Self-locking railway fastener high in continuity and convenient to install

A railway fastener and continuity technology, applied in the directions of roads, tracks, buildings, etc., can solve the problems that affect the popularization and use of type III railway fasteners, cannot achieve continuous height adjustment and simplified installation, etc., and achieve convenient installation and self-locking. And the effect of simple installation and convenient post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

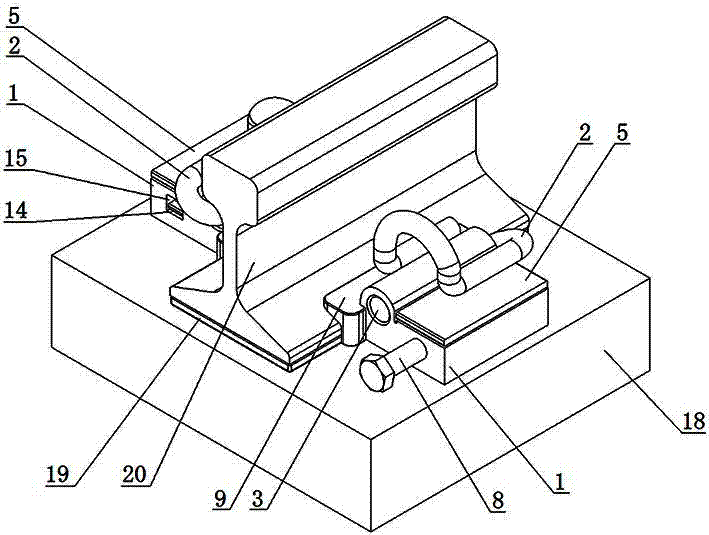

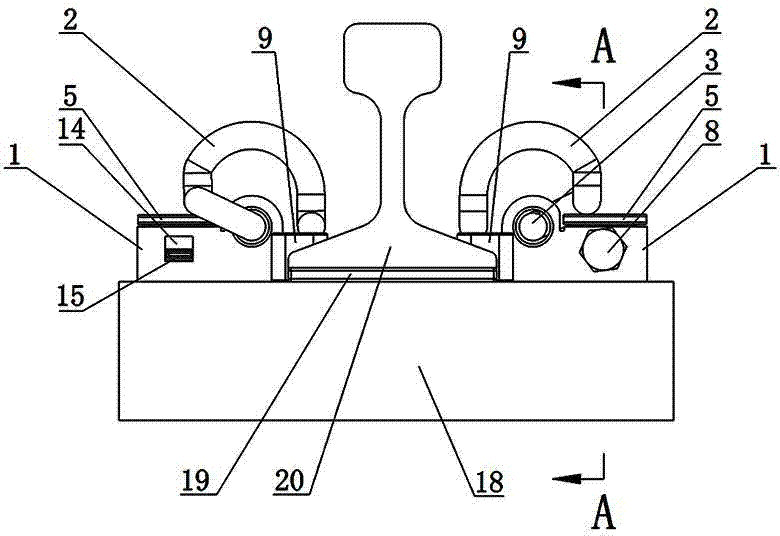

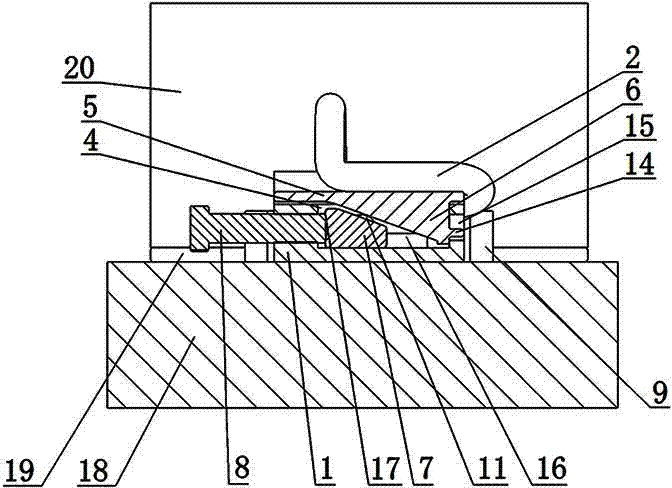

[0027] Such as figure 1 , figure 2 , image 3 As shown, the self-locking railway fastener that can be continuously adjusted in height and is easy to install includes a pre-embedded insert seat 1 and a type III spring bar 2. The left part of the pre-embedded insert seat 1 is provided with a jack 3 of strip 2, such as image 3 , Figure 4 As shown, the right part of the embedded insert seat 1 is provided with an upper opening cavity 4, the cavity 4 is cube-shaped, the top cover of the cavity 4 is equipped with a top cover 5, and the bottom of the top cover 5 is provided with The wedge-shaped part 6 protruding into the cavity 4, the thickness of the wedge-shaped part 6 increases gradually along the direction from front to back, the rear end surface of the wedge-shaped part 6 is pressed against the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com