Carbon fiber thin-wall steel tube concrete composite column with internal FRP sectional material and method

A thin-walled steel pipe and concrete technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems of increased self-weight of the structure, achieve the effects of reducing weight, facilitating seismic design, and improving bearing capacity and ductility

Inactive Publication Date: 2015-12-30

SHENYANG JIANZHU UNIVERSITY

View PDF7 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Although the steel pipe concrete structure has many advantages, it is lighter than the reinforced concrete structure, and slightly heavier than the steel structure, but the self-weight of the structure increases with the increase of the storey height

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

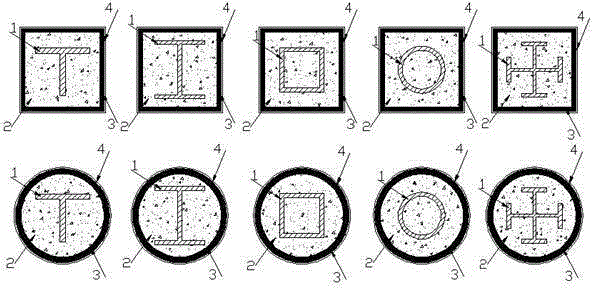

[0026] The section of the FRP profile is T-shaped, and the section of the thin-walled steel pipe is circular.

Embodiment 2

[0028] The cross-section of the FRP profile is I-shaped, and the cross-section of the thin-walled steel pipe is circular.

Embodiment 3

[0030] The cross-section of the FRP profile is square, and the cross-section of the thin-walled steel pipe is circular.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention aims to provide a carbon fiber thin-wall steel tube concrete composite column with an internal FRP sectional material and a method. The carbon fiber thin-wall steel tube concrete composite column comprises the FRP sectional material, a thin-wall steel tube, an outer protection layer and concrete, wherein the FRP sectional material is arranged at the center of the thin-wall steel tube; the space between the FRP sectional material and the thin-wall steel tube is filled with concrete; the thin-wall steel tube is covered by the outer protection layer in a winding manner; the outer protection layer is carbon fiber reinforced plastic; the cross section of the FRP sectional material is crisscross, I-shaped, T-shaped, circular or square; the cross section of the thin-wall steel tube is circular or polygonal; the ratio of the cross-sectional area of the internal FRP sectional material to the integral cross-sectional area of the composite column is not greater than 15%. The manufacturing method of the composite column comprises the following specific steps: 1, putting the FRP sectional material into the steel tube, and fixing the FRP sectional material at the center of the steel tube; 2, covering the outer layer of the steel tube with the carbon fiber reinforced material layer; 3, pouring concrete inside the steel tube; 4, performing periodical maintenance.

Description

technical field [0001] The invention belongs to the technical field of civil engineering, and in particular relates to a carbon fiber thin-walled steel pipe concrete composite column with built-in FRP profiles and a method thereof. Background technique [0002] Like all other industries in the national economy, my country's construction industry has experienced a process of rapid development since the reform and opening up. With the continuous development of urbanization in our country, infrastructure investment is in a period of large-scale construction, making the civil engineering industry always in a state of continuous expansion. Thin-walled concrete-filled steel tube (Concrete-Filled Steel Tube, abbreviated as CFST) is a new structural form that combines and works together with thin-walled plates, cold-formed thin-walled steel (including thin-walled steel tubes) and concrete. It is made by pouring concrete in steel pipes, which makes full use of the characteristics of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E04C3/34

Inventor 徐诚皓徐亚丰张月牟璐朱绍杰

Owner SHENYANG JIANZHU UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com