Continuous preparation method and anchoring method of FRP pultruded profile

A technology of pultrusion profiles and anchoring methods, which is applied in the fields of civil engineering and composite materials, can solve the problems of FRP profiles such as difficult anchorage, poor ductility, and low FRP shear strength, so as to shorten the anchorage length, increase the bonding surface area, and improve The effect of anchoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

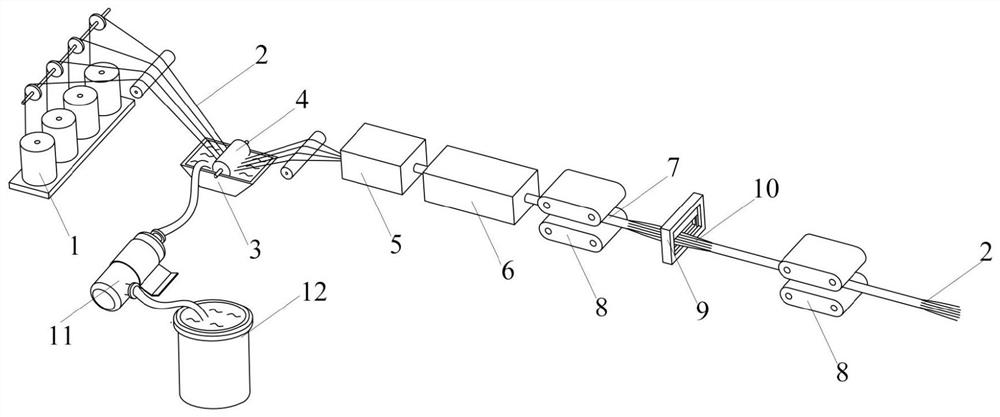

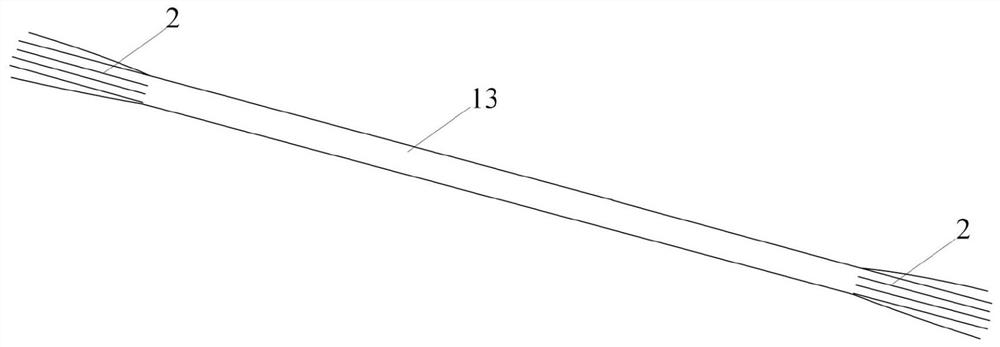

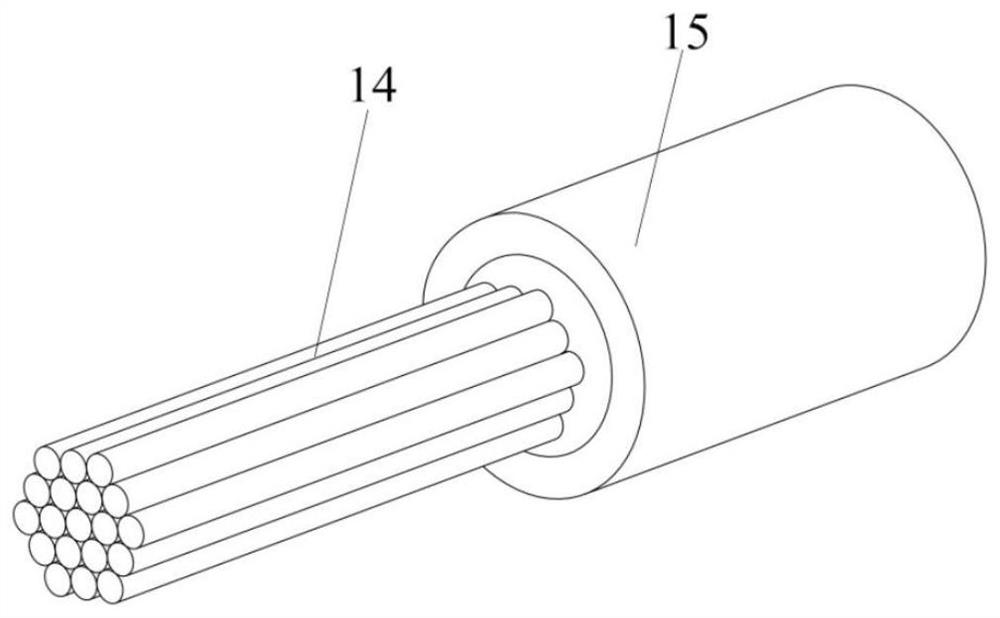

[0032] Such as figure 1 As shown, a continuous preparation method of FRP pultruded rods with loose filaments at the end, fibers 2 are drawn out from the creel 1, and are evenly and neatly arranged, pulled by a traction device 8, and guided by a roller 4, Entering and passing through the impregnation tank 3 filled with resin, the impregnated fiber first passes through the preforming mold 5 and gradually transitions into the shape of a bar while extruding excess resin, and then passes through the forming mold 6 to solidify and form.

[0033] Connect a two-way pump 11 and the glue container 12 for the dipping tank 3, when the fiber 2 does not need to be dipped, use the bidirectional pump 11 to suck out a part of the resin in the dipping tank 3 and inject it into the glue container 12, so that the dipping The water level of the resin in the groove 3 drops, and at this moment, the fiber 2 cannot soak the resin, thereby forming a loose filament section 10, which is cut at the middle...

Embodiment 2

[0036] Such as Figure 4As shown, a continuous preparation method of FRP pultruded sheets with loose filaments at the ends, fibers 2 are drawn out from the creel 1, and are evenly and neatly arranged, pulled by a traction device 8, and guided by a roller 4, Entering and passing through the impregnation tank 3 filled with resin, the impregnated fiber first passes through the preforming mold 5 and gradually transitions into the shape of a sheet while extruding excess resin, and then passes through the forming mold 6 to solidify and form.

[0037] The dipping tank 3 can move up and down. When the fiber 2 does not need to be dipped, the dipping tank 3 moves downward. At this time, the fiber 2 cannot be soaked with resin, thus forming a loose filament section 10. When the fiber 2 needs to be dipped , the dipping tank 3 moves upwards and returns to its original position, and at this time, the fiber 2 begins to infiltrate the resin again, and is cut at the middle position of the loos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com