Basalt and polypropylene hybrid fiber reinforced concrete and preparing method

A polypropylene fiber and basalt fiber technology, which is applied in the field of modified concrete, can solve the problems of durability and engineering cost limitations, small improvement in concrete performance, and difficulty in adapting to large-scale use, etc., and achieves low price, obvious anti-cracking effect, and thermal stability. Sexually superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

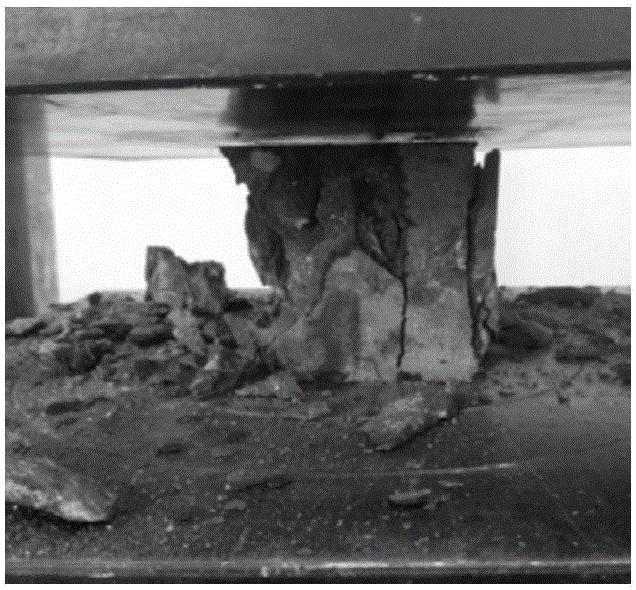

[0042] Splitting tensile strength: The specific ingredients and components involved in this embodiment are: the design water-cement ratio is 0.32, the cement strength is 42.5, and a total of 7 groups of test pieces are made, of which 1 group does not add any fiber as a control group, and 6 groups Hybrid fiber concrete was used as the experimental group.

[0043] Base concrete mix ratio:

[0044]

[0045] The splitting tensile strength test uses ф150×300 prism specimens, and each group makes 3 specimens, a total of 7 groups. The test groups and test results are as follows:

[0046]

[0047] Note: BF stands for basalt fiber, PP stands for polypropylene fiber, 0 stands for fiber volume content of 0%, 10, 15, 20, 30, 45 stands for fiber volume content of 0.1%, 0.15%, 0.2%, 0.3% and 0.45%, the same below.

[0048] From the test data in the table, it can be seen that (1) compared with plain concrete, the splitting tensile strength of concrete with added fibers has been impro...

Embodiment 2

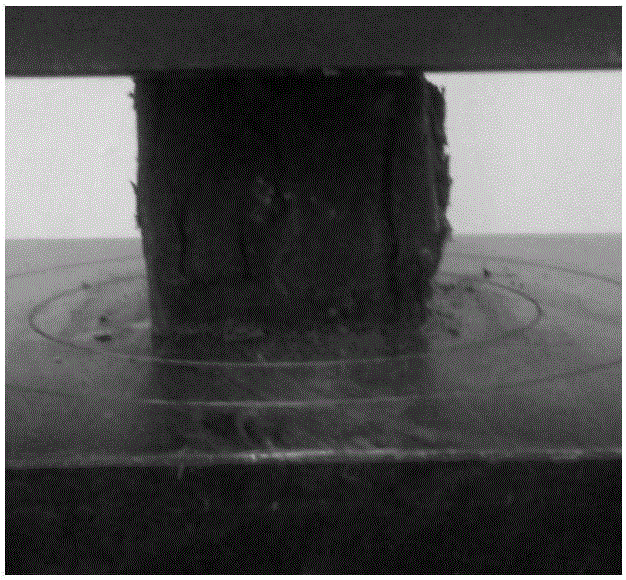

[0050]Flexural strength: The specific ingredients and components involved in this example are: the design water-cement ratio is 0.32, and the cement strength is 42.5. A total of 7 groups of test pieces are produced, of which 1 group does not add any fiber as the control group, and 6 groups of mixed fiber Concrete was used as the test group.

[0051] The matrix concrete mix ratio is the same as in Example 1.

[0052] The flexural strength test uses 100mm×100mm×400mm prism specimens, and each group makes 3 specimens, a total of 7 groups. The test groups and test results are as follows:

[0053]

[0054]

[0055] From the analysis of the above results, it can be seen that the flexural strength of basalt-polypropylene hybrid fiber concrete is higher than that of matrix concrete, and the maximum can be increased by 16.67%. The concrete shows good toughness.

Embodiment 3

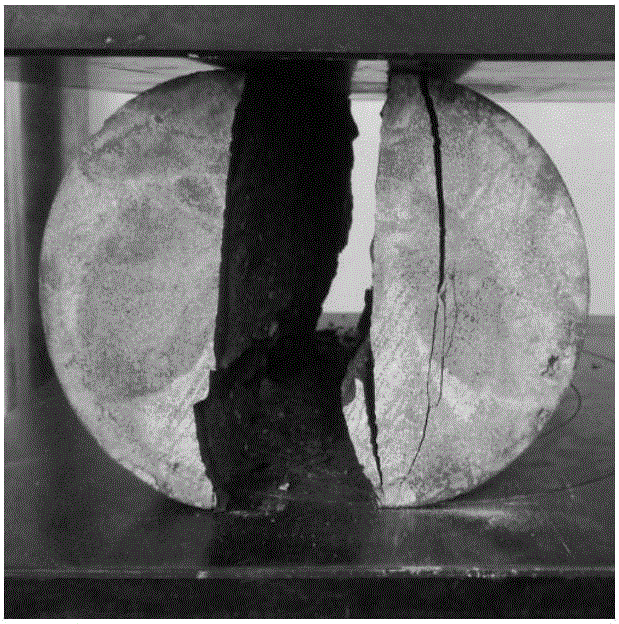

[0057] Antifreeze performance: The specific ingredients and components involved in this example are: the design water-cement ratio is 0.32, the cement strength is 42.5, and a total of 7 groups of test pieces are produced, of which 1 group does not add any fiber as the control group, and 6 groups mix fiber Concrete was used as the test group.

[0058] The matrix concrete mix ratio is the same as in Example 1.

[0059] The frost resistance performance test uses 100mm×100mm×400mm prism specimens for rapid freeze-thaw cycles, and each group makes 3 specimens for a total of 7 groups. The test groups and test results are as follows:

[0060]

[0061] From the analysis of the above results, it can be seen that after 400 freeze-thaw cycles, the relative dynamic elastic modulus of ordinary concrete loses 20.78%, while the loss of basalt-polypropylene hybrid fiber concrete is within 5%; after 600 freeze-thaw cycles, ordinary concrete has The loss of the largest group of basalt-polyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com