Steel rail surface jacking device

A technology of jacking device and rail, applied in the direction of track, track maintenance, track superstructure, etc., can solve the problems of contact spots, large workload, polygons, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

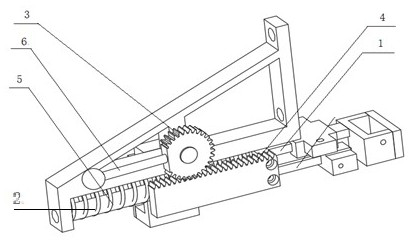

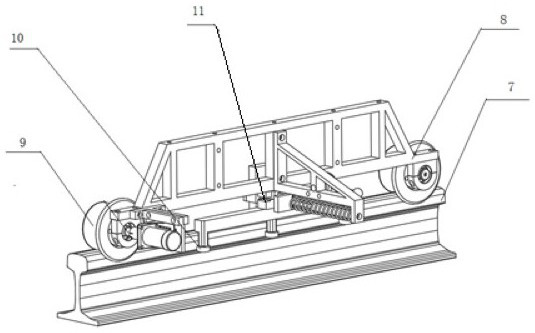

[0015] The specific implementation of the rail surface tightening device of the present invention is as follows: figure 1 , figure 2 As shown, the guide wheel 9 in the spring tensioning device is placed on the inner side of the left rail 7 when in use, and is close to the inner edge of the rail, so that the guide wheel is more stable during walking;

[0016] The sleeve 2 is connected with the slider 11, which can play the role of shock absorption;

[0017] The slide block 11 and the guide wheel 10 mounting seat on the left side rail 7 are connected together, so that the spring clamping device obtains supporting force from the mounting seat;

[0018] When the guide wheel 10 is not in contact with the side of the rail head of the rail 7, the spring moves outward against the sleeve 2 to contact the side of the rail, maintaining the relative perpendicular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com