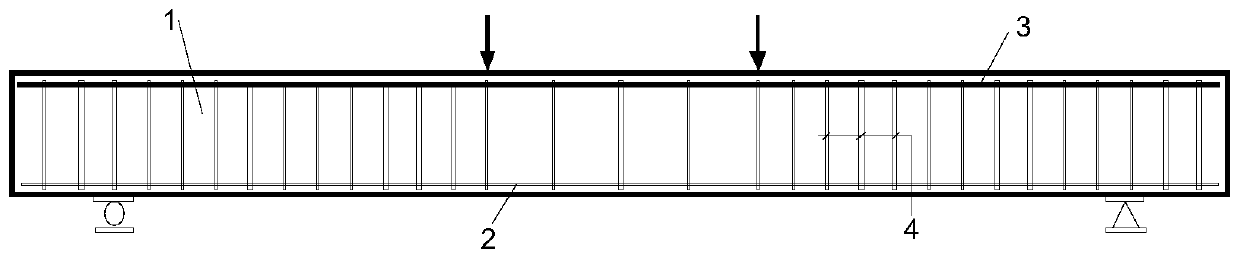

Fiber reinforce plastic (FRP) rib fiber high-strength light-weight aggregate concrete beam member and manufacturing method

A lightweight aggregate concrete and manufacturing method technology, applied to building components, bridge parts, bridges, etc., can solve problems such as corrosion of steel bars, poor durability, and reduce structural self-weight, so as to improve seismic performance, reduce structural self-weight, and reduce component deflection and crack width effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

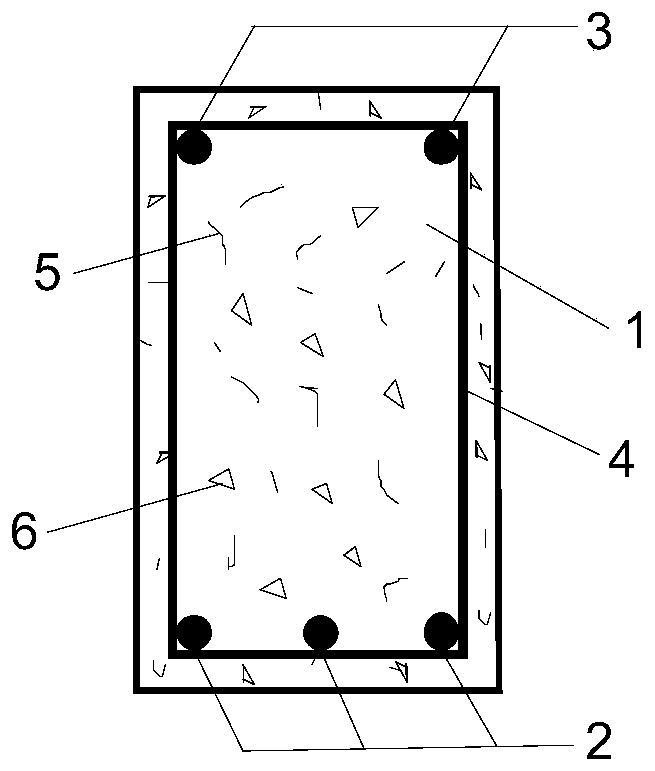

[0034] The manufacturing method of FRP reinforced fiber high-strength lightweight aggregate concrete beam member comprises the following steps:

[0035] Step 1, according to the construction drawing, bind the reinforcement cage formed by the CFRP reinforcement, the longitudinal erection reinforcement 3 and the stirrup 4; Water agent, 370 parts of cement, 70 parts of silica fume and 670 parts of fine aggregate;

[0036] Step 2, wetting the gravel-type ceramsite 6 with additional water evenly, adding a water reducing agent into the water and stirring evenly to obtain a mixture A;

[0037] Step 3, after mixing the wetted gravel-type ceramsite 6 with cement, silicon powder and fine aggregate, add steel fiber, so that the volume content of steel fiber in fiber lightweight aggregate concrete 1 per cubic meter is 0.4% , uniformly mixed to obtain mixture B;

[0038] Step 4, add the mixture A to the mixture B in two times, stir well and complete the production of the fiber lightweigh...

Embodiment 2

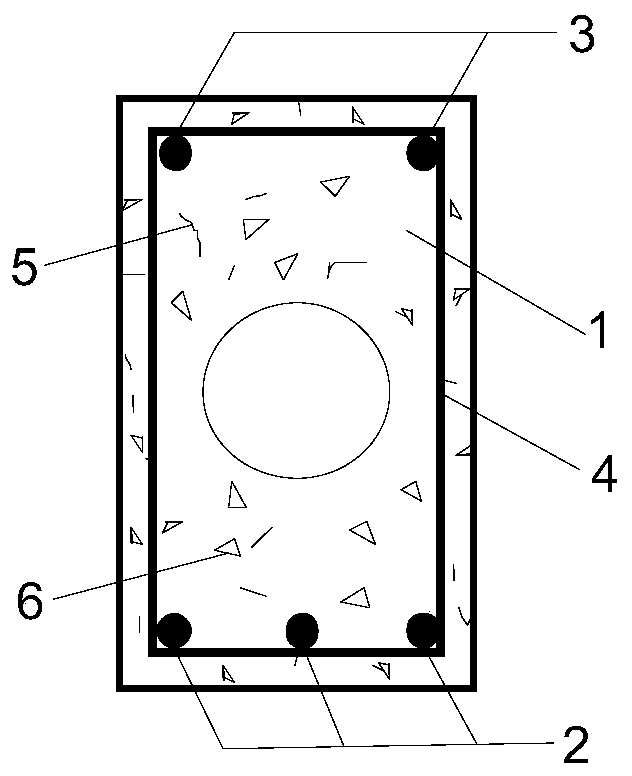

[0042] The manufacturing method of FRP reinforced fiber high-strength lightweight aggregate concrete beam member comprises the following steps:

[0043] Step 1, according to the construction drawing, bind the reinforcement cage composed of BFRP reinforcement, vertical erection reinforcement 3 and stirrup 4; and weigh 650 parts of gravel-type ceramsite 6, 180 parts of water, and 5 parts of Water reducing agent, 430 parts of cement, 30 parts of fly ash and 730 parts of fine aggregate;

[0044] Step 2, wetting the gravel-type ceramsite 6 with additional water evenly, adding a water reducing agent into the water and stirring evenly to obtain a mixture A;

[0045] Step 3: After mixing the wetted gravel-type ceramsite 6 with cement, fly ash and fine aggregate, add the mixed fiber of plastic steel fiber and polypropylene fiber, so that every cubic meter of fiber lightweight aggregate concrete 1 is mixed The volume dosage of the fiber is 0.8%, uniformly mixed to obtain the mixture B;...

Embodiment 3

[0050] The manufacturing method of FRP reinforced fiber high-strength lightweight aggregate concrete beam member comprises the following steps:

[0051] Step 1, according to the construction drawing, bind the reinforcement cage composed of AFRP reinforcement, longitudinal erection reinforcement 3 and stirrup 4; and weigh 620 parts of gravel-type ceramsite 6, 150 parts of water, 4 parts Water reducing agent, 400 parts of cement, 100 parts of auxiliary cementitious material and 700 parts of fine aggregate;

[0052] Step 2, wetting the gravel-type ceramsite with additional water evenly, adding a water reducing agent into the water and stirring evenly to obtain a mixture A;

[0053] Step 3, mix the wetted crushed stone type ceramsite 6 with cement, auxiliary cementitious material and fine aggregate, and add the mixed fiber of polyacrylonitrile fiber and lignin fiber to make the fiber lightweight aggregate concrete 1 The volume dosage of the mixed fibers in the medium is 0.6%, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com