Aramid fiber reinforced high temperature resistance nylon composite material and preparation method thereof

A technology of nylon composite material and aramid fiber, which is applied in the field of nylon composite material and its preparation, can solve the problems not related to high temperature resistant nylon/aramid fiber composite material, and achieve good dimensional stability, high heat distortion temperature, water absorption low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

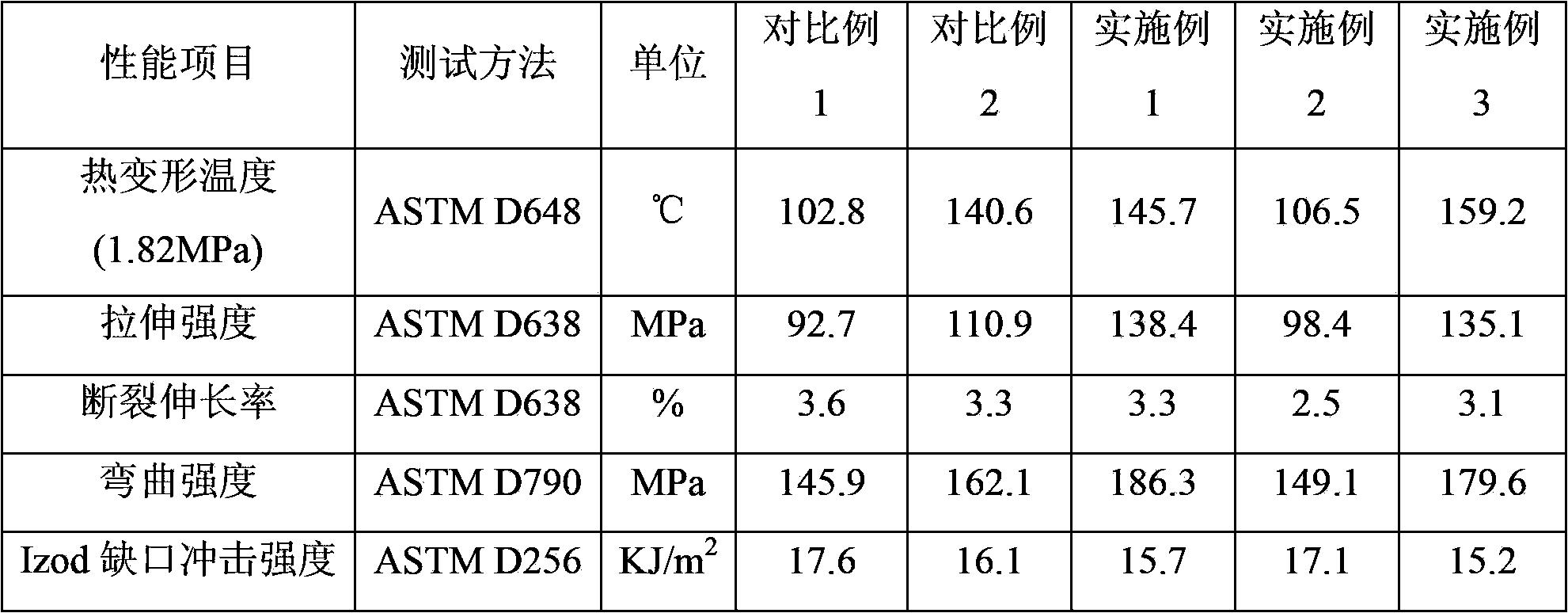

Examples

Embodiment 1

[0044] 1) Weigh 100 parts by weight of nylon 10T salt, 10 parts by weight of aramid 1414 fiber with a diameter of 12 μm and a length of 0.5 mm, 0.5 parts by weight of benzoic acid, and 0.4 parts by weight of sodium hypophosphite, And the above components are added into the autoclave;

[0045] 2) Weigh 50 parts by weight of deionized water and 1 part by weight of nano-montmorillonite and dissolve them in deionized water to prepare a solution. Stir the prepared solution under ultrasound for 1-2 hours, then add into the autoclave;

[0046] 3) Replace the air in the autoclave with nitrogen for at least three times, and then pass in nitrogen as a reaction protection gas; raise the temperature to 150°C, and make the pressure reach 2.5MPa within 50 minutes, and keep the pressure at 2.5MPa, the constant pressure reaction time is 2 hours; then the pressure in the reactor is released to normal pressure, and the material is discharged. During the reaction process, the temperature in the...

Embodiment 2

[0048] 1) Weigh 100 parts by weight of nylon 10T salt, 1 part by weight of aramid 1414 fiber with a diameter of 12 μm and a length of 0.5 mm, 0.1 parts by weight of benzoic acid, and 0.1 parts by weight of sodium hypophosphite, And the above components are added into the autoclave;

[0049] 2) Weigh 30 parts by weight of deionized water and 0.2 parts by weight of nano-montmorillonite and dissolve them in deionized water to prepare a solution. Stir the prepared solution under ultrasound for 1-2 hours, then add into the autoclave;

[0050] 3) Replace the air in the autoclave with nitrogen for at least three times, and then pass in nitrogen as a reaction protection gas; raise the temperature to 150°C, and make the pressure reach 2.5MPa within 50 minutes, and keep the pressure at 2.5MPa, the constant pressure reaction time is 2 hours; then the pressure in the reactor is released to normal pressure, and the material is discharged. During the reaction process, the temperature in th...

Embodiment 3

[0052] 1) Weigh 100 parts by weight of nylon 10T salt, 13 parts by weight of aramid 1414 fiber with a diameter of 12 μm and a length of 0.5 mm, 1 part by weight of benzoic acid, and 0.6 parts by weight of sodium hypophosphite, And the above components are added into the autoclave;

[0053] 2) Weigh 60 parts by weight of deionized water and 1 part by weight of nano-montmorillonite and dissolve them in deionized water to prepare a solution. Stir the prepared solution under ultrasound for 1-2 hours, then add into the autoclave;

[0054] 3) Replace the air in the autoclave with nitrogen for at least three times, and then pass in nitrogen as a reaction protection gas; raise the temperature to 150°C, and make the pressure reach 2.5MPa within 50 minutes, and keep the pressure at 2.5MPa, the constant pressure reaction time is 2 hours; then the pressure in the reactor is released to normal pressure, and the material is discharged. During the reaction process, the temperature in the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com