Method for additionally anchoring reinforced concrete beam strengthened with FRP cloth material in anti-bending way

A technology of reinforced concrete beams and reinforced concrete, which is applied in building maintenance, construction, building construction, etc., and can solve the problems of stripped and damaged steel plate U-shaped hoop construction, FRP material damage at anchor bolts, and easy to be cut at corners, etc. , to achieve the effect of increasing the pasting surface area, reducing the workload of surface treatment, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

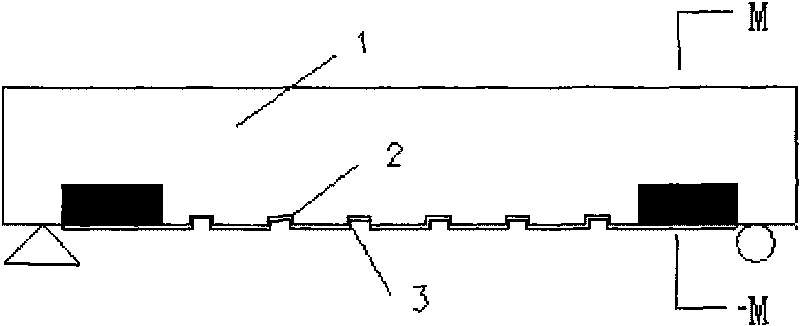

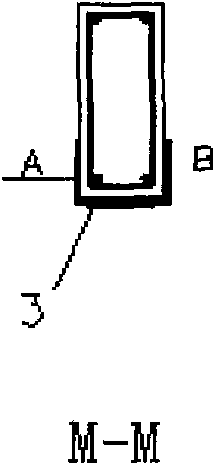

[0018] First, grooves are made on the bottom of the reinforced concrete beam according to the size. The direction of the groove is perpendicular to the long axis of the bottom of the beam and at a certain distance. The width of the groove is 80mm, the depth is 25mm, and the distance between grooves is 400mm. After the slotting is completed, clean up the slot dust, and use a grinding wheel to smooth the bottom surface of the beam, and grind the corners of the slot into a smooth chamfer. Apply primer to the bottom of the beam, and use leveling glue to level the concrete defects on the surface after the primer is cured. Then paint the surface glue, first paste two layers of unidirectional fiber cloth with different fiber directions on the end of the beam bottom, and then paste the unidirectional fiber cloth required for bending reinforcement, and insert the fiber cloth in the groove Inside, finally fill the groove with glue to form an inner lock anchor system. Experiments have p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com