Fair-faced concrete structure beam and column joint formwork reinforcement system

A fair-faced concrete and formwork reinforcement technology, applied in the field of column joint formwork reinforcement system and veneer fair-faced concrete concrete structural beams, can solve the problems of long construction period, increased construction cost, long construction period of a single layer, etc., saving resources, operating simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

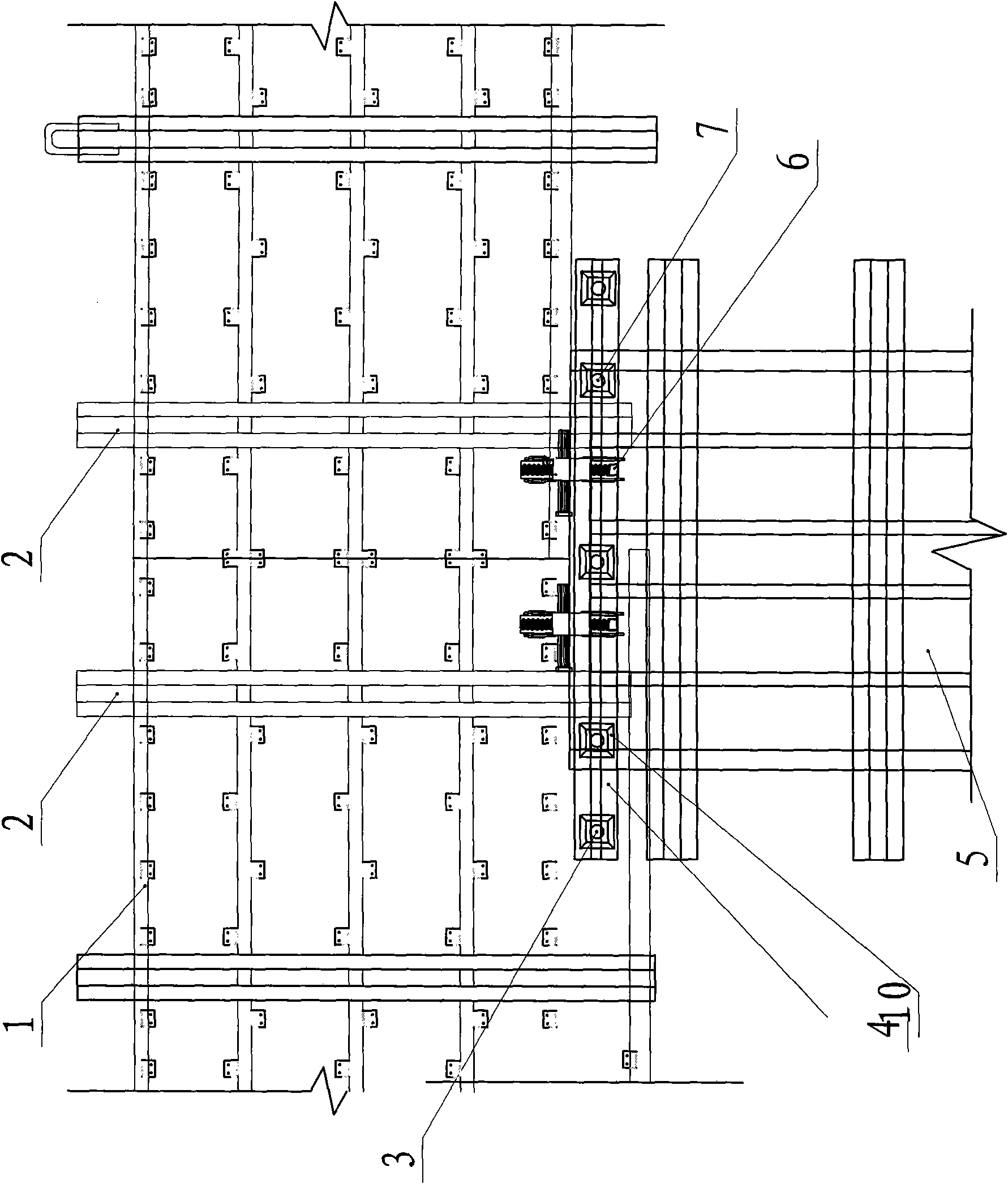

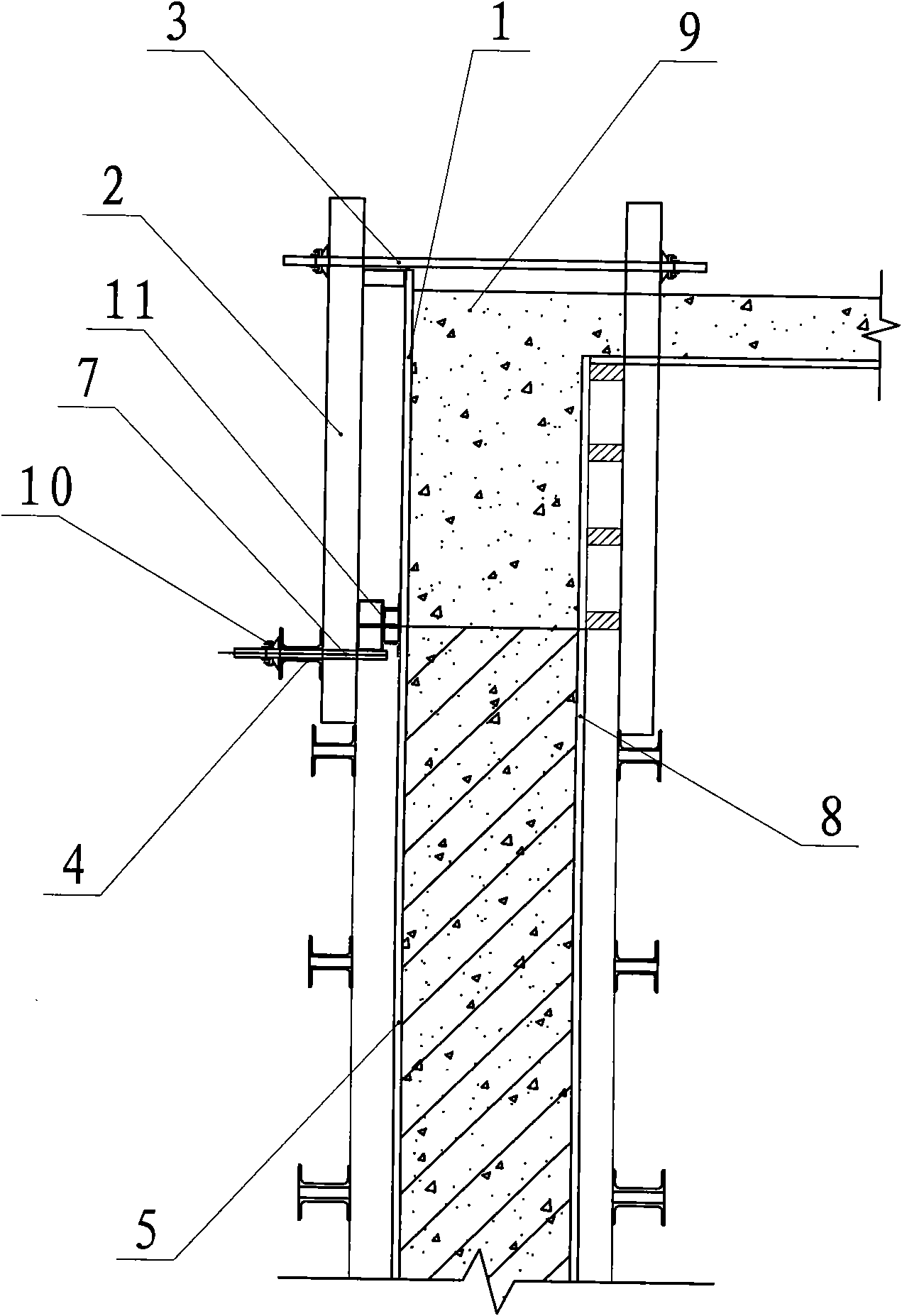

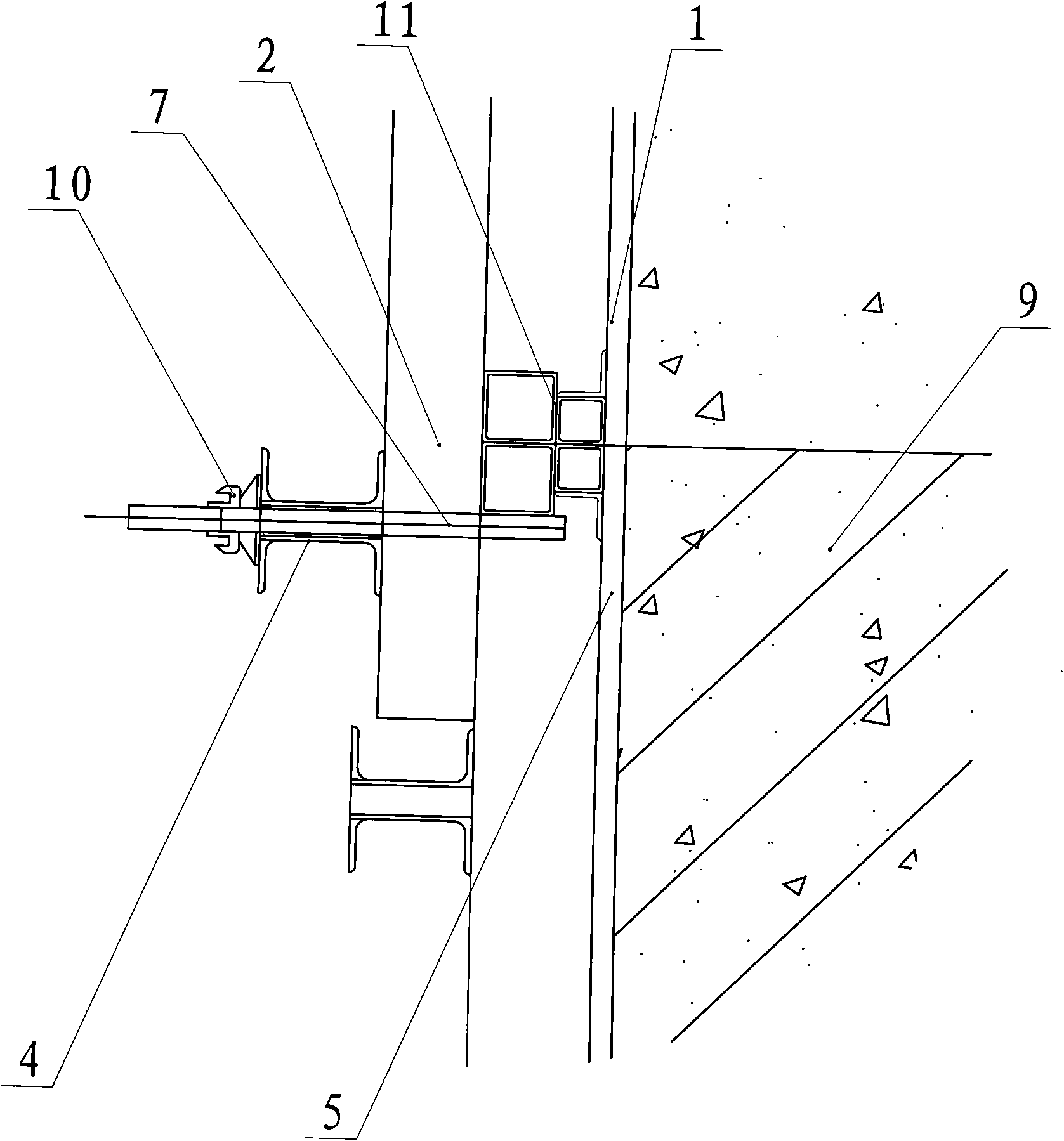

[0019] see Figure 1-Figure 3 , in the figure 1. Beam formwork, 2. Beam formwork back corrugated, 3. Pull bolts, 4. Pressure rods, 5. Clean water surface column formwork, 6. Adjustable fixture, 7. Screw rod, 8. Non-clear water surface column Formwork, 9. Fair-faced concrete to be poured, 10. Nut, 11. Formwork frame.

[0020] As shown in the figure, a facing concrete structure beam and column joint formwork reinforcement system includes a column formwork and a beam formwork. The back of the column formwork and the beam formwork has back corrugations. The back of the butt joint edge is provided with a frame that matches each other, and the frames of the column formwork and the beam formwork are clamped by clamps for jointing; The back flute has at least two lower end lengths protruding to the back of the column formwork, and a horizontal pressure bar is pressed on the outside of the back flute. Several screw rods perpendicular to the main formwork are welded on the frame of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com