Locking type drill gripping head

A technology for drill chucks and locking discs, which is applied to the accessories of tool holders, pipes/pipe joints/fittings, turning equipment, etc., which can solve the problems of insufficient effective clamping and anti-loosening, and achieve reasonable structure, stable performance, The effect of easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

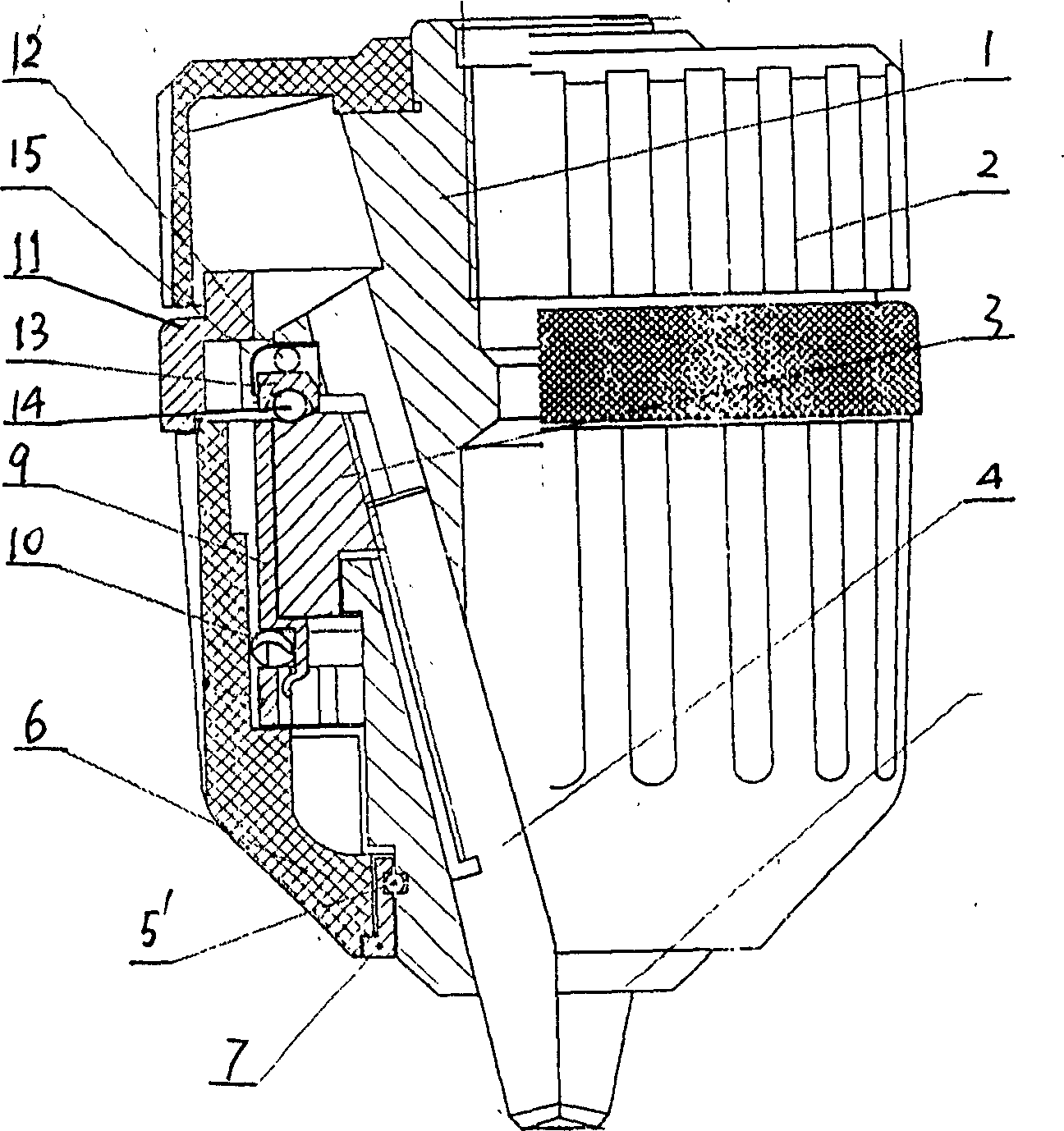

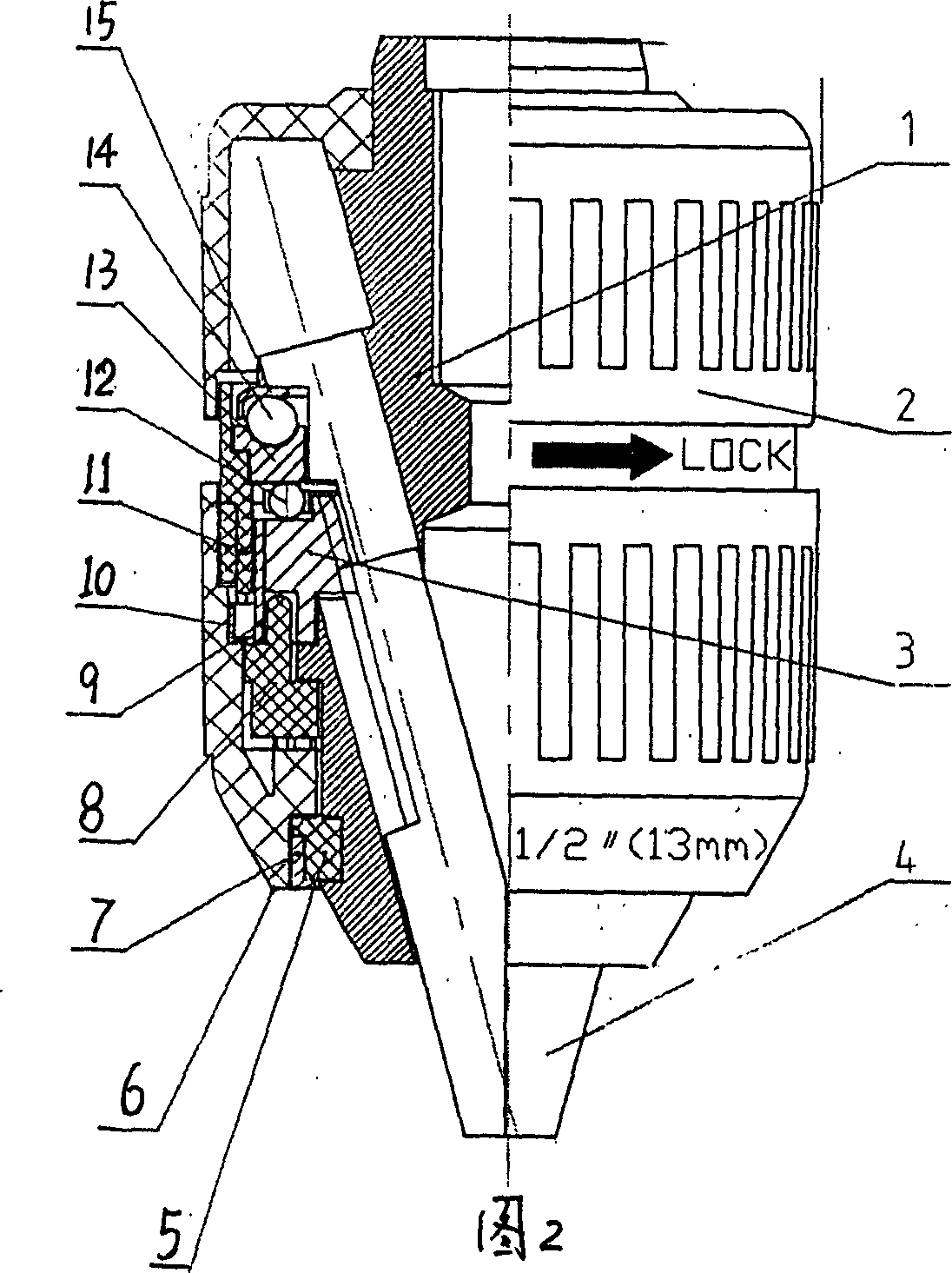

[0018] Such as figure 1 2. As shown in Figure 2, a locking drill chuck of the present invention includes a drill body 1, a clamping jaw 4, a nut 3, a front sleeve 6, a rear sleeve 2, a bearing 12, and the rear end of the drill body 1 is provided with The axial hole that the drive shaft of the drive tool engages with the rear sleeve 2 is connected and fixed by interference. The three clamping jaws 4 are respectively installed in the three equally divided oblique holes in the drill body 1, and the nut 3 is installed in the drill body. The clamping jaw 4 in the oblique hole engages, and the nut 3 is externally connected and fixed with a front sleeve 6, and a nut sleeve 9 can also be provided between the front sleeve 6 and the nut 3, which acts as a connecting drive. The above-mentioned composition, structure, and the relationship between the connected components belong to the prior art and will not be detailed here.

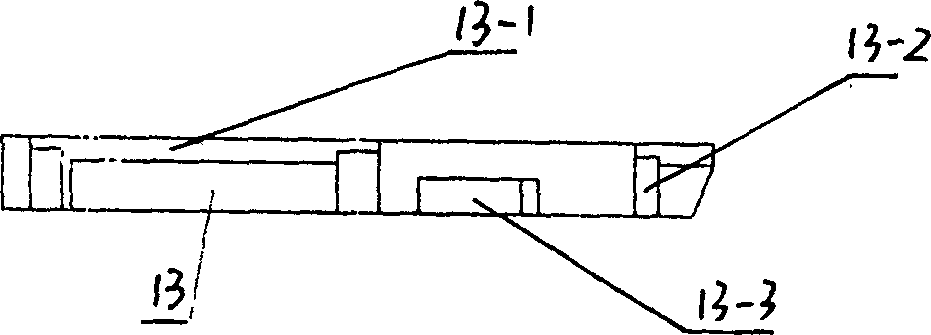

[0019] The feature of the present invention is that a locking sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com