Powder metallurgical planetary gear for high-power starter

A technology of powder metallurgy and planetary gear, applied in the direction of belt/chain/gear, mechanical equipment, components with teeth, etc., can solve the problem of insufficient pull-out force of planetary gear bearings, and achieve the effect of improving pull-out force and avoiding pull-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

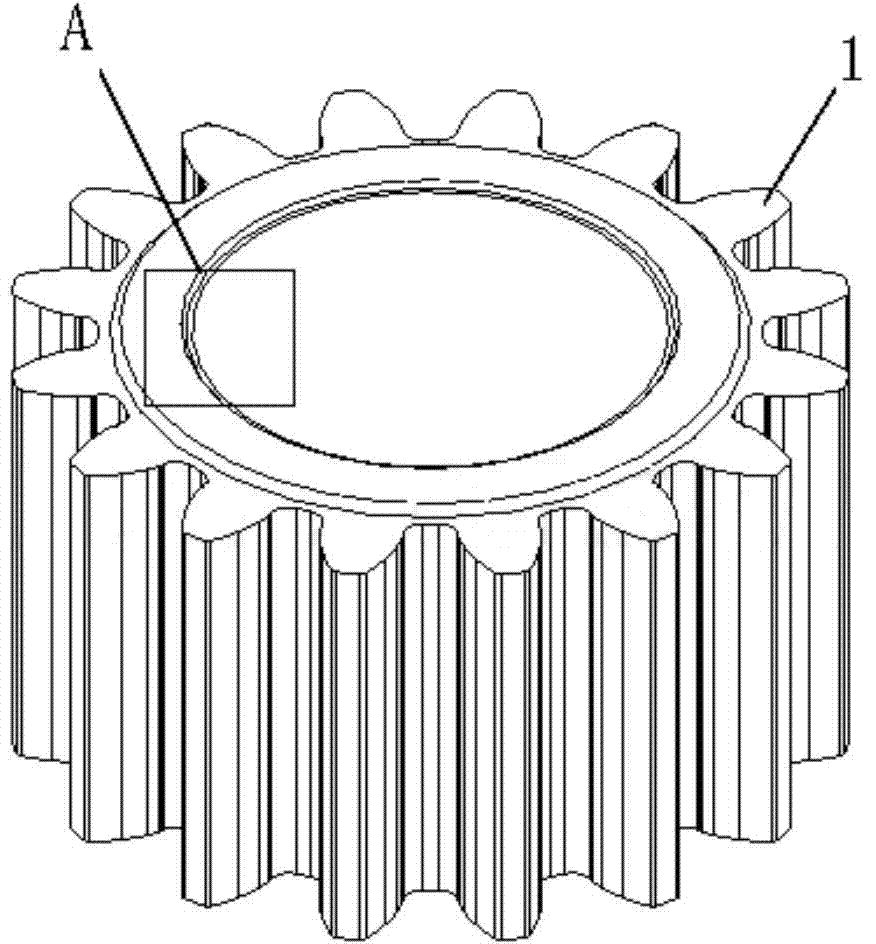

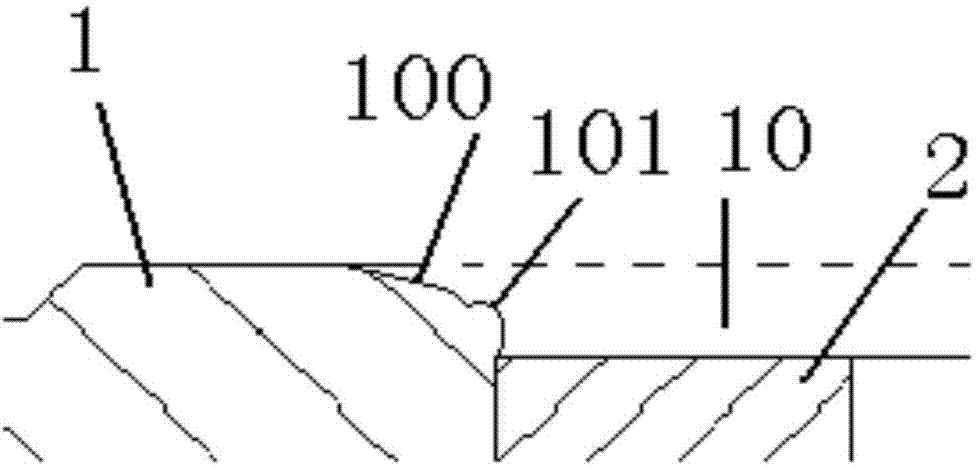

[0011] figure 1 Shown is a schematic diagram of a planetary gear according to a preferred embodiment of the present invention. figure 2 shown as figure 1 Schematic cross-sectional view of area A shown. Please also refer to figure 1 and figure 2 .

[0012] In this embodiment, the powder metallurgy planetary gear used for a high-power starter includes a gear body 1 and a bearing 2, the gear body 1 has a gear inner hole 10, the bearing 2 is arranged in the gear inner hole 10, and the end surface of the gear body 1 passes through The inclined surface 100 and the arc-shaped surface 101 extend to the inner hole wall of the gear, the inclined surface 100 and the arc-shaped surface 101 are continuous, and the arc-shaped surface 101 protrudes from the inner hole wall of the gear by 0.5mm, resisting the edge of the end face of the bearing 2, and blocking the bearing 2 from the inner hole of the gear 10 out.

[0013] In this embodiment, the gear body 1 can smoothly extend the arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com