Pulling device for gas pumping and draining drill rod

A gas pumping and drilling technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of economic loss, insufficient pulling force, and inability to increase the cross-sectional area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

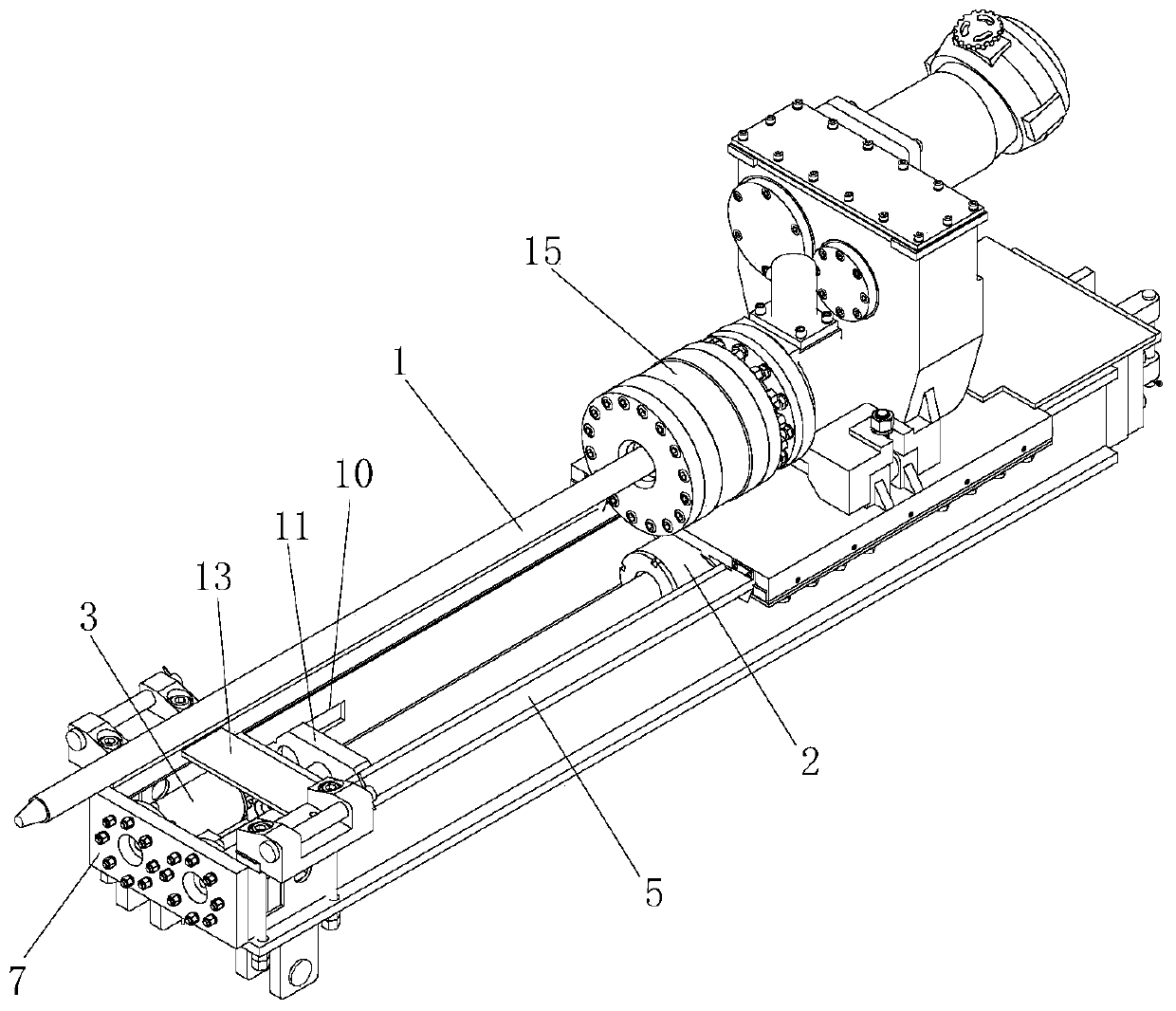

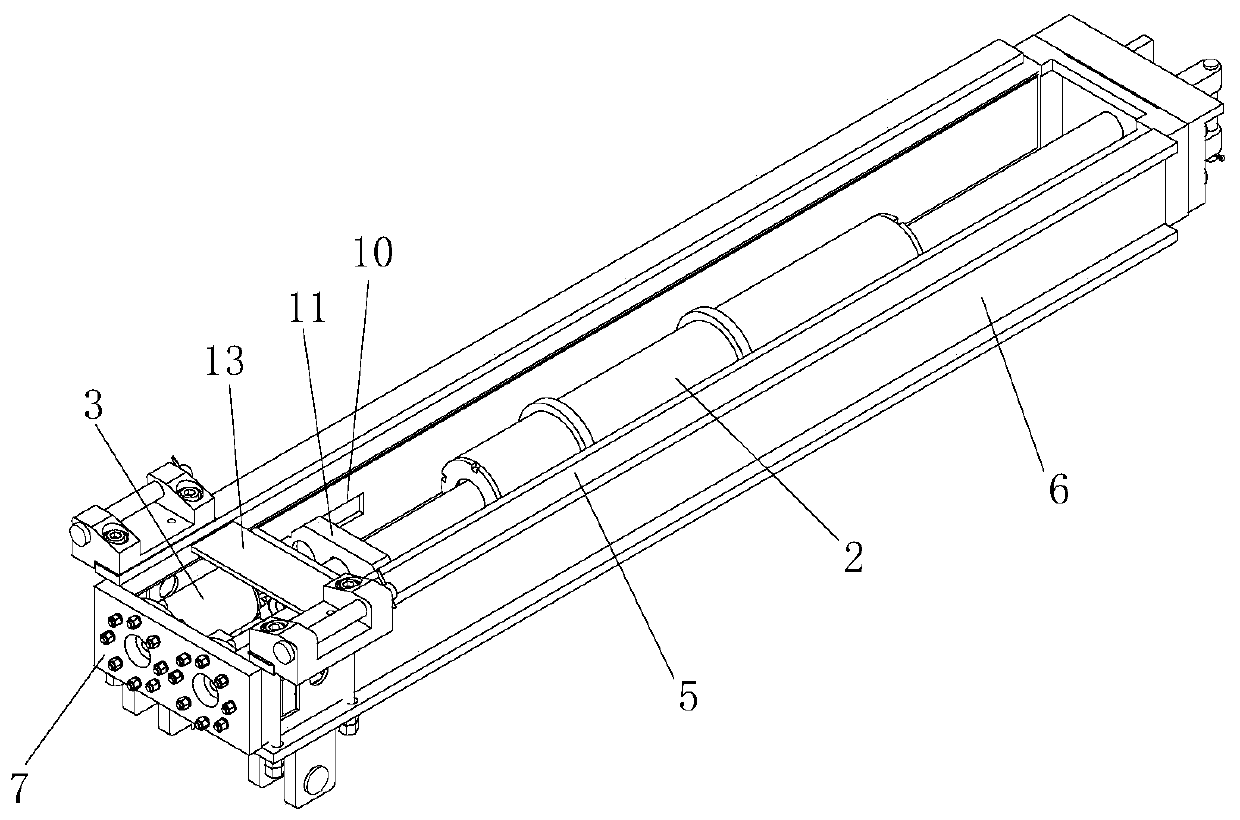

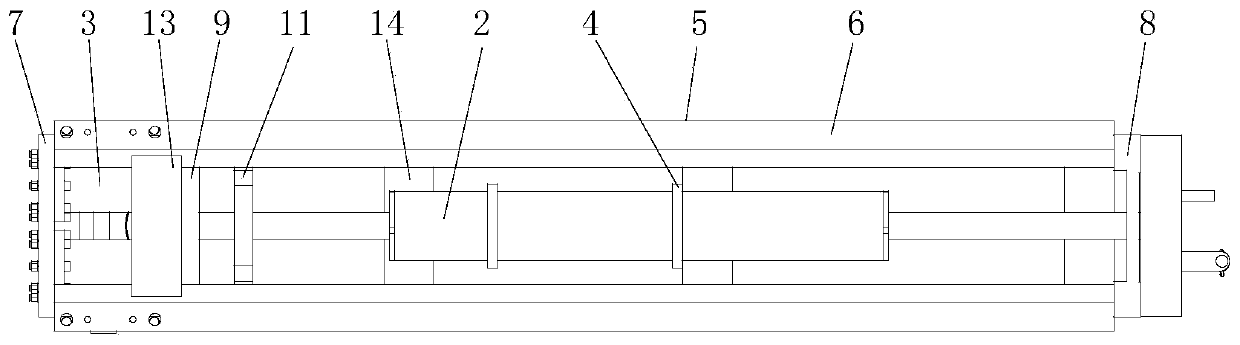

[0019] Such as Figure 1 to Figure 4 As shown, a lifting device for gas pumping and discharging drill pipes includes a main hydraulic cylinder 2 and a drawing hydraulic cylinder 3 for driving the movement of the drill pipe 1. The two ends of the piston rod of the main hydraulic cylinder 2 are fixed on the device, and the main hydraulic cylinder 2 The cylinder body of the hydraulic cylinder 2 can slide on its piston rod by pressurization, and then drive the drill pipe 1 to move; the drawing hydraulic cylinder 3 is fixed on the device, and the piston rod of the drawing hydraulic cylinder 3 can withstand the main hydraulic pressure when it is pushed out. The cylinder body of the cylinder 2 moves toward the pulling out direction of the drill pipe 1. When the drill pipe 1 is pulled out, the pulling hydraulic cylinder 3 and the main hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com