Preparation method and application of basalt fiber surface nano-coated multi-scale reinforcement

A basalt fiber and multi-scale technology, applied in the field of fiber reinforced composite materials, can solve the problems of poor interface bonding and low mechanical properties of composite materials, and achieve the effects of alleviating stress concentration, improving comprehensive performance, and improving interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

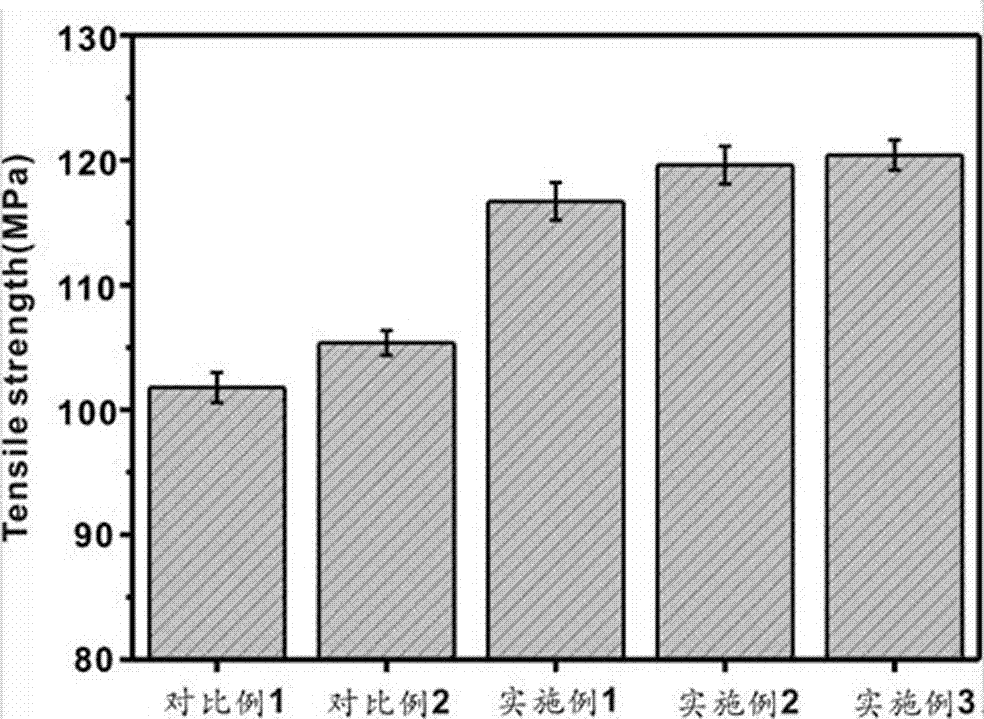

Embodiment 1

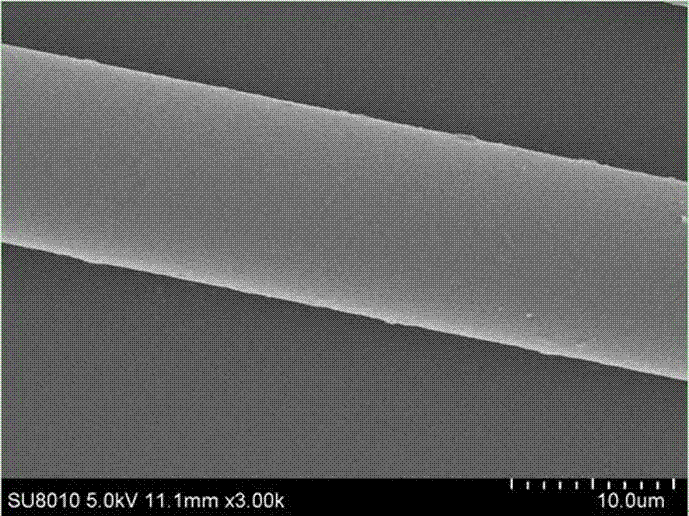

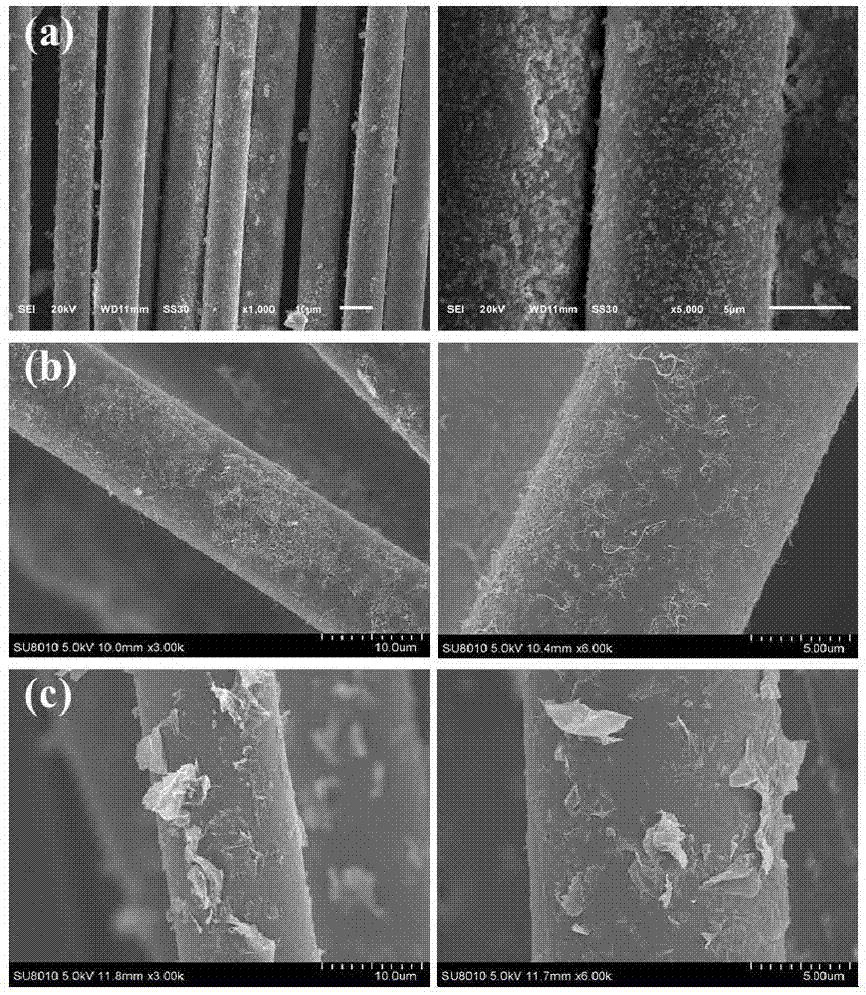

[0026] A preparation method of a composite material with a nano-coated multi-scale reinforcement on the surface of basalt fiber, comprising the following steps: 1) Nano particle functionalization: adding nano-silica into absolute ethanol, ultrasonic dispersion forming a concentration of 50mg / mL Add 5mg / mL γ-aminopropyltriethoxysilane (KH550) dropwise to the nanoparticle dispersion liquid, and stir in a water bath at 75°C for 4 hours, then centrifuge to precipitate, wash and dry; 2) Preparation of coating solution: Use deionized water to configure the water-soluble polyurethane film-forming agent diluent (concentration of 3wt%), drop 1wt% of γ-(2,3-glycidoxy)propyltrimethoxysilane (KH560) into it, and stir After uniformity, add the above-mentioned dried functionalized nano-silica (concentration of 10mg / mL), ultrasonically vibrate and stir evenly to obtain the coating solution; 3) Surface coating: ultrasonically clean the basalt fiber in acetone and clean it. After drying, add it...

Embodiment 2

[0028] A method for preparing a composite material with a nano-coated multi-scale reinforcement on the surface of basalt fiber includes the following steps: 1) Nanoparticle functionalization: adding carboxylated carbon nanotubes to absolute ethanol, and ultrasonic dispersion to form a concentration of 10 mg / mL of nanoparticle dispersion liquid, into which 0.3mg / mL γ-aminopropyltriethoxysilane (KH550) was added dropwise, stirred in a water bath at 70°C for 24 hours, centrifuged to precipitate, washed and dried; 2) coating liquid Preparation: Use deionized water to prepare the water-soluble polyurethane film-forming agent diluent (concentration is 1wt%), and 1wt% of γ-(2,3-glycidoxy)propyltrimethoxysilane (KH560) is added dropwise to it After stirring evenly, add the above-mentioned dried functionalized carbon nanotubes (concentration 10mg / mL), ultrasonically shake and stir evenly to obtain the coating solution; 3) Surface coating: ultrasonically clean the basalt fiber in acetone...

Embodiment 3

[0030] A method for preparing a nano-coated multi-scale reinforcement composite material on the surface of basalt fibers includes the following steps: 1) Nanoparticle functionalization: adding graphene oxide to absolute ethanol, ultrasonically dispersing to form nanometers with a concentration of 4 mg / mL To the particle dispersion, 20mg / mL of γ-(2,3-glycidoxy)propyltrimethoxysilane (KH560) was added dropwise, stirred in a water bath at 75°C for 24 hours, centrifuged to precipitate, washed, and dried. 2) Preparation of coating solution: Use deionized water to prepare a water-soluble polyurethane solution film-forming agent diluent (concentration is 1.5wt%), and 1wt% of γ-(methacryloxy)propyltrimethoxy is added dropwise to it Silane (KH570), after stirring uniformly, add the above-mentioned dried functionalized graphene oxide (concentration 0.5mg / mL), sonicate and stir uniformly to obtain a coating solution. 3) Surface coating: After ultrasonically cleaning the basalt fiber in ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com