Connecting pipe device

A technology for connecting pipes and connecting interfaces, which is applied in the direction of pipeline connection layout, pipes, pipes/pipe joints/pipe fittings, etc. It can solve the problems of easy leakage at the joint between the clamp and the hose, small pull-out force, and heavy hose weight, etc., to achieve Increase life cycle safety, increase pull-out force, and reduce vehicle weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

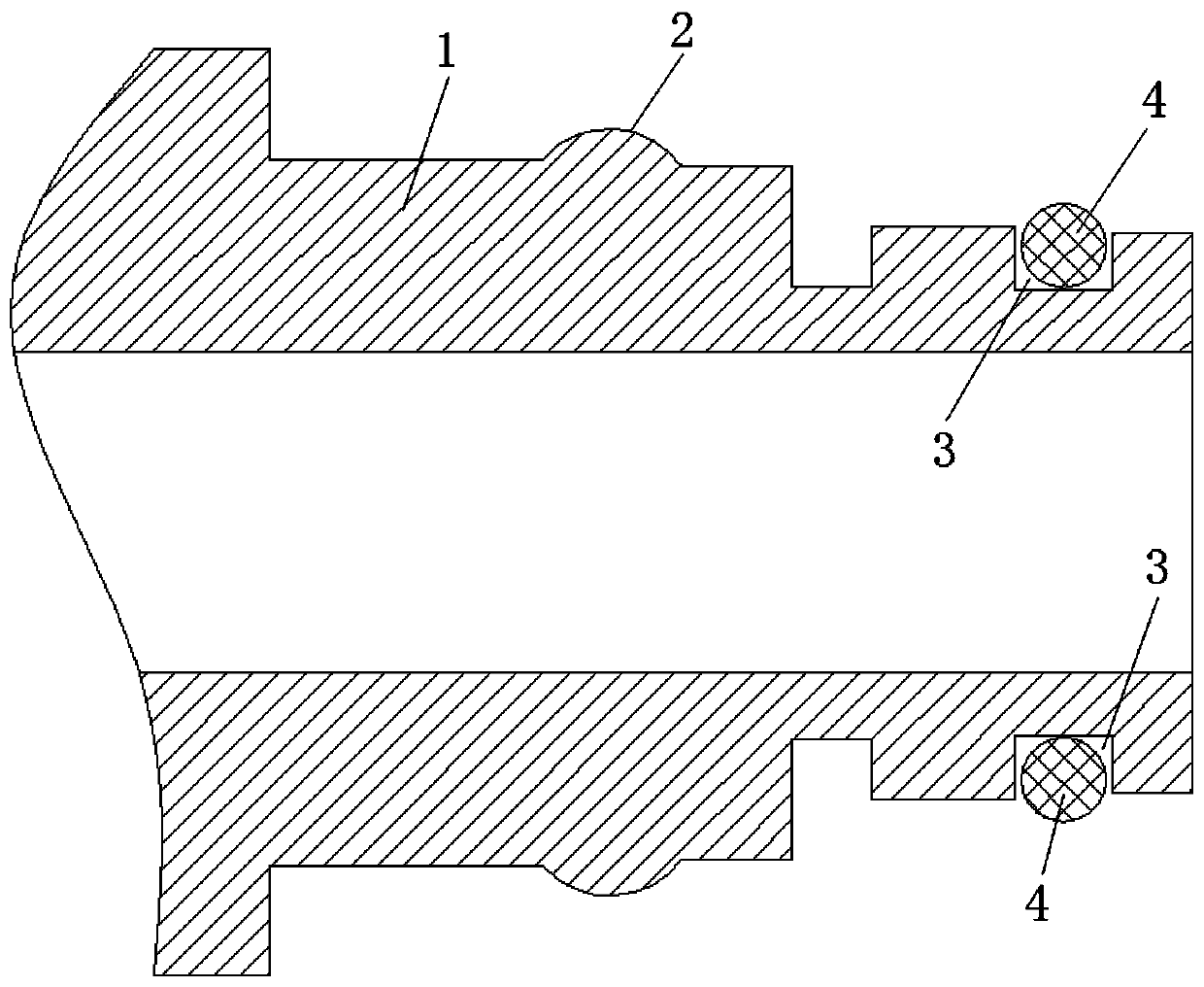

[0021] specific embodiment figure 1 , figure 2 and image 3 As shown, the present invention includes a connection interface 1, a limiting boss 2, an interface groove 3, an O-ring 4, a plastic tube 5, and a fixing clip 6. The limiting boss 2 and the interface groove 3 are arranged on the connecting interface 1 On the top, the O-ring 4 is arranged in the interface groove, and the fixing clamp 6 is arranged on the outer wall of the plastic pipe 5; the plastic pipe 5 is connected with the connection interface 1, and is sealed by the O-ring 4 , and by the limit boss 2 and the fixed clamp 6 are fastened, and the O-ring 4 is an EPDM rubber sealing ring; the plastic pipe 5 is a plastic light pipe, and is a single-layer pipe, and the material is PA6. It can be seen from the figure that this embodiment has only one O-ring and one limiting boss 2 .

Embodiment 2

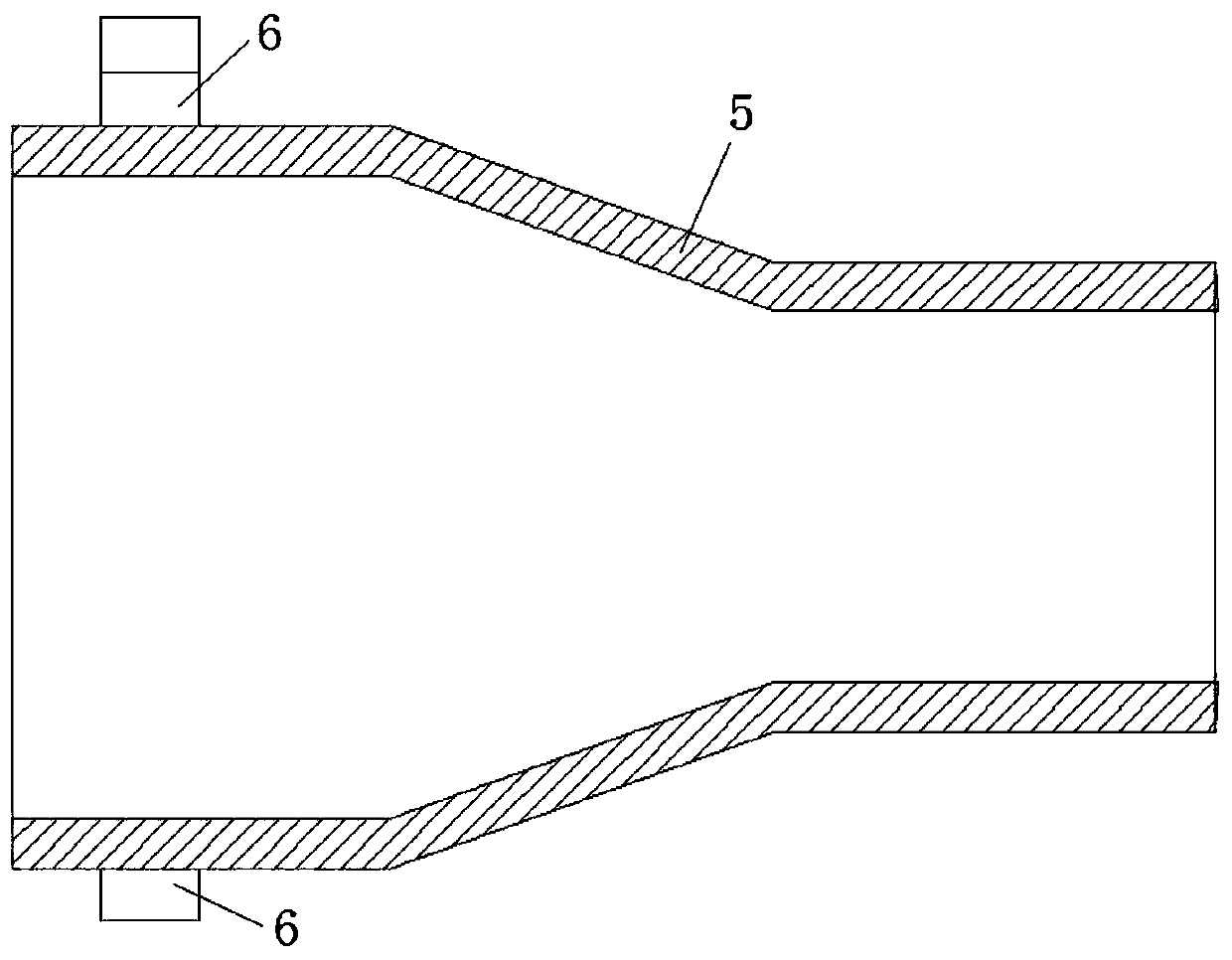

[0023] specific embodiment Figure 4 As can be seen from the figure, there are two limiting bosses 2 in this embodiment, the O-ring is eliminated, and the plastic pipe 5 has corrugations in part.

Embodiment 3

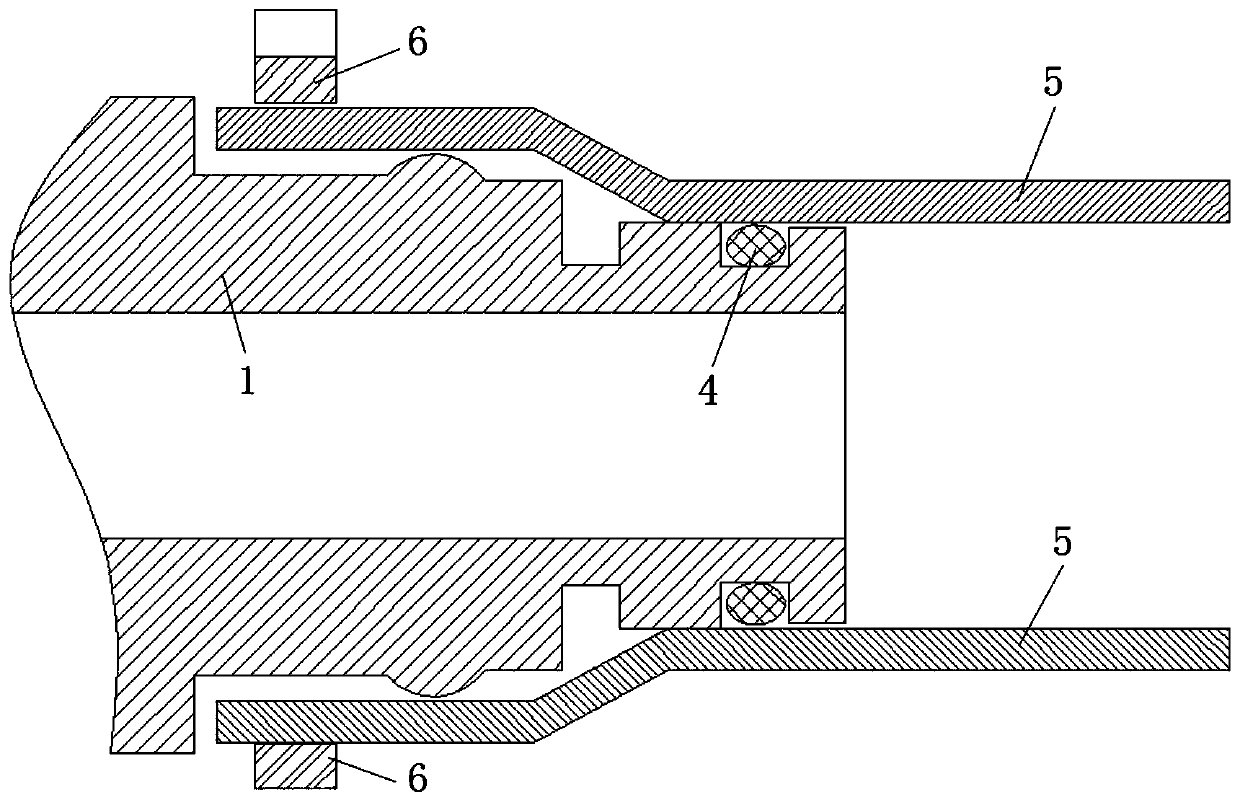

[0025] specific embodiment Figure 5 As shown, it can be seen from the figure that in this embodiment, there is a limiting boss 2 and an O-ring 4, and a part of the plastic pipe 5 has corrugations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com