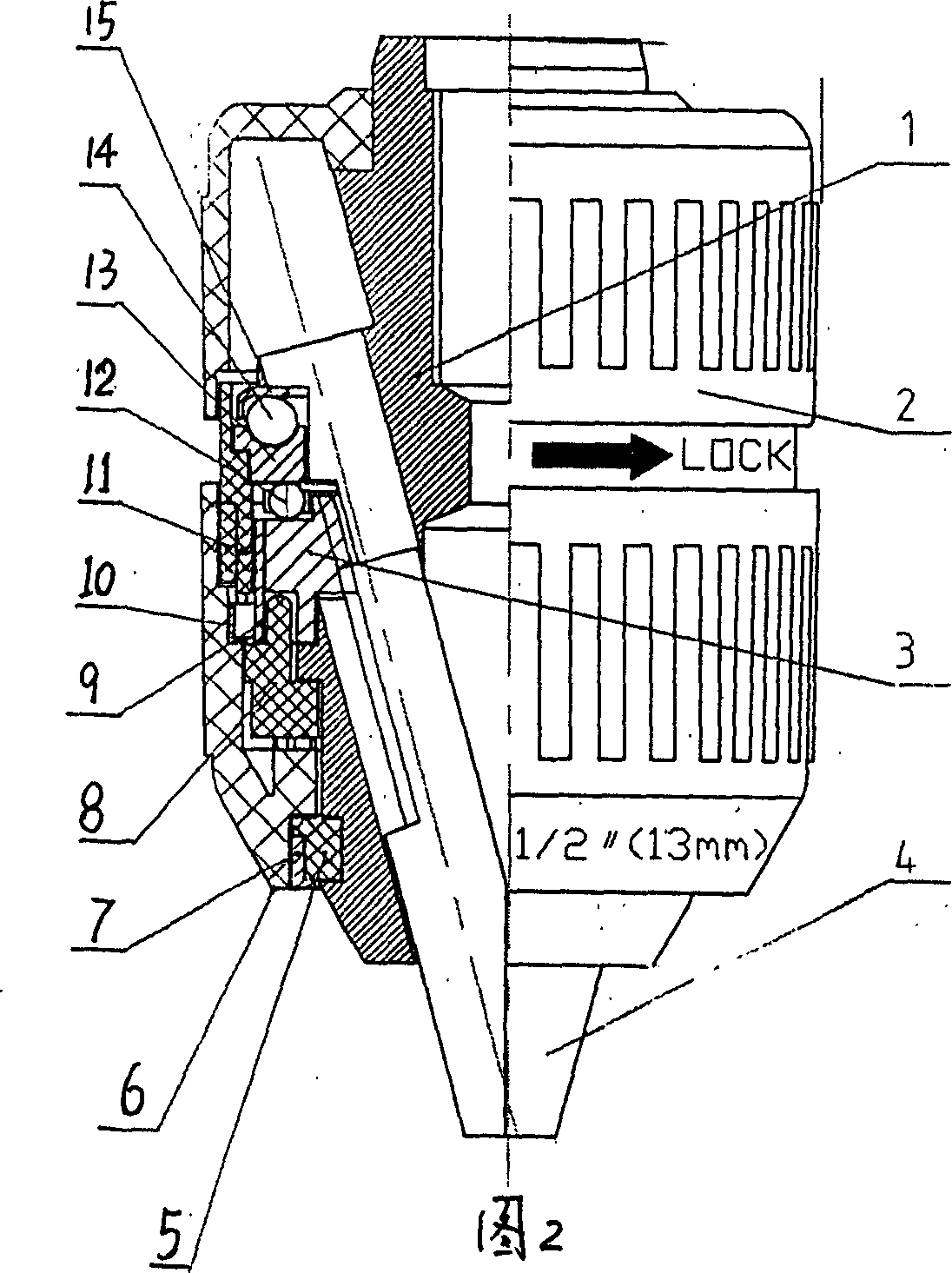

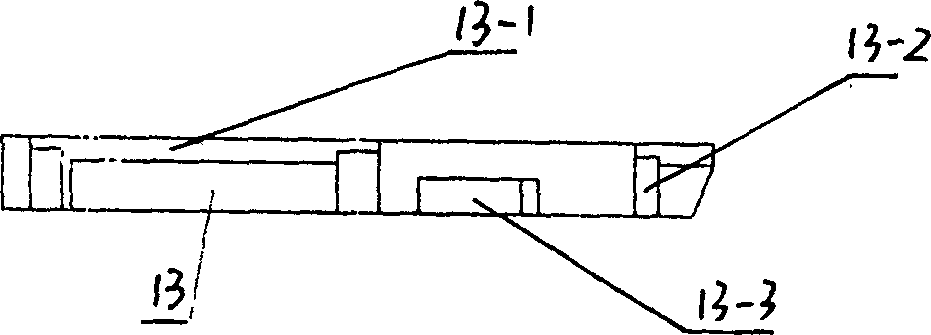

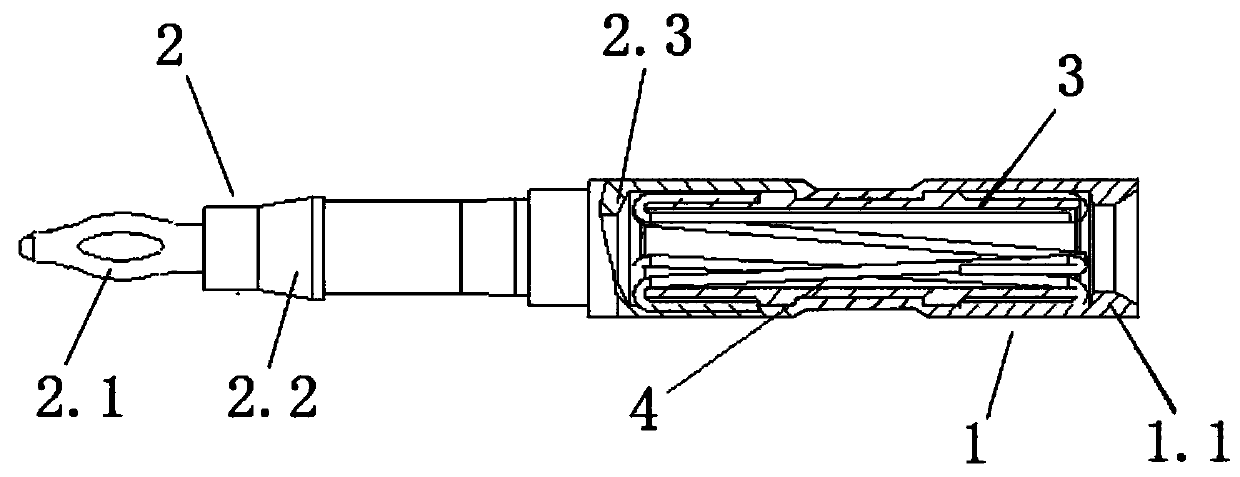

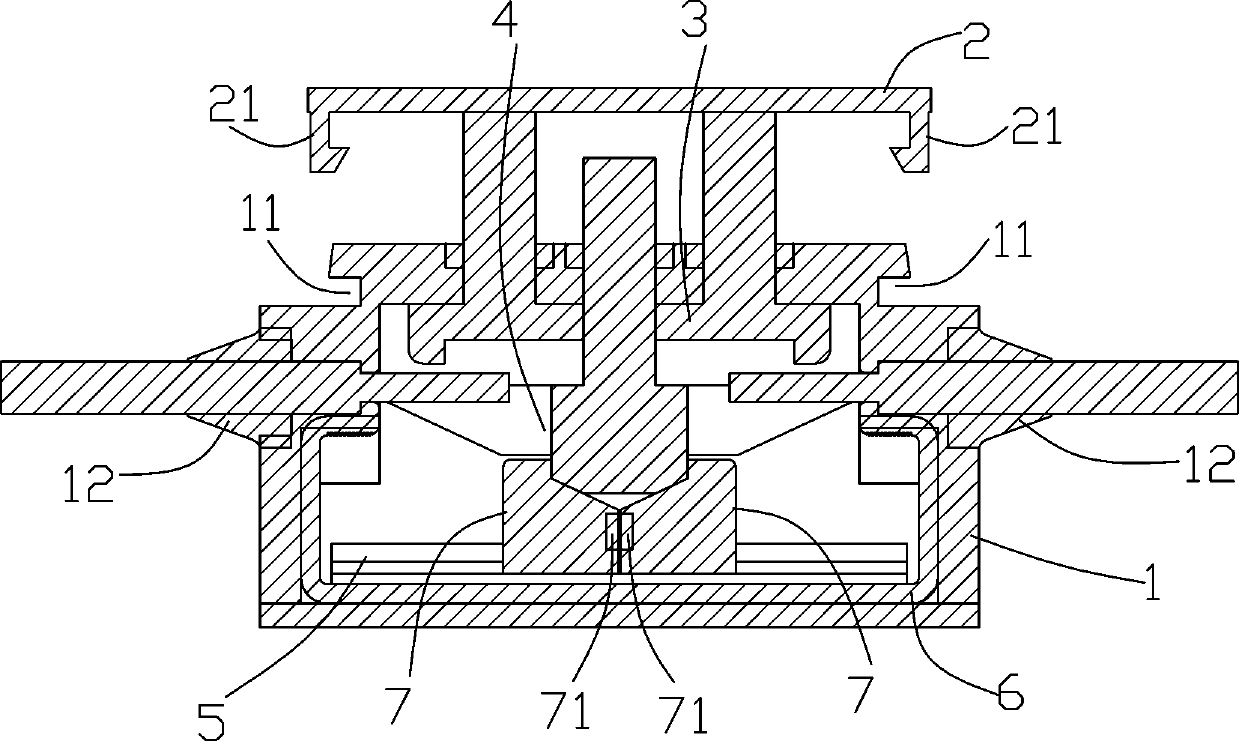

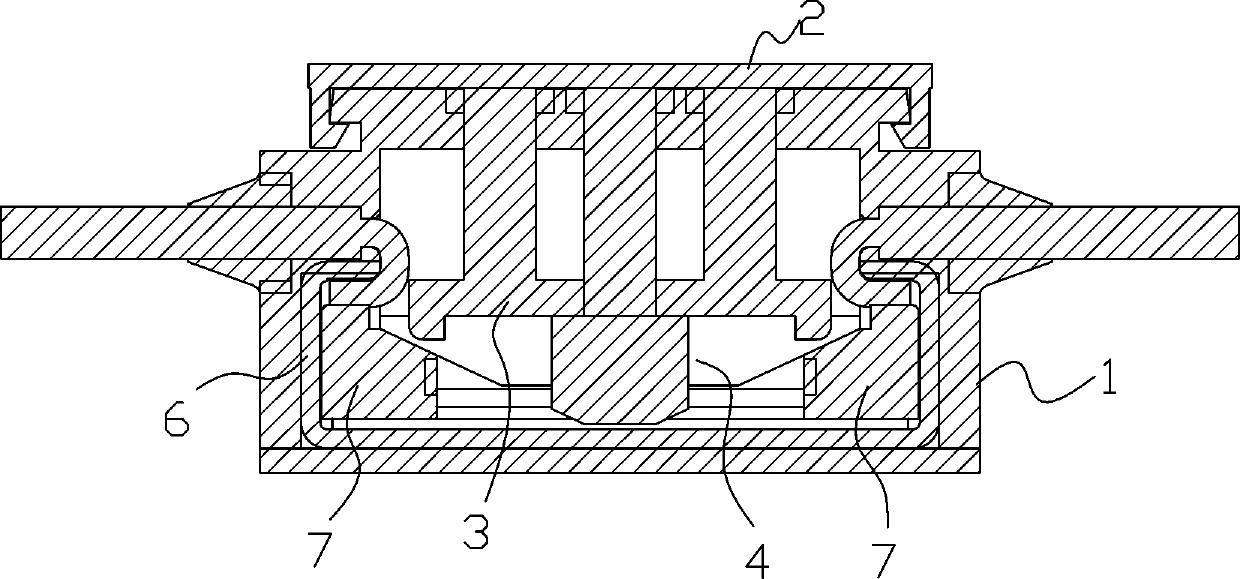

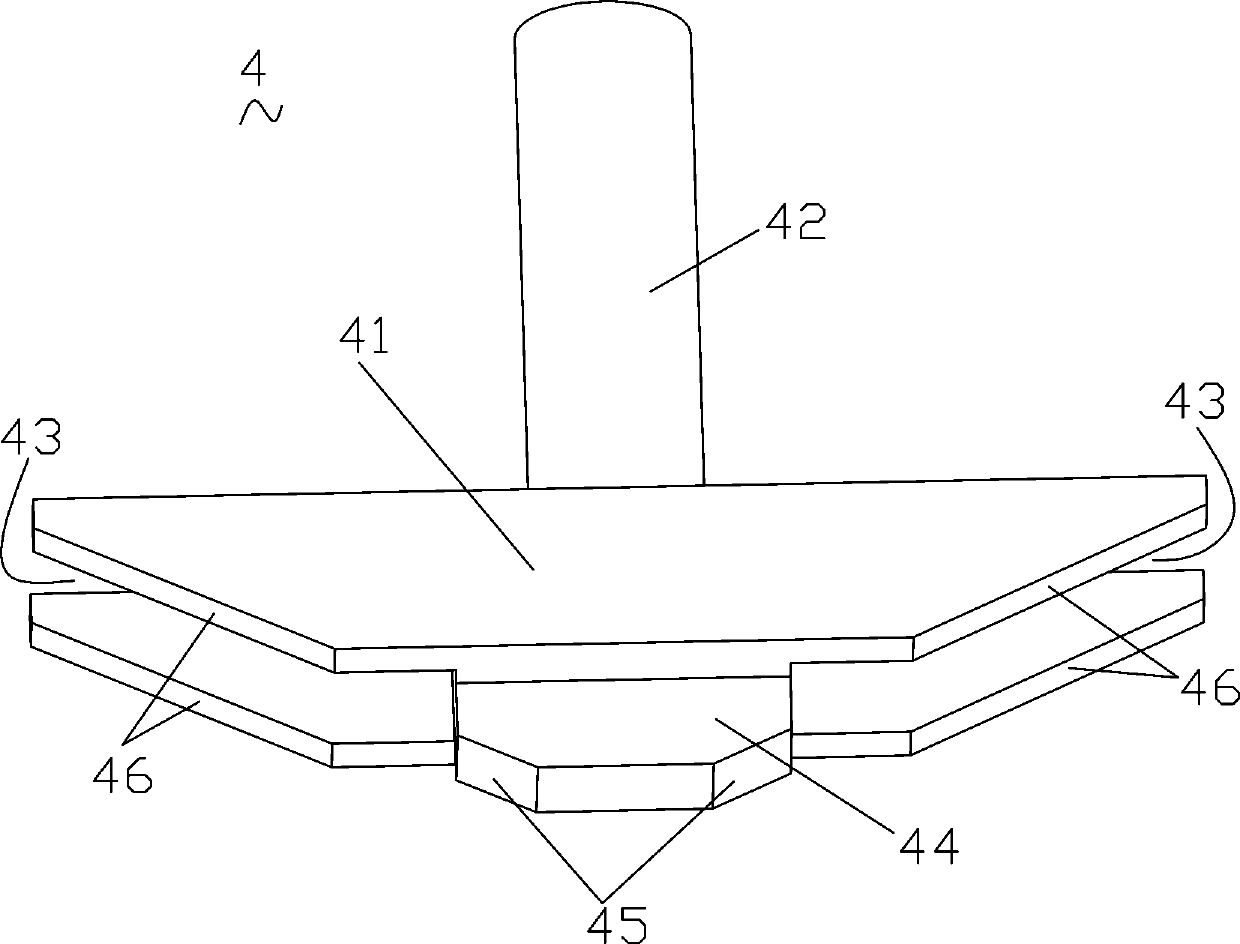

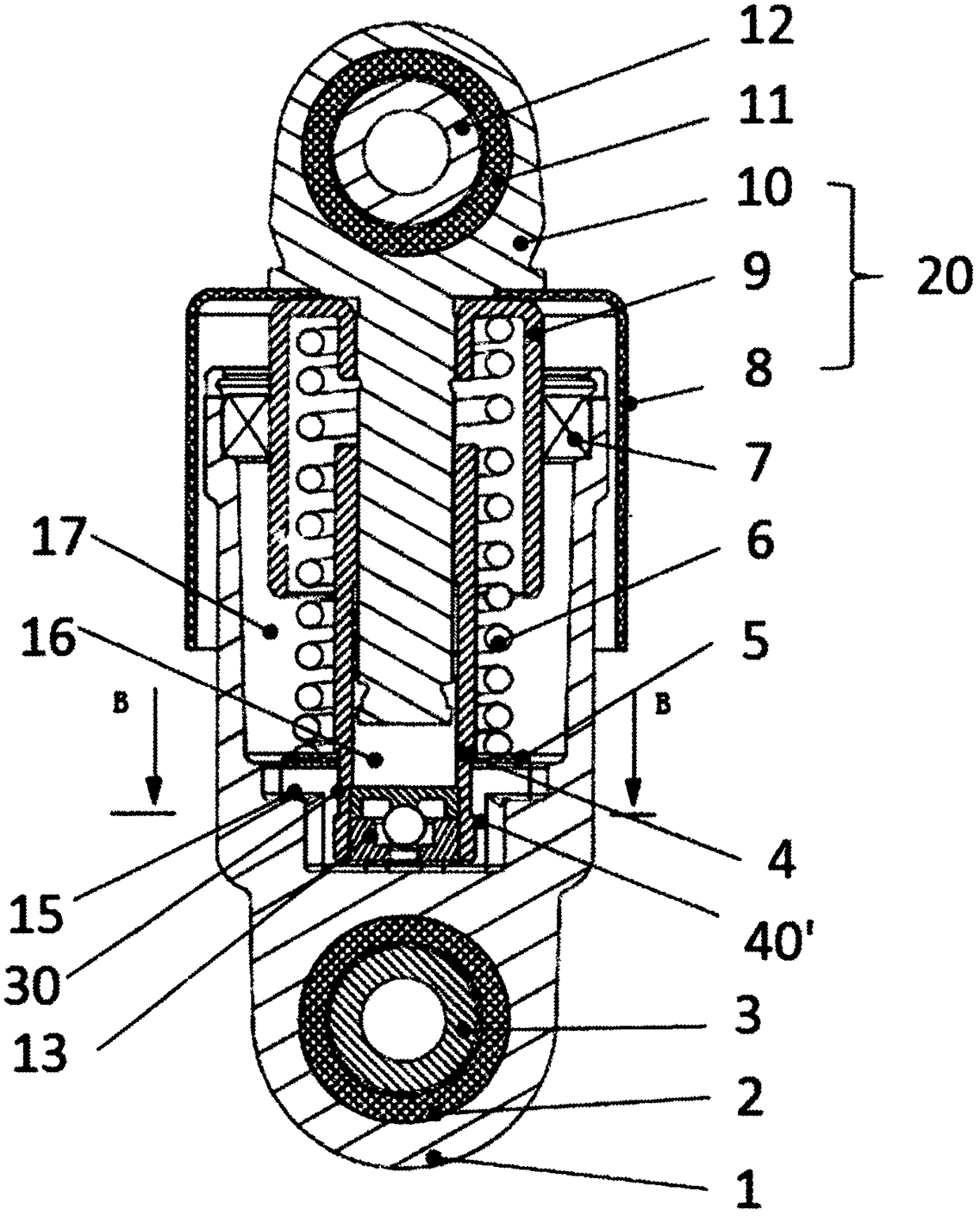

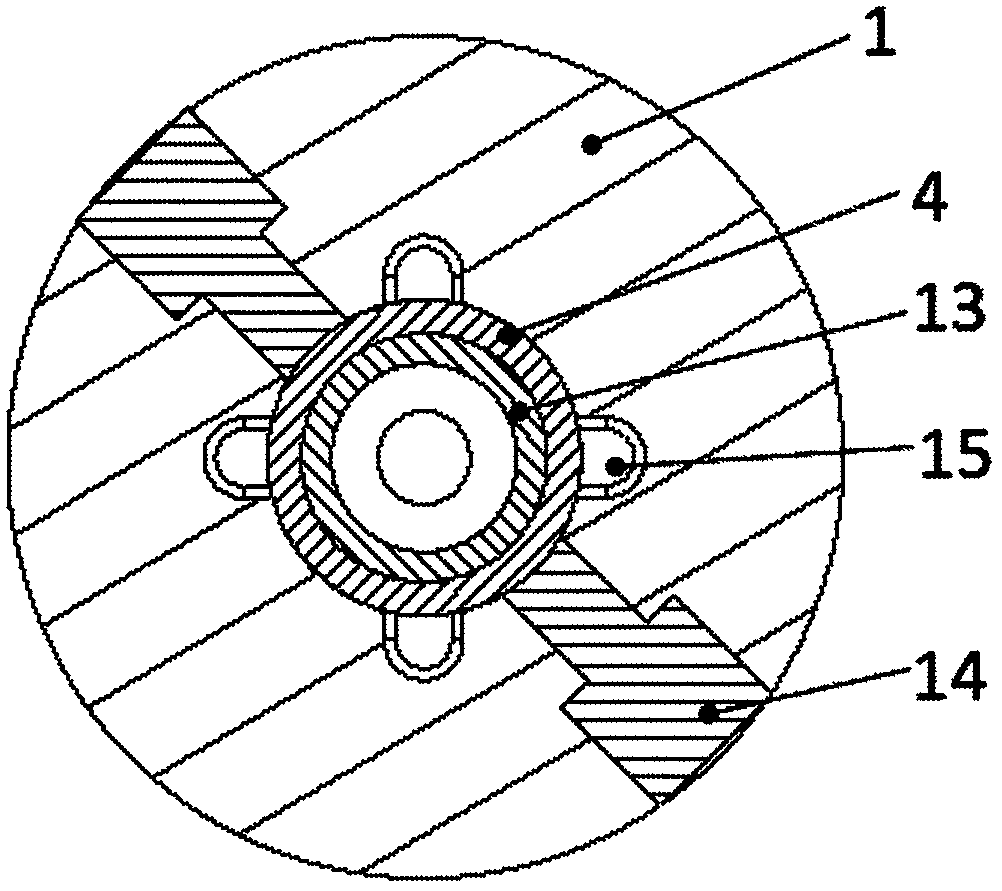

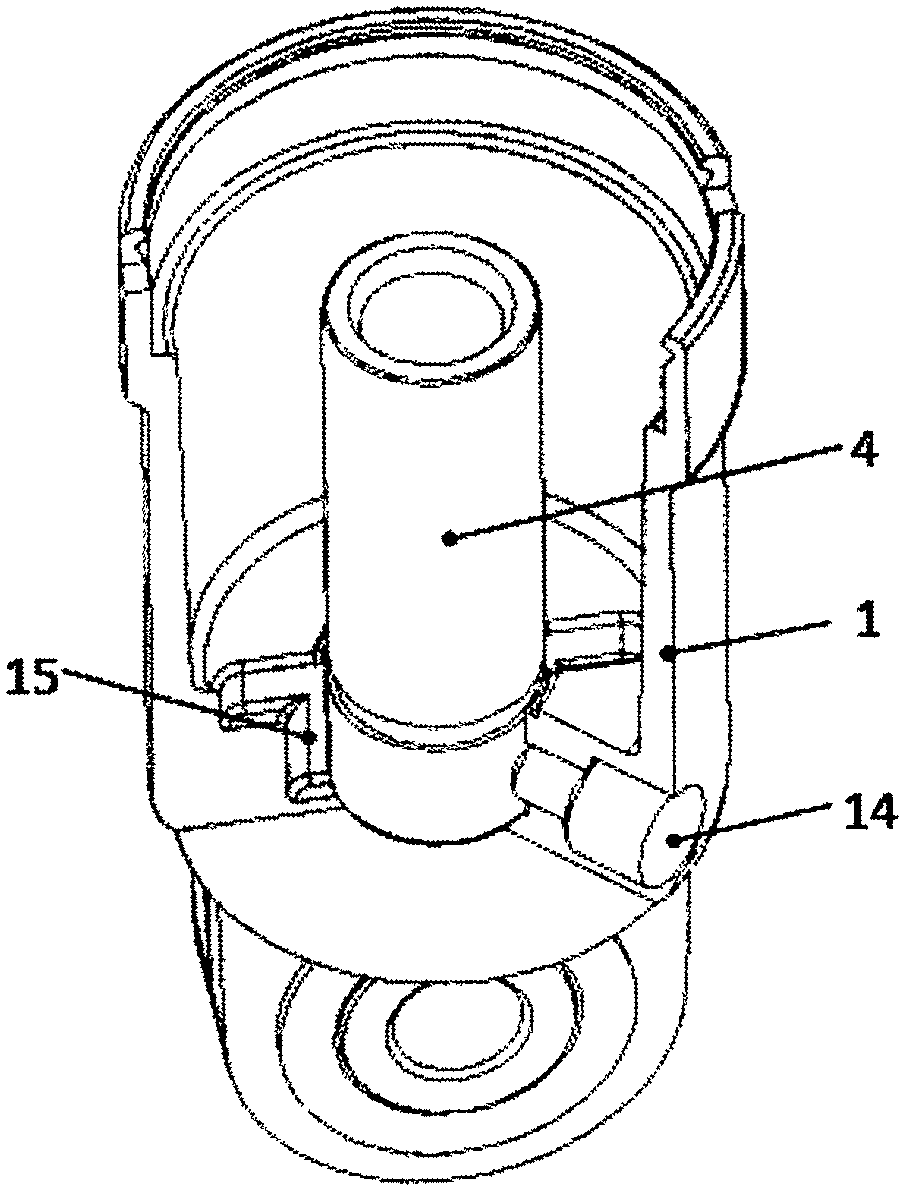

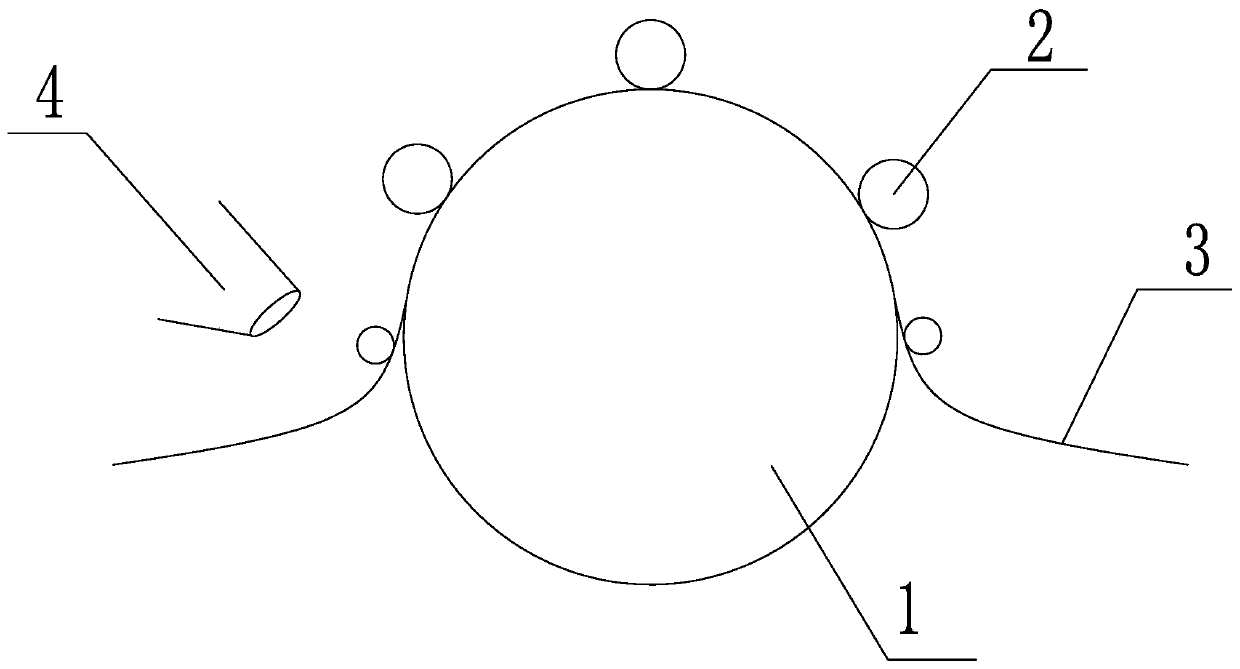

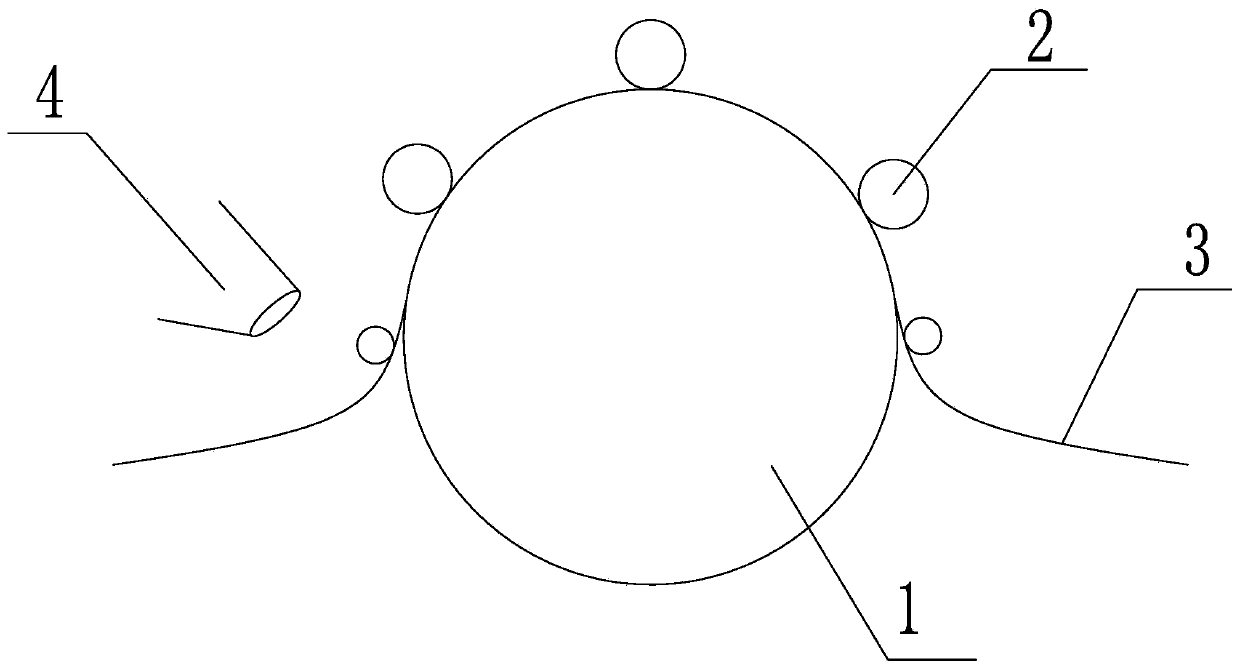

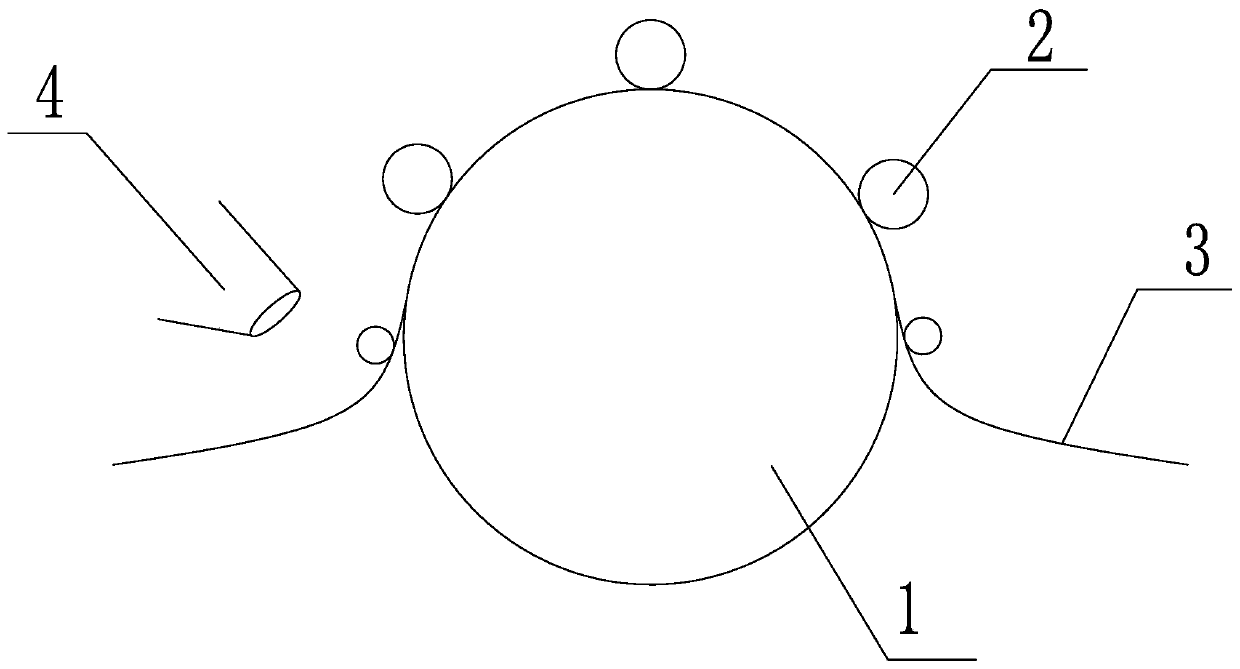

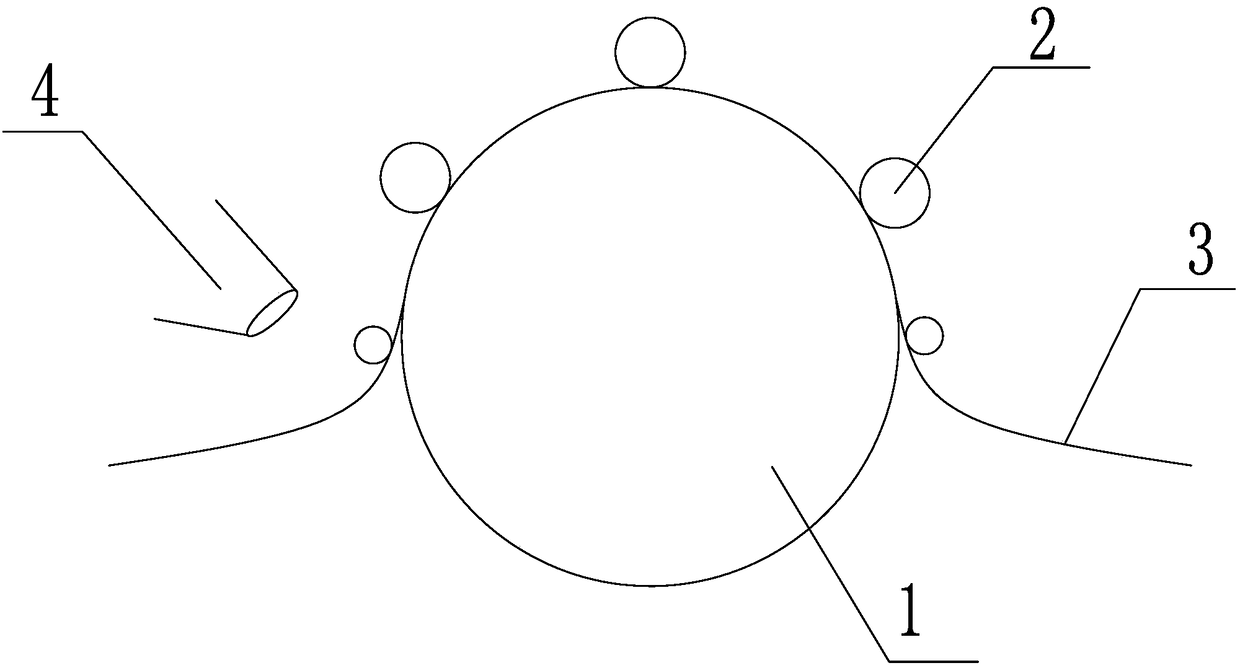

Locking type drill gripping head

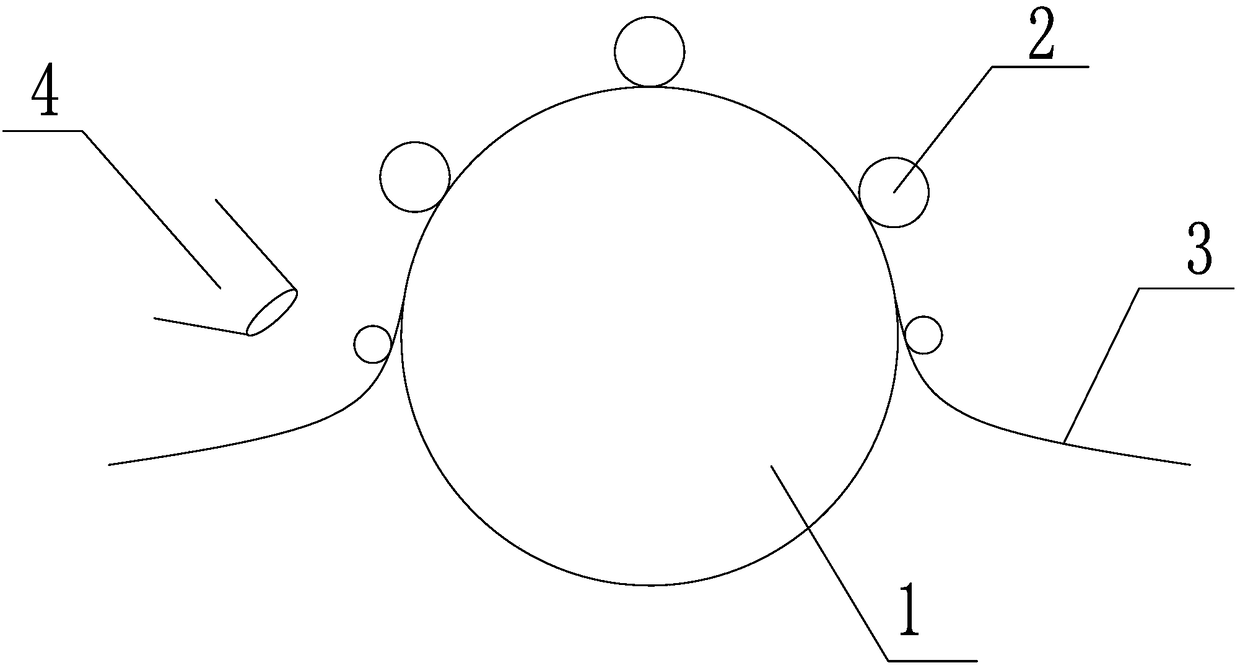

InactiveCN1569371AImprove pull-out forceRealize the locking functionSleeve/socket jointsChucksDrillBody surface

The invention relates to a locked drill chuck, including drilling body, clamp claw, silk screw, silk screw cover, the front cover, the back cover, the back end of the drilling body is arranged with an axial aperture connected to the driving tool, the external part is connected to the back cover. The three claws are assembled in the oblique apertures; the silk screw is engaged with the clamp claw in the oblique aperture. There has a locked cover between the front cover and the back cover. There has an elastic locking device made up of locking cap, rolling body, and locking plate between the drilling body surface and the silk screw. The locking plate has several concave slots, in which there arranges with rolling bodies, the elastic claw of the locking cap fixes the locking plate and several rolling bodies, and the locking cover is connected to the locking plate slots. The structure of the invention is reasonable, the locking function is strong, and the torque inputting efficiency is high.

Owner:SHANDONG WEIDA MASCH CO LTD

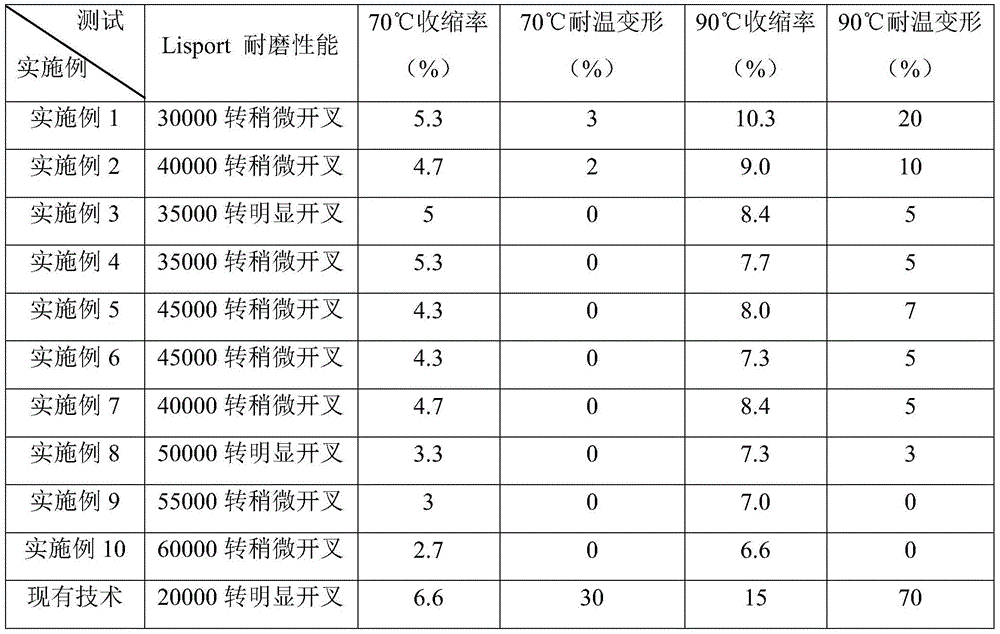

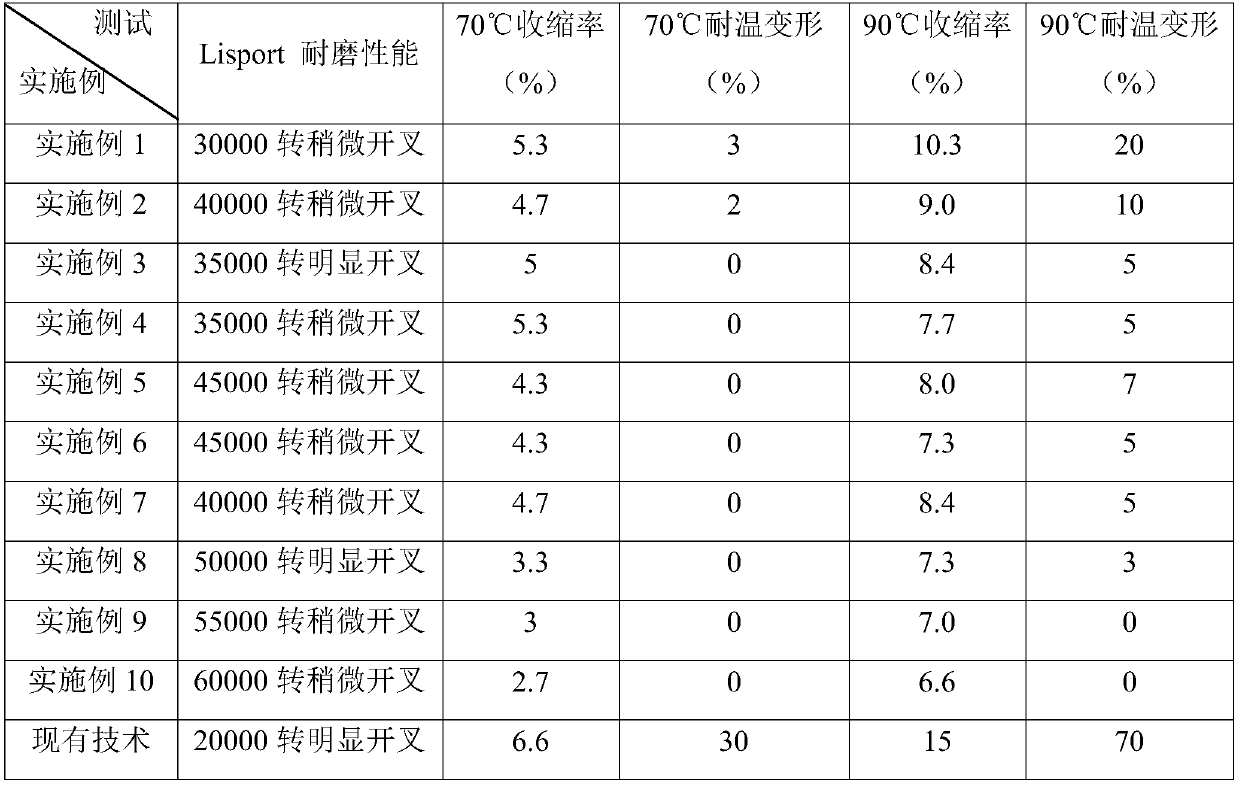

Wear-resistant and temperature-resistant artificial turf and preparation method thereof

ActiveCN105568425AImprove wear resistanceImprove performanceGround pavingsConjugated synthetic polymer artificial filamentsFiberWear resistant

The invention discloses a wear-resistant and temperature-resistant artificial turf. The wear resistance of the artificial grass fiber is improved; meanwhile, the temperature resistance of the artificial turf fiber is improved; the acting force between the artificial grass fiber and a bottom back is improved; the artificial grass fiber falling phenomenon is avoided. The wear-resistant and temperature-resistant artificial turf comprises the artificial grass fiber, wherein the artificial grass fiber is prepared from the following ingredients in parts by weight: 35 to 90 parts of base body resin, 5 to 30 parts of thermoplastic elastomer, 5 to 20 parts of wear-resistant and temperature-resistant master batch, 0.01 to 5 parts of anti-aging agents and 0.5 to 10 parts of master batch.

Owner:COCREATION GRASS CO LTD

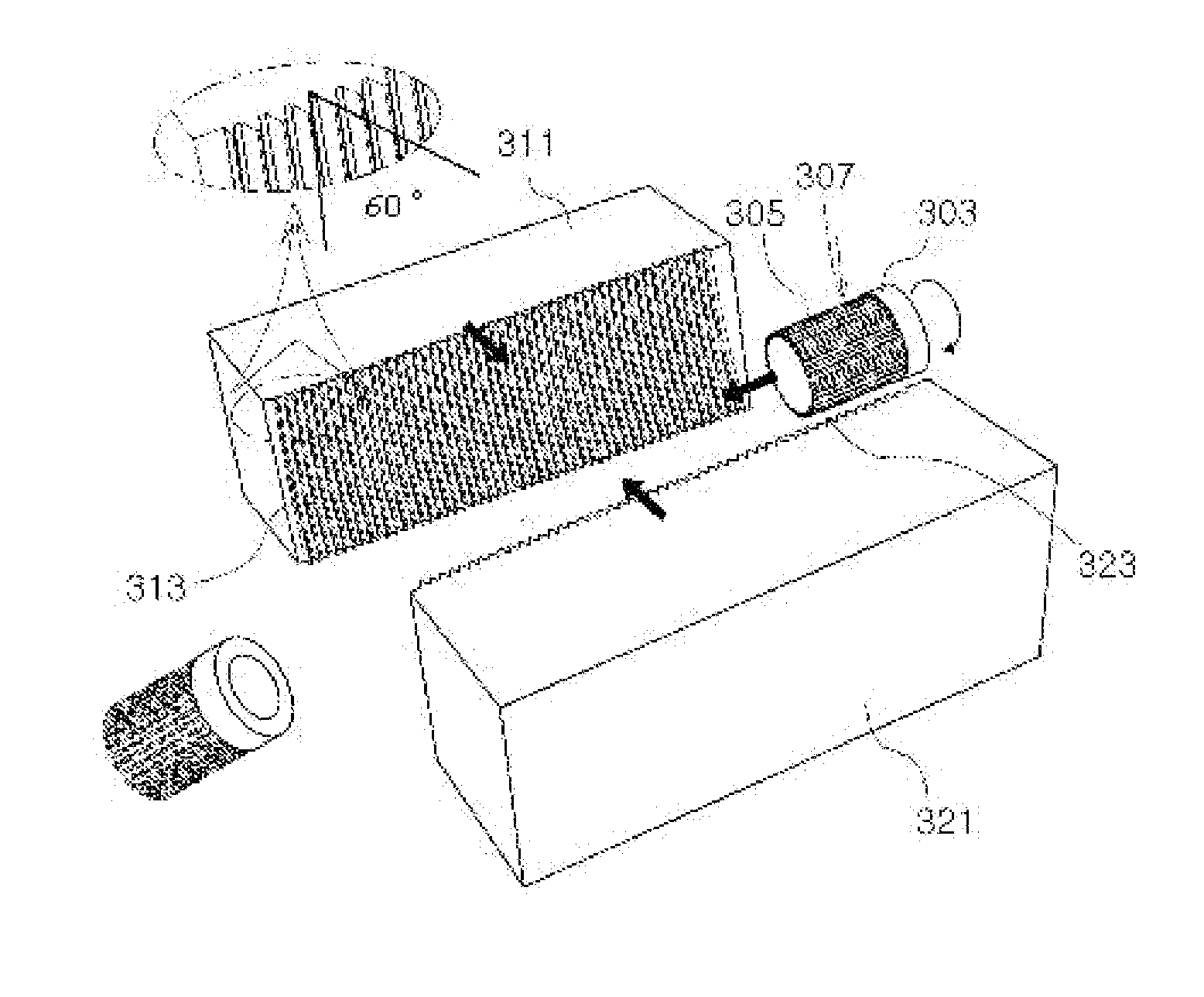

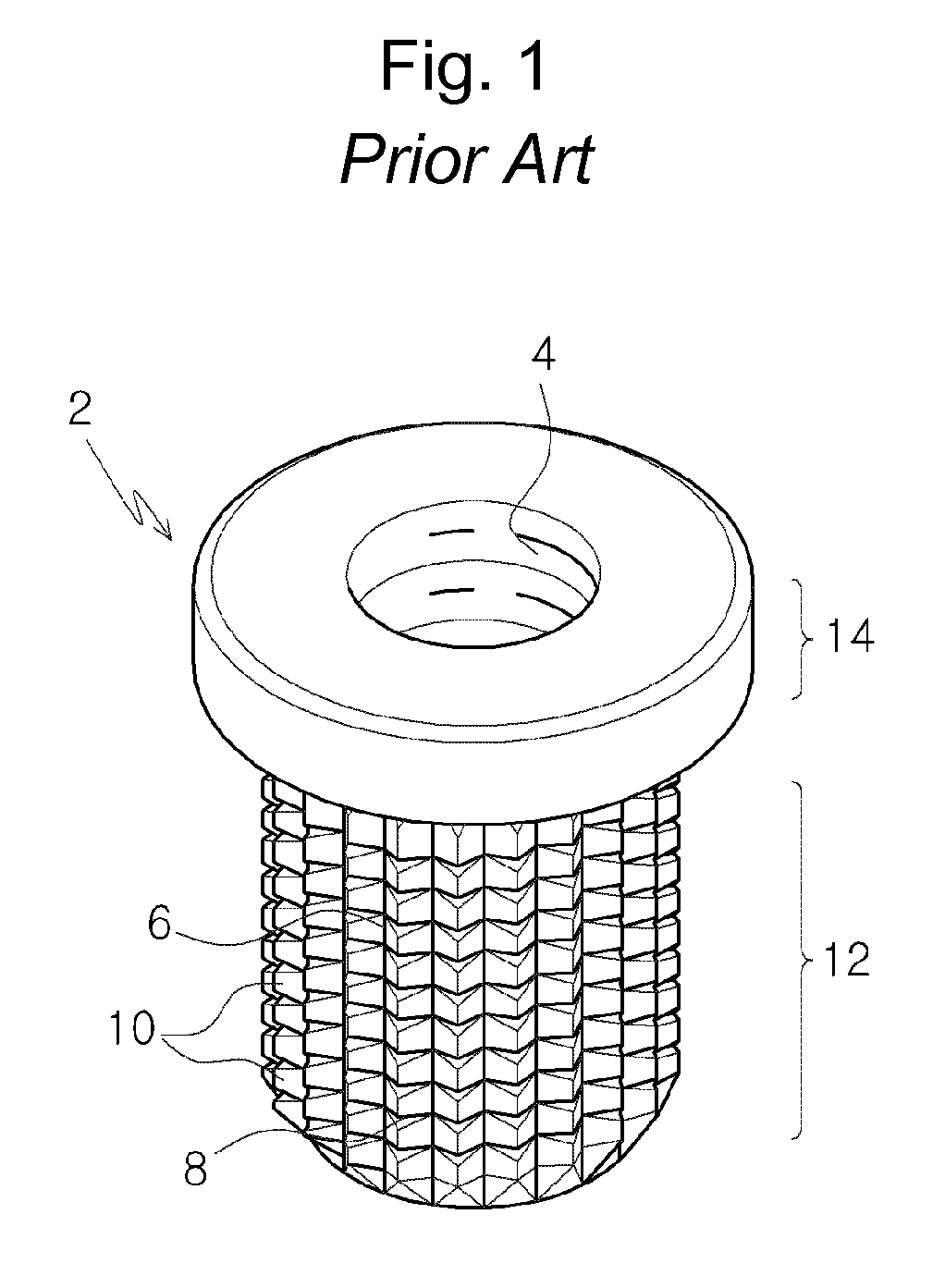

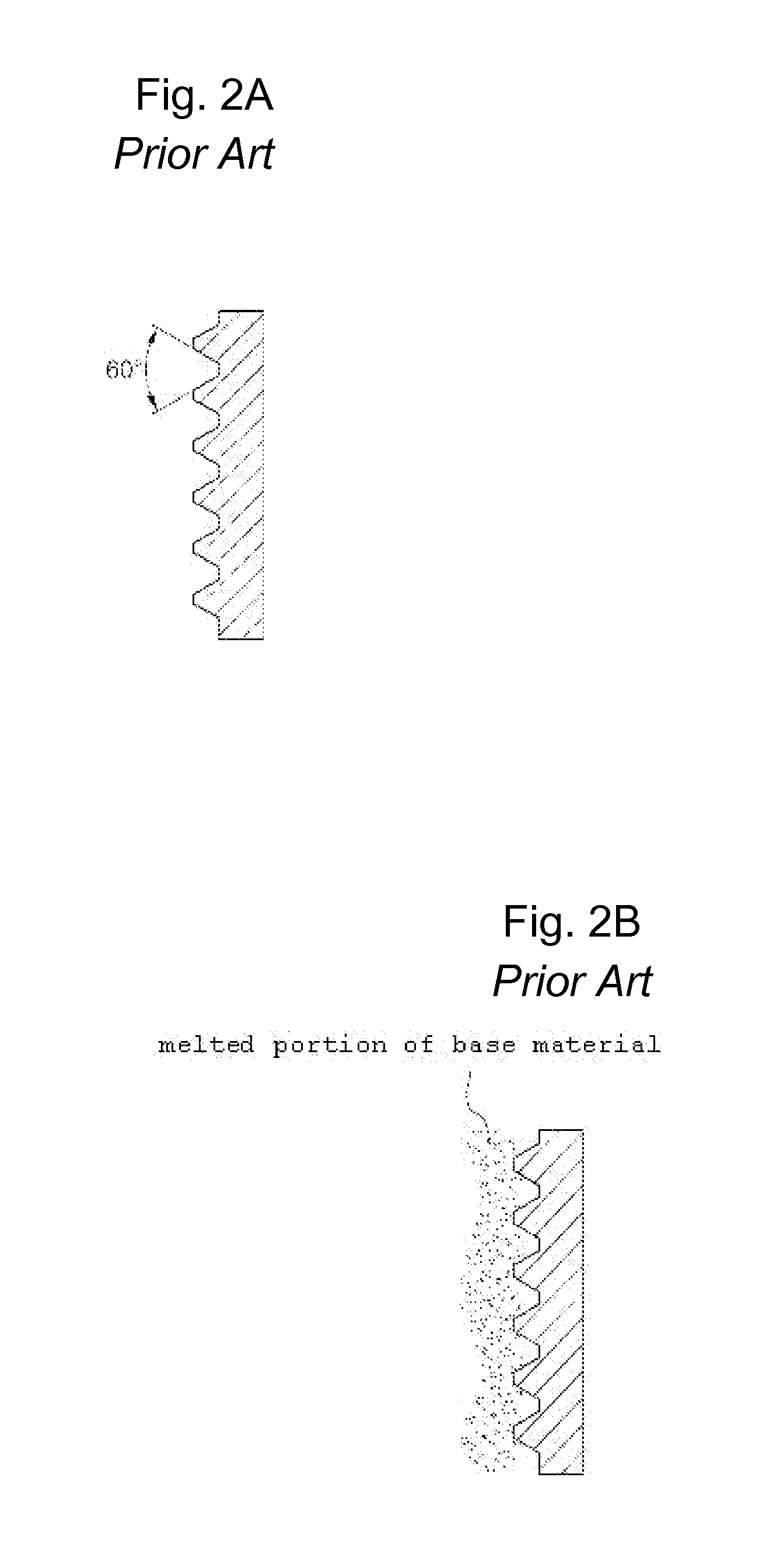

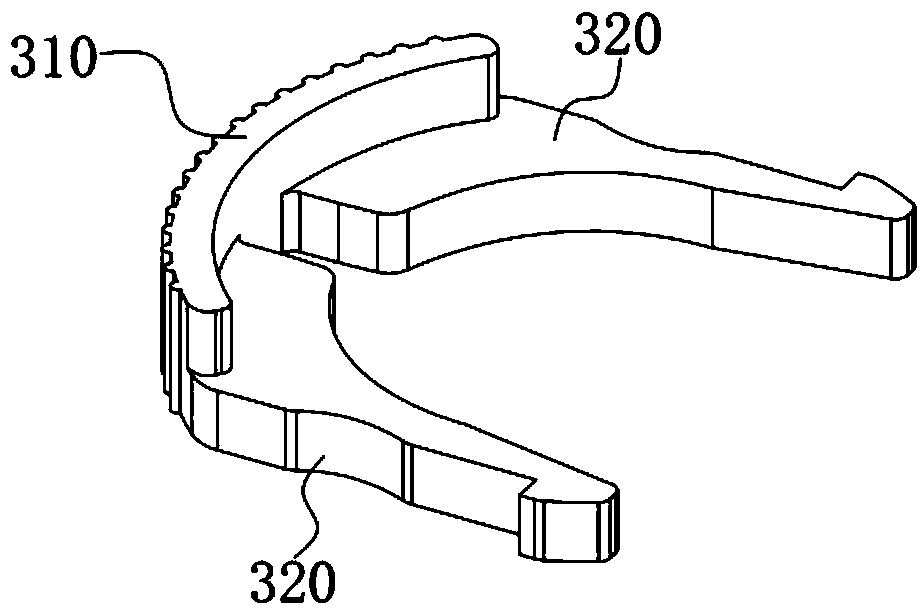

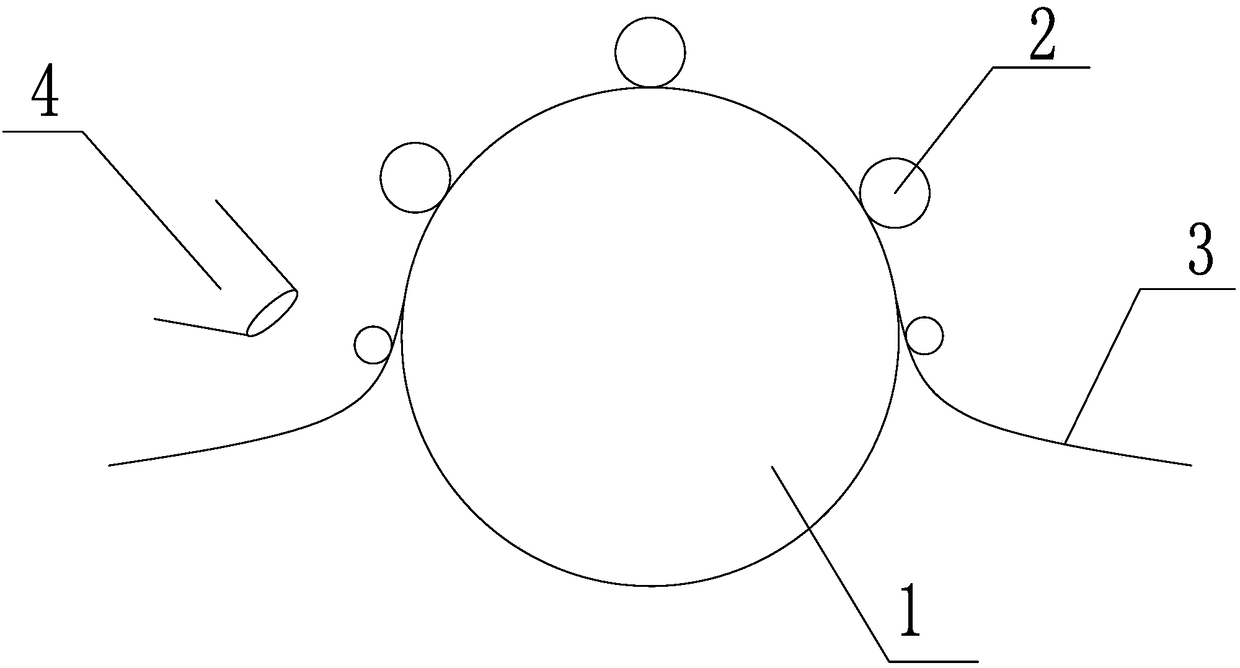

Insert nut having rectangular lattic structure and manufacturing method thereof

A method of manufacturing the insert nut having the rectangular lattice structure, comprises preparing a forged article having a flange and a nut body formed with a serration, which are formed by a forging process; pressing the forged article with a thread rolling die in which a diagonal line inclined at an angle of 15° to 30° with respect to a vertical line to a length direction thereof is formed, and a circular arc is defined by the diagonal line, and a curved die protrusion is provided to have a curvature R so that the vertical line is tangentially contacted with the circular arc, and thus an angle between rectangular lattices is maintained to 50° to 40°; and performing a thread rolling process by pressing-in and rotating the forged article.

Owner:GENERAL CO LTD

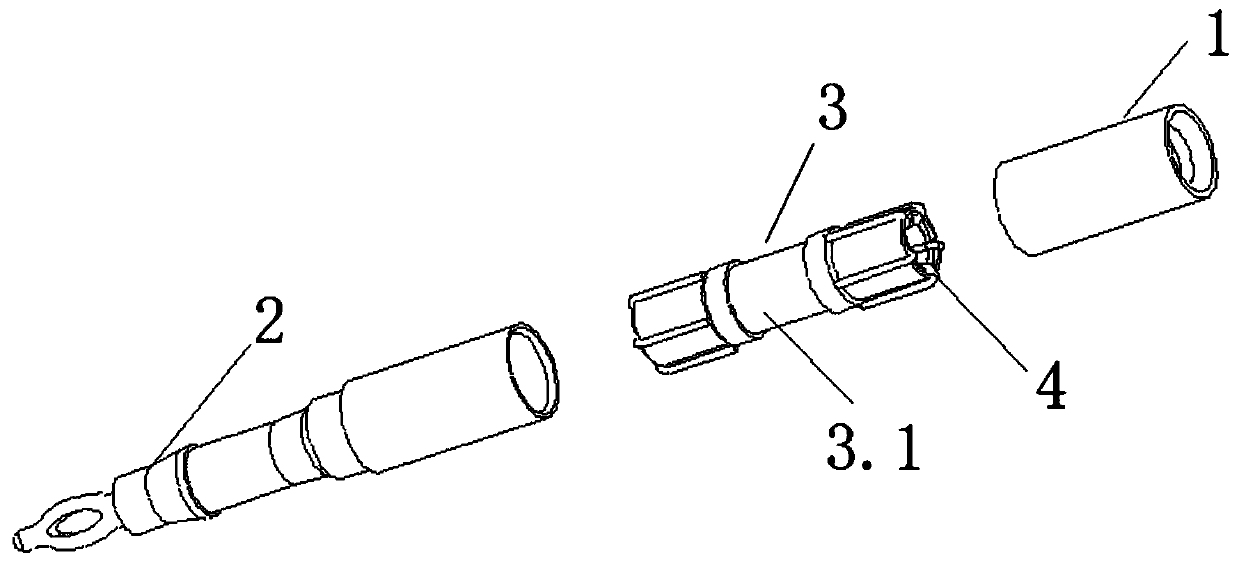

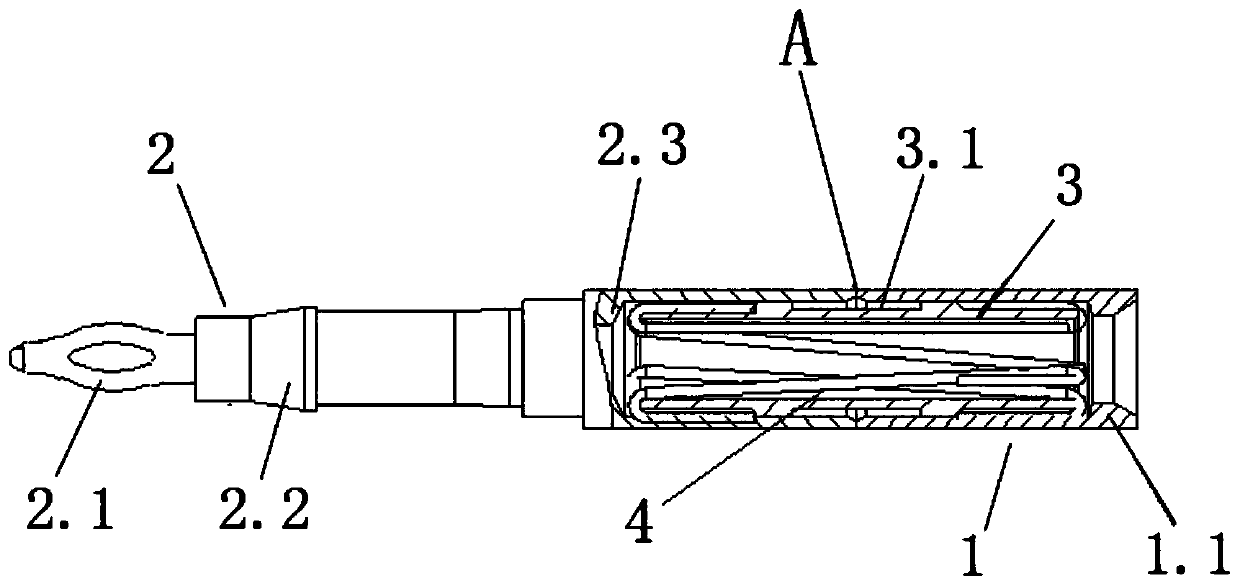

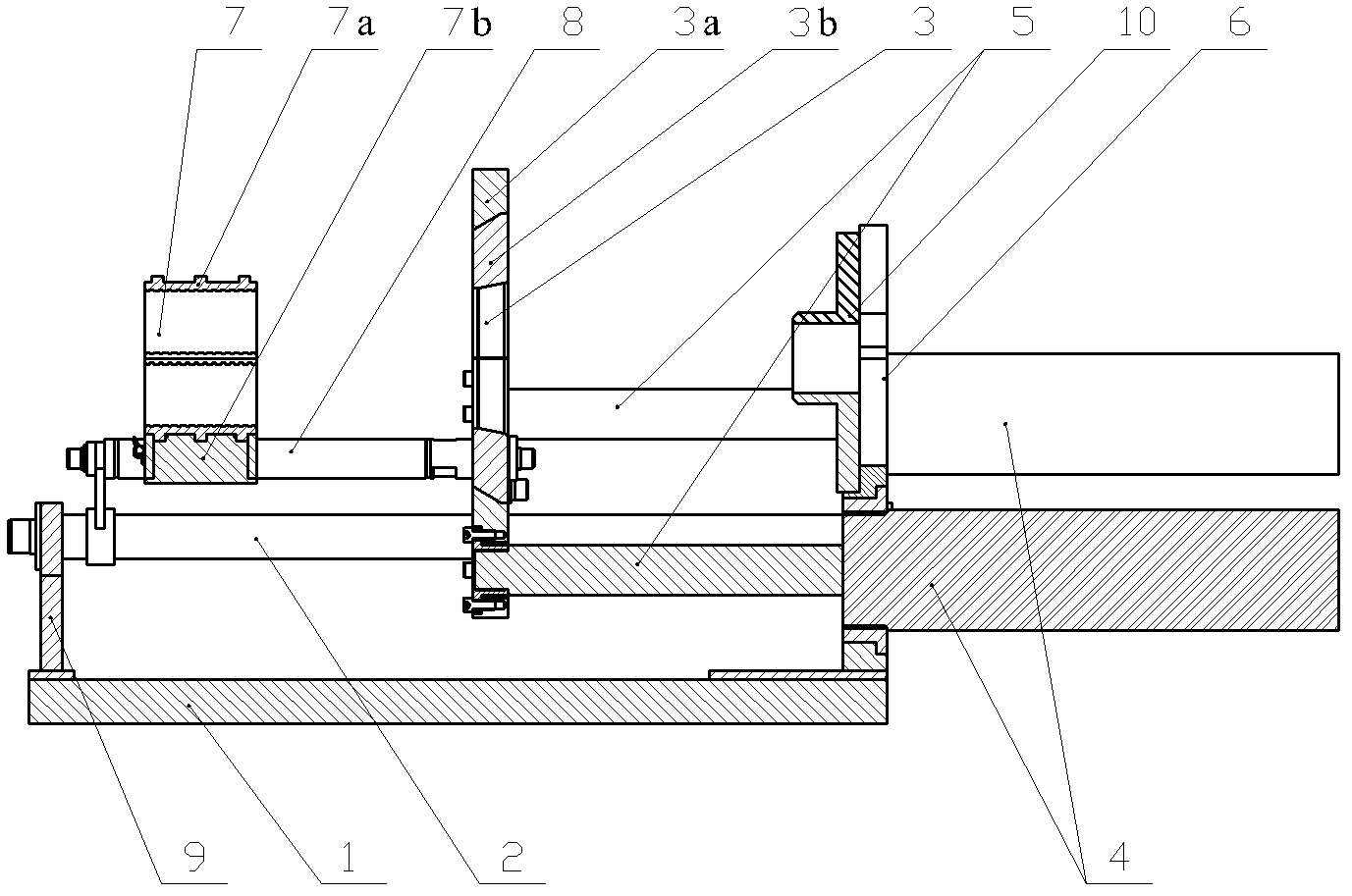

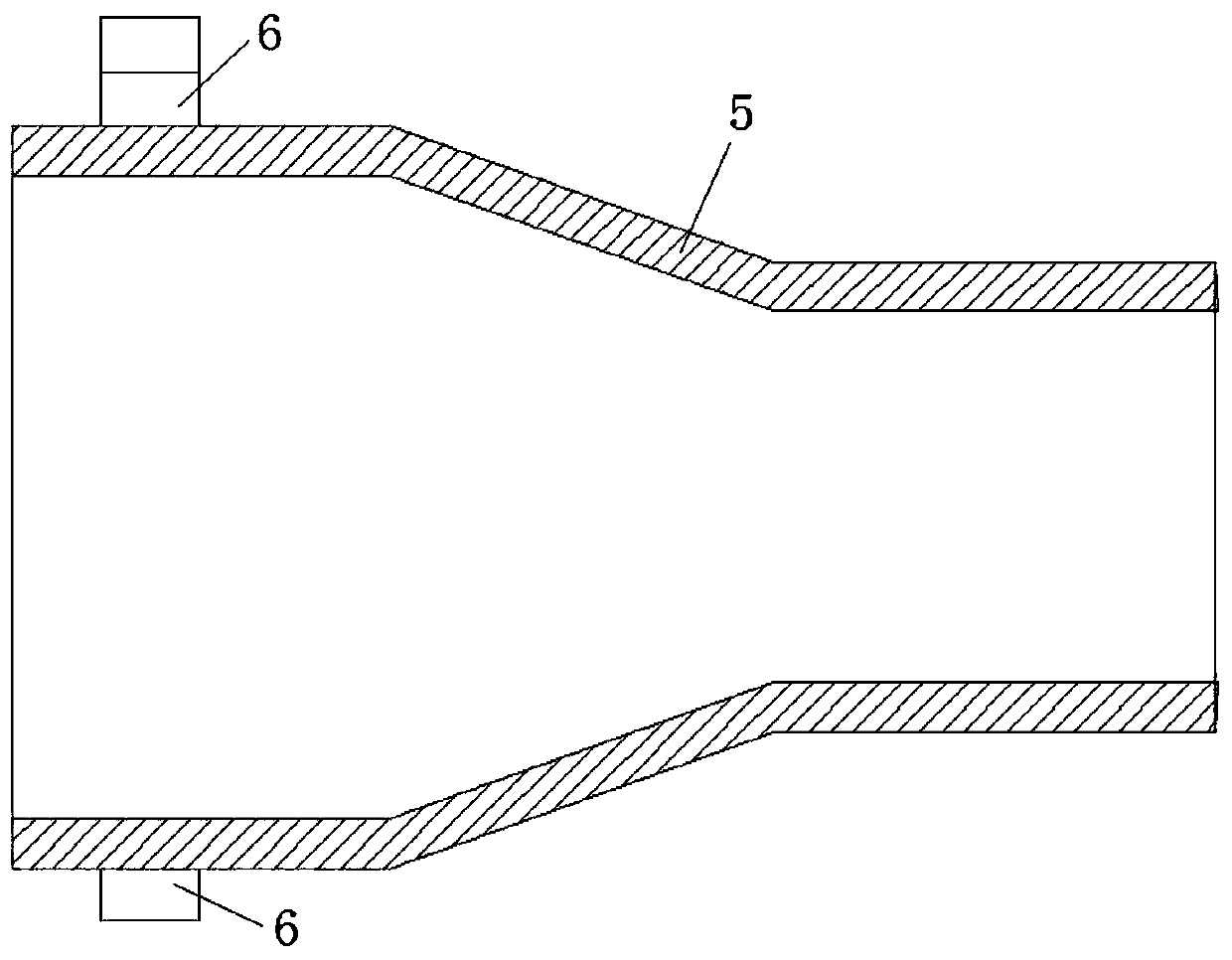

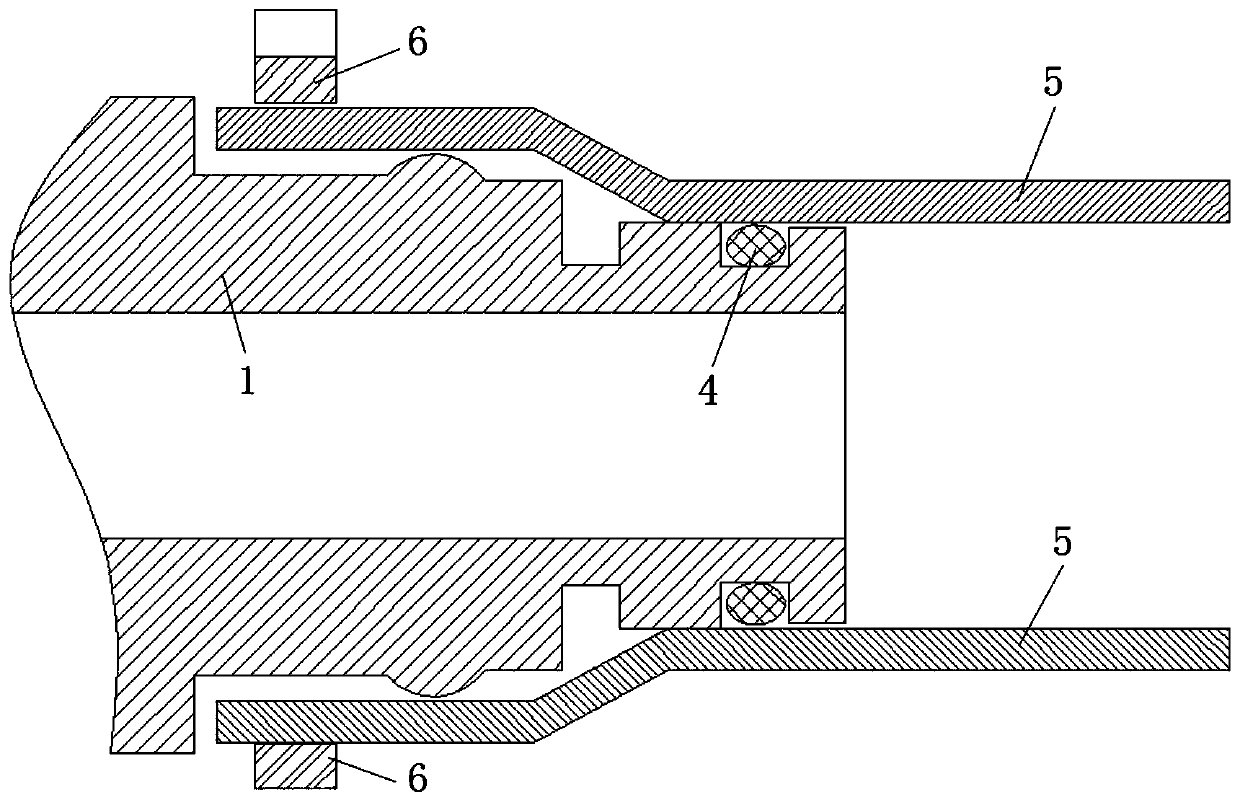

Small high-reliability wire spring hole fisheye crimping type jack

InactiveCN110890637AImprove pull-out forceRequirements for machining dimensional accuracy are reducedElectrically conductive connectionsCoupling contact membersElectrical resistance and conductanceHigh density

A small high-reliability wire spring hole fisheye crimping type jack comprises a front sleeve, a rear sleeve and a jack pipe. A crimping annular groove is formed in the middle of the outer circular surface of the jack pipe, one end of the outer circular surface of the jack pipe is inserted into the inner pipe wall of the front sleeve, and the other end of the outer circular surface of the jack pipe is inserted into the inner pipe wall of the rear sleeve; orifices of the front sleeve and the rear sleeve, which are positioned in the crimping ring groove, are crimped with the crimping ring groove; and a fisheye structure is arranged at one end, far away from the jack pipe, of the rear sleeve. According to the invention, through a crimping mode, the plugging and pulling-out force of the jack is increased, the processing size precision requirement of the jack is reduced, and the yield is improved; by arranging the wire spring wire in the jack tube, the reliability of electrical connection between the jack and the pin is enhanced, so that the jack has the characteristics of high vibration level, long plugging life, flexible plugging force, reliable contact part and small contact resistance. The structure is compact, and the high-density requirement of the jack is met; and fisheye crimping is adopted, so that the problem of impedance mismatching at the via hole is solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

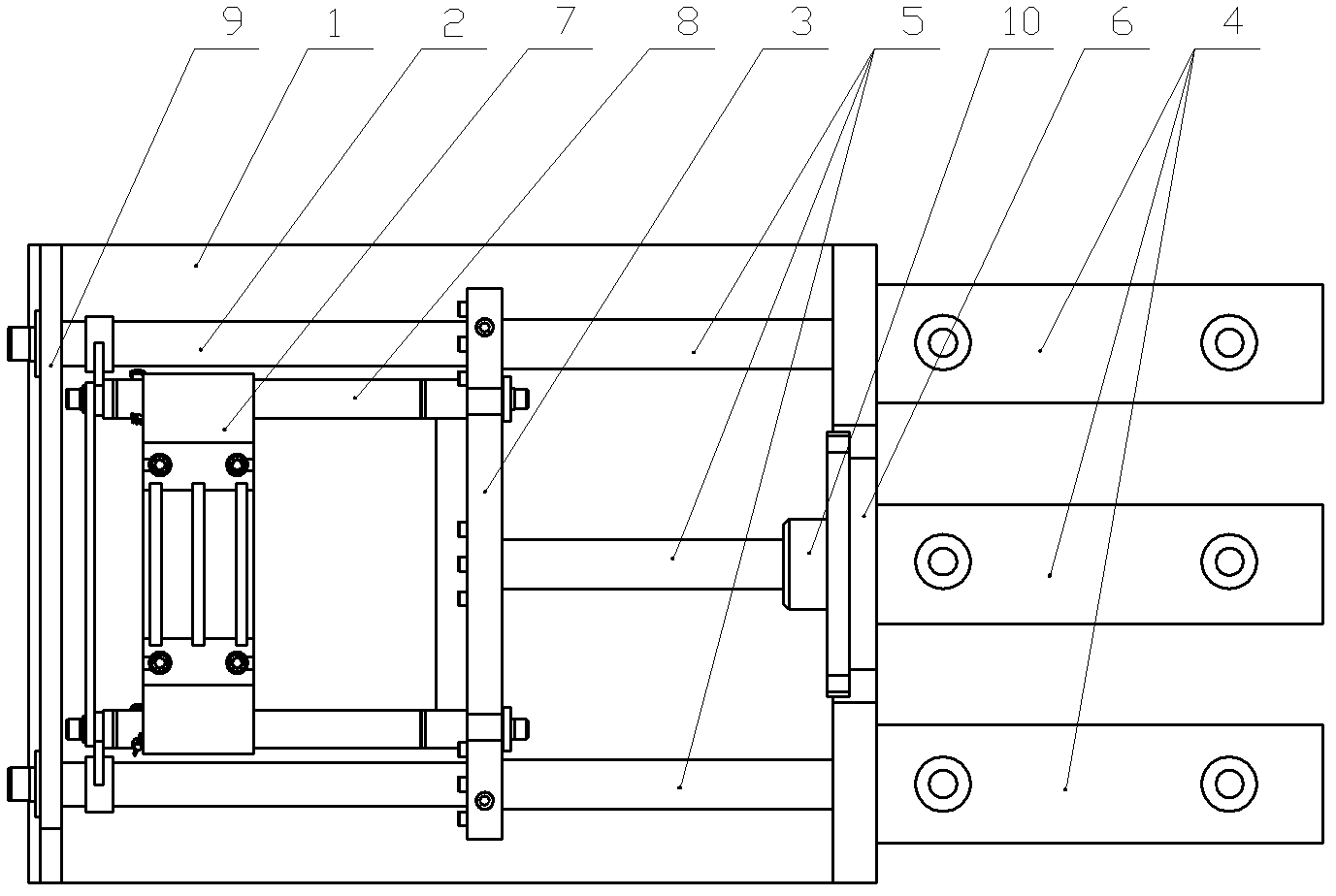

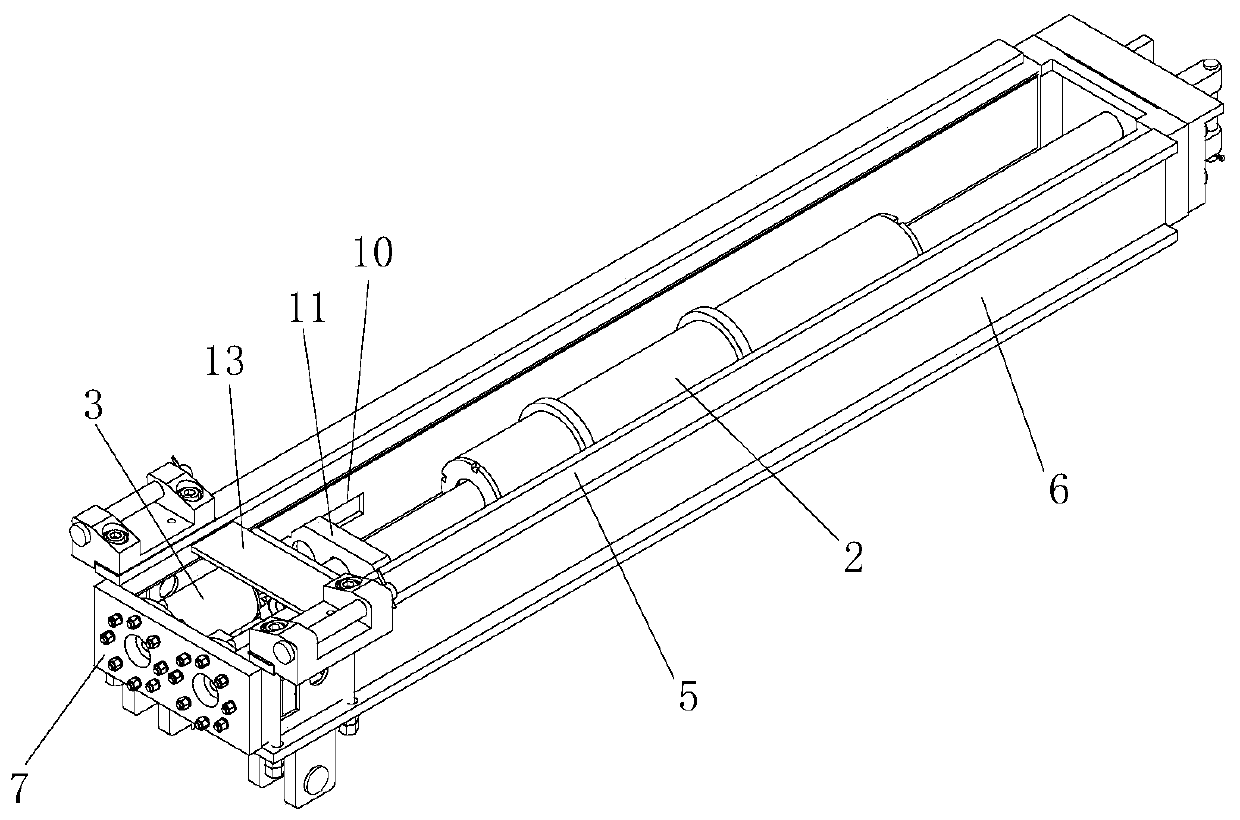

Pipe drawing and crimping integrated machine for pipeline connection and use method of pipe drawing and crimping integrated machine

InactiveCN102430911ASimple and reasonable structureEasy to operateMetal working apparatusHydraulic cylinderPipe fitting

The invention discloses a pipe drawing and crimping integrated machine for pipeline connection, comprising a base, at least two guide pillars, a crimping shifting plate, a hydraulic cylinder, a hydraulic shifting lever, a pipe fitting fixing plate, a pipe material fixing piece and a connecting rod, wherein the at least two guide pillars are arranged on the base in parallel; the crimping shifting plate is slidably arranged on the guide pillars and is connected with the hydraulic cylinder through the hydraulic shifting lever; the inner wall of the hydraulic shifting lever is in a shape of slant surface, and the pipe fitting fixing plate is located on one side of the crimping shifting plate; the connecting rod is parallel to the guide pillars, one end of the connecting rod is slidably arranged on the guide pillars, and the other end of the connecting rod is connected with the other side of the crimping shifting plate; and the pipe material fixing piece is arranged on the connecting rod. The invention also discloses a used method of the pipe drawing and crimping integrated machine. The pipe drawing and crimping integrated machine provided by the invention has a reasonable and simple structure and easiness in operation, two functions of pressing an core sleeve of pipe fitting into a pipe product and crimping an outer sleeve of the pipe fitting can be realized at the same time, the mounting difficulty is reduced, the working efficiency is improved, and the application field of pipeline laying is enlarged conveniently.

Owner:李志雄

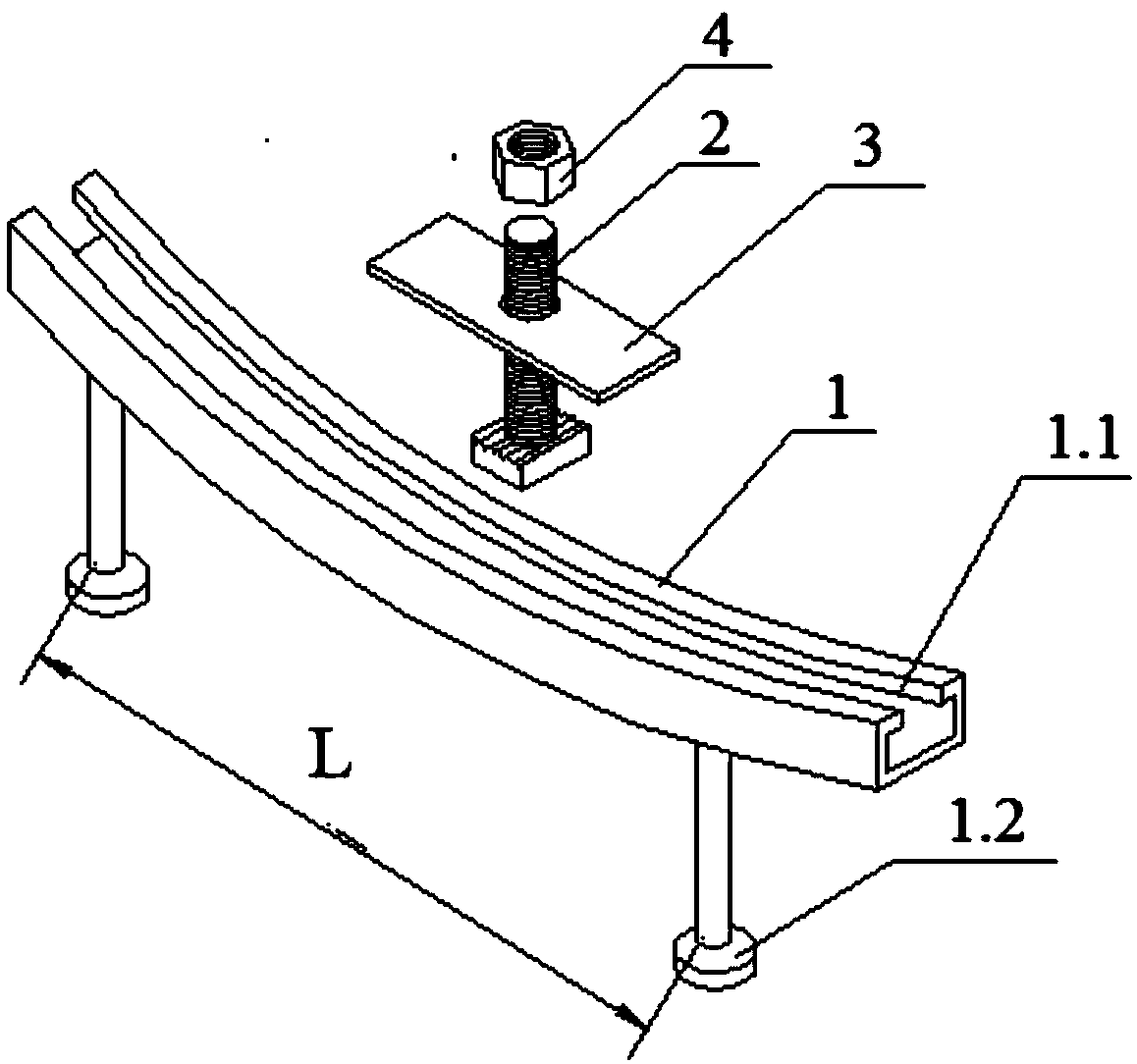

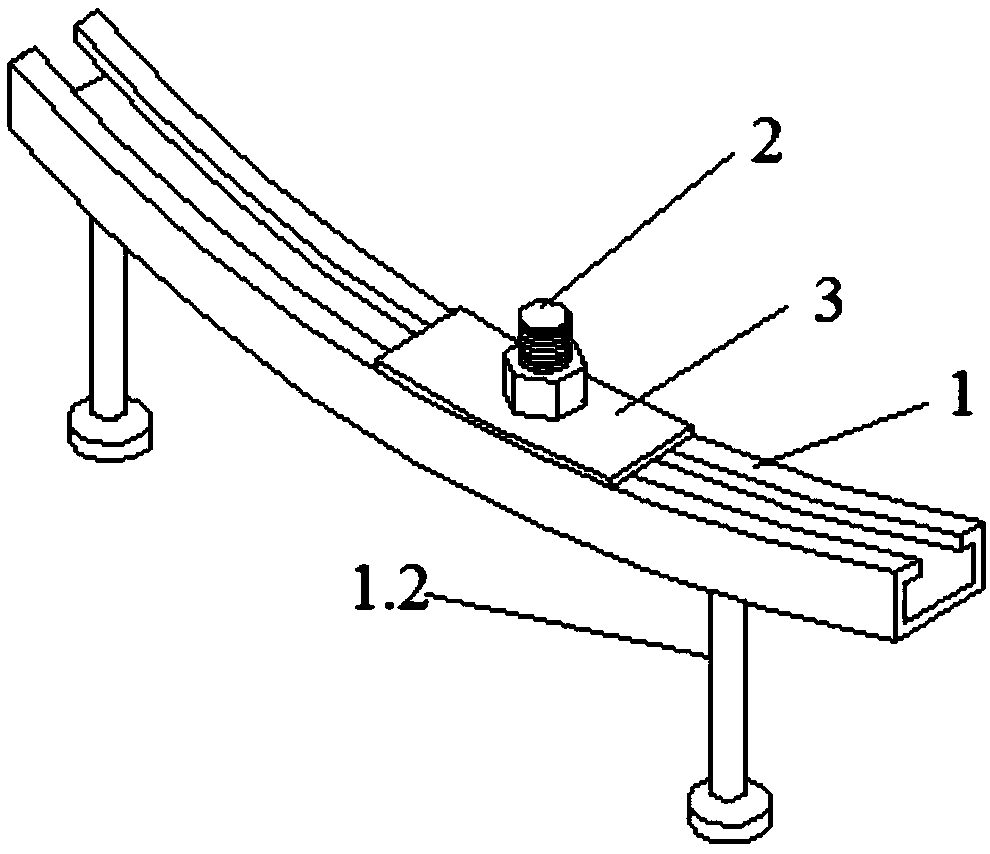

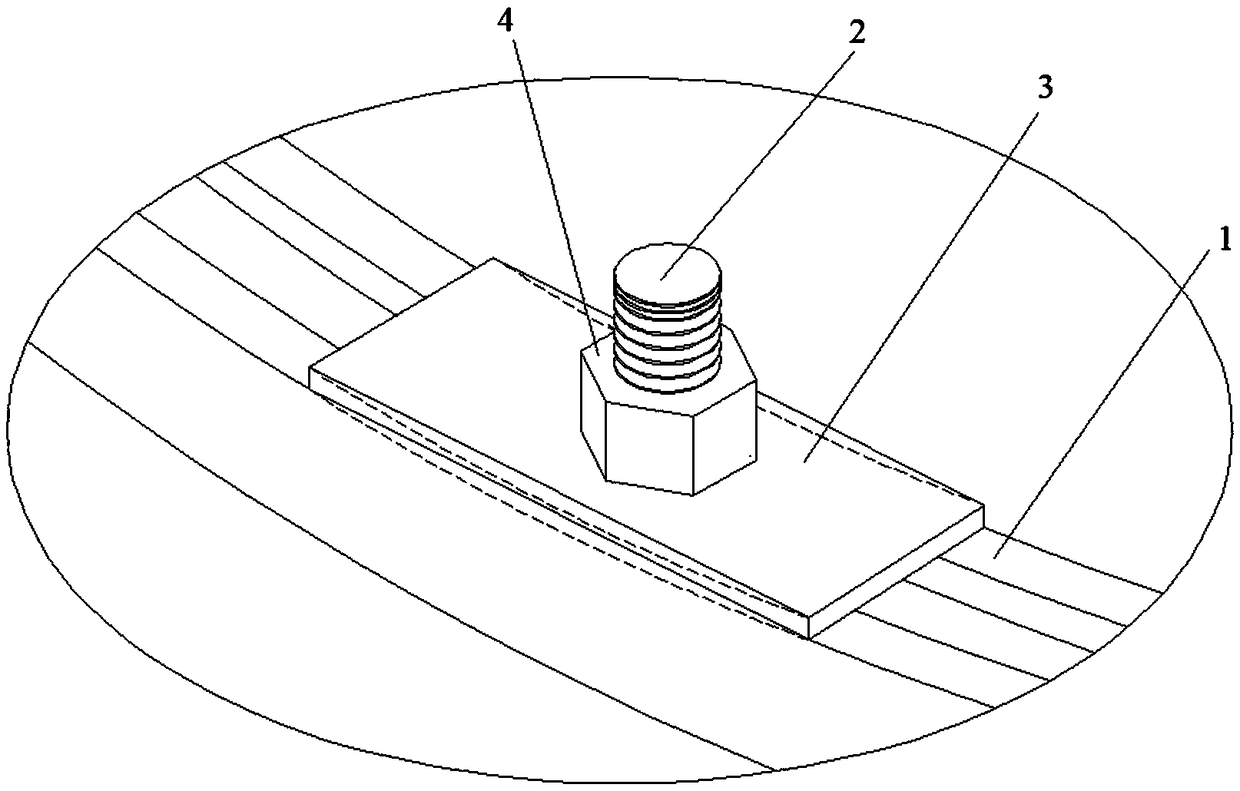

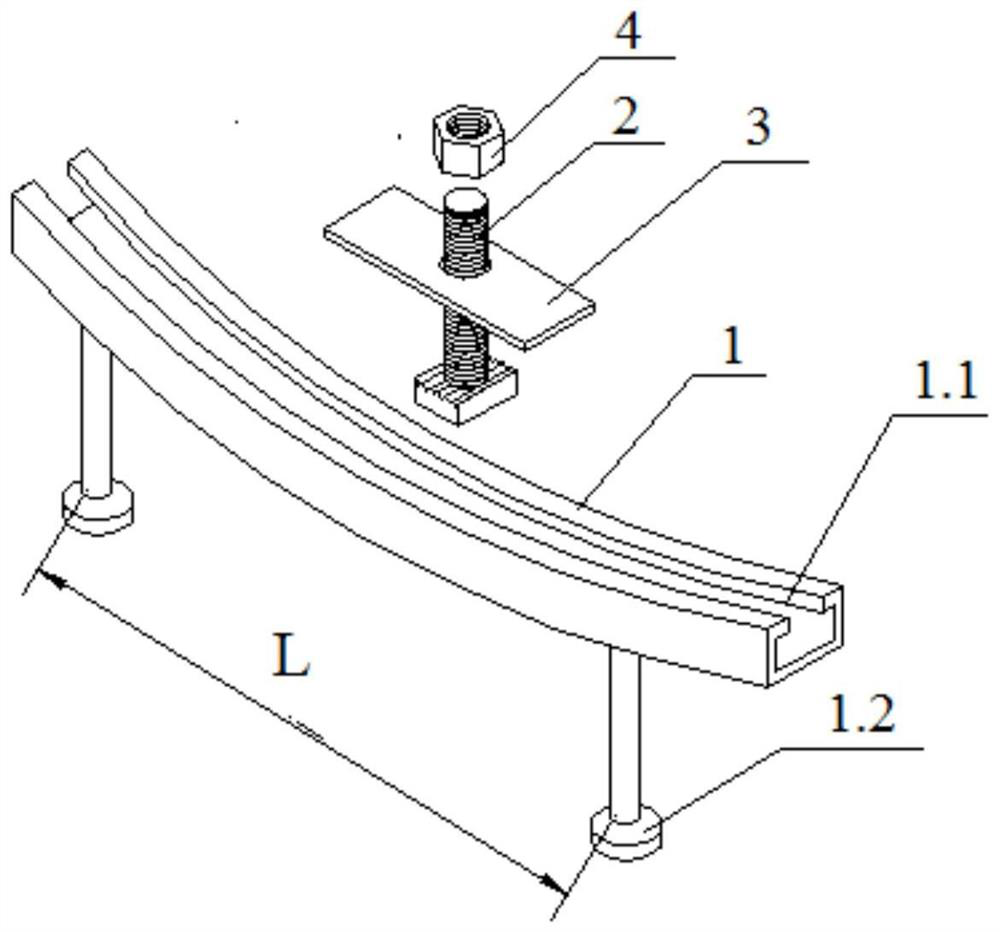

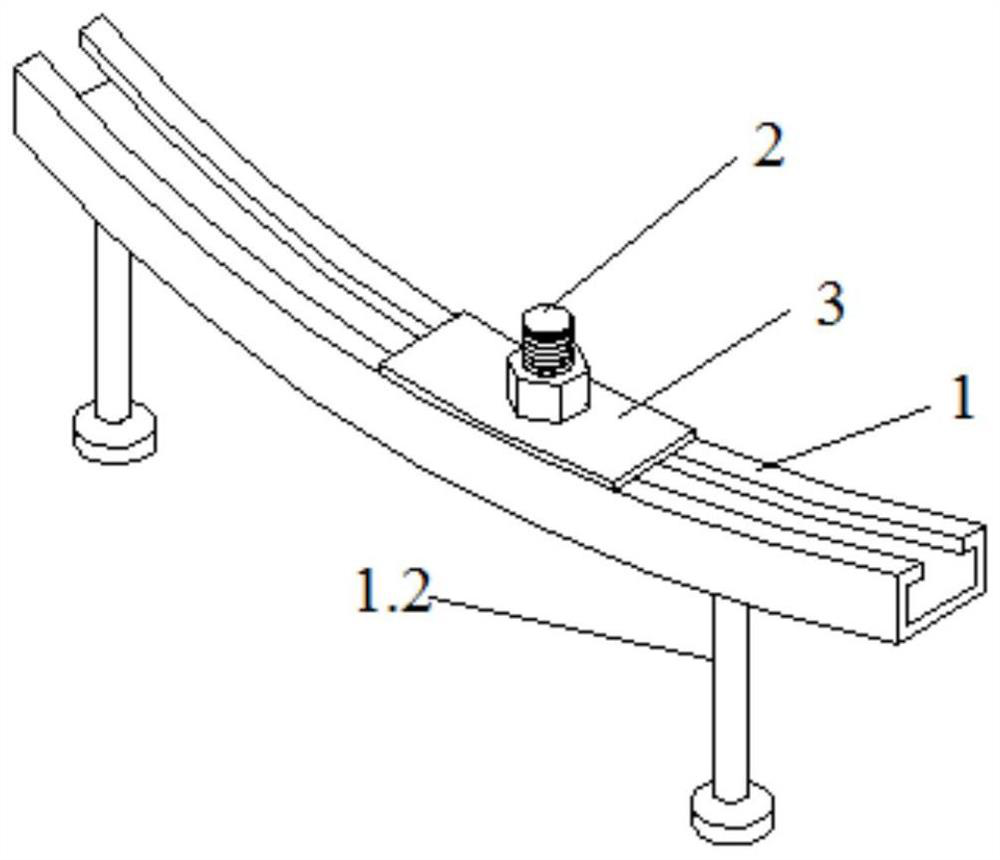

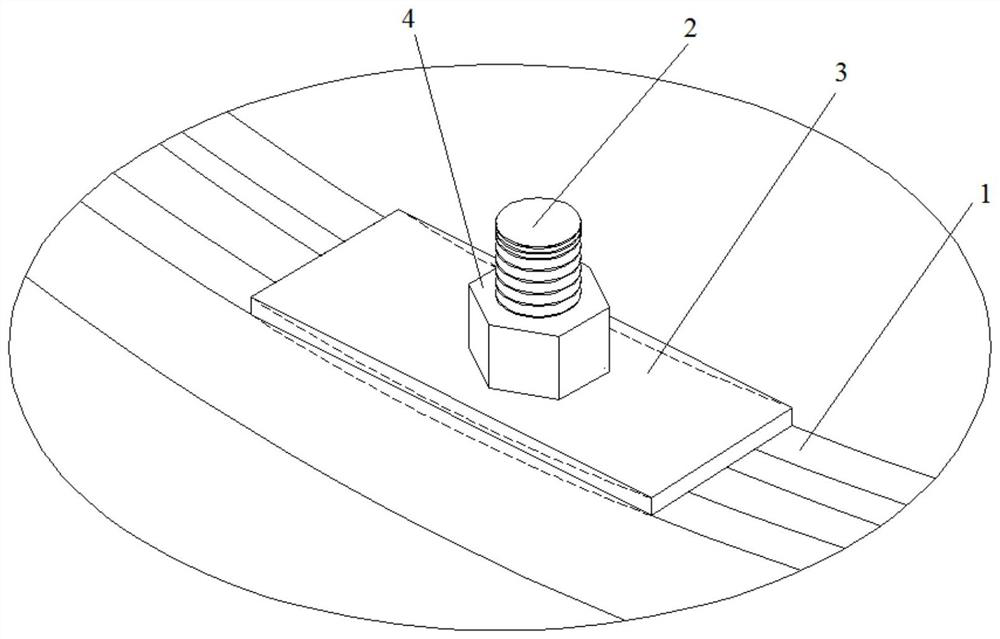

Method for improving pre-buried-channel peripheral-concrete peeling drawing force and anchor device

ActiveCN109057860AReduce stress concentrationImprove pull-out forceMining devicesUnderground chambersEngineeringThreaded rod

The invention discloses a method for improving pre-buried-channel peripheral-concrete peeling drawing force and an anchor device. A pre-buried channel is a pre-buried arc channel; the method includesthe steps that a T-shaped head of a T-shaped bolt is arranged in a channel body of the arc channel; a threaded rod of the T-shaped bolt is sleeved with a straight-strip rigid padding plate provided with a bolt hole, and the length direction of the straight-strip rigid padding plate is same as the channel direction of the arc channel; the straight-strip rigid padding plate is fastened on the threaded rod through a nut, the straight-strip rigid padding plate is deformed to compactly fit with the arc surface of the arc channel, and the extending part of the threaded rod serves as an installing point of ancillary facilities in a tunnel. According to the method, the pre-buried-channel peripheral-concrete peeling drawing force is greatly improved; the technology cost is low, the cost performanceis high, the low drawing force peeling problem of a large-anchor-rod-interval pre-buried channel can be effectively solved, and a drawing value of a normal-anchor-rod-interval pre-buried channel canalso be greatly improved.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Bow-type drop cable with physical rat-proof function and manufacturing method of drop cable

InactiveCN106772854AReduce design difficultyReduce maintenance difficultyFibre mechanical structuresEngineeringMechanical property

The invention provides a bow-type drop cable with physical rat-proof function and a manufacturing method of the drop cable. The bow-type drop cable comprises a bow-type cable, an optical fiber and an optical fiber armor, wherein the bow-type cable is provided with a suspension wire reinforcing part, a first reinforcing part and a second reinforcing part which are fixed in an outer sheath through injection molding, V-shaped tearing ports are formed in two sides of the outer sheath and located between the first reinforcing part and the second reinforcing part, the optical fiber is arranged between the V-shaped tearing ports on the two sides, and the periphery of the optical fiber is wrapped with the optical fiber armor. The manufacturing method comprises the steps as follows: molding of the optical fiber with the optical fiber armor and extrusion molding of the outer sheath. The problems of poor physical rat-proof and mechanical performance of the bow-type drop cable are solved, the periphery of the optical fiber is wrapped with a stainless steel pipe, the outer sheath can still have the physical rat-proof function after being bitten, and the tensile property and lateral pressure resistance of the bow-type drop cable are improved.

Owner:德阳汇川科技有限公司

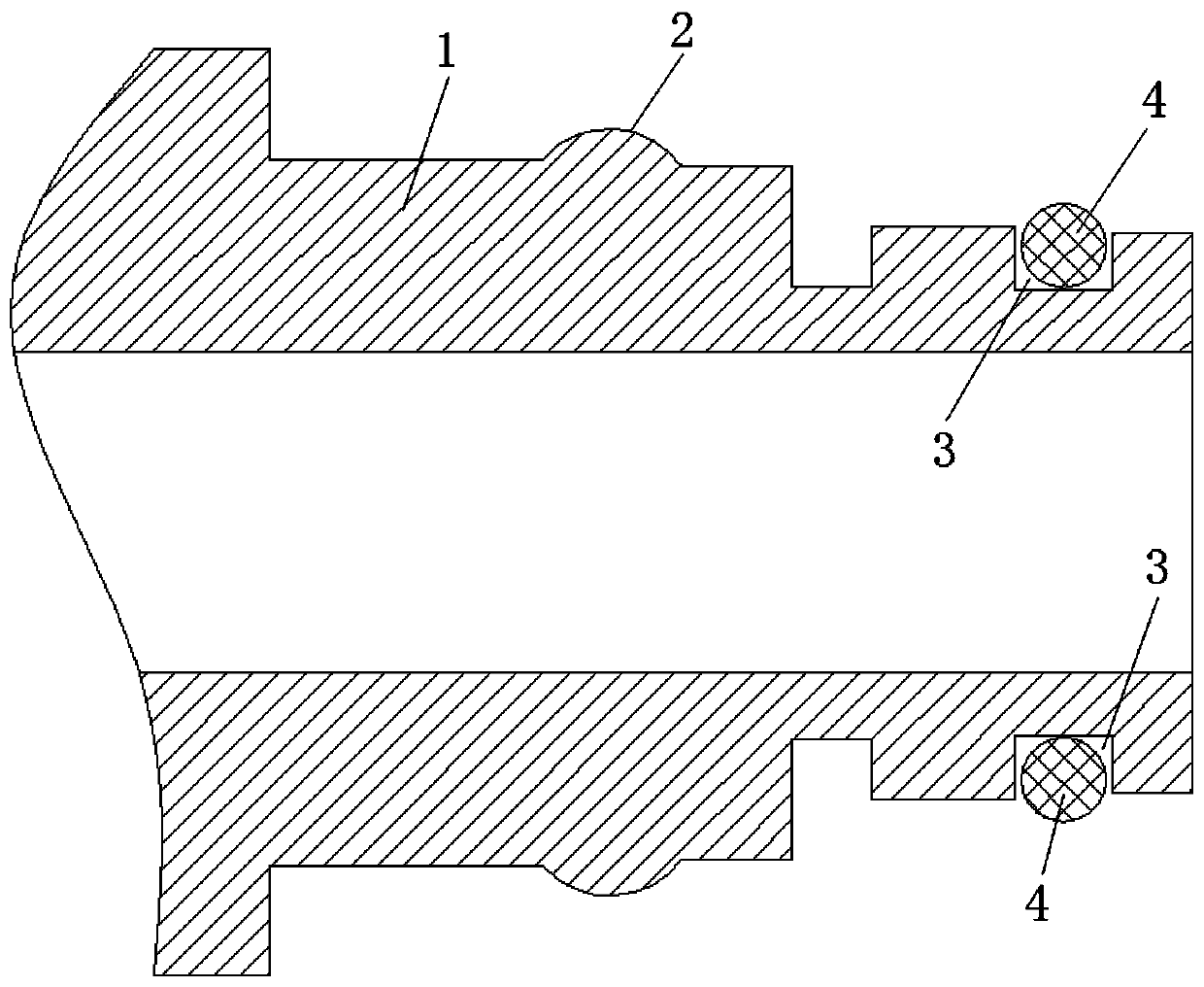

Anchoring connector of ductile cast iron pipe

InactiveCN104344112AStrong anti-off abilitySimple structureJoints with sealing surfacesEngineeringDuctile iron

The invention discloses an anchoring connector of a ductile cast iron pipe. The anchoring connector comprises an inserting hole, a receiving hole and a pressure flange, wherein an annular conical inner hole is formed in the inner surface of the pressure flange; an annular groove matched with a convex ring is formed in the right side of the conical inner hole; a fixing ring is positioned in the conical inner hole and the diameter of the fixing ring is greater than that of the left side of the conical inner hole. According to the anchoring connector, the annular groove and the conical inner hole are formed in the pressure flange, and the strength of the pressure flange is fully utilized for connecting the inserting hole with the receiving hole without assistance of other accessories; the anchoring connector is simple in structure and convenient to mount; meanwhile, the structure can bear relatively large pull-out force and is good in anti-separation capability.

Owner:山东球墨铸铁管有限公司

Sealed anti-falling single-core wire butt joint manipulator

ActiveCN111146667AImprove reliabilityImprove pull-out forceLine/current collector detailsElectrically conductiveManipulator

The invention discloses a sealed type anti-falling single-core wire butt joint mechanical arm. The mechanical arm comprises a terminal body, a lower pressing plate, a first bending pressing block, aninclined plane push block, a guide sheet fixing seat, a U-shaped conductive sheet and two second bending pressing blocks. A lock catch part is arranged on the terminal body, and a sealed cavity is formed by the guide sheet fixing seat and the terminal body; the U-shaped conducting sheet is arranged on a conducting sheet fixing seat; a permanent magnet is embedded in the second bending pressing blocks; the first bending pressing block comprises a pressing block bending part and two first connecting rods; the pressing block bending part is provided with a lower pressing head, and the two first connecting rods penetrate through the terminal body and then are connected to the lower pressing plate; the inclined plane push block comprises a push block body and a second connecting rod, wherein the push block body is provided with a notch, the second connecting rod penetrates through the top of the terminal body and then extends outwards, and the lower pressing plate is provided with a lockinghook. According to the invention, the mechanical arm can greatly improve the reliability of wire connection, effectively prevents the loosening of wire connection, is convenient to use, can avoid corrosive media in the external environment, and improves durability of wire butt joint.

Owner:羽源洋(宁波)科技有限公司

Wear-resistant and temperature-resistant artificial turf and preparation method thereof

ActiveCN105568425BImprove wear resistanceImprove performanceGround pavingsConjugated synthetic polymer artificial filamentsFiberThermoplastic elastomer

The invention discloses a wear-resistant and temperature-resistant artificial turf. The wear resistance of the artificial grass fiber is improved; meanwhile, the temperature resistance of the artificial turf fiber is improved; the acting force between the artificial grass fiber and a bottom back is improved; the artificial grass fiber falling phenomenon is avoided. The wear-resistant and temperature-resistant artificial turf comprises the artificial grass fiber, wherein the artificial grass fiber is prepared from the following ingredients in parts by weight: 35 to 90 parts of base body resin, 5 to 30 parts of thermoplastic elastomer, 5 to 20 parts of wear-resistant and temperature-resistant master batch, 0.01 to 5 parts of anti-aging agents and 0.5 to 10 parts of master batch.

Owner:COCREATION GRASS CO LTD

Preparation method of woven carpet without gumming process

ActiveCN108411460AEnhanced shape retention and dimensional stabilityOmit the adhesive processHeating/cooling textile fabricsWoven fabricsCopolyesterWeft yarn

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber-formed filament or a staple fibre yarn, a first coating layer is apolyester fiber filament or a staple fibre yarn, the second coating layer accounts for 20%-50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass ofthe composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt copolyester fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt copolyester fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, the pile and weft yarns as well as the weftyarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpet are enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

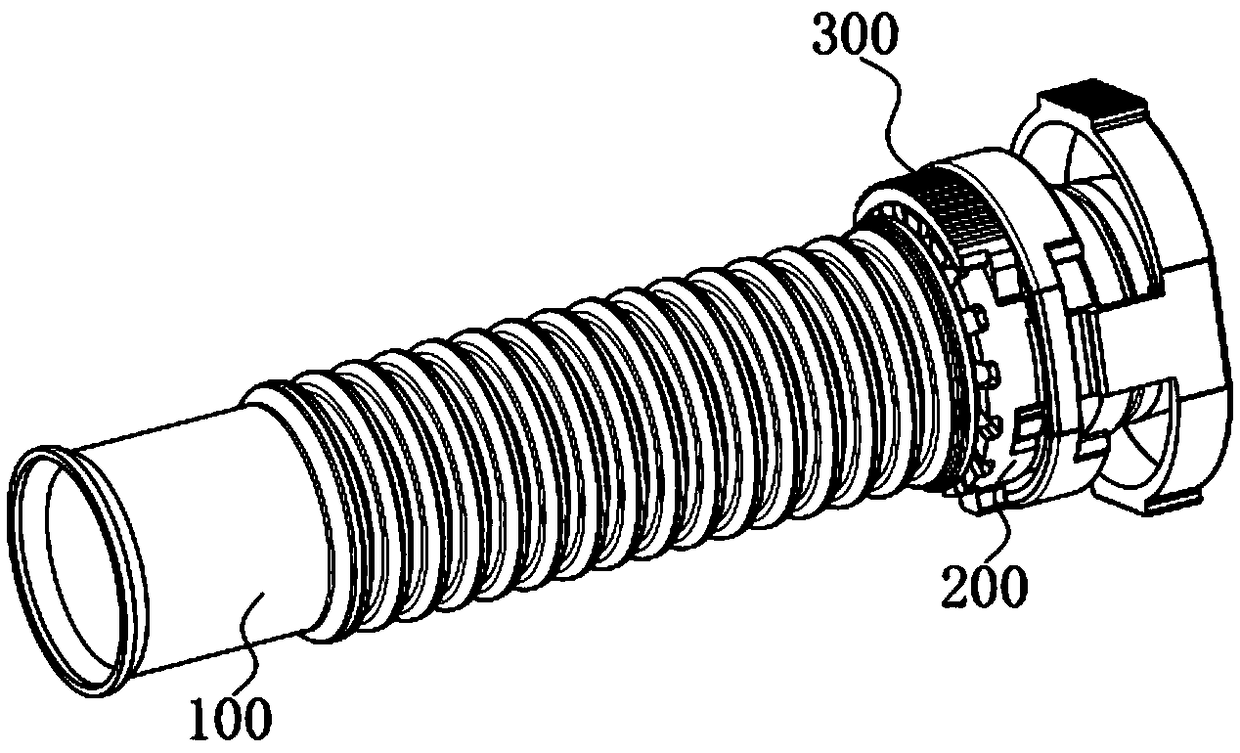

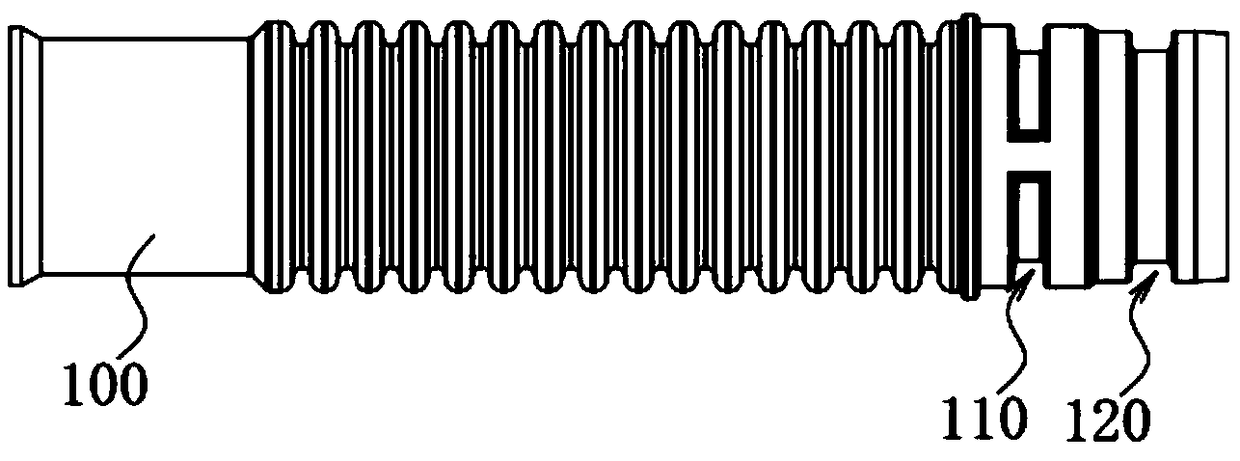

Quick-plug connector and automotive pipeline system

PendingCN109210304AAvoid assembly damage and deformationEmission reductionCouplingsPipe connection arrangementsClamp connectionCoupling

The invention provides a quick-plug connector and an automotive pipeline system, and relates to the technical field of nylon tube connection. An object of the invention is to solve the technical problem that an existing quick coupling is required to be pressed into a nylon tube, the quick coupling is damaged and deformed and a tube end of the nylon tube is cracked, and therefore the leakproofnessbetween the quick coupling and the nylon tube is poor. The invention relates to a quick-plug connector, comprising: a first tube body, a connector buckle and a connector lock; a tube end of the firsttube body is provided with a limiting neck, the first tube body is sleeved with the connector buckle, the connector lock comprises a fixing portion and elastic locking portions located in the limitingneck, an end portion, far from the fixing portion, of each elastic locking portion is in clamping connection with the connector buckle, and the first tube body is closely clamped between the elasticlocking portions. The invention further relates to an automotive pipeline system comprising the quick-plug connector. According to the quick-plug connector and the automotive pipeline system, the connector is not required to be pressed into the nylon tube, and the conditions that the connector is damaged and deformed when assembled and the tube end of the nylon tube is cracked are effectively avoided.

Owner:弗兰科希管件系统(上海)有限公司

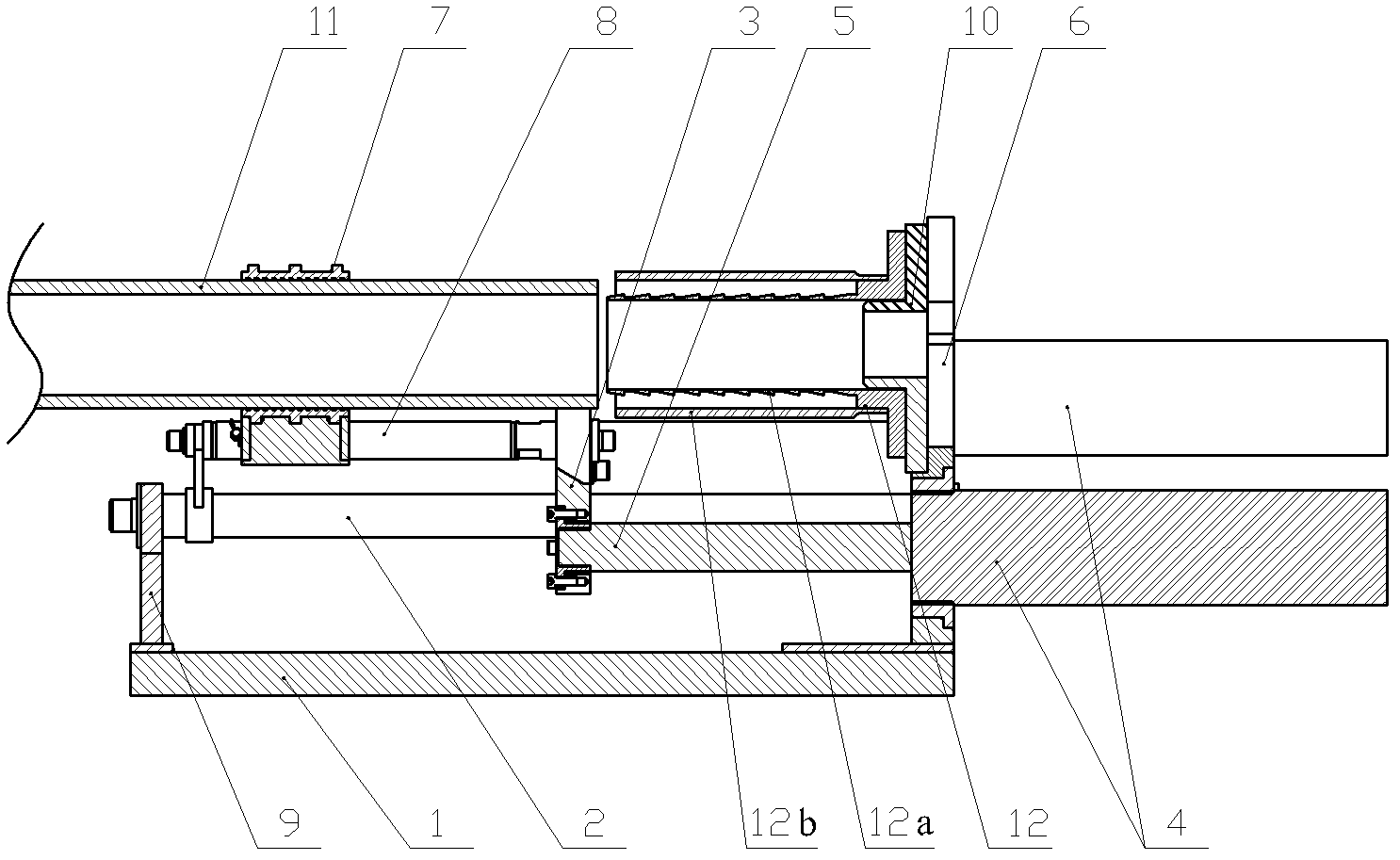

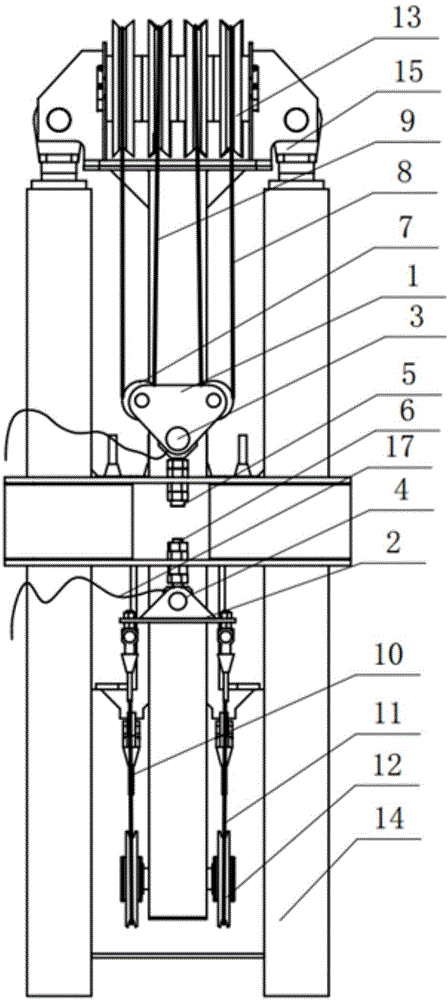

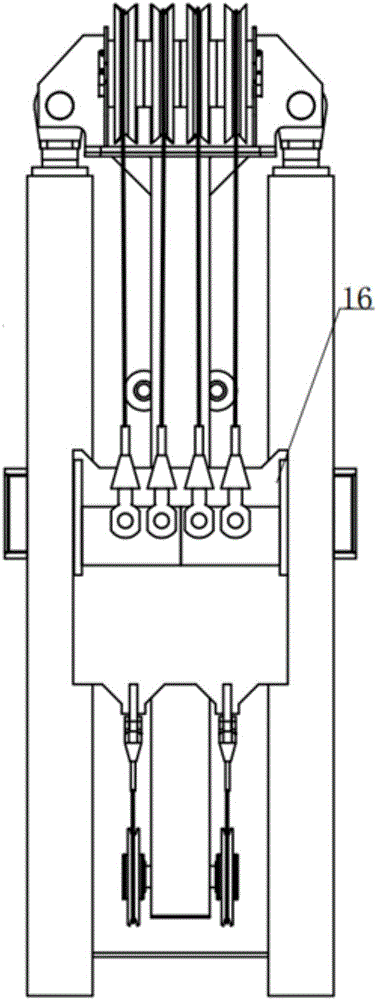

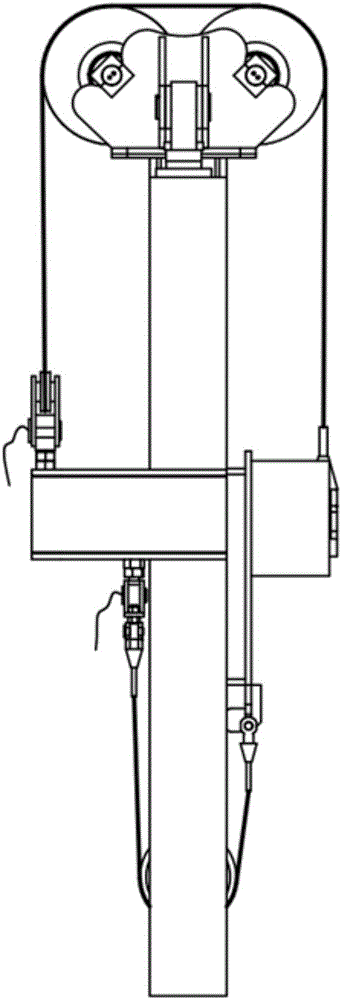

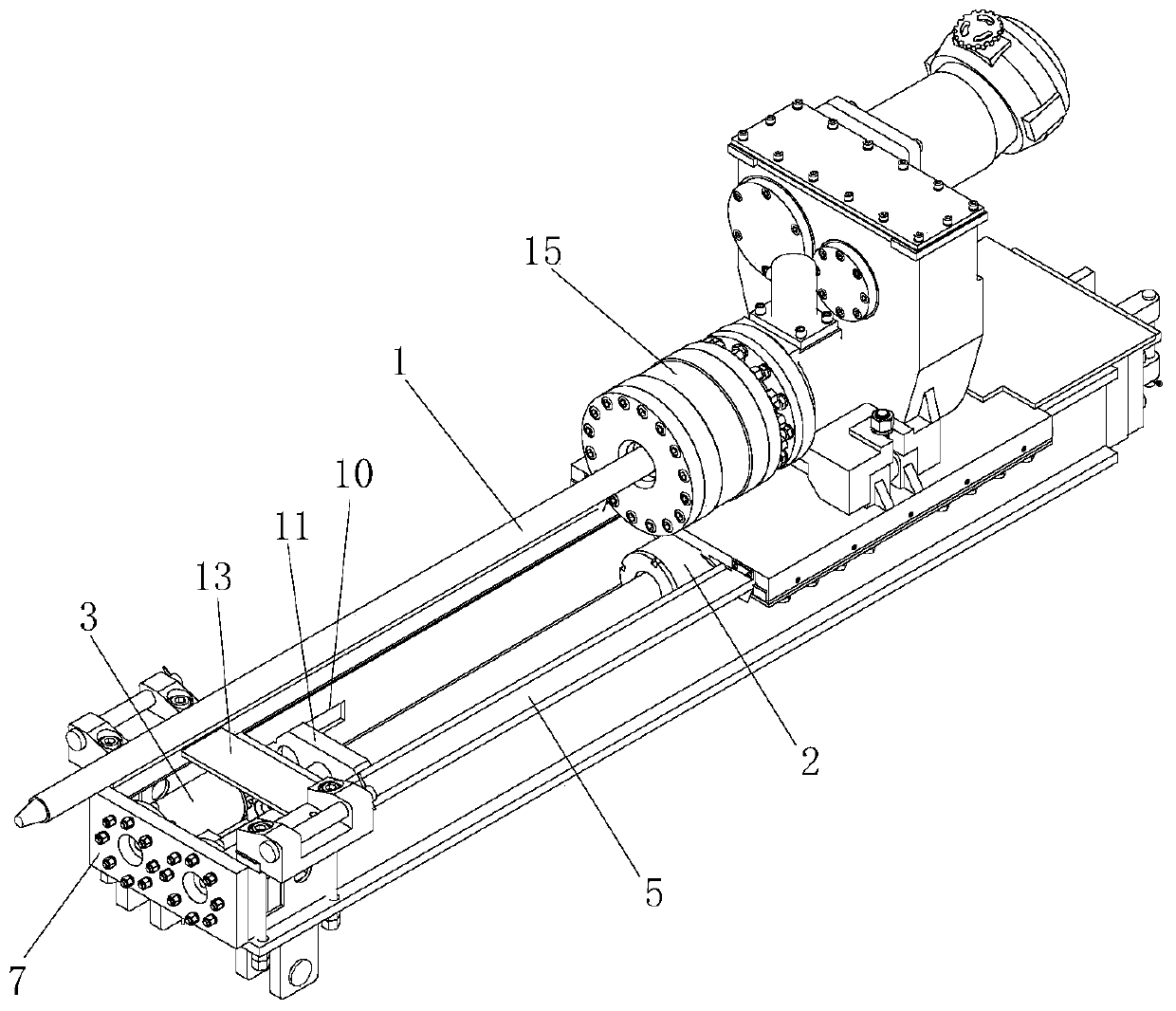

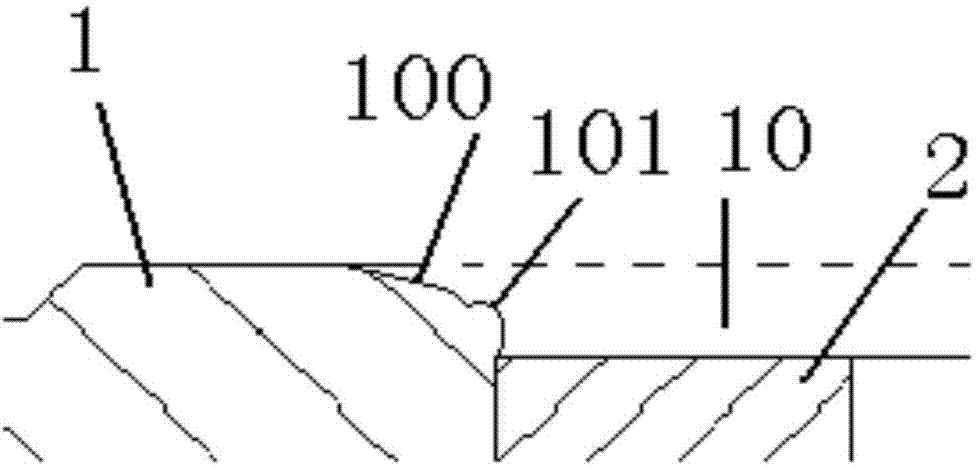

Self-balancing drilling and pulling-out mechanism with real-time bit pressure monitoring function

ActiveCN106194151AAvoid weight-on-bit distortionAvoid force imbalanceDrilling rodsConstructionsVertical motionEngineering

A self-balancing drilling and pulling-out mechanism with a real-time bit pressure monitoring function comprises a first-stage fixed machine body, a second-stage oil cylinder feeding machine body and a power head supporting plate. The second-stage oil cylinder feeding machine body is arranged on the first-stage fixed machine body through an oil cylinder in a telescopic mode. The second-stage oil cylinder feeding machine body comprises a machine body part located between hollow square steel on the two sides. The upper end of the machine body part is connected to the free end of an oil cylinder telescopic rod in the first-stage fixed machine body through a cross beam. The power head supporting plate is located on the front side of the first-stage fixed machine body, and is connected to the first-stage fixed machine body after an upper self-balancing mechanism and a lower self-balancing mechanism wind around the upper end and the lower end of the second-stage oil cylinder feeding machine body correspondingly. Vertical motion of the power head supporting plate is achieved through vertical movement of the second-stage oil cylinder feeding machine body. Due to the facts that the self-balancing drilling and pulling-out mechanism is simple in structure, convenient to operate and capable of improving the pulling-out force and conducting real-time monitoring, the self-balancing drilling and pulling-out mechanism has practicability and applicability.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Hydraulic rod and hydraulic tensioner with hydraulic rod

Owner:GATES UNITTA POWER TRANSMISSION SHANGHAI

A kind of preparation method of latex-free machine-woven carpet

ActiveCN108396397BGuaranteed pull-out forceReduce dosageCarpetsWoven fabricsPolymer scienceLatex rubber

The invention discloses a method for preparing a latex-free woven carpet. The second coating layer is filament or spun yarn formed of hot-melt fibers, and the first coating layer is fiber long yarn formed of nylon 6 or nylon 66. Silk or spun yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn. Pile weft. When hot-melt copolyamide fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of nylon or wool fibers, when the hot-melt copolyamide fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the carpet pile and The shape retention and dimensional stability of the carpet, thereby omitting the back glue process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:BINZHOU COC CARPET

A kind of preparation method of machine-woven carpet without back glue process

ActiveCN108411460BGuaranteed pull-out forceReduce dosageHeating/cooling textile fabricsWoven fabricsFiberPolymer science

The invention discloses a preparation method of a machine-woven carpet without adhesive backing process. The second coating layer is filament or staple fiber yarn formed by hot-melt fibers, and the first coating layer is polyester fiber filament or staple yarn. Fiber yarn, the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn . When hot-melt copolyester fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt copolyester fibers are heated above their melting point in the hot-pressing process, they melt, and the fibers The conformation of the macromolecular chain changes, and through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. After curing, the pile and weft yarn as well as the weft and warp yarn are effectively consolidated, which enhances the pull-out strength of the pile and the carpet Excellent shape retention and dimensional stability, thereby omitting the back glue process in the carpet preparation process, making the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

External wall heat-preserving decoration wall and its construction process

InactiveCN101487335BAvoid dangerAvoid it happening againCovering/liningsHeat proofingInjection portBrick

The invention relates to an insulated decorating wall for an external wall and a construction technology thereof, which is characterized in that the insulated decorating wall comprises a plurality of insulated decorating plates which are spliced and fixed on the base wall surface of the external wall, each insulated decorating wall comprises a moisture-proof film layer, an insulating layer is bonded on the upper surface of the moisture-proof film layer, and a finishing coat is bonded on the upper surface of the insulating layer through a bonding layer; the finishing coat is formed by splicinga plurality of face bricks, marks of positions for anchoring are arranged at the brick work joints of the face bricks, circulation grooves for injecting adhesive are oppositely arranged on the insulating layer at the joint of adjacent insulated decorating walls correspondingly, and injection ports and pressure relief ports can be arranged to be communicated with the circulation grooves. As basic sections of the insulated decorating plates are manufactured in advanced and can be assembled directly on site, or only need partial cutting at the most, without sticking the face bricks onto the wallon site, the time is greatly saved and the danger of aloft work is avoided, moreover, all-weather working conditions can be adapted.

Owner:李建中

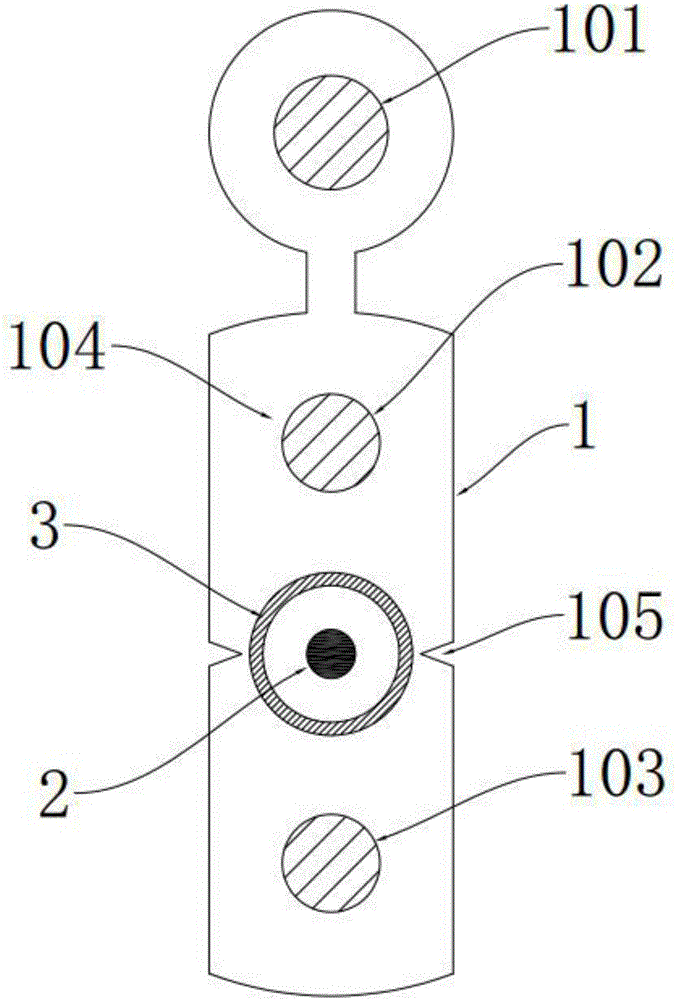

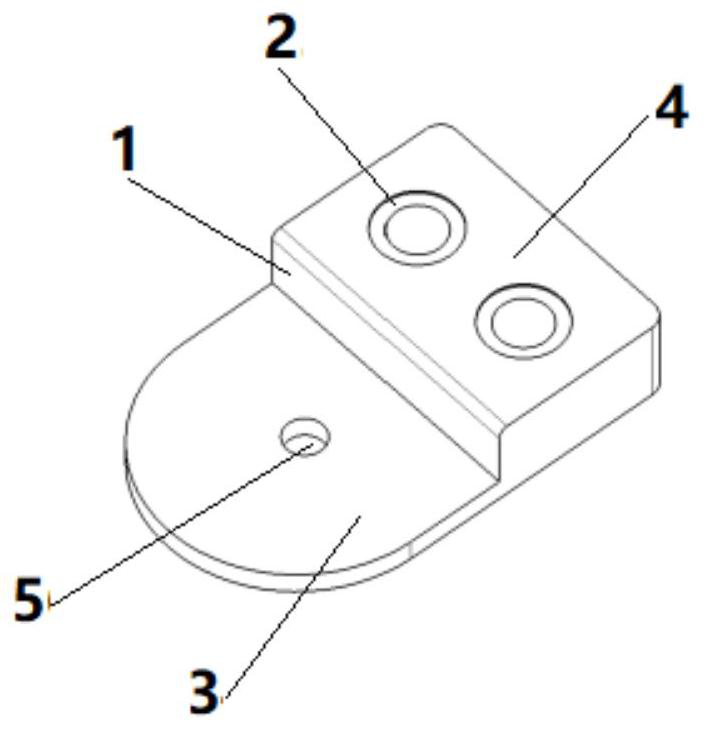

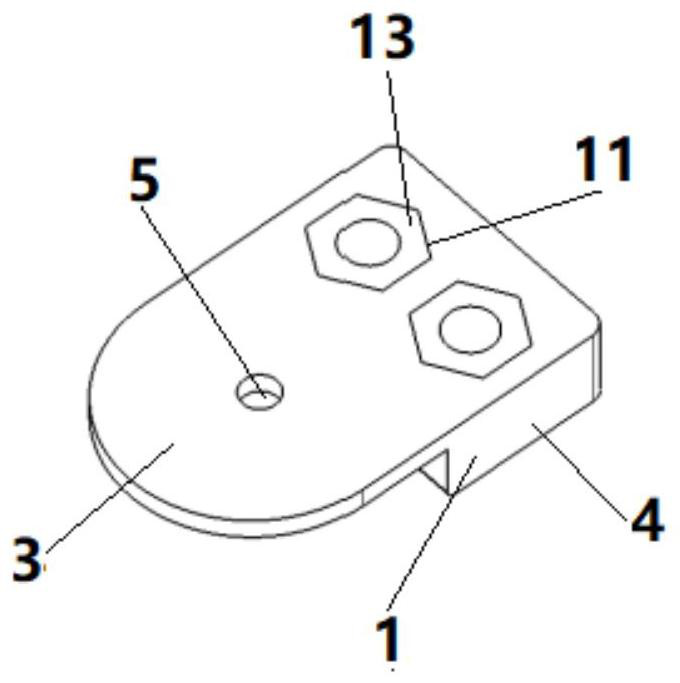

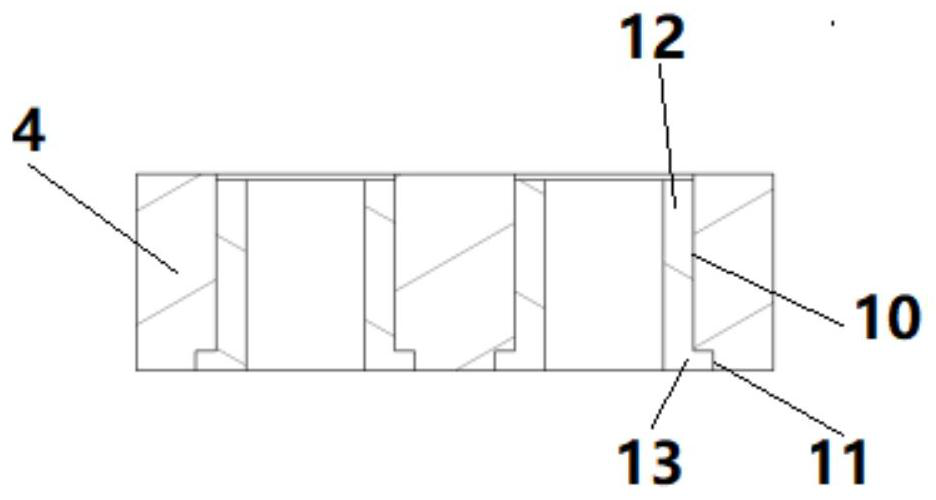

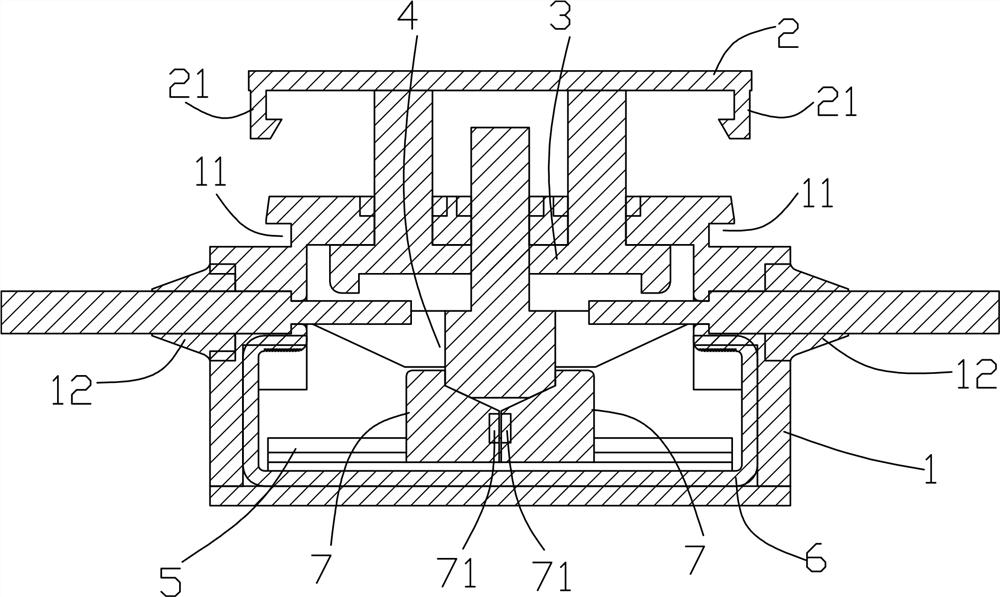

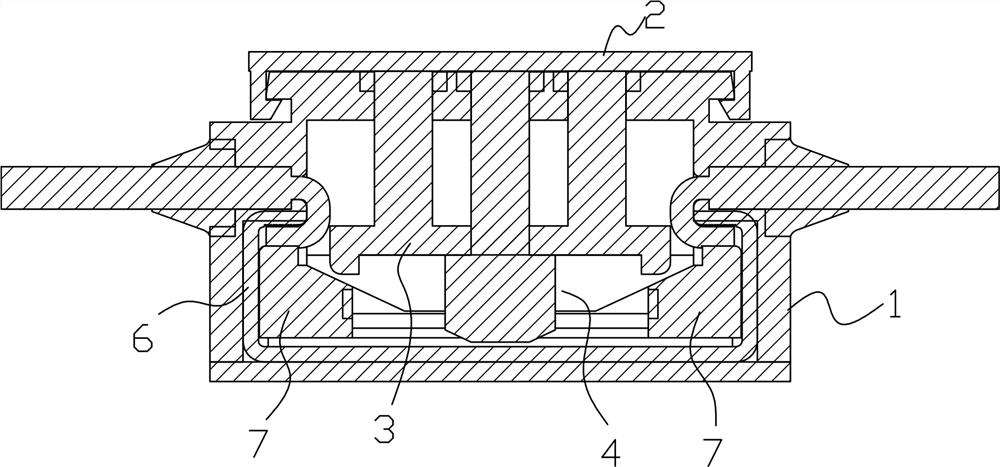

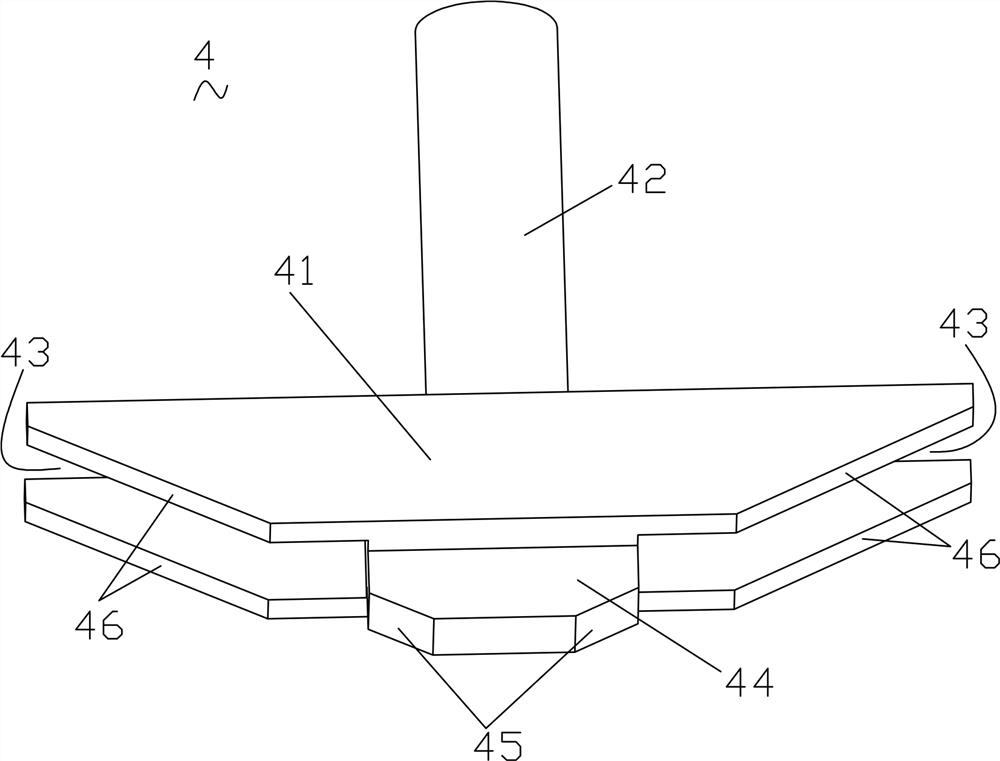

Battery cell electric connection switching sheet

InactiveCN112234319APrevent pull outImprove pull-out forceCell component detailsStructural engineeringMechanical engineering

The invention provides a battery cell electric connection switching sheet applied to the technical field of lithium batteries. A switching sheet body (1) of the battery cell electric connection switching sheet comprises a body low position part (3) and a body high position part (4), a T-shaped through hole (6) is formed in the body high position part (4), a fastening part (2) is of a T-shaped structure, the fastening part (2) is installed in the T-shaped through hole (6), a thread (7) is arranged in the fastening part (2), body low position part (3) is welded to a battery cell pole (8), and the body high position part (4) is connected with a battery cell connection bar by a bolt (9). According to the battery cell electric connection switching sheet, the connection between the battery cellconnection bar and the battery cell is conveniently and reliably realized, the welding goodness rate of the switching sheet and the battery cell pole is effectively realized, the connection reliability when the bolt is fixedly connected with the battery cell connection bar is realized, the safety and reliability of installation at the connection position are enhanced, the quality is comprehensively improved, and the maintenance cost of a battery cell product with the switching sheet is reduced.

Owner:芜湖天量电池系统有限公司

Production method of woven carpet with no latex

InactiveCN108396441AGood shape retentionGood dimensional stabilityCarpetsWoven fabricsLow-density polyethyleneViscous flow

The invention discloses a production method of a woven carpet with no latex. A second covering layer is made with hot-melt fiber filaments or staple yarns; a first covering layer is made with high-density polyethylene fiber filaments or staple yarns; the second covering layer accounts for 20-50% of total mass of composite yarn; the first covering layer accounts for 10-15% of the total mass of thecomposite yarn; the balance is core yarns; pile wefts are therefore produced. During the production of a no-gum carpet with hot-melt low-density polyethylene fiber as an adhesive material, pile yarnsare made in conjunction with nylon fiber or wool; the hot-melt low-density polyethylene fiber melts down when heated to above its melting point in a hot pressing step, and fiber macromolecular chain conformation varies; segmer transition allows the whole macromolecular chain to slide, a viscous flow occurs, piles, wefts and warps are effectively fixed after solidifying, pull-out strength of the piles is enhanced, and shape-maintaining property and dimensional stability are enhanced for the carpet; therefore, the gumming step in the carpet production process is omitted, so that the carpet produced is more environmentally friendly.

Owner:QINGDAO UNIV

Preparation method of latex-free woven carpet

InactiveCN108411459ASolve the problem of impermeabilityOmit the adhesive processCarpetsWoven fabricsViscous flowEngineering

The invention discloses a preparation method of a latex-free woven carpet. A second wrapping layer is made of filaments or short fiber yarn formed by hot melt fiber, and a first wrapping layer is madeof polyester fiber filaments or short fiber yarn. Composite yarn comprises, by mass, 20-25% of second wrapping layer, 10-15% of first wrapping layer and the balance pile weft prepared from core yarn.When the latex-free carpet is produced from hot-melt copolyester fiber serving as an adhesive material and pile yarn prepared from nylon fiber or wool, the hot-melt copolyester fiber is melted when heated to be higher than the melting point in the hot pressing procedure, and a fiber macromolecular chain conformation changes; through transition of a chain segment, the whole macromolecular chain slides, viscous flow is generated, cured piles and the weft are effectively solidified, and the weft and warp are effectively solidified, so that the drawing strength of the piles and the shape preservation and size stability of the carpet are enhanced, then the gumming procedure in the carpet preparation process is omitted, and the prepared carpet is more environmentally friendly.

Owner:QINGDAO UNIV

A sealed anti-dropping single-core wire butt joint manipulator

ActiveCN111146667BImprove reliabilityImprove pull-out forceLine/current collector detailsStructural engineeringManipulator

Owner:羽源洋(宁波)科技有限公司

Connecting pipe device

PendingCN111594688AImprove operational efficiencyLong-term safe and effective connectionPipe connection arrangementsRigid pipesStructural engineeringMechanical engineering

The invention discloses a connecting pipe device in the technical field of liquid conveying pipelines. A connecting connector, a plastic pipe, a limiting boss, a connector groove, a seal component anda fixing clamp are included. The limiting boss and the connector groove are formed in the connecting connector, and the seal component is arranged in the connector groove. The fixing clamp is arranged on the outer wall of the plastic pipe. The plastic pipe is connected with the connecting connector, sealed through the seal component and fastened through the limiting boss and the fixing clamp. Theconnecting pipe device is reasonable in design, the vehicle weight is effectively reduced, the whole-vehicle running efficiency is improved, and the pulling disengaging force is greatly increased; and connection of the clamp and the plastic pipe is safe and effective for a long term, and life period safety of the system is greatly improved.

Owner:上海保岭新能源科技有限公司

A kind of preparation method of woven carpet without back glue process

ActiveCN108411458BSolve the problem of impermeabilityImprove bindingHeating/cooling textile fabricsCarpetsPolyesterFiber

The invention discloses a method for preparing a woven carpet without a backing process. The second coating layer is hot-melt fiber filament or spun yarn, and the first coating layer is polypropylene fiber filament or spun yarn. , the second covering layer accounts for 20%-50% of the total mass of the composite yarn, the first covering layer accounts for 10%-15% of the total mass of the composite yarn, and the rest is the core yarn to obtain the pile weft yarn. When hot-melt ethylene-vinyl acetate copolymer fibers are used as bonding materials to produce adhesive-free carpets, and pile yarns made of polyester fibers, when the hot-melt ethylene-vinyl acetate copolymer fibers are heated to Melting occurs when the melting point is above the melting point, and the conformation of the fiber macromolecular chain changes. Through the transition of the chain segment, the entire macromolecular chain slips and viscous flow occurs. The pull-out strength of the head and the shape retention and dimensional stability of the carpet, thereby omitting the adhesive backing process in the carpet preparation process, makes the prepared carpet more environmentally friendly.

Owner:QINGDAO UNIV

A method and an anchoring device for increasing the pull-out force of the concrete around the pre-embedded channel

ActiveCN109057860BReduce stress concentrationImprove pull-out forceMining devicesUnderground chambersPull forceEngineering

The invention discloses a method for improving pre-buried-channel peripheral-concrete peeling drawing force and an anchor device. A pre-buried channel is a pre-buried arc channel; the method includesthe steps that a T-shaped head of a T-shaped bolt is arranged in a channel body of the arc channel; a threaded rod of the T-shaped bolt is sleeved with a straight-strip rigid padding plate provided with a bolt hole, and the length direction of the straight-strip rigid padding plate is same as the channel direction of the arc channel; the straight-strip rigid padding plate is fastened on the threaded rod through a nut, the straight-strip rigid padding plate is deformed to compactly fit with the arc surface of the arc channel, and the extending part of the threaded rod serves as an installing point of ancillary facilities in a tunnel. According to the method, the pre-buried-channel peripheral-concrete peeling drawing force is greatly improved; the technology cost is low, the cost performanceis high, the low drawing force peeling problem of a large-anchor-rod-interval pre-buried channel can be effectively solved, and a drawing value of a normal-anchor-rod-interval pre-buried channel canalso be greatly improved.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

Pulling device for gas pumping and draining drill rod

PendingCN111379529AForce balanceReduce wearDrilling rodsDrilling casingsHydraulic cylinderPull force

The invention provides a pulling device for a gas pumping and draining drill rod. The pulling device comprises a main hydraulic cylinder and a drawing hydraulic cylinder which are used for driving thedrill rod to move, wherein the two ends of a piston rod of the main hydraulic cylinder are fixed on the device; a cylinder body of the main hydraulic cylinder can slide on the piston rod of the mainhydraulic cylinder through pressurization; the drawing hydraulic cylinder is fixed on the device; and the piston rod of the drawing hydraulic cylinder is ejected out to be capable of propping againstthe cylinder body of the main hydraulic cylinder to move towards the pulling direction of the drill rod. According to the pulling device for the gas pumping and draining drill rod, the drawing hydraulic cylinder is arranged, so that the pulling force of the drill rod is increased, and the problem that the drill rod is blocked is solved.

Owner:贵州能安机电设备制造有限公司

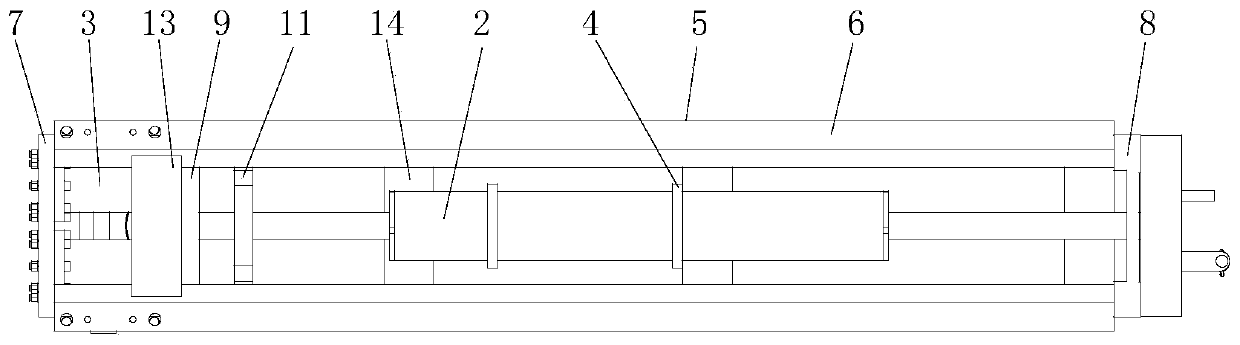

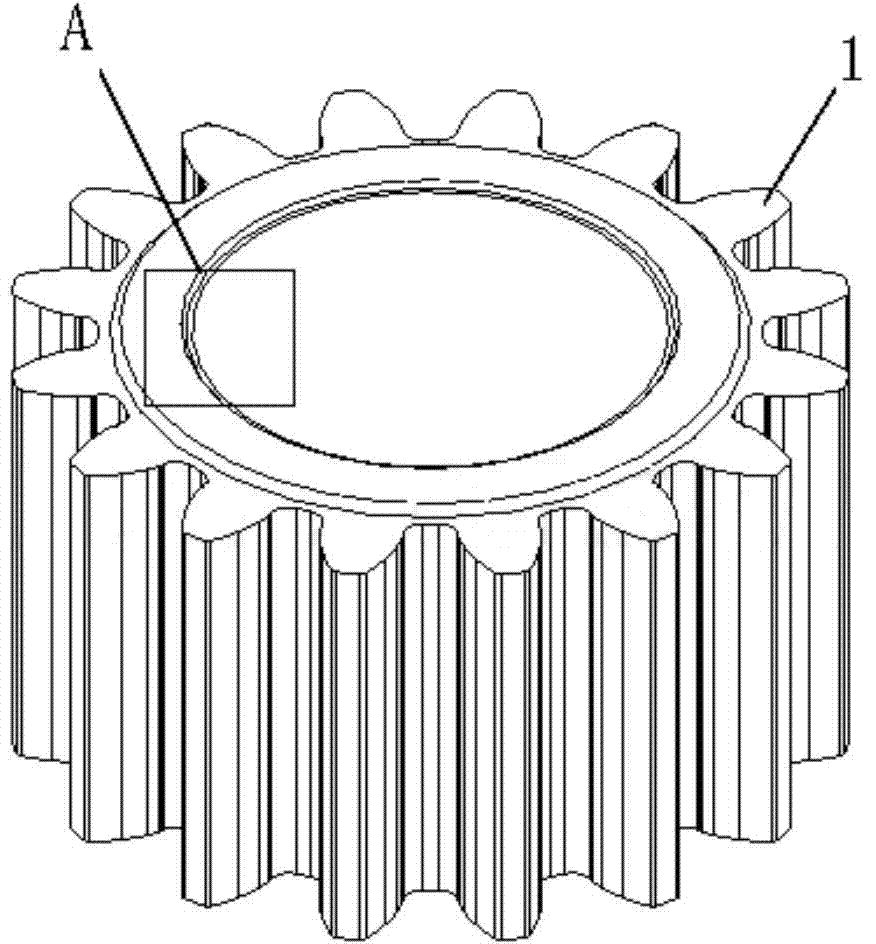

Powder metallurgical planetary gear for high-power starter

InactiveCN104265864APrevent prolapseImprove pull-out forcePortable liftingGearing elementsMechanical engineeringHigher Power

The invention provides a powder metallurgical planetary gear for a high-power starter. The powder metallurgical planetary gear comprises a gear body and a bearing, the gear body is provided with a gear inner hole, the bearing is arranged in the gear inner hole, the end face of the gear body extends to the wall of the gear inner hole through a inclined surface and a cambered surface which are continuous, and the cambered surface projects over the wall of the gear inner hole and is abutted to the edge of the end face of the bearing to stop the bearing from leaving the gear inner hole. The planetary gear solves the problem of insufficient pullout force of a bearing of a planetary gear in the prior art.

Owner:常熟市华德粉末冶金有限公司

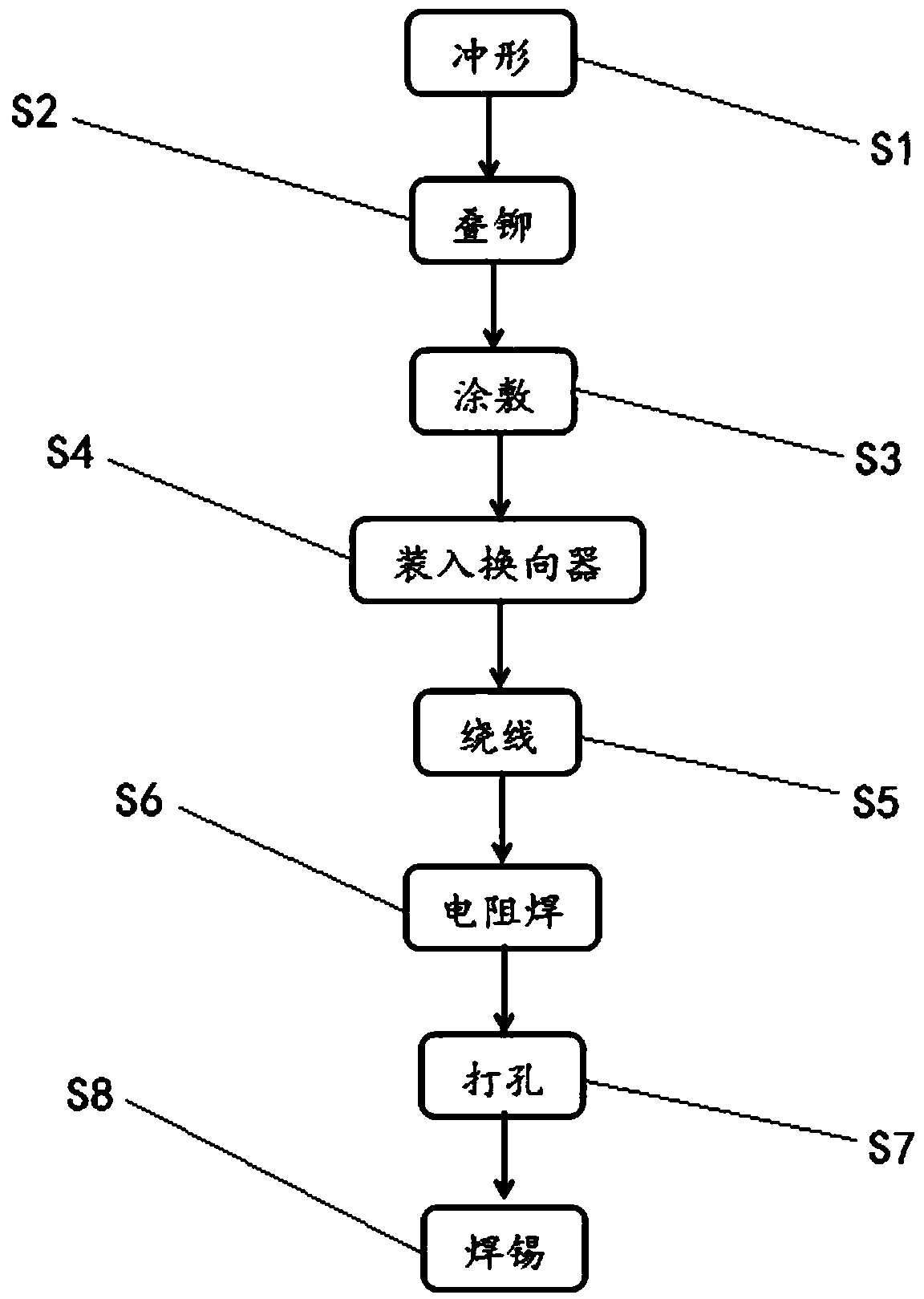

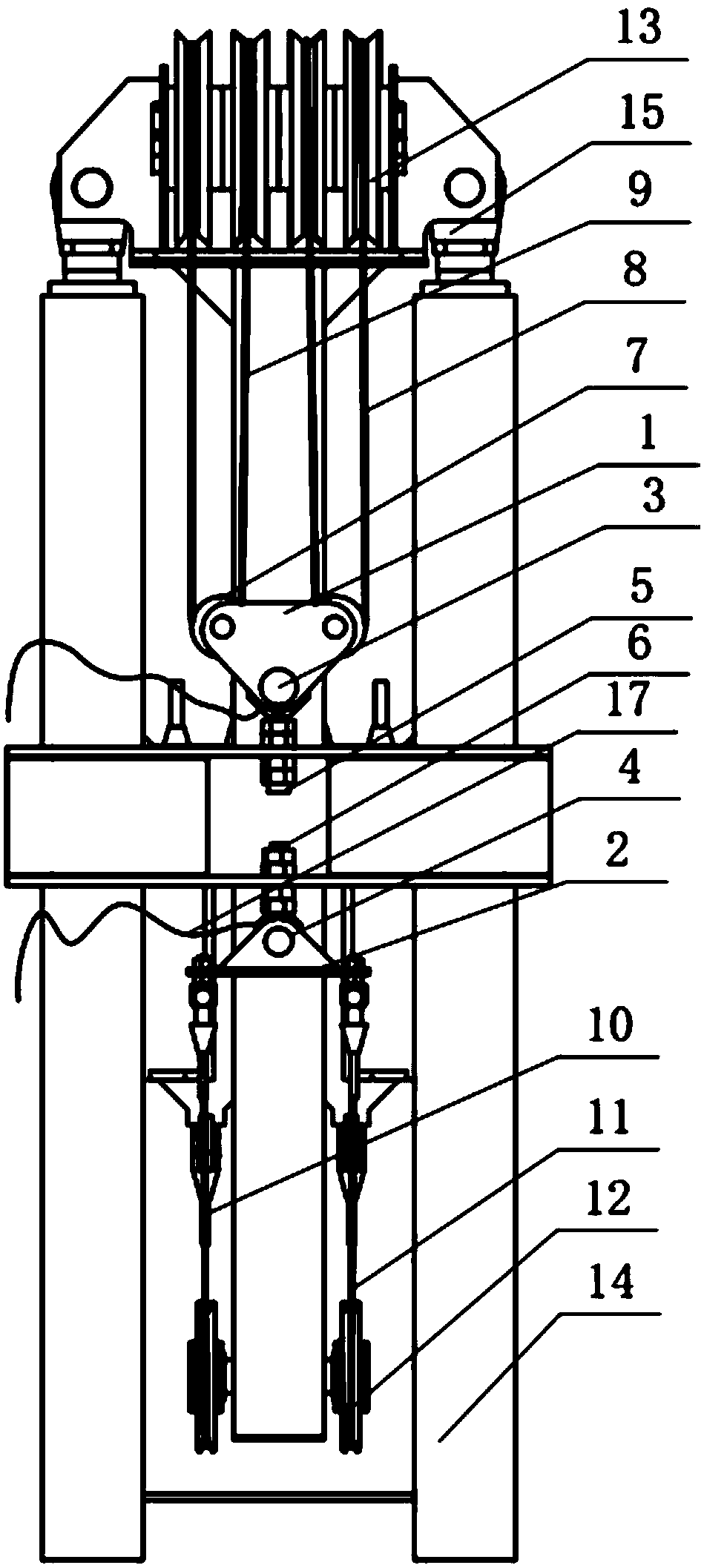

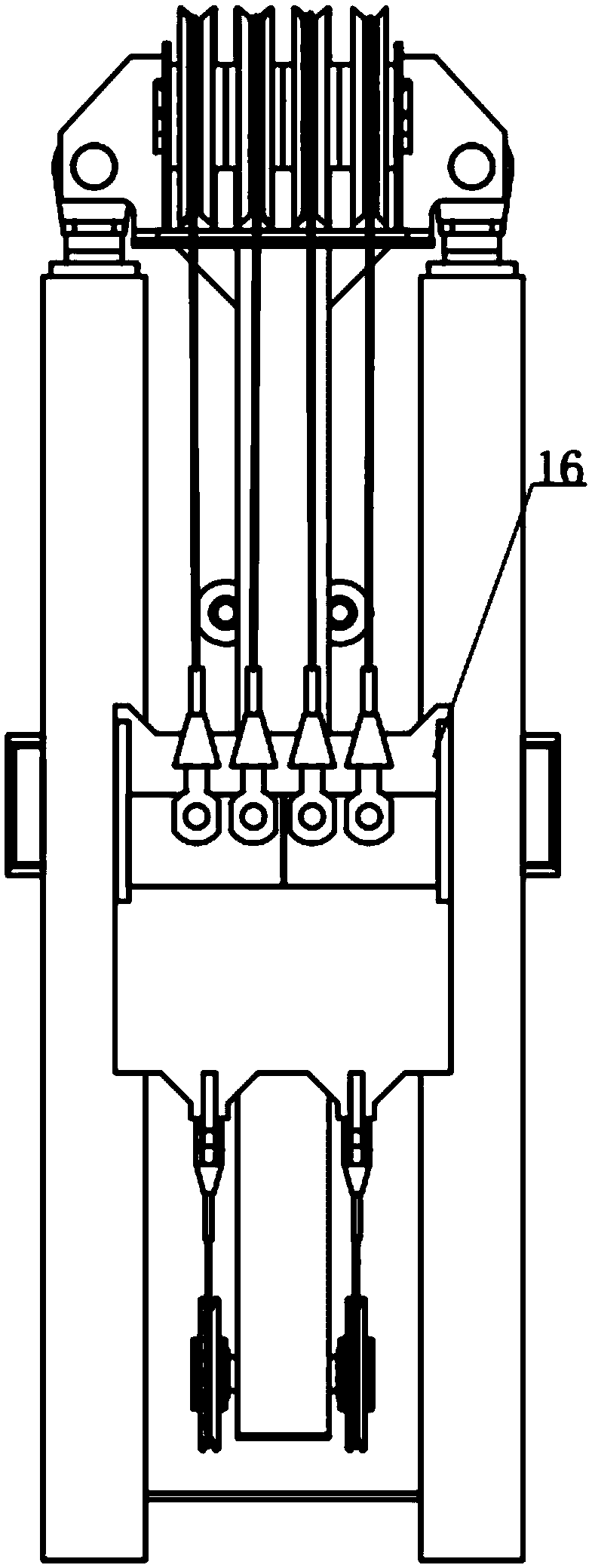

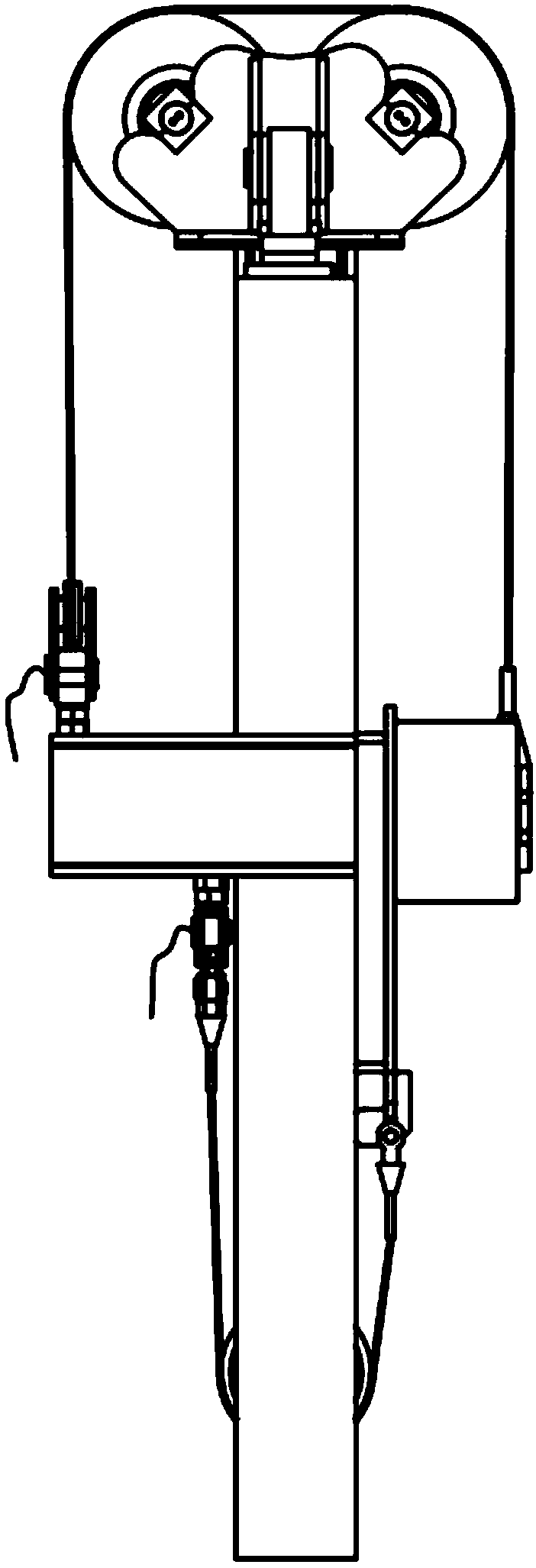

Method for manufacturing carbon brush motor rotors

The invention discloses a method for manufacturing carbon brush motor rotors. The method comprises the following steps of contour stamping, superposed riveting, coating, commutator assembling, wire wrapping, electric resistance welding, electric resistance welding conducted on commutator feet, punching and tin soldering. By means of the method for manufacturing the carbon brush motor rotors, work efficiency of the tin soldering procedure can be improved, and the good product rate of the tin soldering procedure can be raised.

Owner:深圳市科美达自动化设备有限公司

Self-balancing drilling and pulling mechanism with real-time monitoring function of bit pressure

ActiveCN106194151BAvoiding weight-on-bit distortion problemsAutomatically adjust the balanceDrilling rodsConstructionsEngineeringWeight on bit

A self-balancing drilling and pulling mechanism with the function of real-time monitoring of bit pressure, including a primary fixed fuselage, a secondary oil cylinder feeding the fuselage and a power head support plate, and the secondary oil cylinder feeding the fuselage passes through the oil cylinder It is telescopically arranged on the primary fixed fuselage, and the secondary oil cylinder feed fuselage includes a fuselage body located in the middle of the hollow square steel on both sides. The free end of the telescoping rod of the oil cylinder, the power head supporting plate is located at the front side of the first-level fixed fuselage, and is connected to the The first stage fixes the fuselage to realize the up and down movement of the power head support plate through the up and down movement of the feeder fuselage through the second stage oil cylinder; thus, the present invention has simple structure, convenient operation, not only improves the pulling force, but also can carry out real-time monitoring, More practical and applicable.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Preparation method of woven carpet without gumming process

ActiveCN108411458AImprove stabilityOmit the adhesive processHeating/cooling textile fabricsCarpetsViscous flowHot melt

The invention discloses a preparation method of a woven carpet without a gumming process. A second coating layer is a hot-melt fiber filament or a staple fibre yarn, a first coating layer is a polypropylene fiber filament or a staple fibre yarn, the second coating layer accounts for 20%- 50% of the total mass of a composite yarn, the first coating layer accounts for 10%-15% of the total mass of the composite yarn, the balance is a core yarn, and a pile weft yarn is obtained by adopting the manner. When the non-adhesive carpet is produced by using a hot-melt ethylene-vinyl acetate copolymer fiber as a bonding material in combination with the pile yarn made of a polyester fiber, the melting occurs when the hot-melt ethylene-vinyl acetate copolymer fiber is heated to be higher than the melting point in a hot pressing process, the conformation of a fiber macromolecular chain is changed, the whole macromolecular chain slips through the transition of chain segments, viscous flow occurs, thepile and weft yarns as well as the weft yarns and warp yarns are effectively solidified after curing, and the pull strength of the pile and the shape retention and dimensional stability of the carpetare enhanced, so that the gumming process in the carpet preparation process is omitted, and the produced carpet is more environmentally friendly.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com