High-ductility fiber concrete and construction method for reinforcing beam by using high-ductility fiber concrete

A technology of fiber-reinforced concrete and fiber-reinforced concrete layers, which is applied in the reinforcement construction field of concrete beams, to achieve the effects of cost reduction, easy operation, and improvement of integrity and seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

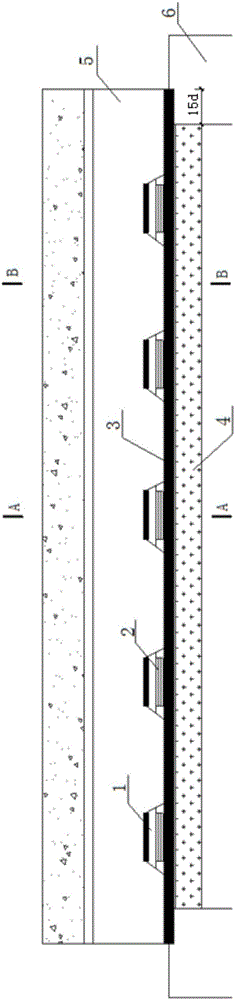

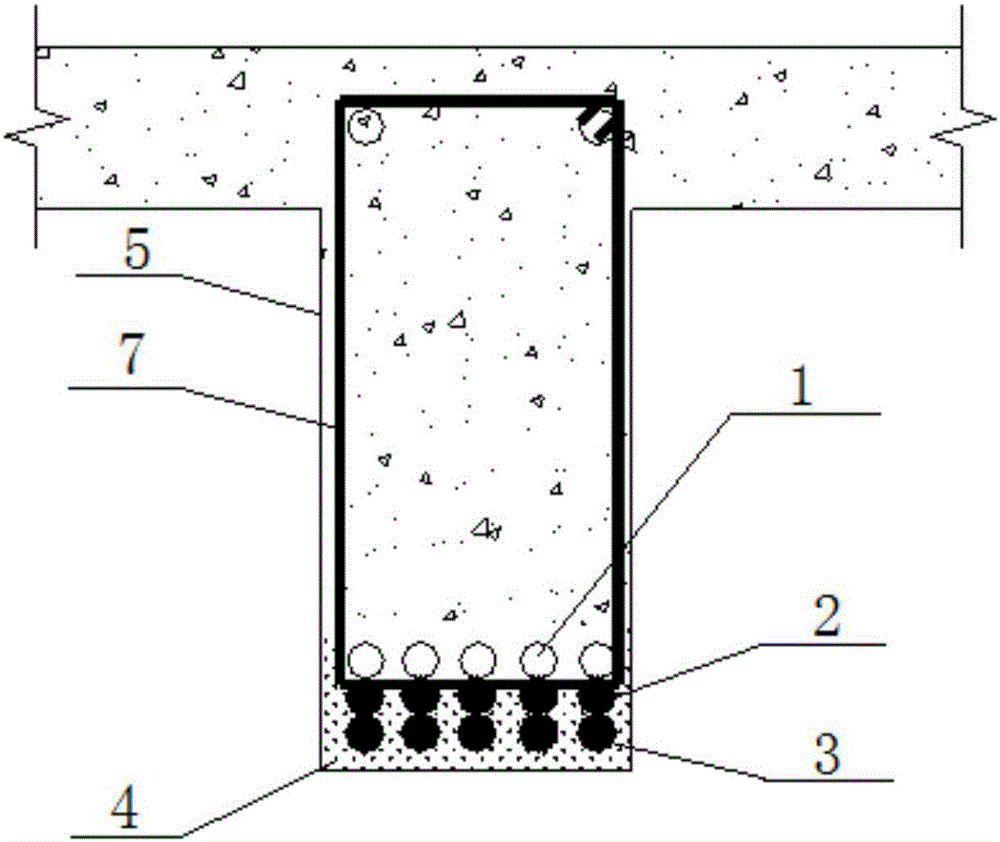

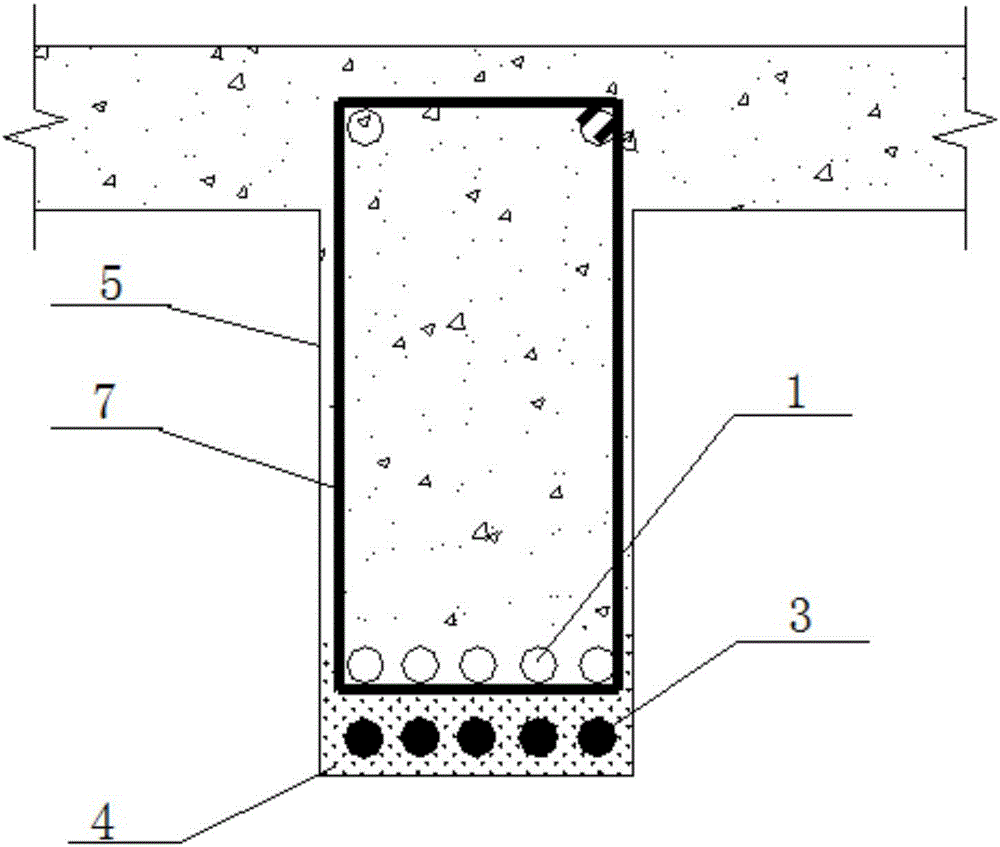

[0034] combine Figure 1-3 , the cross-sectional size of the concrete beam 5 to be reinforced in this embodiment is 500×900mm, the beam span is 8.1m, and five first stressed steel bars 1 are arranged in double rows at the bottom of the beam, and the diameter is tertiary steel of 25mm;

[0035] During construction: first chisel off the plaster layer on the surface of the concrete beam 5 to the concrete structure layer, so that at least half of the section of the first stressed steel bar 1 at the bottom of the beam is exposed; the defective parts of the concrete (concrete loose, damaged) should be cleaned to a solid base;

[0036] Secondly, drill a hole at the junction of the concrete beam 5 and the concrete column 6 and implant the second stressed steel bar 3. The second stressed steel bar 3 at the bottom of the beam is a third-grade steel with a diameter of 25mm. 15d, use a blower and a brush to clean the hole until there is no floating dust on the inner wall of the hole;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com