Basalt particle-containing compositions and articles for protective coatings and ballistic shield mats/tiles/protective building components

a technology of composite compositions and articles, applied in the direction of protective garments, building components, armour, etc., can solve the problems of inability to protect against multiple projectiles, performance degradation, and unsuitability of armor for light vehicles such as automobiles, jeeps, light boats or aircra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0110]One manufacturing process for the manufacture of a handmade, basalt particle-containing plate or panel is as follows:

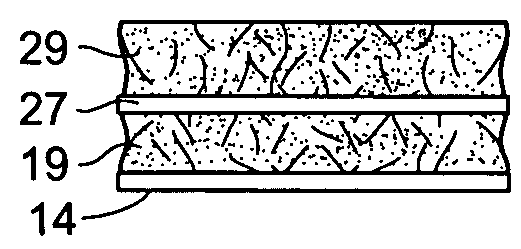

[0111]A homogeneous layer of basalt infused (20% by weight basalt powder) polyester resin was brushed onto a waxed, flat mold surface. One (1) layer of a 1½ oz. chopped strand fiberglass, non-woven mat having a silane binder was then applied over the basalt / resin composition. The following layers are alternated: (1) a non-woven fiberglass mat, (2) 24 oz. woven fiberglass roving, (3) non-woven fiberglass mat, (4) 24 oz. woven fiberglass roving, etc., with a coating of basalt / resin composition brushed onto each applied fiberglass layer. The first fiberglass layer is a mat to achieve a smooth surface finish. After applying five non-woven mats and three woven roving layers, or ⅜″ thickness, the laminated product (resin) is allowed to cure. The plate or sheet is then popped off the mold and trimmed with a jig saw or skill saw. The basalt / resin coating composition was...

example 2

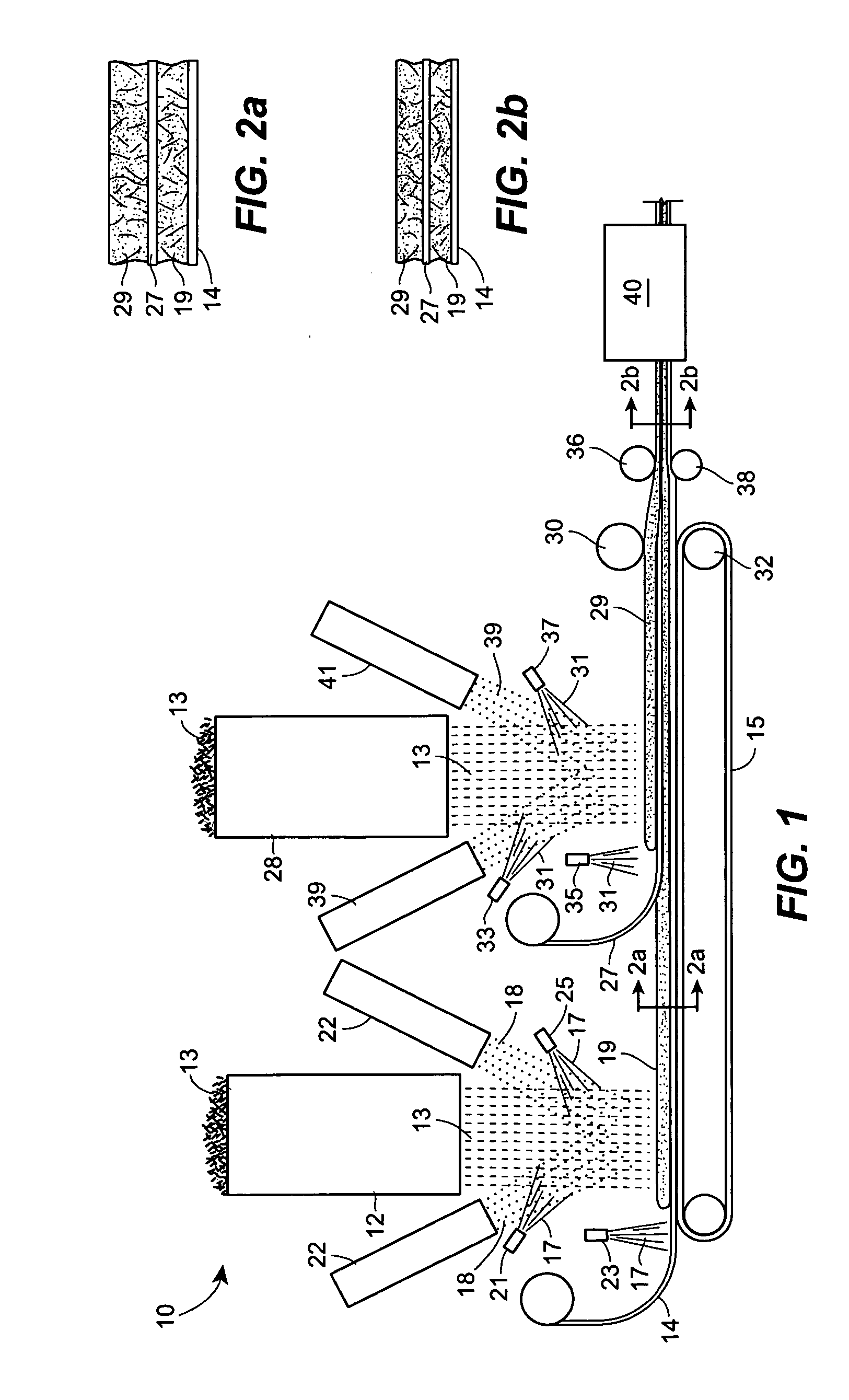

Conduit Manufacturing

[0130]Spiral wrap a 6″ wide 10 mil. thick Mylar film over a rotating steel mandrel. Wrap a 2″ wide 12″ thick foam collar onto one end of the mandrel. Wet the mandrel with the basalt particle-containing resin with a mandrel brush. Spiral alternating layers of 1½ oz.×6″ wide non-woven chopped fiberglass strand mat and followed by 6″ wide×24 oz. woven fiberglass roving, wetting each layer with the basalt particle-containing resin. Leave approximately ⅛″ between edges of each 1½ oz. mat for stretching when wet. Roll each layer with a grooved aluminum roller as the mandrel turns to remove entrapped air. Start and finish with 1½ oz fiberglass non-woven mat for better, smoother surface finish. After five (5) layers of non-woven fiberglass mat and three (3) layers of woven fiberglass roving have been applied to the mandrel, let the mandrel continue to rotate for faster resin solvent evaporation until the resin reaches the gel stage, then turn off the mandrel and let the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com