Sealed anti-falling single-core wire butt joint manipulator

An anti-dropping and sealing technology, which is applied in the direction of connection, line/collector parts, electrical components, etc., can solve the problems of affecting the durability of wire butt joints, low connection reliability, and easy loosening, etc., and achieves improved pull-out force , Improve reliability, avoid corrosion and oxidation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

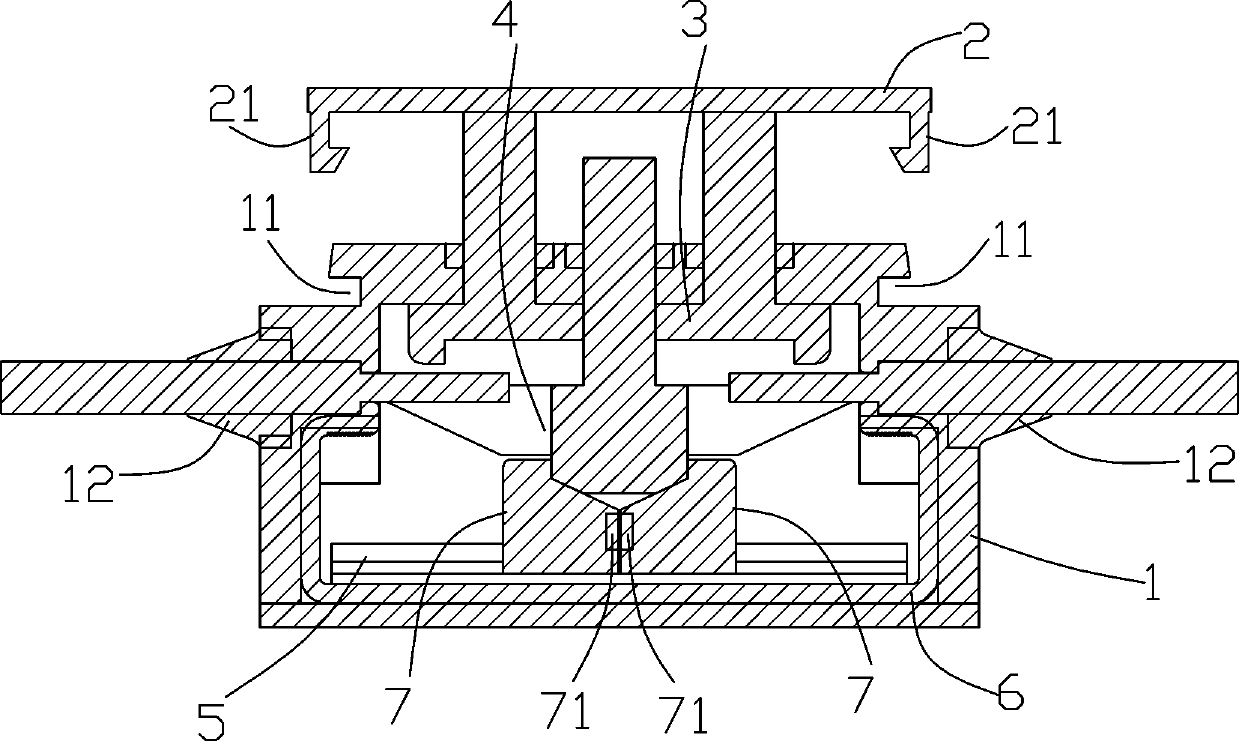

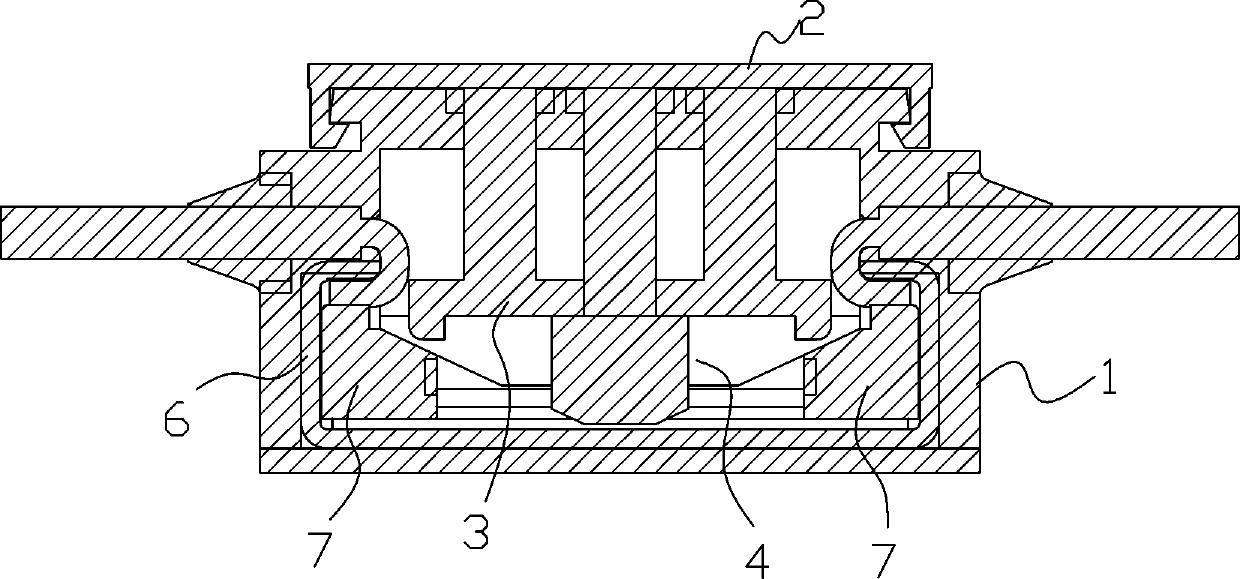

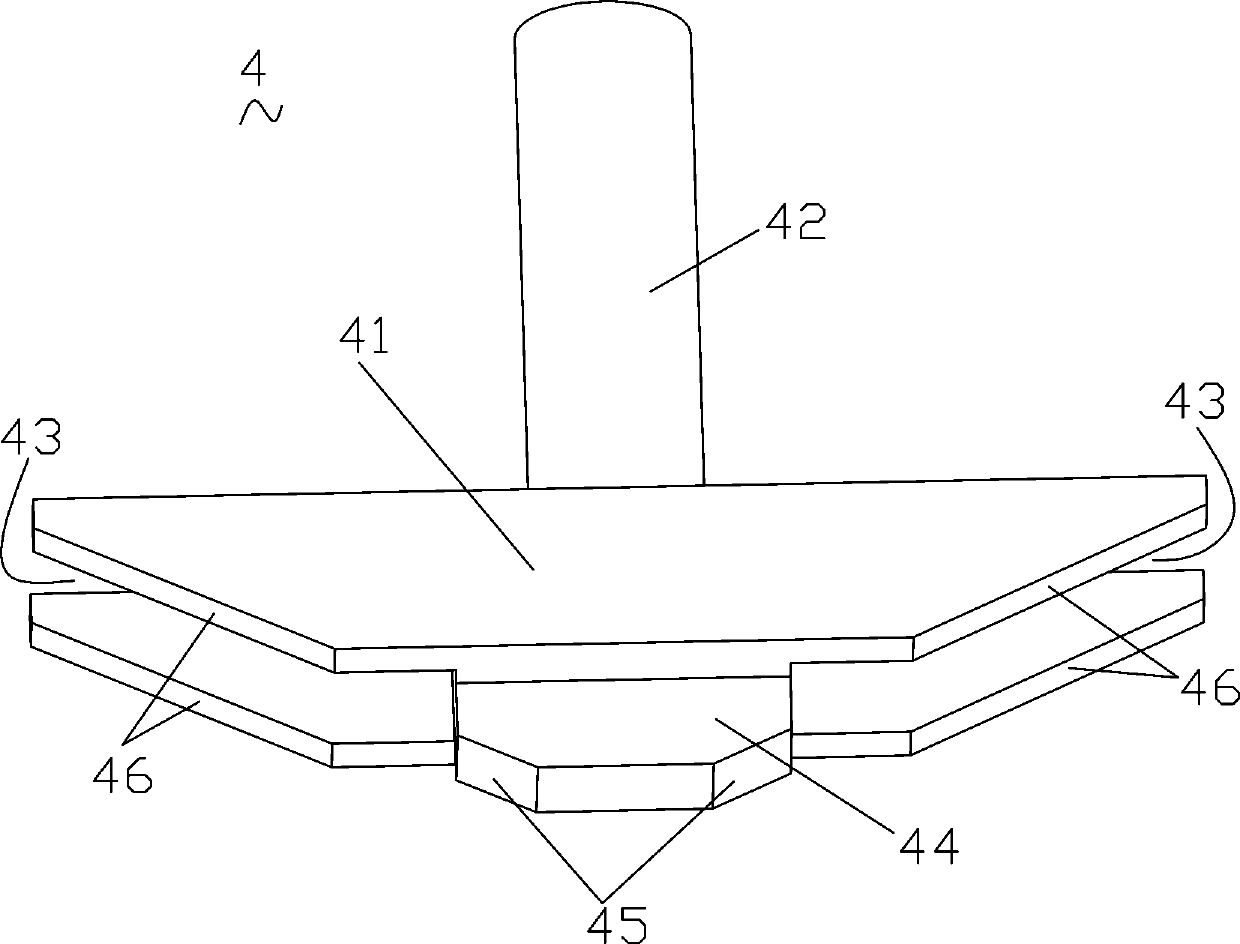

[0029] Such as Figure 1 to Figure 7 As shown, a sealed anti-dropping single-core wire docking manipulator described in this embodiment includes a terminal body 1 with an accommodating groove, a lower pressing plate 2, a first bending pressing block 3, an inclined-plane pushing block 4, and a guide piece The fixing seat 5, the U-shaped conductive sheet 6 and two second bending pressing blocks 7 that are slidably connected to the guide sheet fixing seat 5;

[0030] The bottom of the terminal body 1 has an opening communicating with the accommodating groove, and the top of the terminal body 1 is provided with two symmetrical locking parts 11, and the two ends of the terminal body 1 are respectively provided with a seal for extending the wire. Enter the thread...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com