Self-balancing drilling and pulling mechanism with real-time monitoring function of bit pressure

A self-balancing, real-time monitoring technology, applied in rotary drilling, impact drilling, rotary drilling rigs, etc., can solve the problems of increased cost, complex overall structure, large cumulative error, etc. The effect of avoiding force imbalance and WOB distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

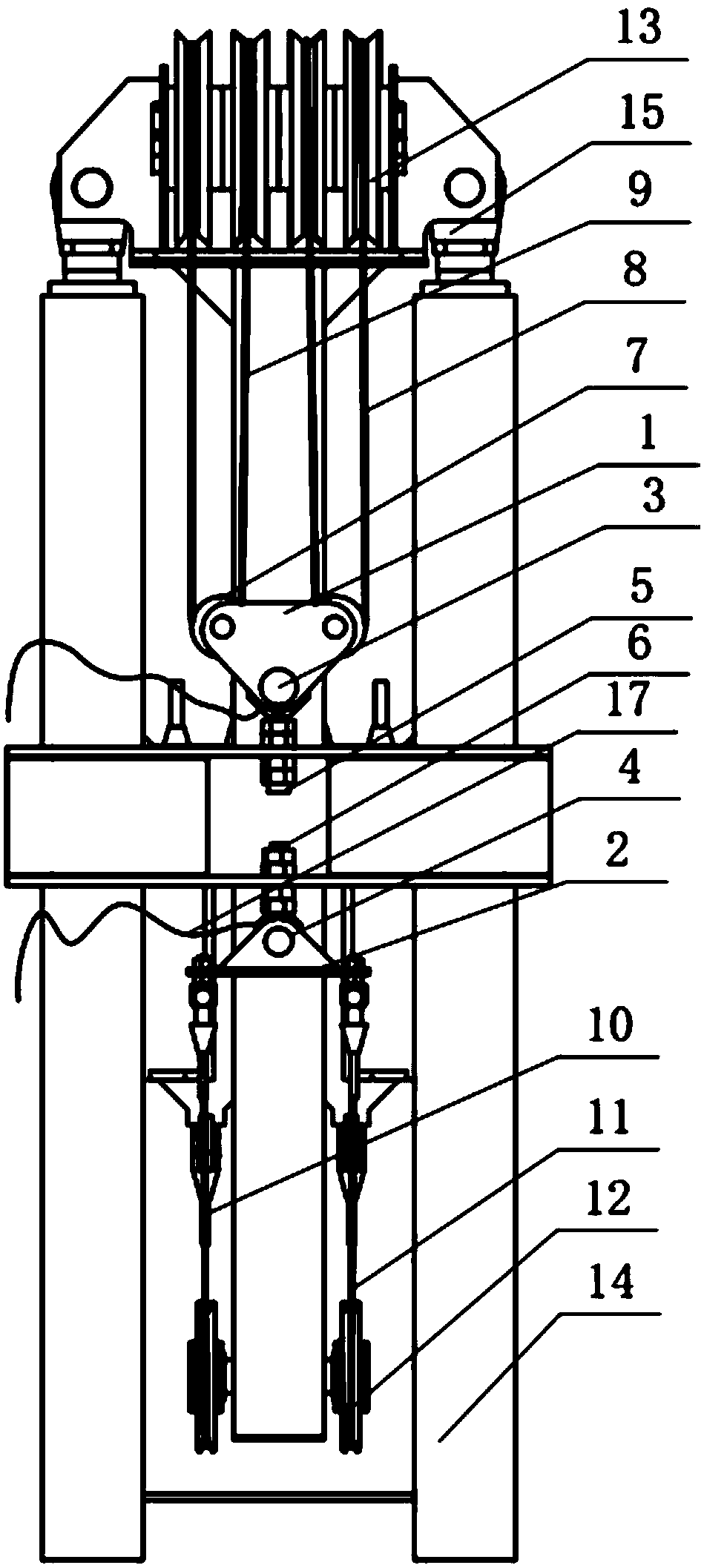

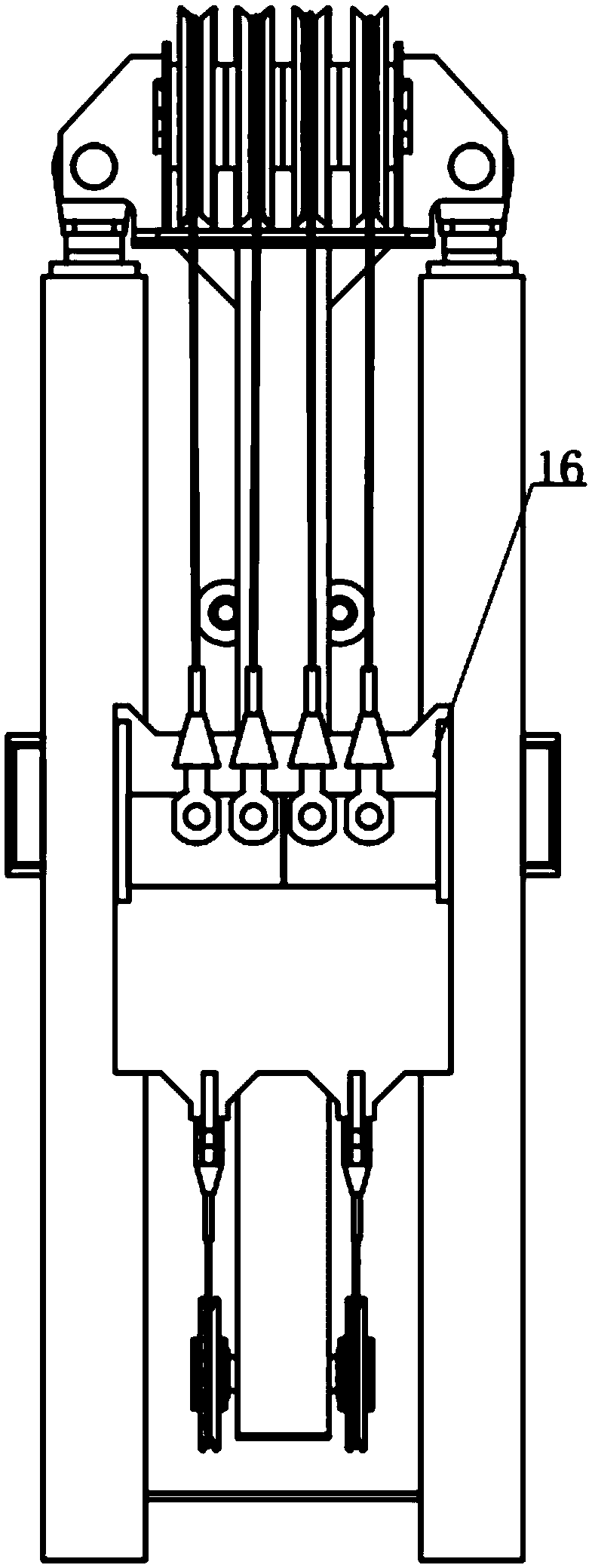

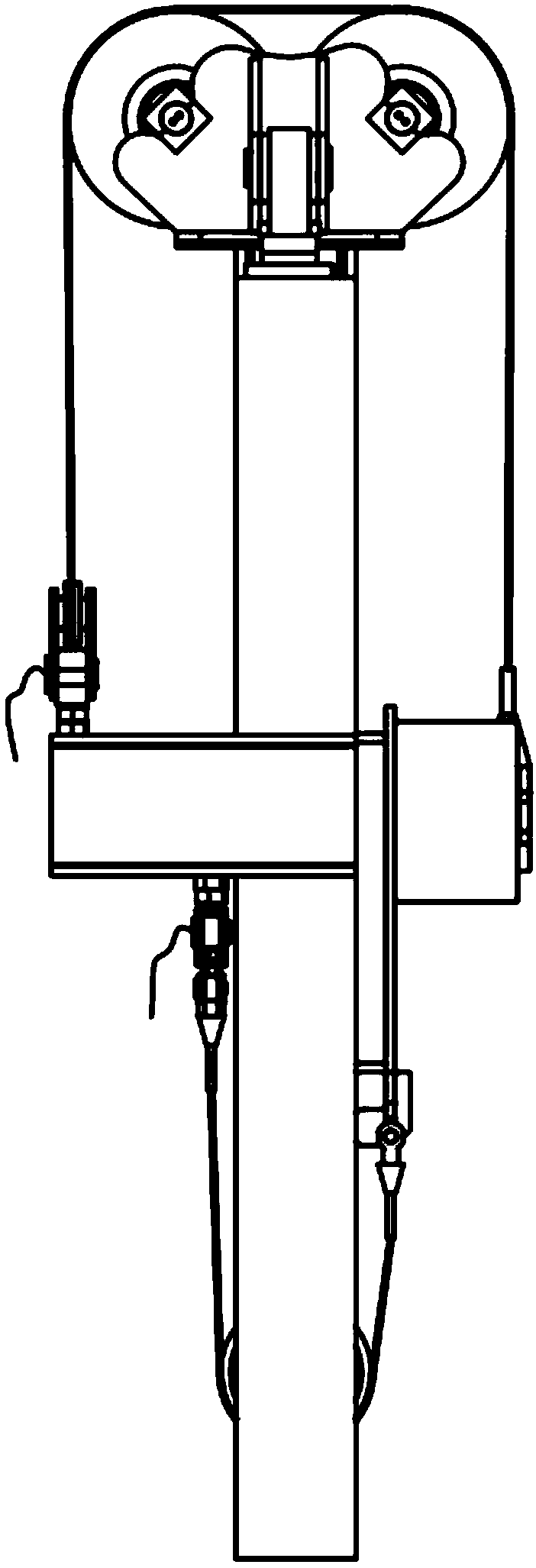

[0027] see Figure 1 to Figure 4 , shows the self-balancing drilling and pulling mechanism of the present invention with the function of real-time monitoring of the weight on bit.

[0028] The self-balancing drilling and pulling mechanism with the function of real-time monitoring of drilling pressure includes a primary fixed fuselage 14, a secondary oil cylinder feeding fuselage 15 and a power head support plate 16, and the primary fixed fuselage 14 is passed through a bolt It is installed on the drilling rig truck or the drilling rig frame in a fixed way, and then fixed. The secondary oil cylinder feeding body 15 is telescopically arranged in the primary fixed body 14 through the oil cylinder, so that it can be driven by the expansion and contraction of the oil cylinder. The secondary oil cylinder feeds the fuselage 15 to move upwards and downwards relative to the primary fixed fuselage 14. The power head supporting plate 16 is located on the front side of the primary fixed f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com