Method for preparing antiskid wearable lightweight steel box girder bridge floor paving layer

A bridge deck pavement, lightweight steel technology, applied in the field of building materials, can solve the problems of epoxy asphalt concrete pavement slip resistance, unsatisfactory noise reduction effect, narrow temperature range for mixing and construction, and high requirements for raw materials and equipment. The effect of improving road performance, good anti-deformation performance and improving anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

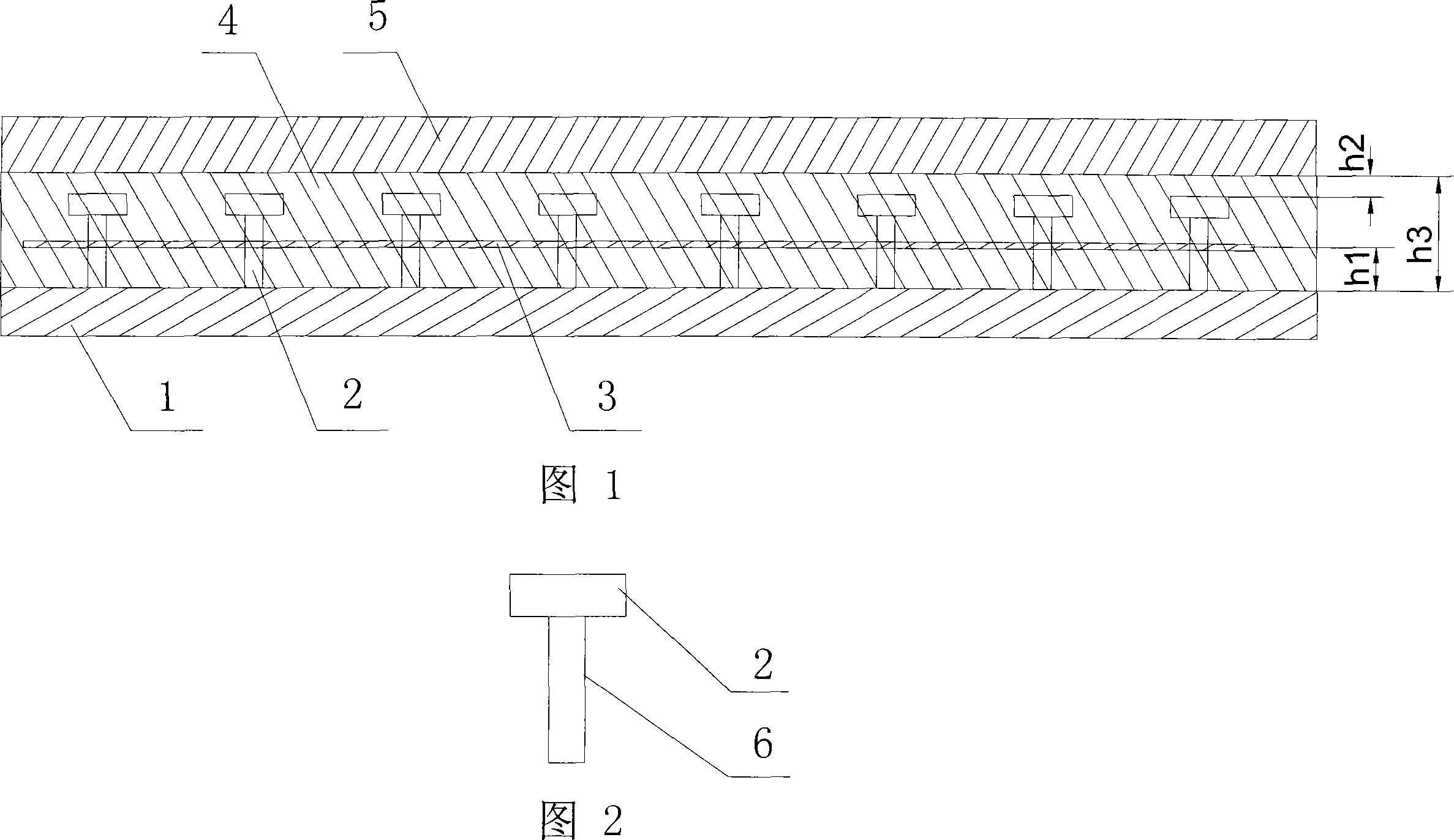

Image

Examples

Embodiment 1

[0033] The preparation method of anti-skid, wear-resistant lightweight steel box girder bridge deck pavement comprises the following steps:

[0034] Raw material preparation:

[0035] Light aggregate: particle size 5-16cm, apparent density 1200-1500kg / m 3 , Bulk density 700~1100kg / m 3 , Clay ceramsite with cylinder compressive strength ≥ 6.5Mpa.

[0036] The cement is 42.5# ordinary Portland cement.

[0037] The fine aggregate is river sand with a fineness modulus of 2.6-2.8.

[0038] The fly ash is Class II fly ash, and the water requirement is ≤105% (mass).

[0039] Polycarboxylate superplasticizer (such as: PC100 polycarboxylate superplasticizer produced by Wuhan Haoyuan Chemical Building Materials Co., Ltd.), the water reducing rate is 20-40%.

[0040] The organic imitation steel wire fiber in step 1) is: 0.5mm in diameter, 30-50mm in length, and breaking strength>410MPa.

[0041] The water-soluble polymer described in step 1) is: a modified polyacrylic polymer emuls...

Embodiment 2

[0065] The preparation method of anti-skid, wear-resistant lightweight steel box girder bridge deck pavement comprises the following steps:

[0066] Raw material preparation:

[0067] Light aggregate: particle size 5-16cm, apparent density 1200-1500kg / m 3 , Bulk density 700~1100kg / m 3 , crushed shale ceramsite with cylinder compressive strength ≥ 6.5Mpa.

[0068] The cement is 42.5# ordinary Portland cement.

[0069] The fine aggregate is river sand with a fineness modulus of 2.6-2.8.

[0070] The fly ash is Class II fly ash, and the water requirement is ≤105% (mass).

[0071] Polycarboxylate superplasticizer (such as: PC100 polycarboxylate superplasticizer produced by Wuhan Haoyuan Chemical Building Materials Co., Ltd.), the water reducing rate is 20-40%.

[0072] The organic imitation steel wire fiber is: 1.0mm in diameter, 30-50mm in length, and breaking strength > 410MPa.

[0073] The water-soluble polymer is: a modified polyacrylic polymer emulsion (such as Shandong...

Embodiment 3

[0097] The preparation method of anti-skid, wear-resistant lightweight steel box girder bridge deck pavement comprises the following steps:

[0098] Raw material preparation:

[0099] Light aggregate: particle size 5-16cm, apparent density 1200-1500kg / m 3 , Bulk density 700~1100kg / m 3 , Fly ash ceramsite with cylinder compressive strength ≥ 6.5Mpa.

[0100] The cement is 52.5# ordinary Portland cement.

[0101] The fine aggregate is river sand with a fineness modulus of 2.6-2.8.

[0102] The fly ash is Class II fly ash, and the water requirement is ≤105% (mass).

[0103] Polycarboxylate superplasticizer (such as: PC100 polycarboxylate superplasticizer produced by Wuhan Haoyuan Chemical Building Materials Co., Ltd.), the water reducing rate is 20-40%.

[0104] The organic imitation steel wire fiber is: 0.5-1.0mm in diameter, 30-50mm in length, and breaking strength > 410MPa.

[0105] The water-soluble polymer is: a modified polyacrylic polymer emulsion (such as Shandong T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com