Fixing tool for plate-permeable embedded casing pipe

A fixed tool and pre-embedded technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the complex structure, cumbersome disassembly process, and difficult to solve the problem of pre-embedded sleeve fixing through the board , positioning and other issues, to achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

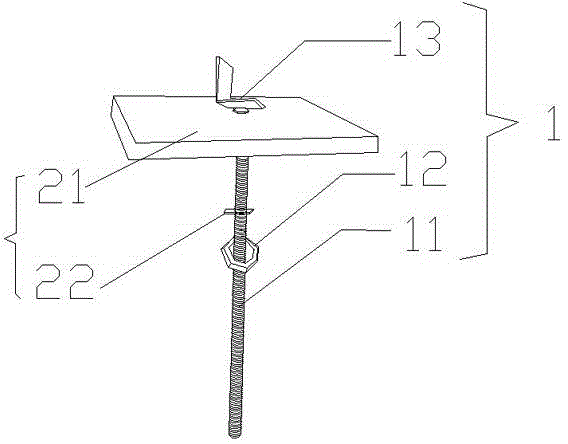

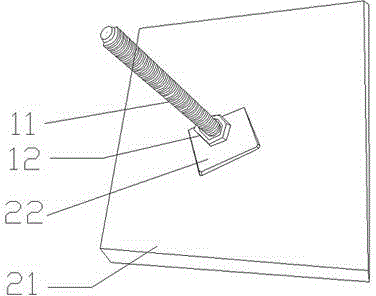

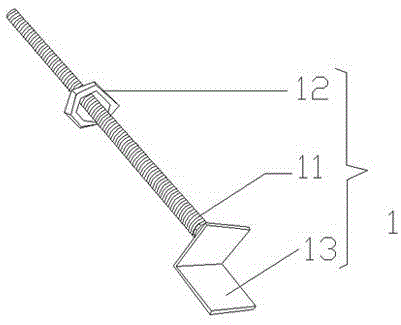

[0021] Such as Figures 1 to 3 As shown, it is a structural schematic diagram of the fixing tool for the embedded casing through the plate of the present invention, including the fixing tool original 1 and the fastening member 2. The fixing tool original 1 includes a screw 11, a nut 12, an angle steel 13, and the screw 11 It is connected with the angle steel 13 through full welding, the fastening member 2 includes a cover plate 21 and a flat iron shim 22, and the screw 11 passes through the center of the 5cm*5cm template cover plate 21 and the flat iron washer 22 , and tighten and fix the fixing tool original 1 and the fastening member 2 through the screw 11 and the nut 12, and form an integral body with the bottom form of the floor, so as to avoid or reduce the displacement of the embedded casing during concrete pouring. The specific operation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com