Combinational design method for radial and circumferential stiffening ribs of flange joints of tower feet of steel tube tower

A flange joint and combined design technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as less than yield stress and failure to exert steel strength, so as to improve ultimate bearing capacity and uniform force degree, the effect of reducing the degree of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Best practice:

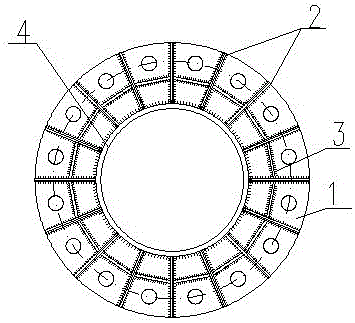

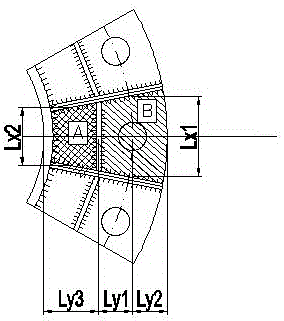

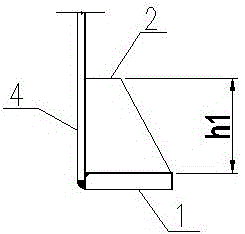

[0031] Refer to attached figure 2 And attached image 3 , a steel pipe tower (rod) tower foot radial and circumferential combined stiffener flange joint, the radial and circumferential combined stiffener flange joint includes a flange bottom plate 1 for connection, a radial stiffener 2. Circumferential stiffeners 3; the flange bottom plate 1 is an annular steel plate welded with the steel pipe 4. The radial stiffener 2 is a stiffener from the center of the steel pipe to the steel pipe wall; the circumferential stiffener 3 is a stiffener parallel to the cutting surface of the outer peripheral surface of the steel pipe; the circumferential stiffener 3 is vertical The radial stiffener 2 is connected with the weld seam; the bottom of the circumferential stiffener 3 is welded with the flange bottom plate 1; the radial stiffener 2 is vertically connected with the steel pipe wall Weld seam connection, the bottom is welded seam connection with the flange bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com