External wall heat-preserving decoration wall and its construction process

A technology of external wall insulation and construction technology, which is applied in the direction of covering/lining, construction, building construction, etc., can solve the problems of facing material construction and safety problems, unreasonable indoor installation, and unfavorable quality control, so as to save time, Avoid cold bridges and avoid dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

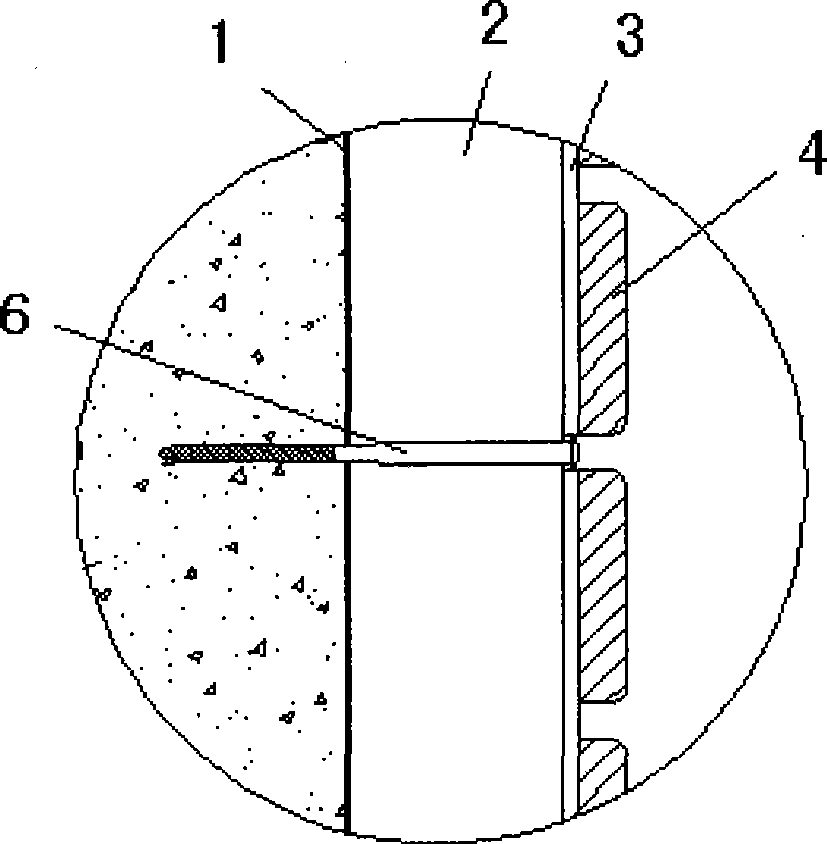

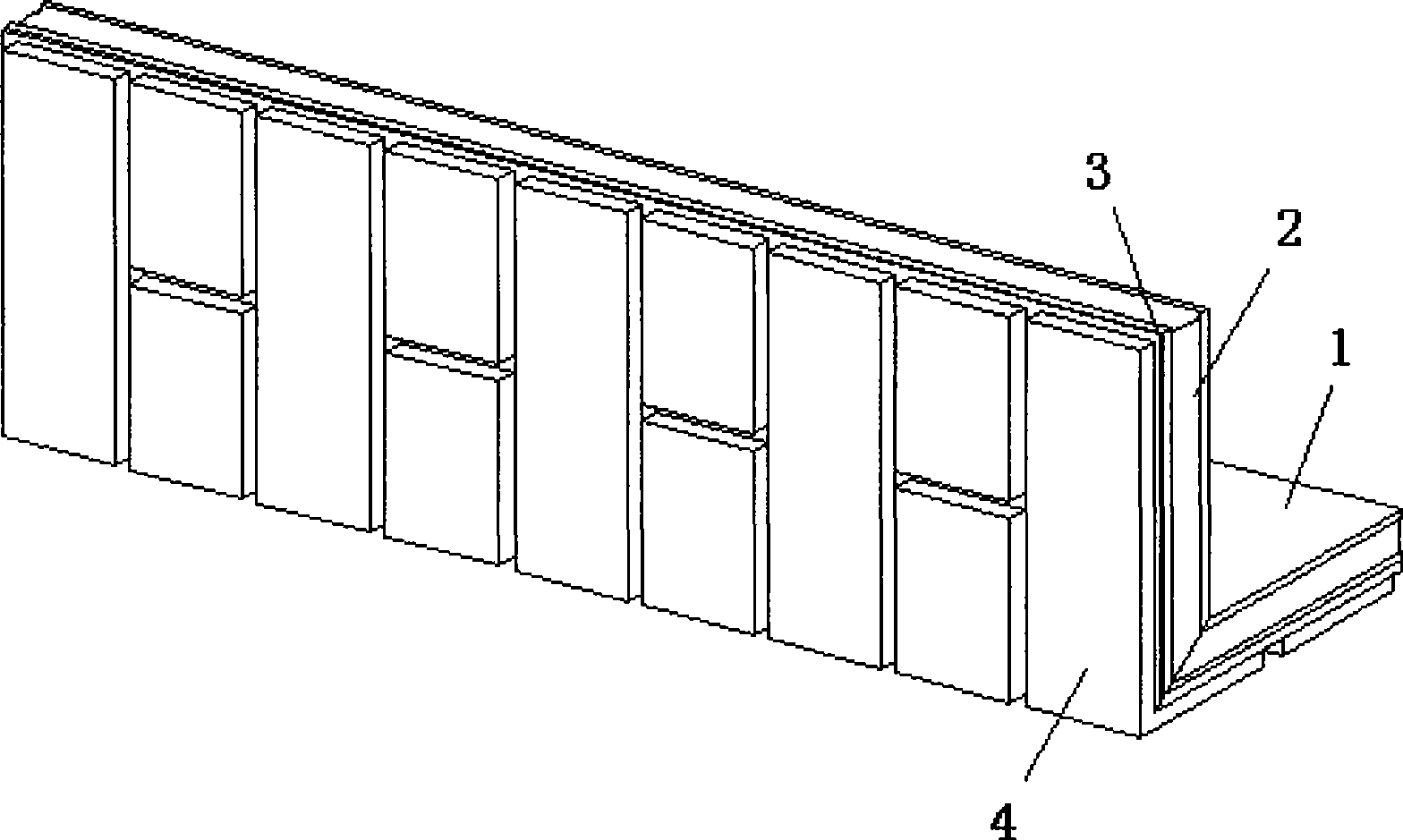

[0034] Such as figure 1 , figure 2 As shown, the thermal insulation board of the present invention includes a layer of moisture-proof film layer 1, and the moisture-proof film layer 1 is attached to the outer wall of the building during construction, and it is generally made of moisture-proof kraft paper. The upper surface of the moisture-proof film layer 1 is bonded with a layer of insulation layer 2, and the insulation layer 2 is made of Freon-free polyurethane foam with pentane foaming agent, or polystyrene molded board, or polystyrene extruded board become. A bonding layer 3 as an adhesive is coated on the upper surface of the thermal insulation layer 2, and a layer of facing layer 4 is glued on the bonding layer 3. The bonding layer 3 is a hybrid bonding material with dual bonding properties of organic and inorganic, and it can bond the organ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com