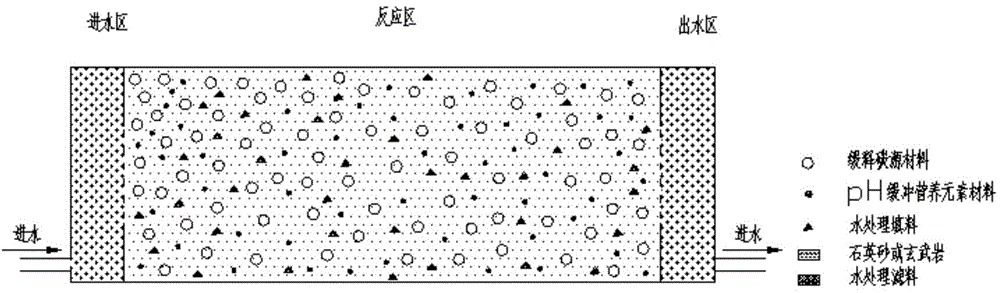

Permeable reactive filler for removing nitrate organisms from underground water, system and filling method thereof

A technology of permeable reaction wall and filling material, which is applied in the field of permeable reaction wall filling material, can solve the problems of weak denitrification and preferential flow, etc., and achieves the advantages of inoculation of microorganisms, reduction of chromaticity and turbidity of effluent, and easy control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

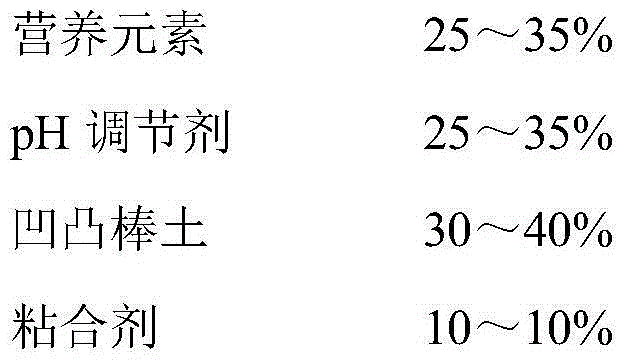

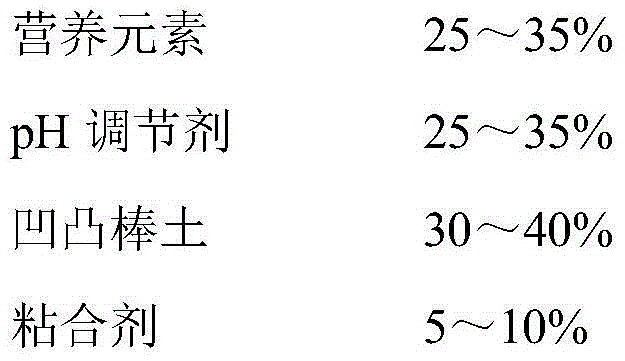

Embodiment 1

[0041]A permeable reaction wall filling material for the biological removal of nitrate in groundwater, which is composed of a mixture of biological slow-release carbon source materials, pH buffering nutrient element materials and bacterial flora enrichment water treatment fillers, and the mass percentages of each component are respectively : Biological slow-release carbon source material 75%, pH buffer nutrient element material 15%, bacterial flora enrichment water treatment filler 10%, among them, biological slow-release carbon source material is carbon iron given in accordance with Nanjing University National Invention Patent Application 201310727268.0 Prepared in Example 1 of the preparation method of the micro-battery slow-release carbon source filler; the core material composition and mass percentage of the pH-buffering nutrient element material are: CuSO 4 ·5H 2 O 15%, CaCl 2 2H 2 O 10%, citric acid 25%, attapulgite 40%, sodium alginate 10%, shell material composition ...

Embodiment 2

[0052] Same as Example 1, the difference is: 10% of the pH buffering nutrient element material, the flora enrichment water treatment filler is a porous spherical filler, and the mass percentage is 15%; the biological slow-release carbon source material is in accordance with the national invention patent application of Nanjing University 201310727268.0 prepared in Example 2 in the preparation method of carbon-iron micro-battery slow-release carbon source filler; the core material composition and mass percentage of the pH buffer nutrient element material are: FeSO 4 ·7H 2 O 15%, ZnSO 4 ·7H 2 O 15%, acetic acid 30%, attapulgite 30%, gum arabic 10%, shell material composition and mass percentage are: ordinary portland cement 28%, attapulgite 60%, diatomite 12%; denitrifying bacteria During the domestication process, the concentration of nitrate in the influent water is 25-30mg / L; both the reaction inlet and outlet areas are filled with bleaching earth, and the filling material a...

Embodiment 3

[0055] Same as Example 1, the difference is that the biological slow-release carbon source material is 80%, the pH buffer nutrient element material is 5%, the bacterial flora enrichment water treatment filler is Pall ring, and the mass percentage is 15%; the biological slow-release carbon source The material is prepared according to Example 3 in the preparation method of carbon-iron micro-battery slow-release carbon source filler given in Nanjing University National Invention Patent Application 201310727268.0; the core material composition and mass percentage of the pH-buffering nutrient element material are: MnCl 2 4H 2 O 20%, ZnSO4 7H 2 O 15%, sodium gluconate 30%, attapulgite 30%, guar gum 5%, shell material composition and mass percentage are: ordinary portland cement 30%, attapulgite 65%, diatomite 5% ;During the domestication process of denitrifying bacteria, the concentration of nitrate in the influent water is 30-40mg / L; both the reaction inlet and outlet water areas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com