Method for manufacturing carbon brush motor rotors

A technology of a motor rotor and a manufacturing method, which is applied to the manufacturing field of a carbon brush motor rotor, can solve the problems of low soldering work efficiency and high defect rate, and achieve the effects of improving work efficiency, yield rate and pulling force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with specific embodiment and description accompanying drawing, the present invention will be further elaborated and described:

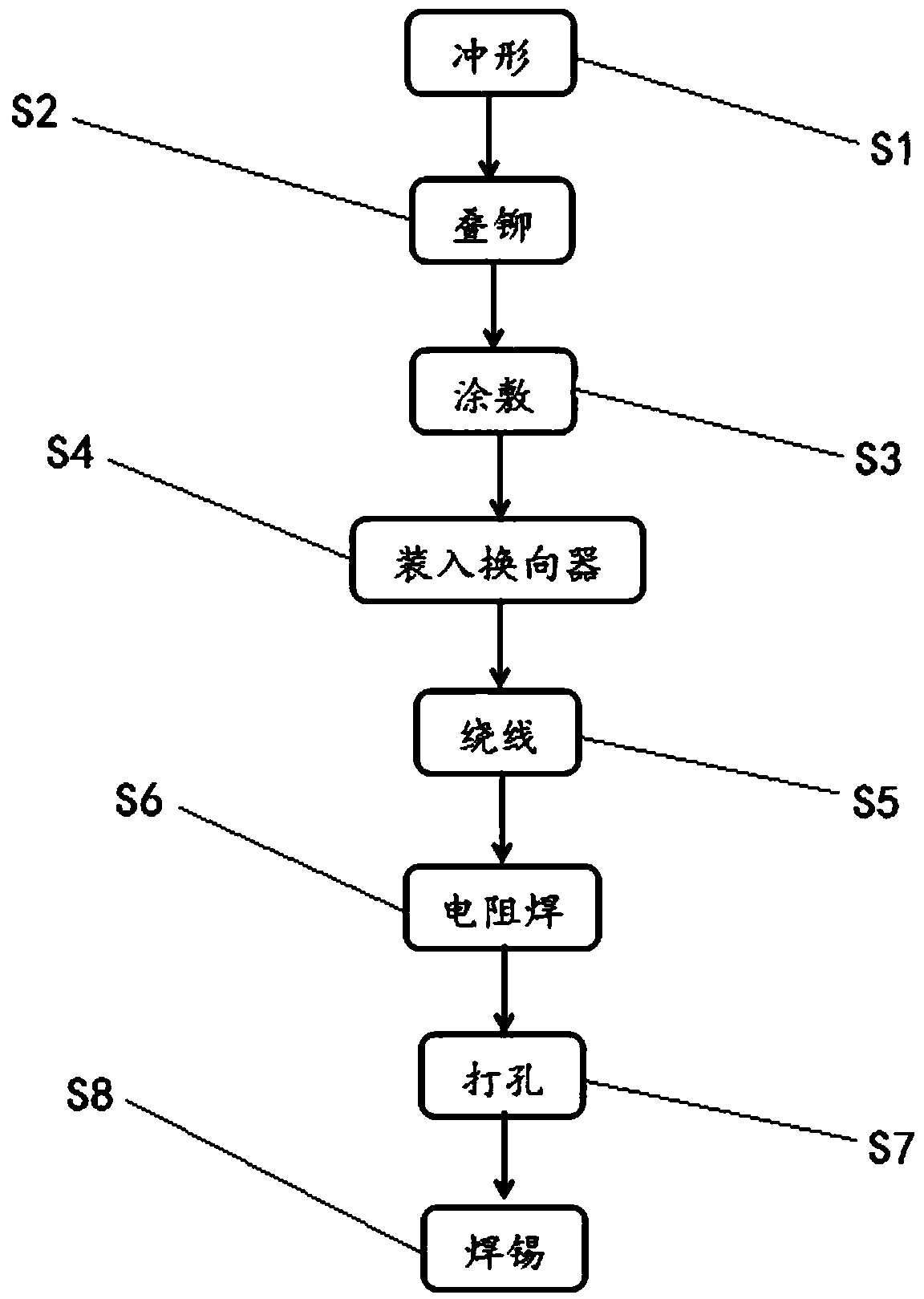

[0010] A manufacturing method of a carbon brush motor rotor, comprising the following steps:

[0011] S1 punching: punching selenium steel sheet or silicon steel sheet;

[0012] S2 stacking riveting: the punched selenium steel sheet or silicon steel sheet is stacked together to form a rotor through the motor shaft;

[0013] S3 coating: apply insulating varnish to the inner winding part of the rotor;

[0014] S4 install the commutator: install the commutator on the motor shaft;

[0015] S5 winding;

[0016] S6 resistance welding: resistance welding the commutator feet;

[0017] S7 Punching: Punch holes on the commutator feet;

[0018] S8 Soldering: Solder the commutator feet and the varistor.

[0019] By punching holes on the commutator feet, the oxide layer on the commutator feet is destroyed, and the metal copper is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com