Pipe drawing and crimping integrated machine for pipeline connection and use method of pipe drawing and crimping integrated machine

An all-in-one machine and pipeline technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of flange connection, pipe movement, and inconvenient connection, etc., so as to reduce the difficulty of installation and expand the application field , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

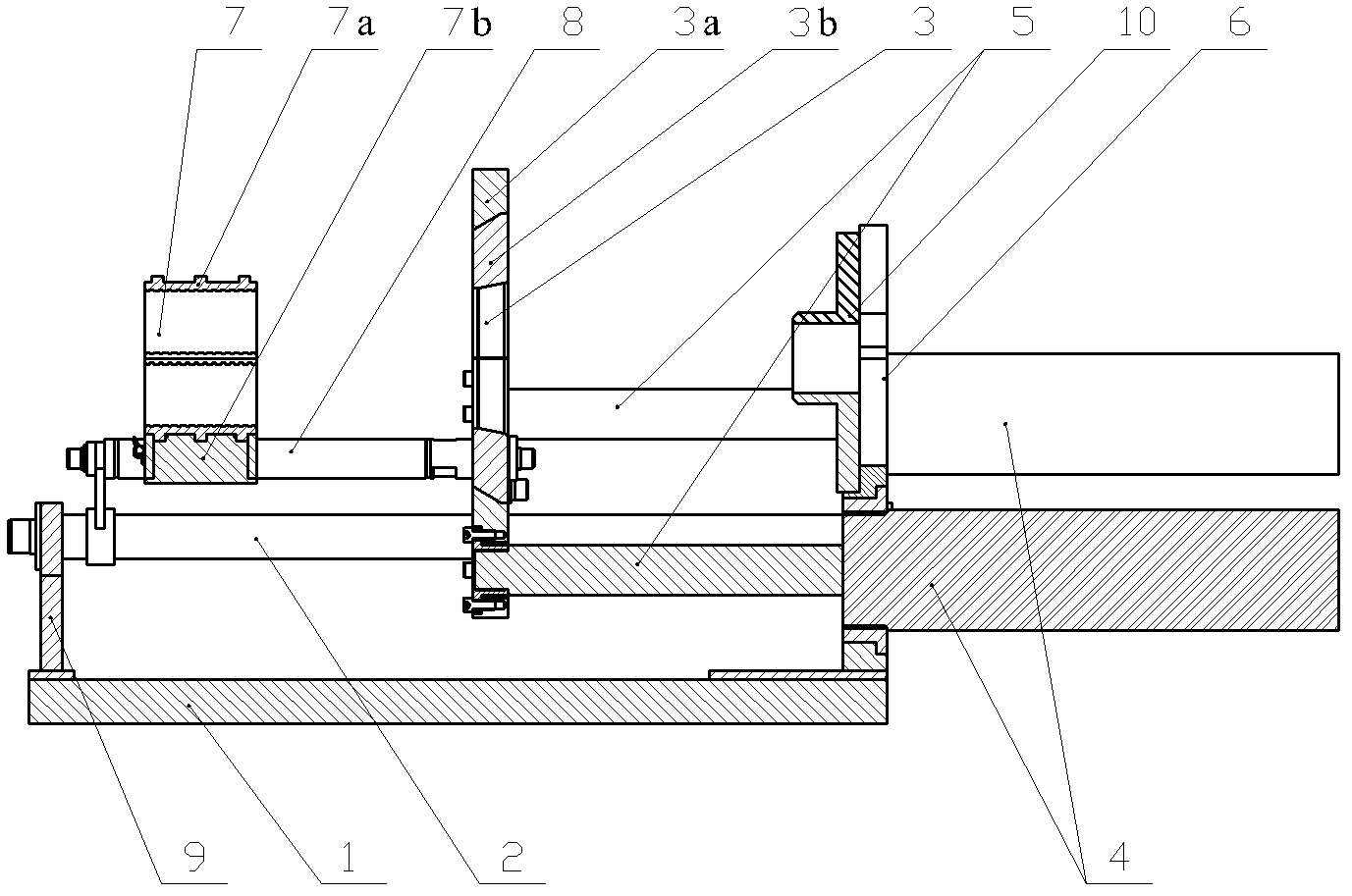

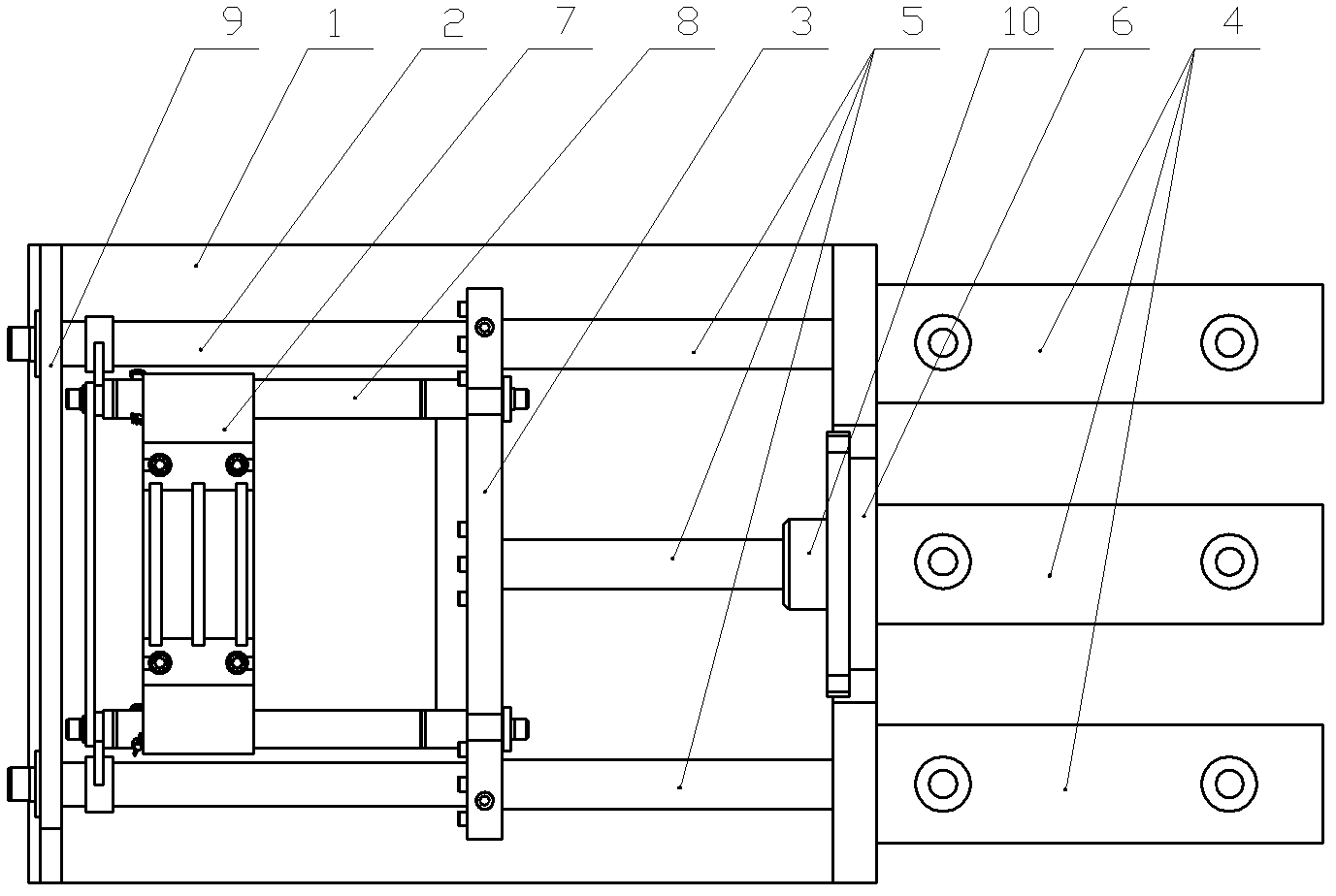

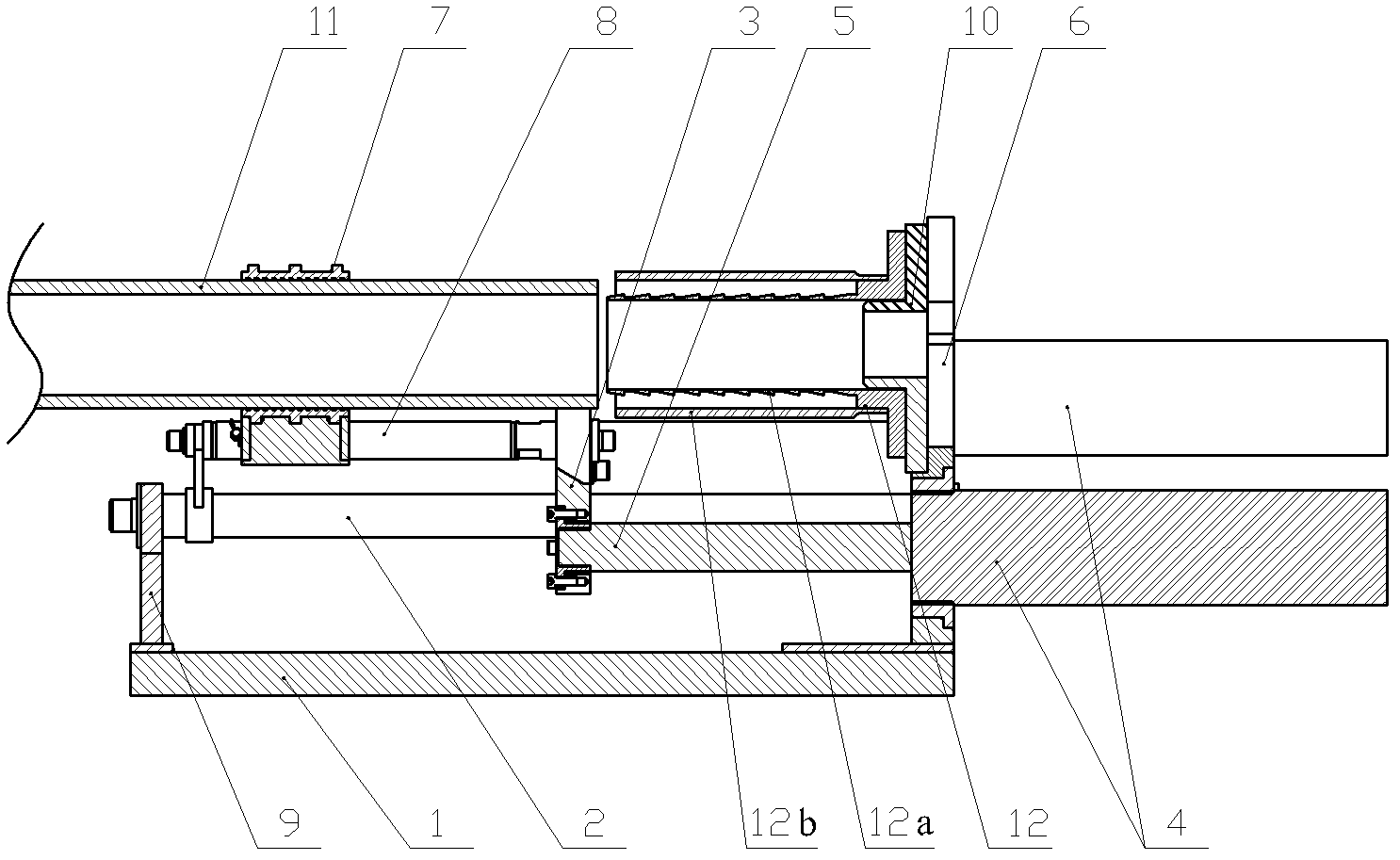

[0038] Figure 1 to Figure 6 Shown is an embodiment of a pipe-drawing and crimping integrated machine for pipe connection according to the present invention, such as figure 1 and figure 2 As shown, it includes a base 1, a guide column 2, a crimping moving plate 3, a hydraulic cylinder 4, a hydraulic moving bar 5, a pipe fixing plate 6, a pipe fixing piece 7, and a connecting rod 8.

[0039]There are two guide posts 2, and they are arranged on the base 1 in parallel through the guide post fixing plate 9 and the pipe fitting fixing plate 6. The guide post fixing plate 9 and the pipe fitting fixing plate 6 are provided with reinforcing ribs to enhance the pulling and crimping operations time tolerance. The crimping moving plate 3 is slidably arranged on the guide column 2 and connected with the hydraulic cylinder 4 through a hydraulic moving bar 5 . The crimping mobile plate 3 is composed of a moving seat 3a and a crimping die 3b, wherein the moving seat 3a is slidably arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com