Construction method of precast concrete pile body carrier pile

A technology of precast concrete and construction method, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problem of diameter reduction of pile end joint, diameter reduction of pile body and pile end joint, broken pile, and adjacent pile squeeze. Soil influence and other issues can be improved to achieve the effect of increasing the ultimate bearing capacity, avoiding unrealistic bonding and avoiding damage to the pile body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below by specific examples.

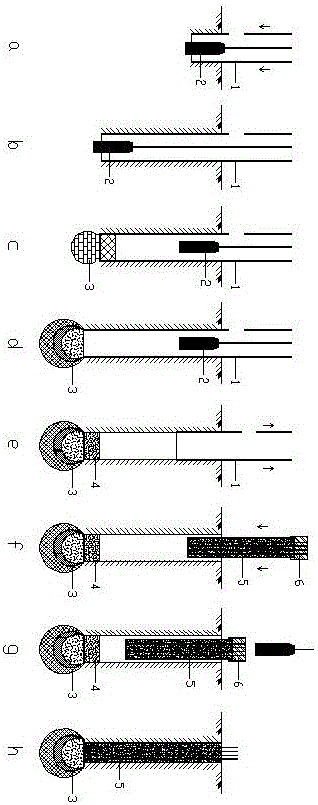

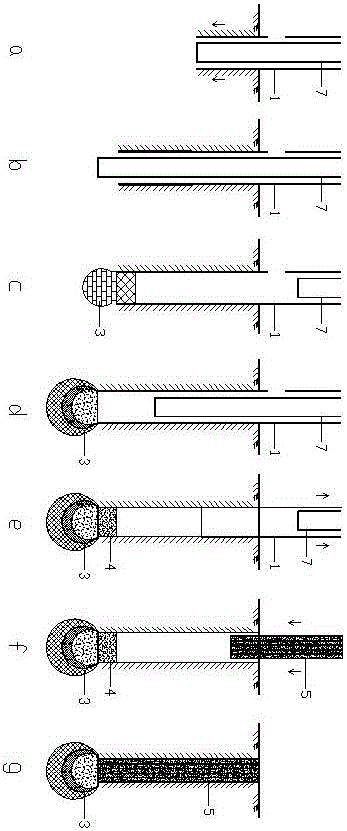

[0038] figure 1 It is a process diagram of an embodiment of the prefabricated concrete pile body carrier pile construction method of the present invention, at first, as figure 1 As shown in a, at the pile position, through the free fall movement of the weight 2 in the casing 1, the foundation soil is punched to form a pile hole, and the casing 1 is vibrated to make the casing 1 sink downward. input, and then, if figure 1 As shown in middle b, the operation of impacting the hammer 2 to form a hole and sinking into the casing 1 is repeated until the design depth; then, as figure 1As shown in c, a certain amount of filling material 3 is filled in the casing 1, and the filling material 3 is tamped with the hammer kinetic energy of the weight 2; then, as figure 1 As shown in d, repeat the operation of filling and tamping to make the soil under the pile end compact within a certain depth and with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com