Method for preparing polypyrrole/gold nano composite

A composite material and gold nanotechnology, which is applied in the preparation field of polypyrrole/gold nanocomposite materials, can solve the problems of cumbersome preparation process, cumbersome template preparation and removal, and high equipment requirements, so as to achieve simple preparation process, improve processability, Effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

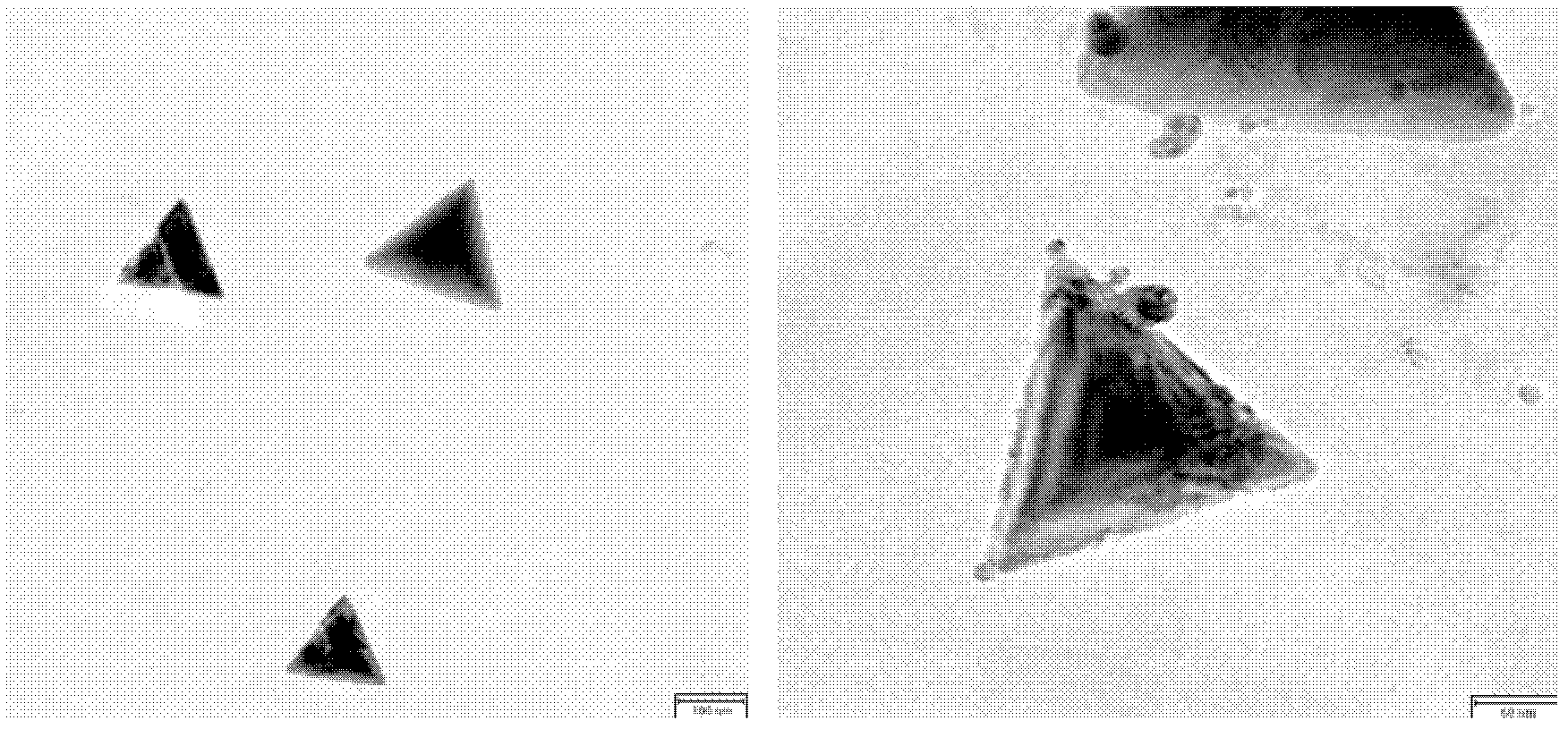

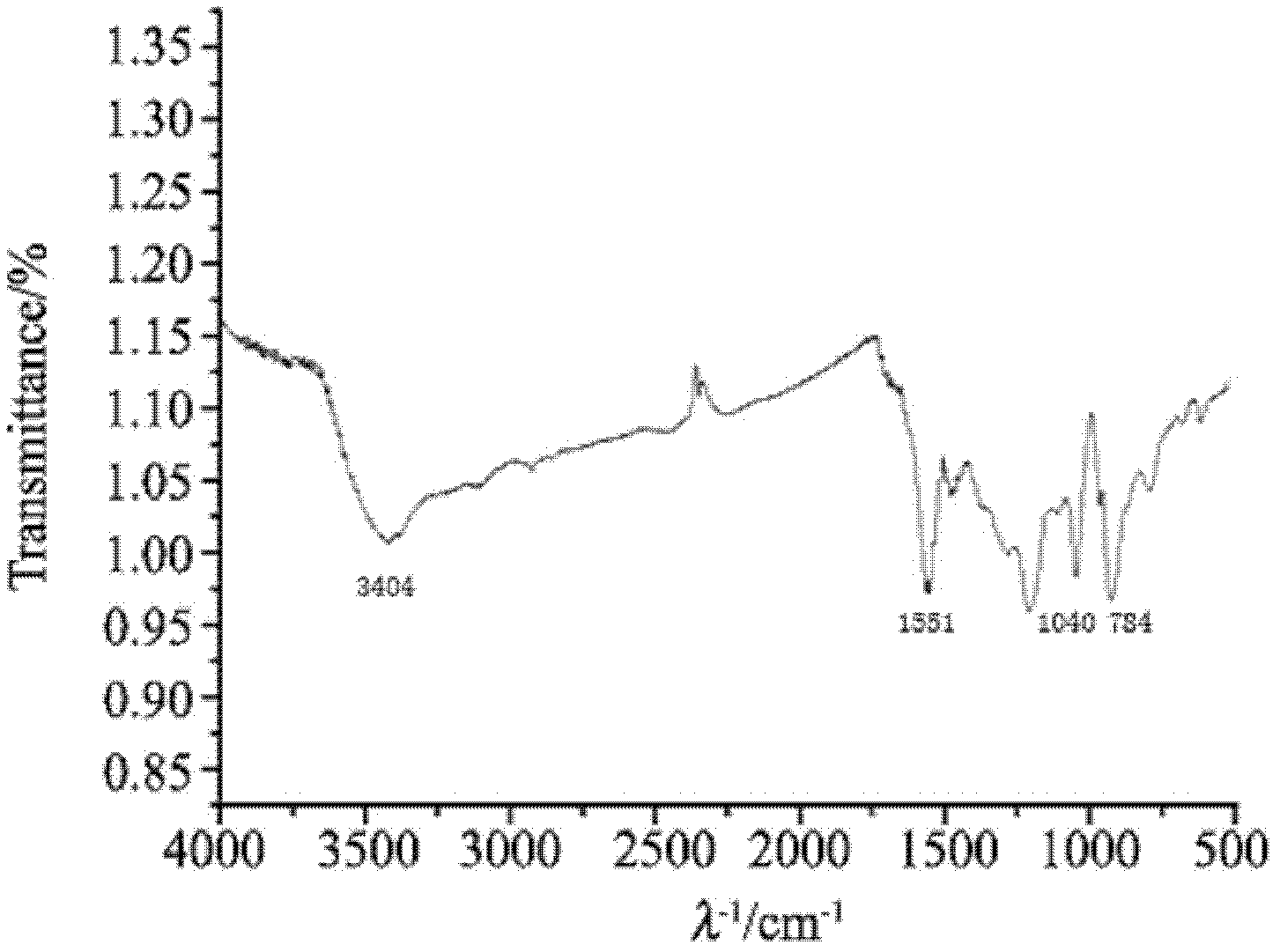

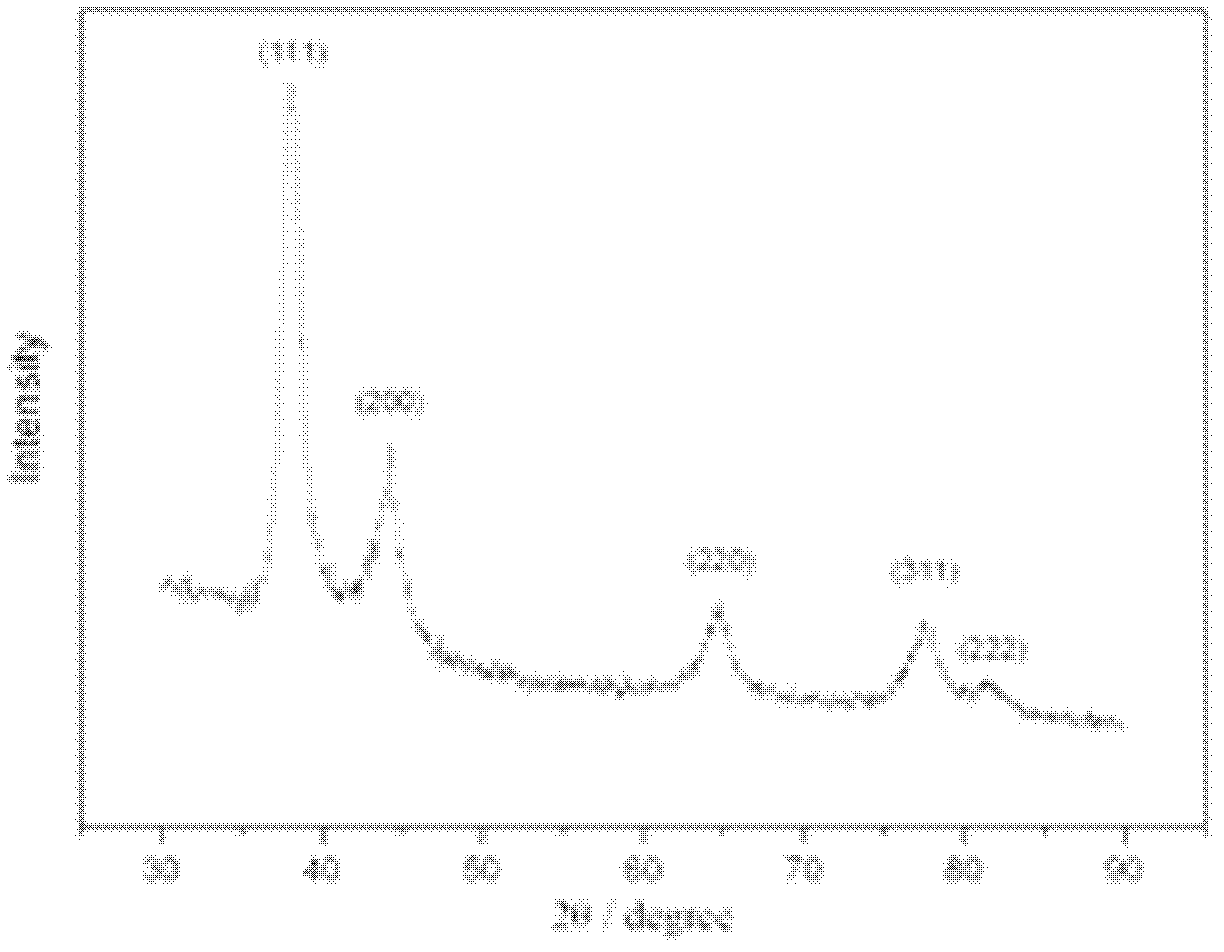

[0027] A kind of polypyrrole / gold nanocomposite material and preparation method thereof

[0028] Proceed as follows:

[0029] ①At room temperature, stir 100g of deionized water, 1.5g of surfactant SDS, and 0.5g of co-surfactant n-amyl alcohol to form a uniform and transparent microemulsion system;

[0030] ②Add 0.01g of pyrrole monomer into the system and stir to obtain a homogeneous system;

[0031] ③Add 0.5g mass fraction of 36% concentrated hydrochloric acid to the system to adjust the pH value of the system;

[0032] ④ Slowly add substances to the system with a concentration of 24.281×10 -3 mol / L of chloroauric acid solution 3g, continue to react for 4h.

[0033] ⑤ After the reaction, the obtained system was demulsified with ethanol, centrifuged, washed repeatedly with deionized water and ethanol, and dried to obtain the polypyrrole / gold nanocomposite material.

Embodiment 2

[0035] A kind of polypyrrole / gold nanocomposite material and preparation method thereof

[0036] Proceed as follows:

[0037] ①At room temperature, stir 100g of deionized water, 1.5g of surfactant PVP, and 0.5g of co-surfactant n-propanol to form a uniform and transparent microemulsion system;

[0038] ②Add 0.05g of pyrrole monomer into the system and stir to obtain a homogeneous system;

[0039] ③Add 1.5g mass fraction of 36% concentrated hydrochloric acid to the system to adjust the pH value of the system;

[0040] ④ Slowly add substances to the system with a concentration of 24.281×10 -3 mol / L of chloroauric acid solution 7g, continue to react for 3h.

[0041] ⑤ After the reaction, the obtained system was demulsified with ethanol, centrifuged, washed repeatedly with deionized water and ethanol, and dried to obtain the polypyrrole / gold nanocomposite material.

Embodiment 3

[0043] A kind of polypyrrole / gold nanocomposite material and preparation method thereof

[0044] Proceed as follows:

[0045] ①At room temperature, stir 100g of deionized water, 3.0g of surfactant PVP, and 1.5g of co-surfactant n-propanol to form a uniform and transparent microemulsion system;

[0046] ②Add 0.03g of pyrrole monomer into the system and stir to obtain a homogeneous system;

[0047] ③Add 1g mass fraction of 36% concentrated hydrochloric acid to the system to adjust the pH value of the system;

[0048] ④ Slowly add substances to the system with a concentration of 24.281×10 -3 mol / L of chloroauric acid solution 5g, continue to react for 5h.

[0049] ⑤ After the reaction, the obtained system was demulsified with ethanol, centrifuged, washed repeatedly with deionized water and ethanol, and dried to obtain the polypyrrole / gold nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com