Inorfil softening intensifier and preparation thereof

An inorganic fiber and reinforcing agent technology is applied in the field of inorganic fiber softening and reinforcing agent and its preparation. Strength, the effect of enhancing the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Adjustment of molecular weight of polyvinyl alcohol

[0016] First, dissolve polyvinyl alcohol 1788 and water at a mass ratio of 1:10 at 85-90°C to obtain a polyvinyl alcohol solution, and then press H in the polyvinyl alcohol solution 2 o 2 The mass ratio of polyvinyl alcohol 1788 is 1:130 by adding H 2 o 2 , then add H to the mixture 2 o 2 Potassium hydroxide with a mass of 4% was reacted at a temperature of 50° C. for 4 hours;

[0017] 2) Etherification of polyvinyl alcohol

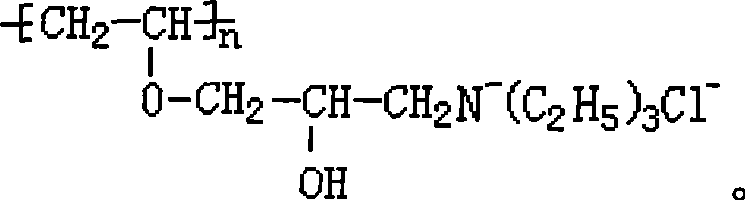

[0018] Take the polyvinyl alcohol treated in step 1) and mix the etherification agent 3-chloro-2-hydroxypropyl-3-methylammonium chloride at a mass ratio of 1:0.4, react at 70°C for 4h, and adjust the pH= 7-8 to obtain an inorganic fiber softening enhancer.

Embodiment 2

[0020] 1) Adjustment of molecular weight of polyvinyl alcohol

[0021] First, dissolve polyvinyl alcohol 1792 and water at a mass ratio of 1:8 at 85-90°C to obtain a polyvinyl alcohol solution, and then press H in the polyvinyl alcohol solution 2 o 2 The mass ratio of polyvinyl alcohol 1792 is 1:110 by adding H 2 o 2 , then add H to the mixture 2 o 2 Potassium hydroxide with a mass of 2% was reacted at a temperature of 55° C. for 3 hours;

[0022] 2) Etherification of polyvinyl alcohol

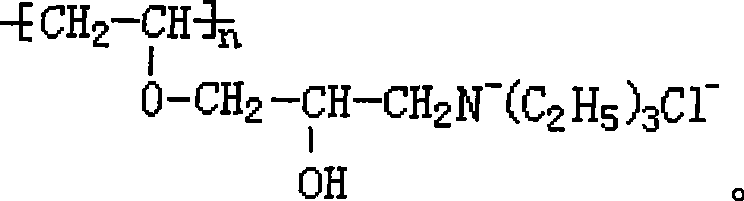

[0023] Take the polyvinyl alcohol treated in step 1) and mix the etherification agent glycidyltriethylammonium chloride at a mass ratio of 1:0.1, react at 50°C for 8 hours, and adjust the pH=7 to 8 to obtain softened inorganic fibers enhancer.

Embodiment 3

[0025] 1) Adjustment of molecular weight of polyvinyl alcohol

[0026] First, dissolve polyvinyl alcohol 1799 and water at a mass ratio of 1:12 at 85-90°C to obtain a polyvinyl alcohol solution, and then press H in the polyvinyl alcohol solution 2 o 2 The mass ratio of polyvinyl alcohol 1799 is 1:150 by adding H 2 o 2 , then add H to the mixture 2 o 2 Potassium hydroxide with a mass of 5% was reacted at a temperature of 60° C. for 2 hours;

[0027] 2) Etherification of polyvinyl alcohol

[0028] Take the polyvinyl alcohol treated in step 1) and mix the etherification agent 3-chloro-2-hydroxypropyl-3-methylammonium chloride at a mass ratio of 1:0.6, react at 65°C for 5h, and adjust the pH= 7-8 to obtain an inorganic fiber softening enhancer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com