Patents

Literature

42results about How to "Displacement does not occur" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

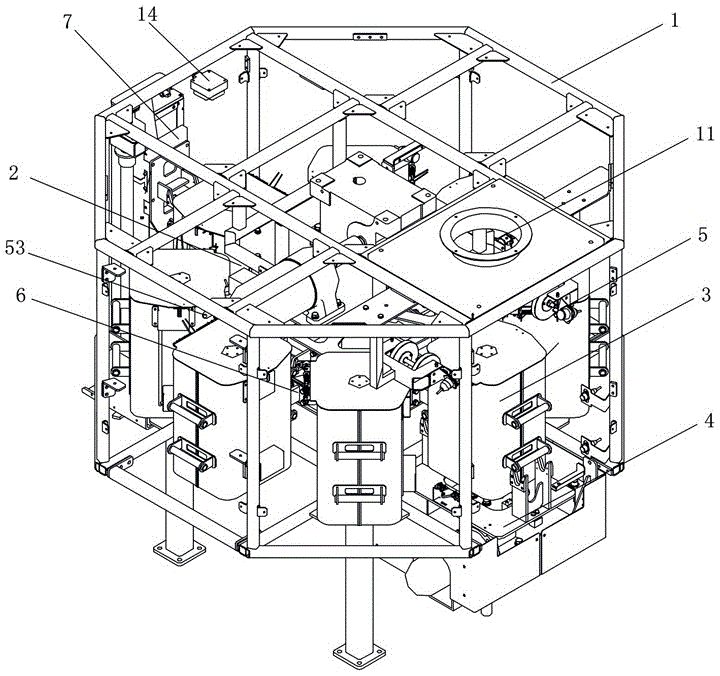

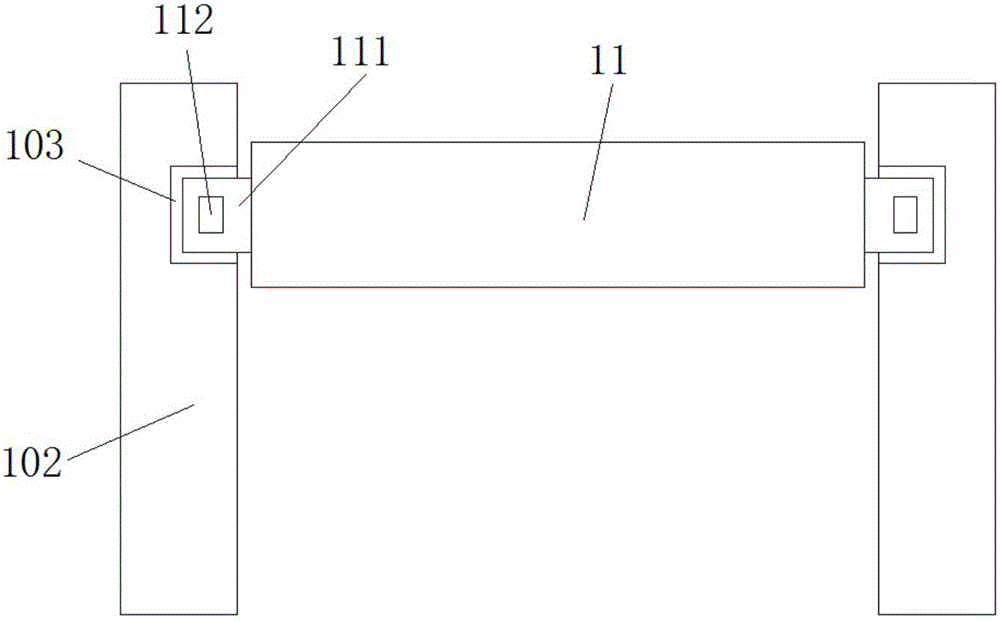

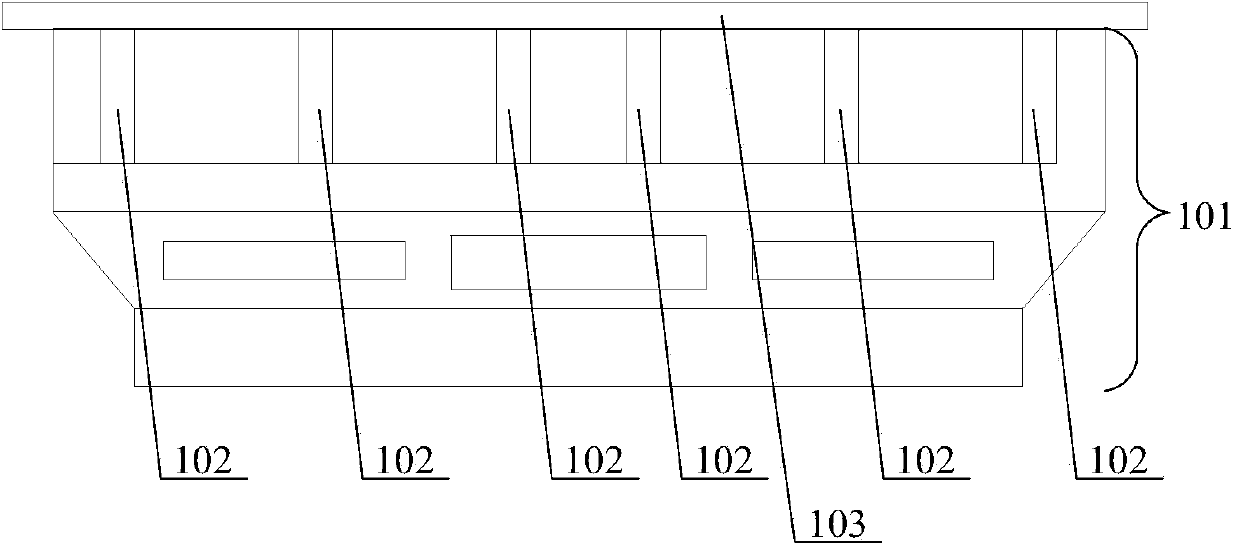

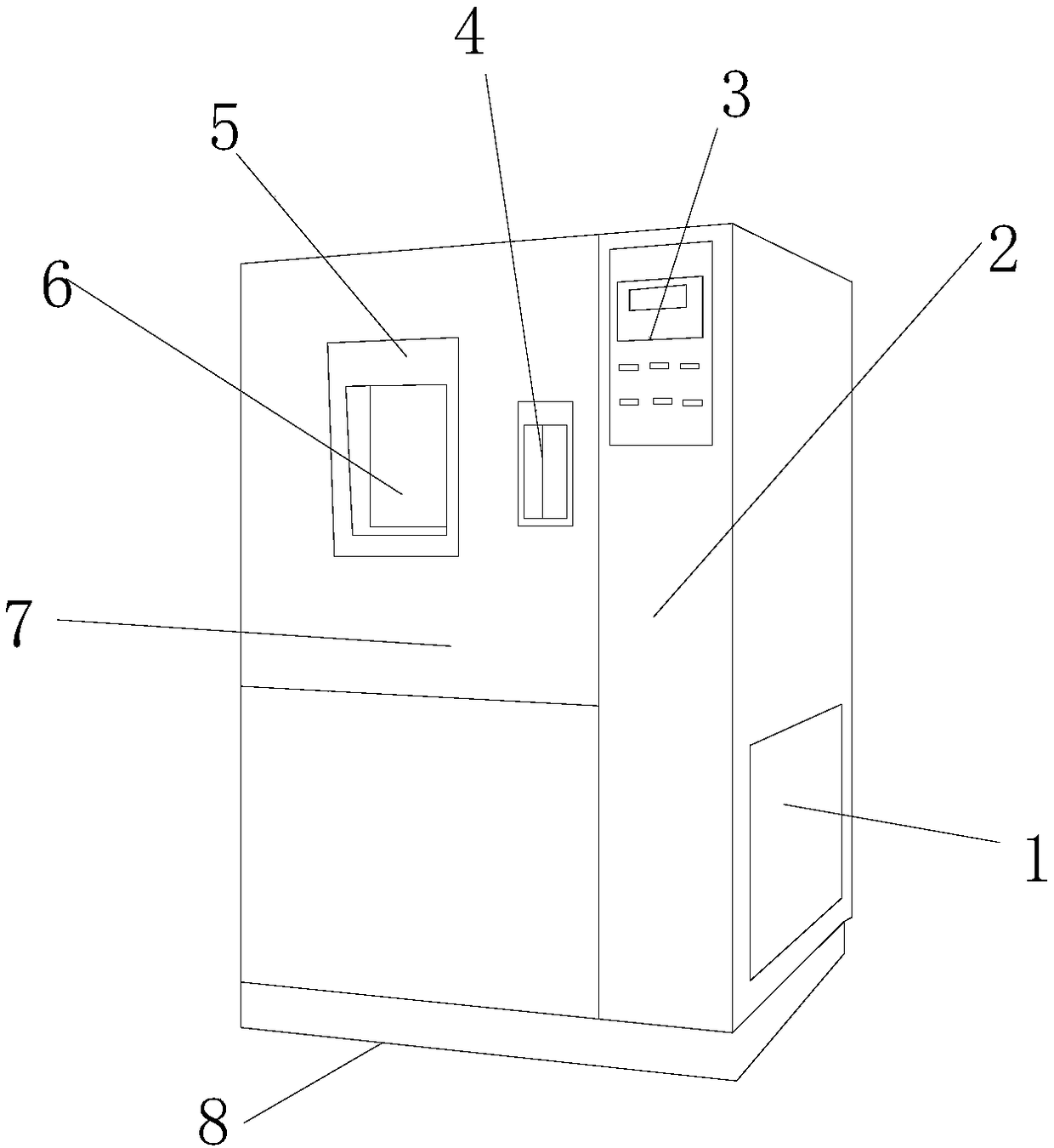

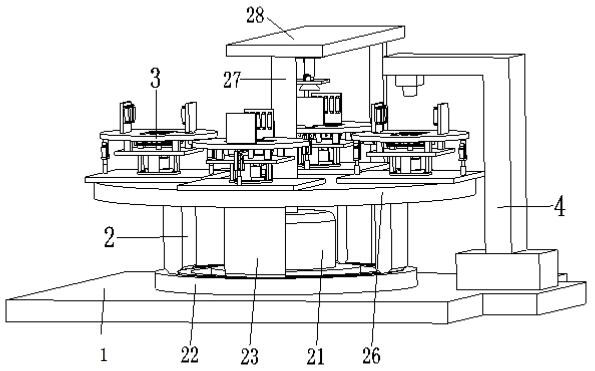

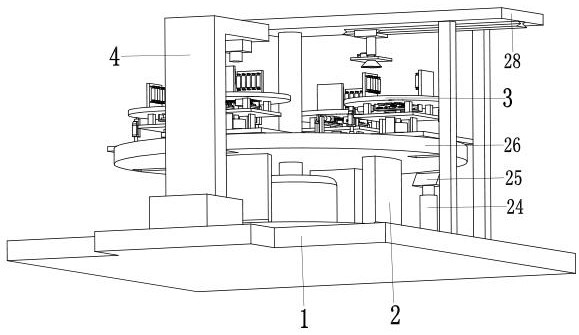

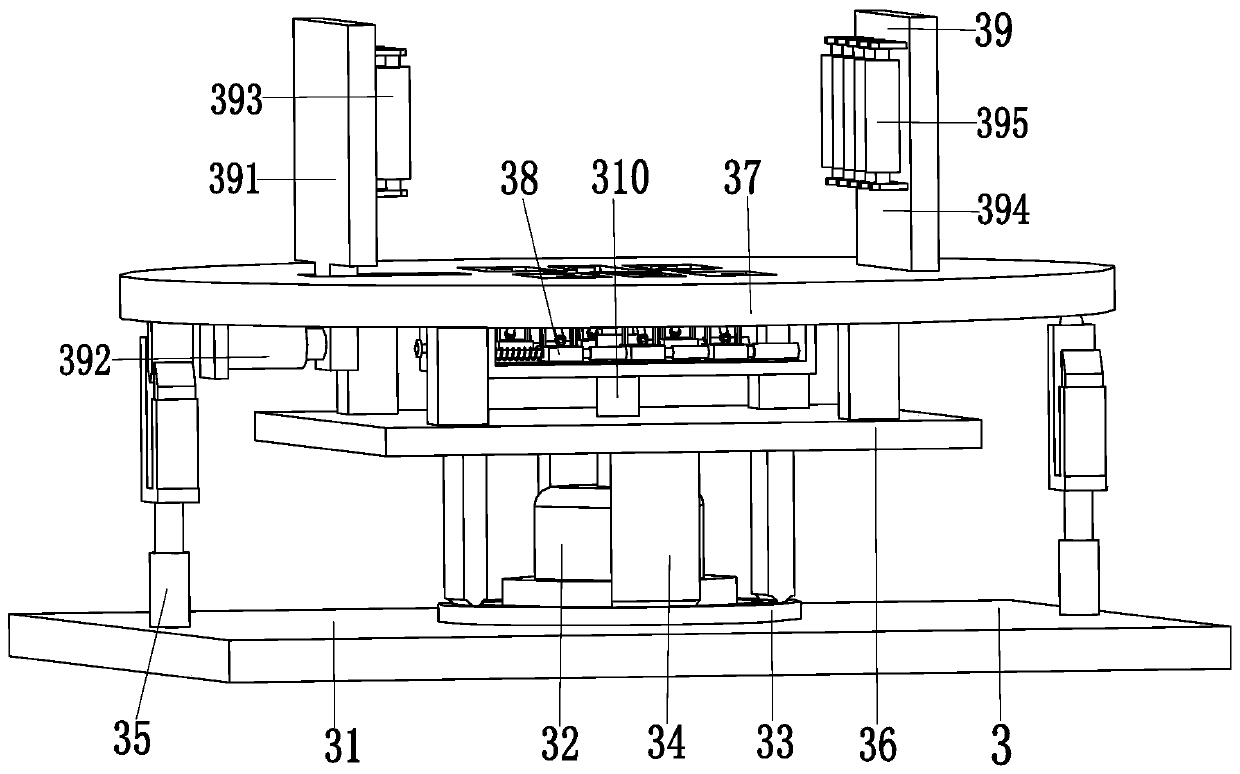

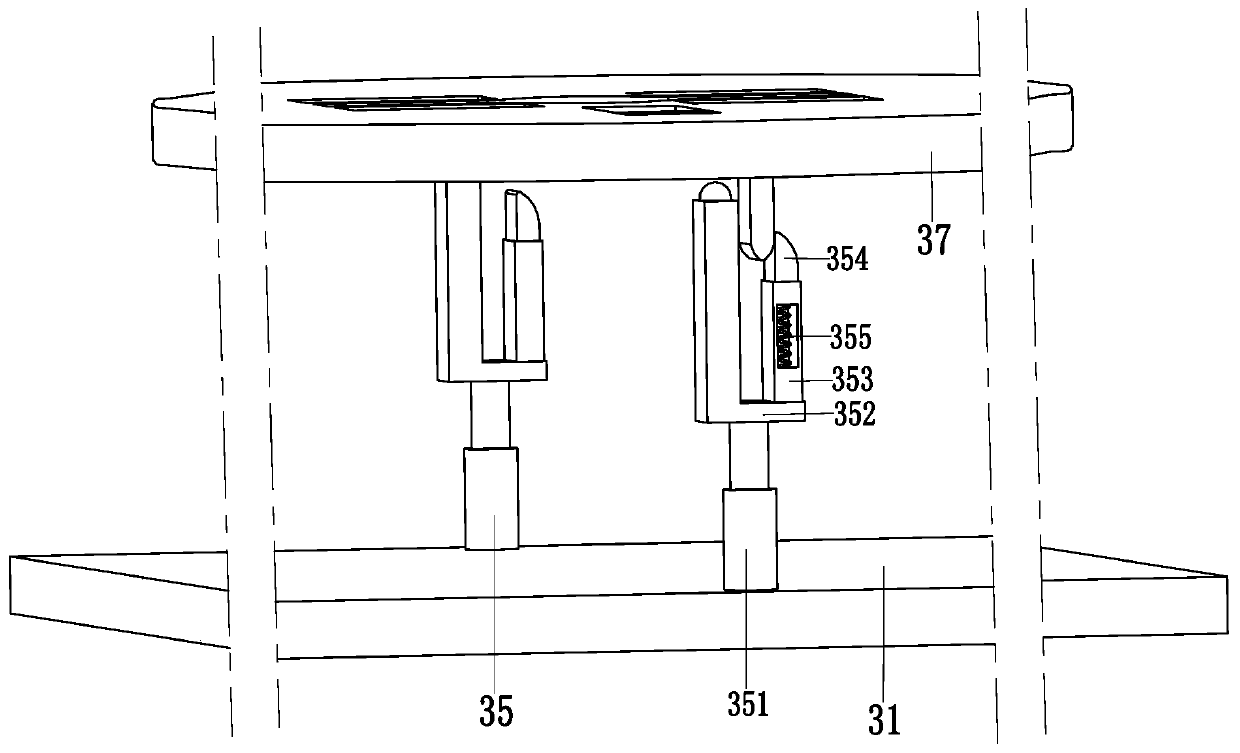

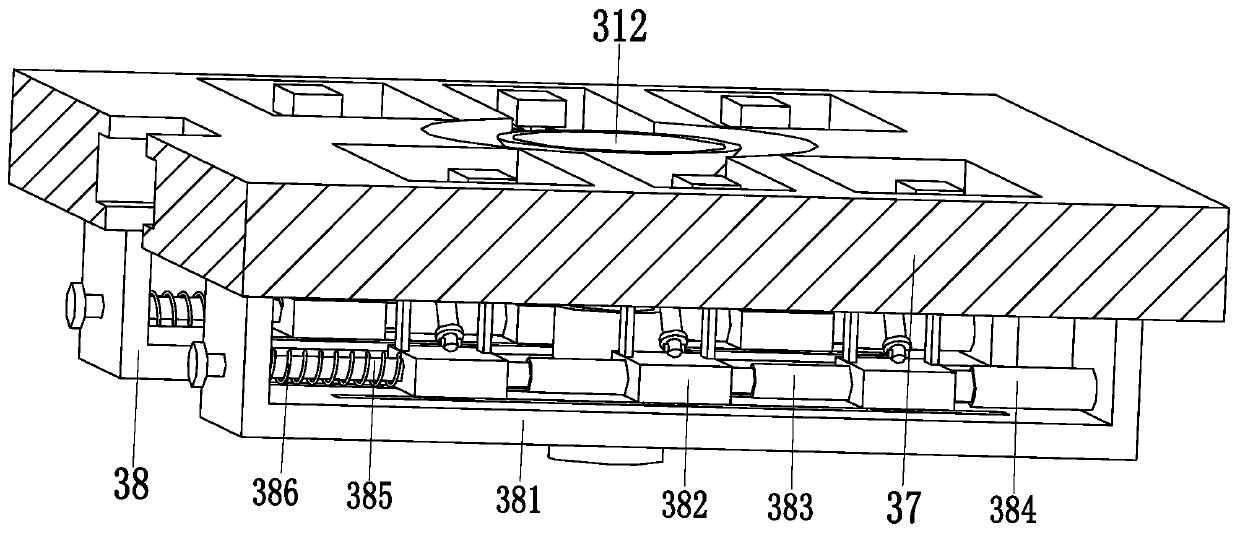

Intelligent sample collecting device

ActiveCN105752470ARisks Affecting Mass AccuracyHigh security for collection and transferLidsNon-removalbe lids/coversLocking mechanismEngineering

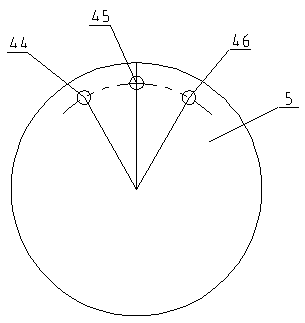

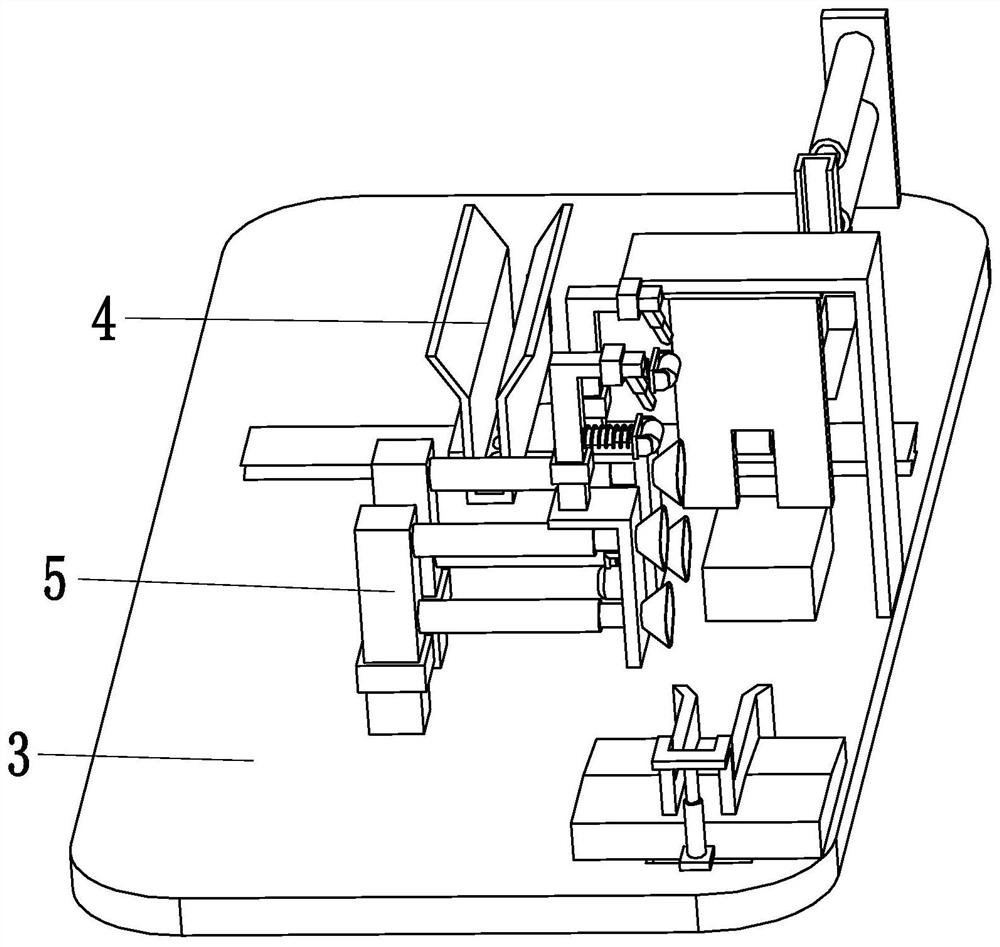

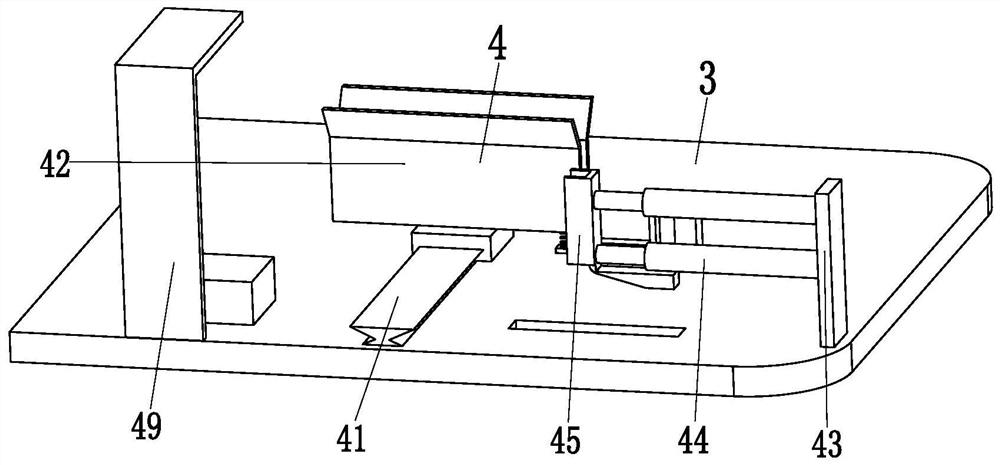

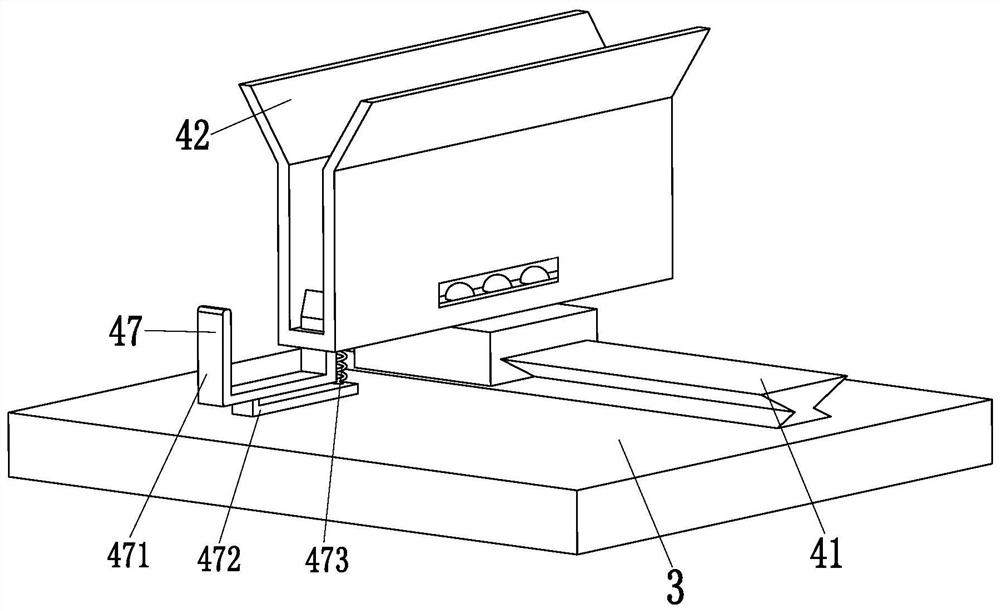

The invention discloses an intelligent sample collecting device which comprises a machine frame. The machine frame is provided with a feed inlet. A rotatable rotating disc mechanism and multiple sample storage barrels used for collecting samples are arranged in a collecting cavity formed by the machine frame. The sample storage barrels are hung on the rotating disc mechanism. Each sample storage barrel is provided with a hinged barrel cover and an induction locking mechanism used for locking the barrel cover. The hinged position of the barrel cover is provided with an elastic part so that the barrel cover can bounce upwards to be opened when not locked. The feed inlet is provided with a liftable weighing mechanism. The weighing mechanism is provided with an induction unlocking assembly matched with the induction locking mechanism. When the rotating disc mechanism drives the sample storage barrels to rotate to the position below the feed inlet, the weighing mechanism raises to lift up the sample storage barrels, so that the induction locking mechanism induces an unlocking signal of the induction unlocking assembly to open the barrel covers for sample connection and weighing operation. The intelligent sample collecting device has the advantages that the structure is simple and compact, the intelligence degree is high, sample collection and transfer safety is high, sample collection quality precision is high, working efficiency is high, and the production cost is low.

Owner:HUNAN SUNDY SCI & TECH DEV

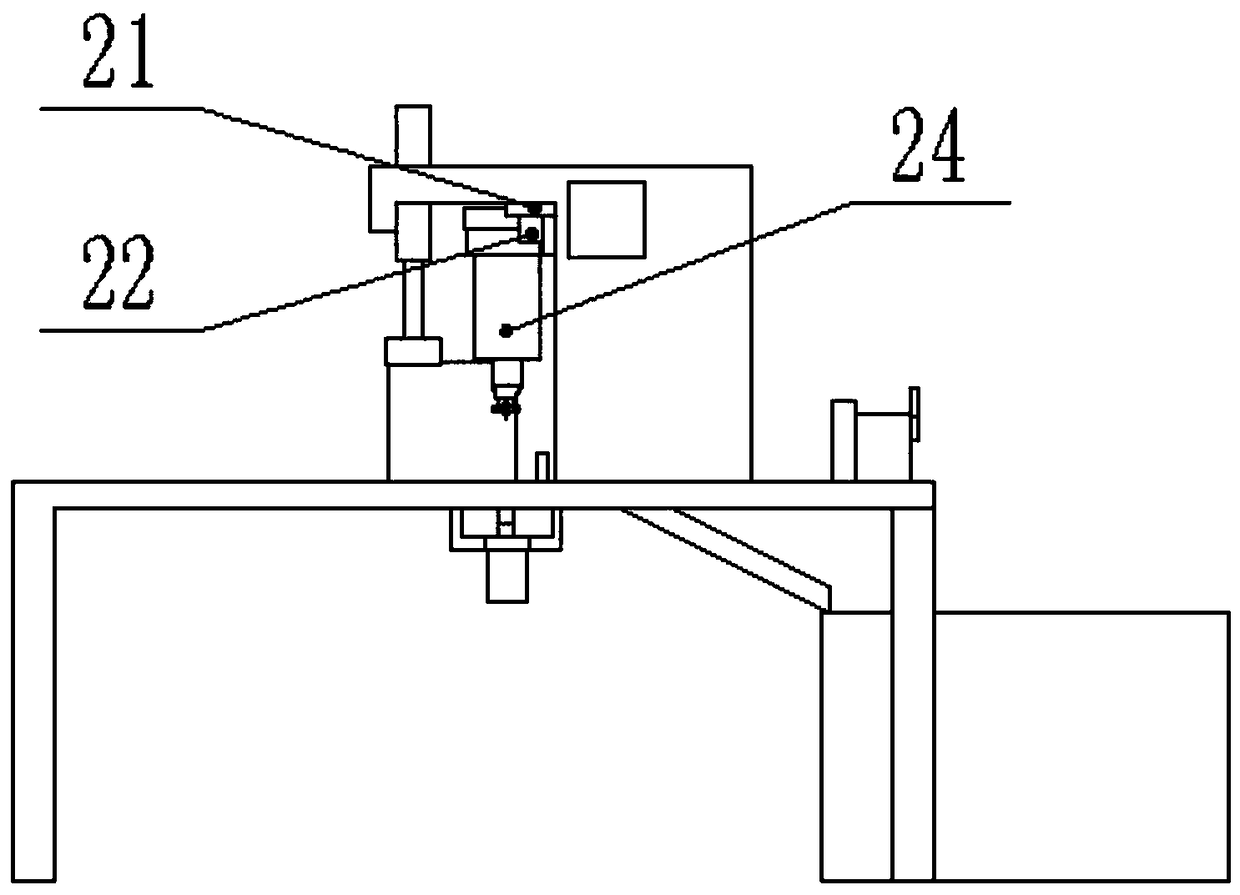

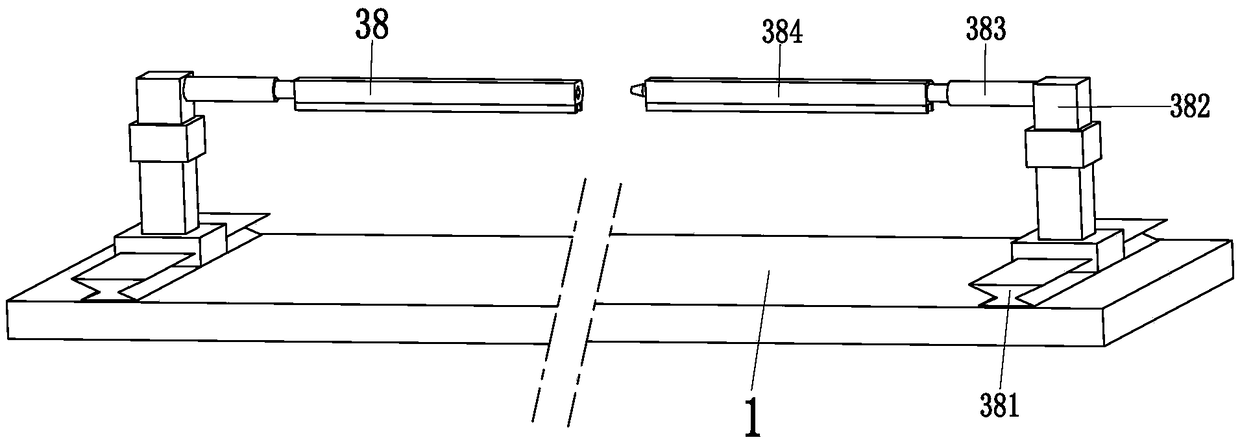

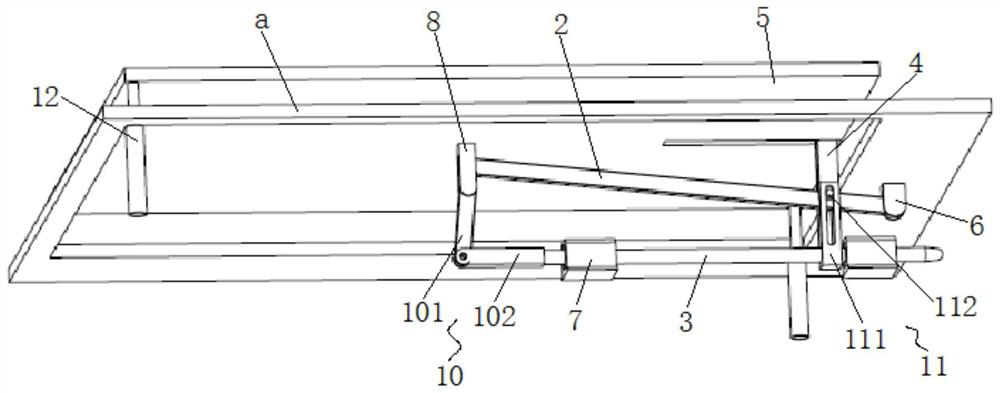

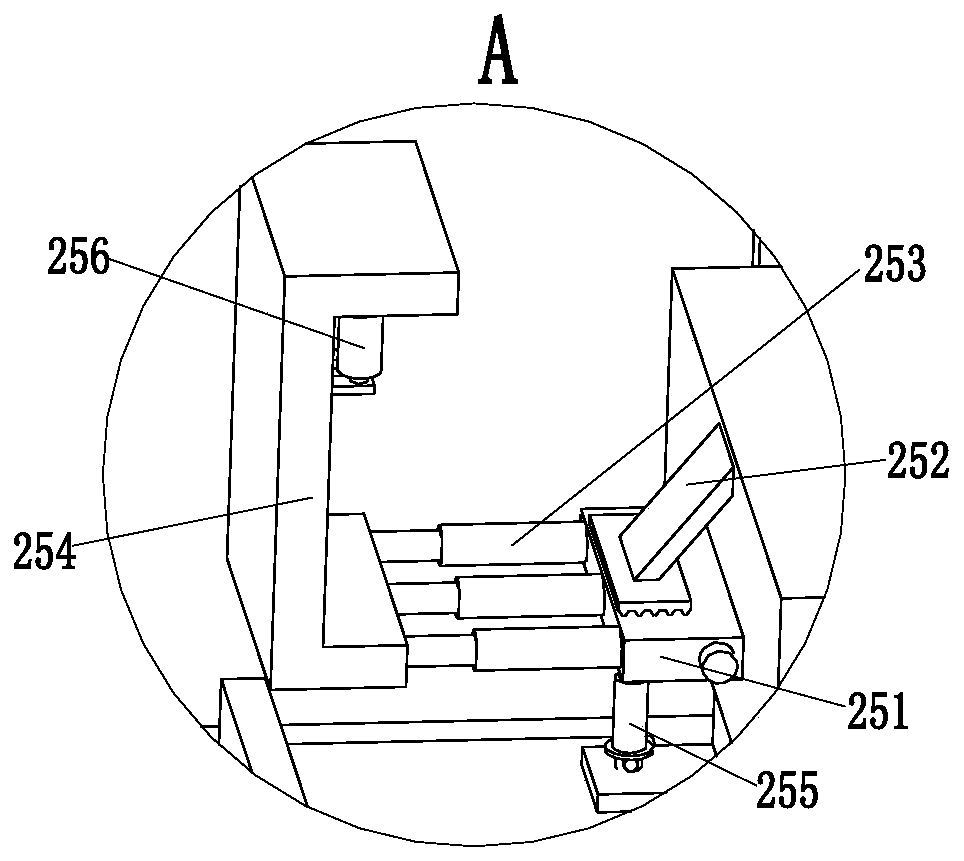

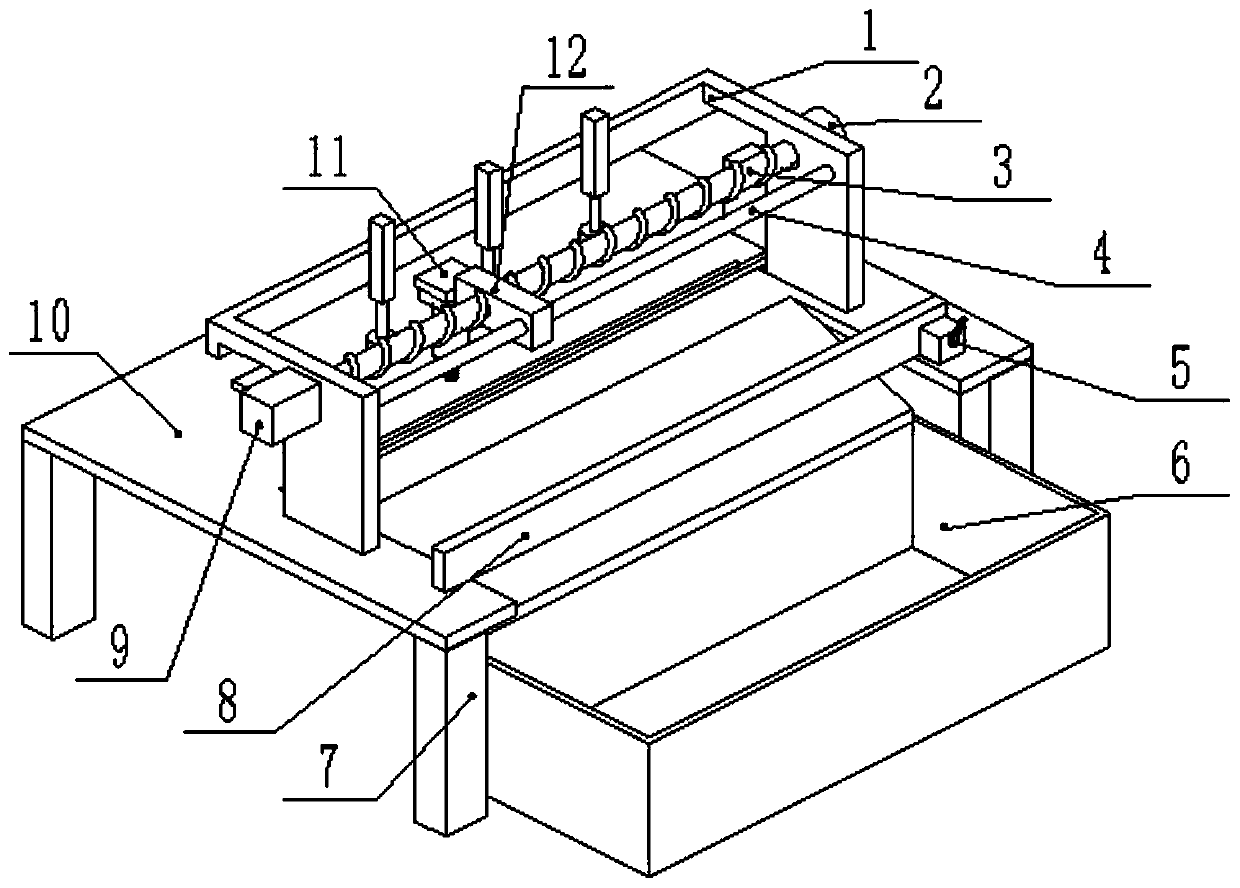

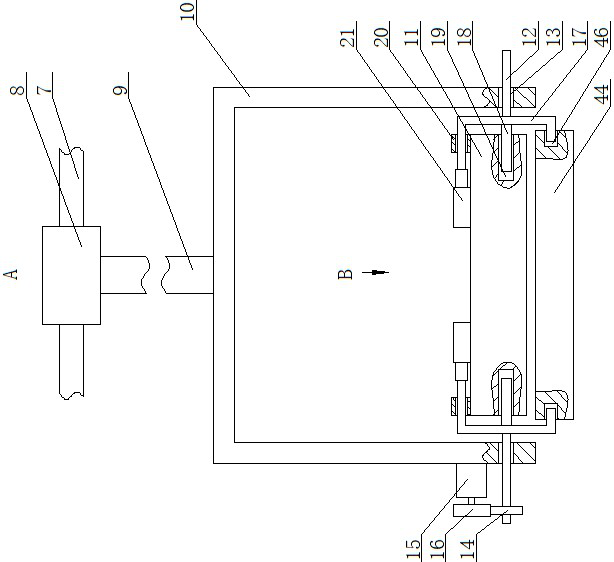

Ceramic tile cutting-off device for architectural engineering

ActiveCN108214946ADisplacement does not occurSo as not to damageWorking accessoriesStone-like material working toolsUltrasonic sensorEngineering

The invention discloses a ceramic tile cutting-off device for architectural engineering, and belongs to the field of architectural engineering equipment. A coder is fixed to one end of a lead screw; the lead screw is installed on a first support; a feed rod is fixed to the front end of the lead screw; a magnetic base is fixed to a dimension location plate; a storage box is a rectangular iron box;a motor is fixed to one end of the first support, and the rotary shaft of the motor is connected with the lead screw; a second support is fixed to a lead screw nut; the lead screw nut is installed between the lead screw and the feed rod; a controller is installed at the left side of a workbench; an ultrasonic sensor is installed on an ultrasonic sensor base; a cutting-off device is fixed below theworkbench; and the cutting device is fixed to the second support. According to the ceramic tile cutting-off device for architectural engineering, hard glaze on the surface of ceramic tiles is cut open through the cutting device, and then the ceramic tiles are thoroughly cut off by the cutting-off device, so that the efficiency of ceramic tile cutting is greatly increased, the quality of the ceramic tile cutting is greatly improved, and the safety of workers is ensured.

Owner:中国机械工业第五建设有限公司

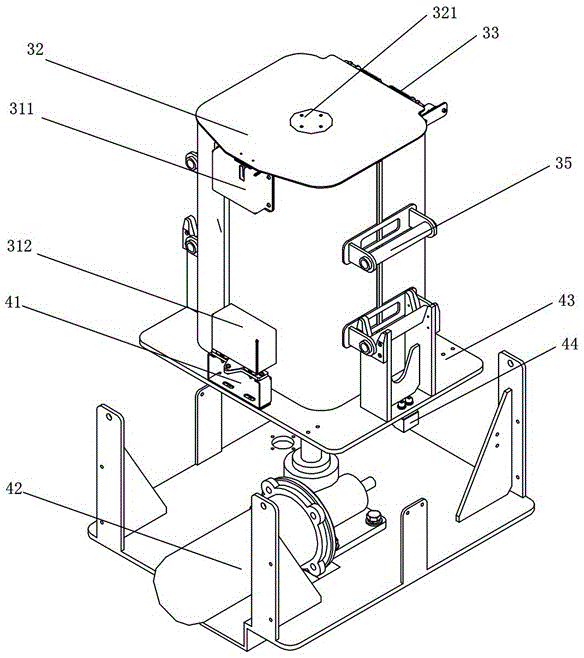

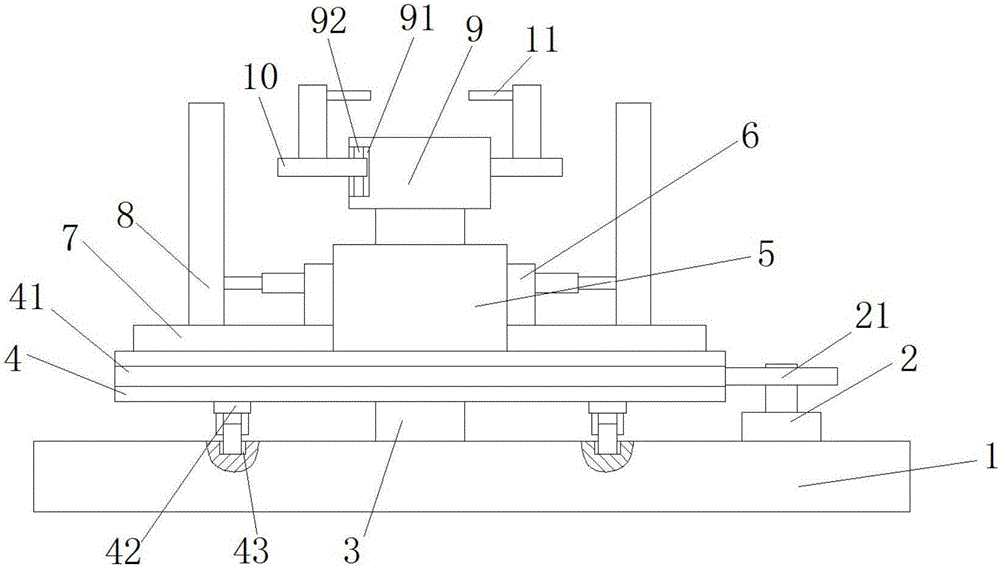

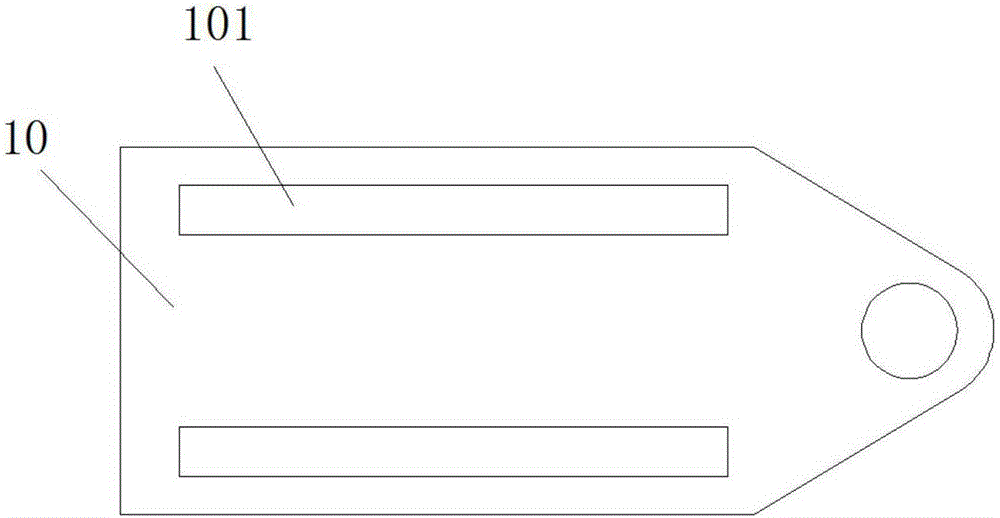

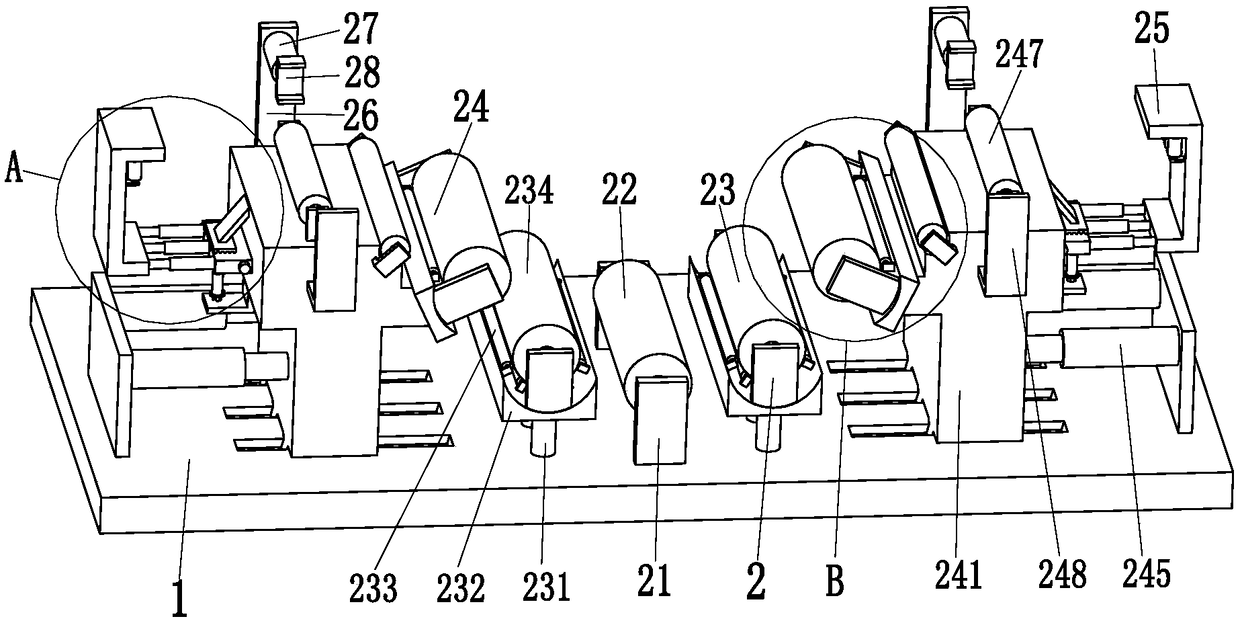

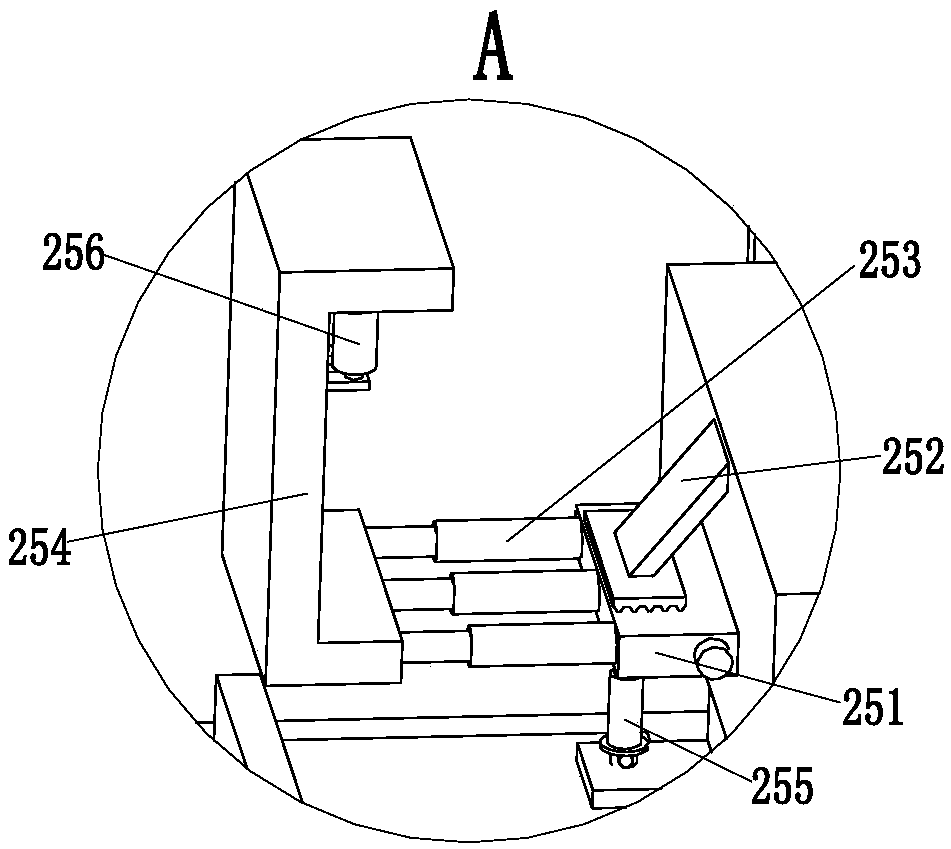

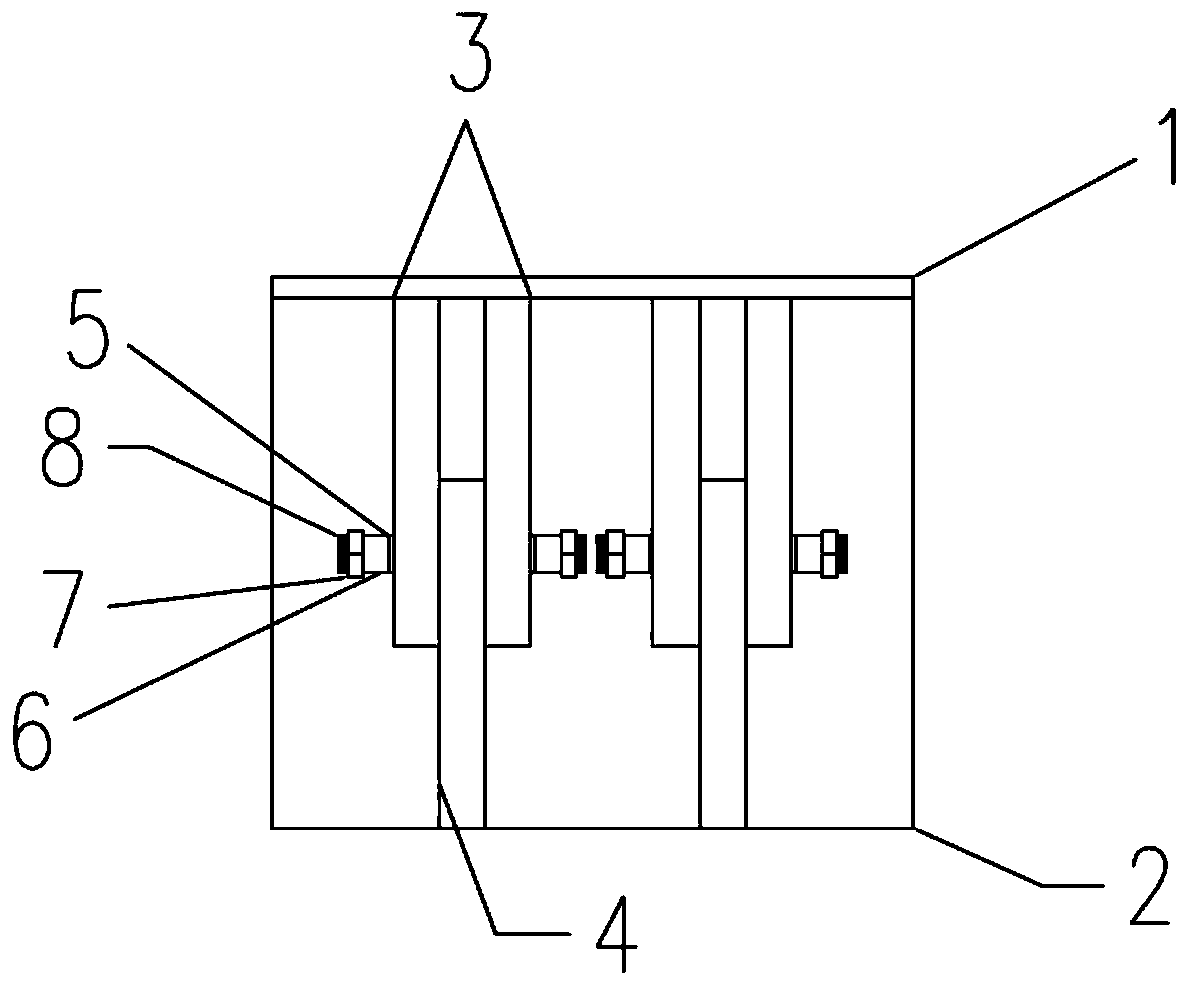

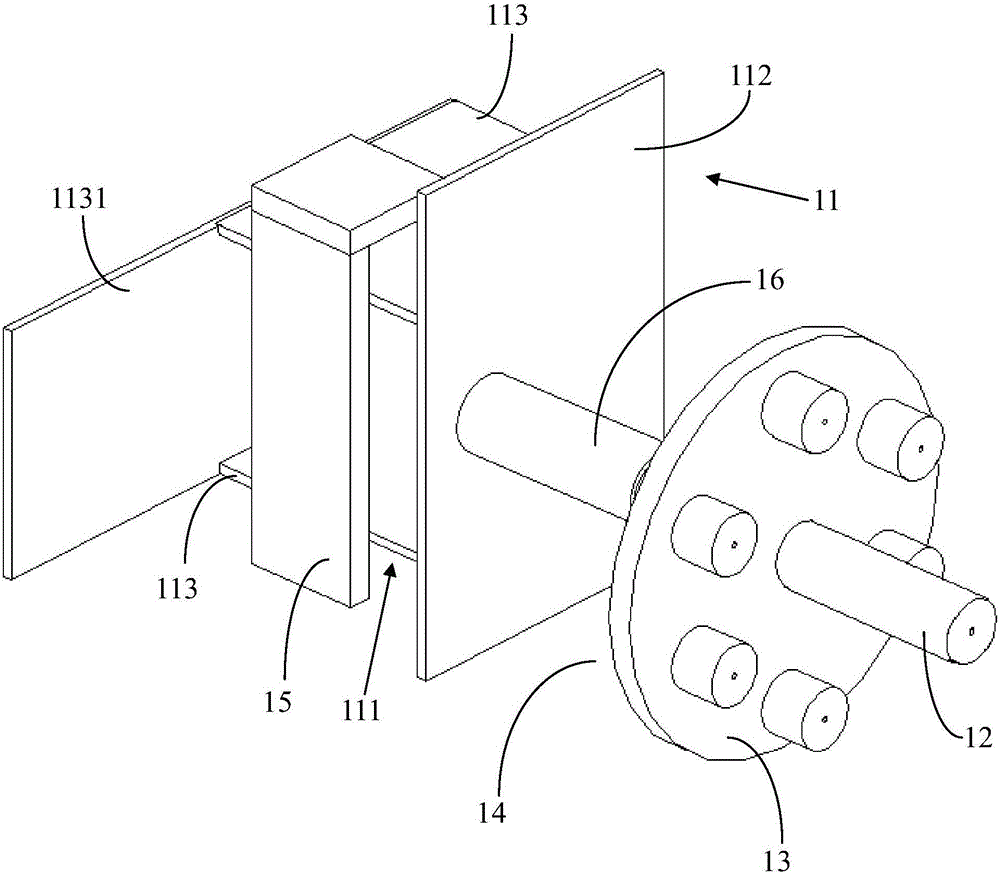

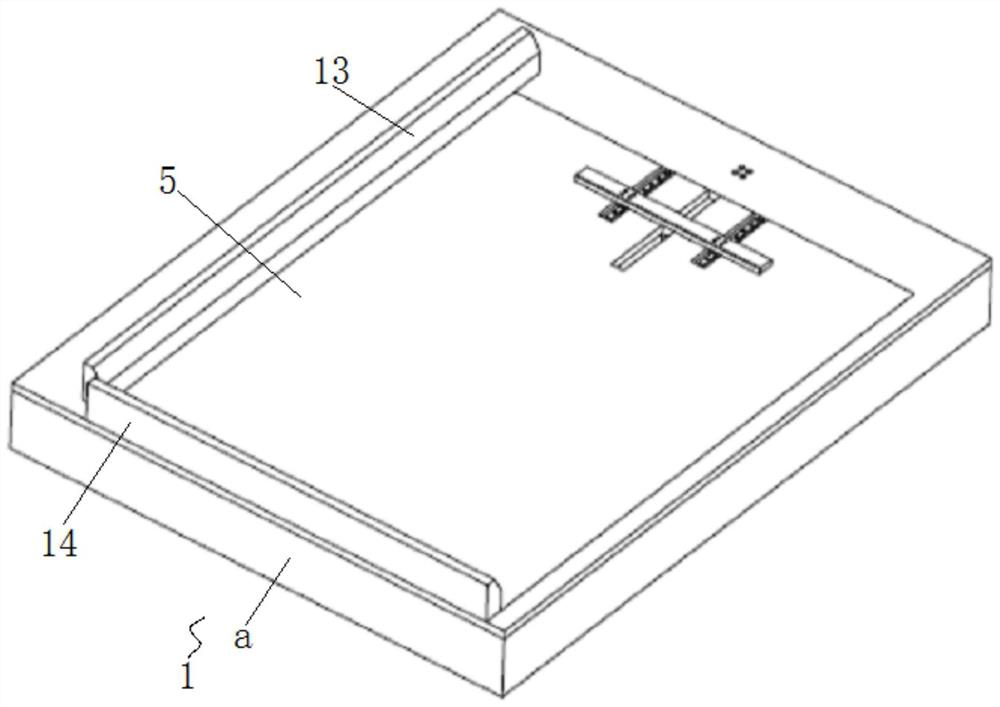

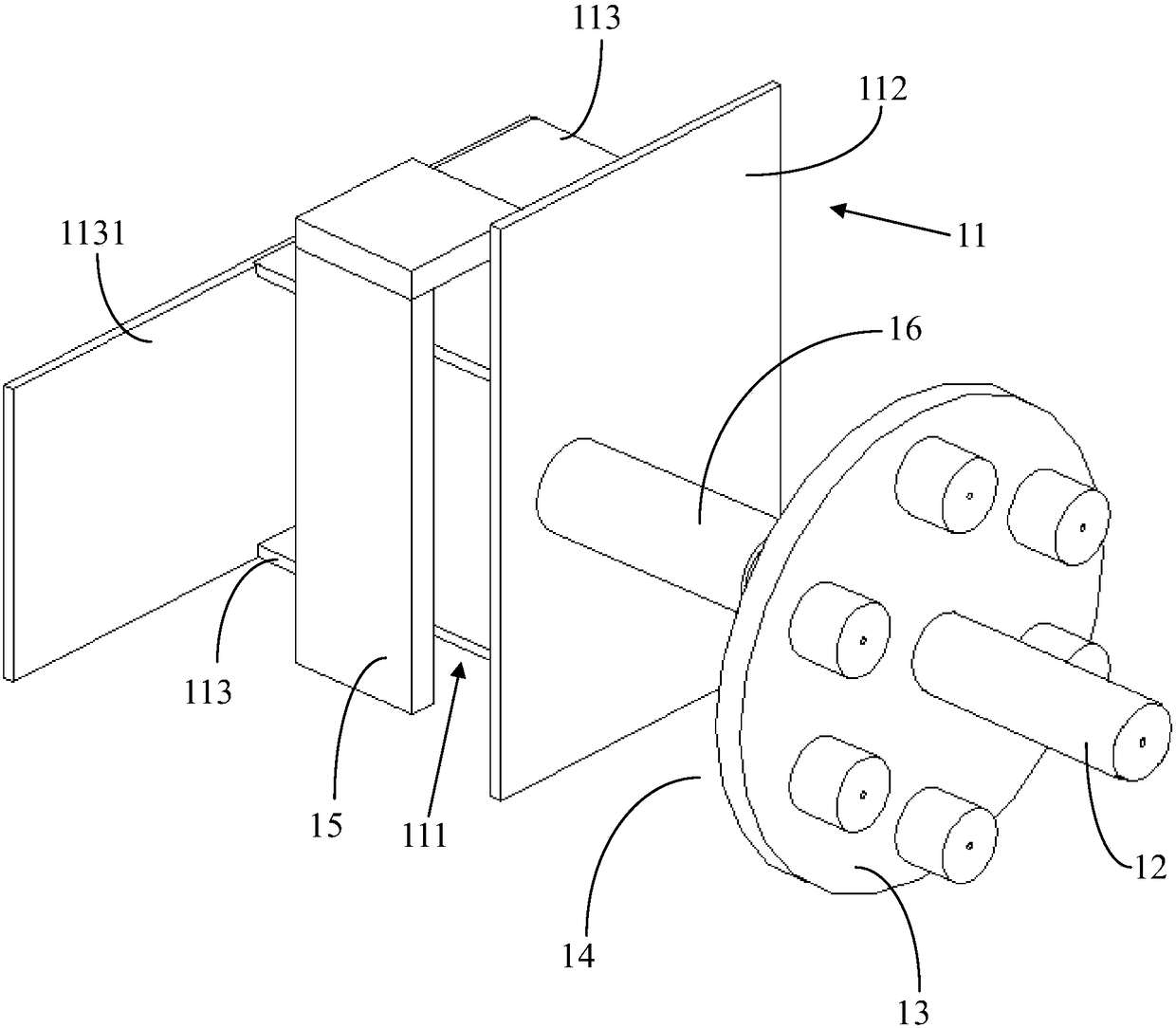

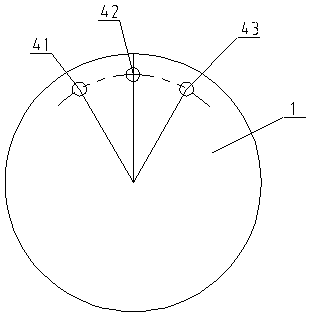

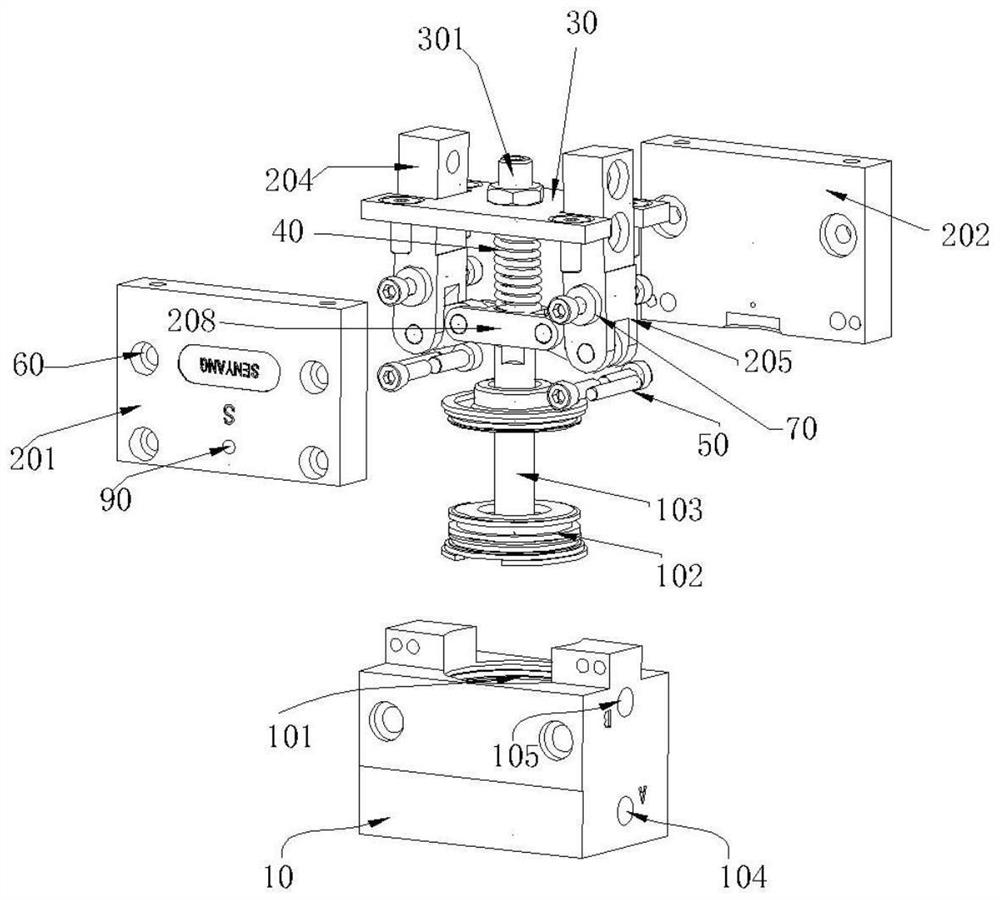

Production clamp for automobile wheel steel ring trimming

ActiveCN106825744AAvoid horizontal displacementDisplacement does not occurShearing machine accessoriesHydraulic cylinderPiston rod

The invention relates to the technical field of automobile wheel steel ring production clamps, in particular to a production clamp for automobile wheel steel ring trimming. The production clamp comprises a base, a stand column is arranged on the base, a rotating disc is mounted on the stand column through a bearing, a sleeve is mounted on the rotating disc, the sleeve and the stand column are coaxially arranged, a plurality of hydraulic cylinders are arranged on the outer wall of the sleeve, a linear guide rail is arranged between each hydraulic cylinder and the rotating disc, and connecting rods are arranged at the ends of the piston rods of the hydraulic cylinders, and are mounted in the linear guide rails in a sliding manner; a round bearing table is arranged at the end of the stand column, a plurality of first grooves are formed in the outer wall of the bearing table, rotating shafts are erected in the first grooves, the rotating shafts are sleeved with a connecting plate in clearance fit with the rotating shafts, two parallel sliding grooves are formed in the upper surface of the connecting plate, sliding rods are arranged in the sliding grooves in a sliding manner, the opposite inner side tops of the two sliding rods are rotatably connected with a baffle, and a bolt hole is formed in the end of the baffle. The production clamp can be applied to multiple automobile steel rings, and it is ensured that during automobile wheel steel ring machining, displacement is not generated, and errors are avoided.

Owner:大楚神驰车轮股份有限公司

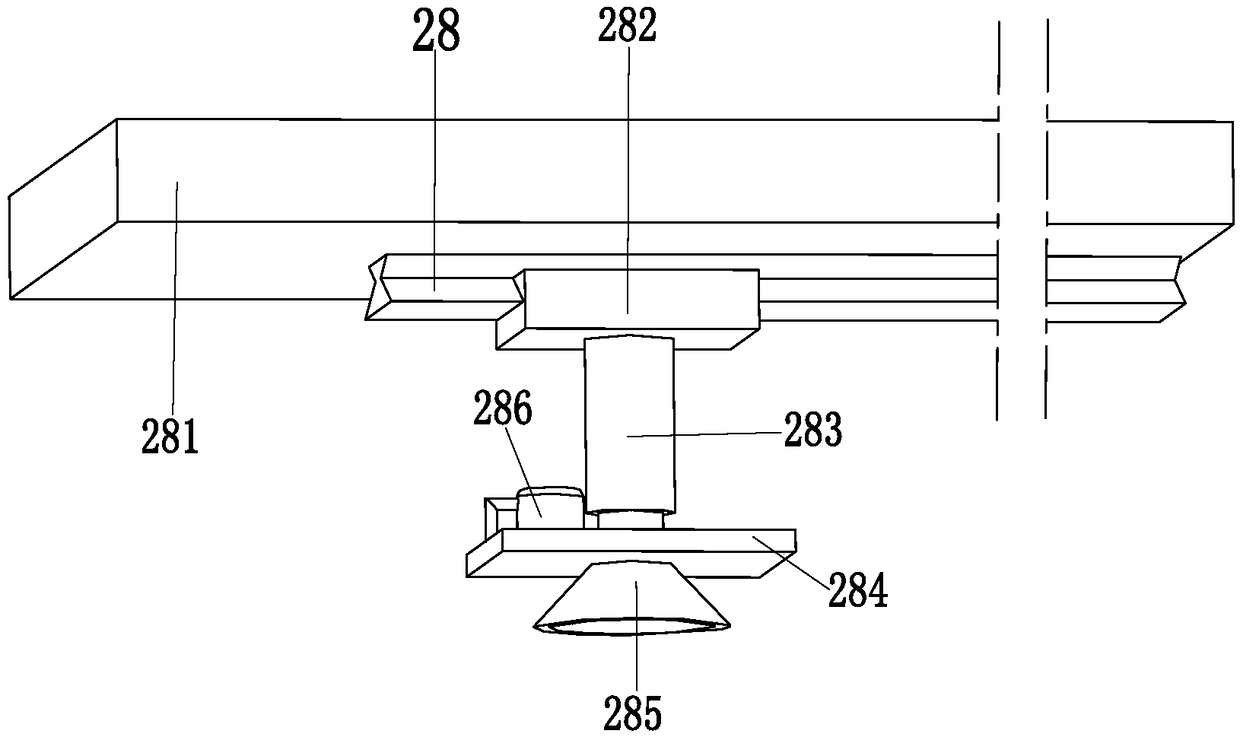

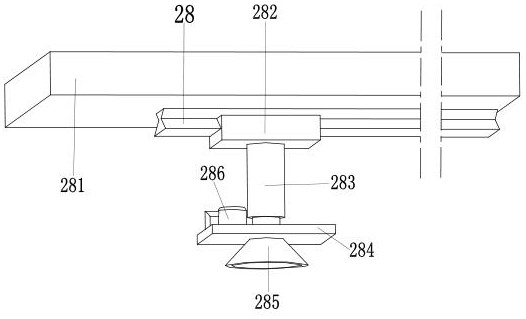

A soft-clad lithium battery aluminum plastic film packaging apparatus and an aluminum plastic film automatic packaging process

ActiveCN109103497AImprove the packaging effectDisplacement does not occurFinal product manufactureElectrolyte accumulators manufacturePlastic filmLithium battery

The invention relates to a soft-clad lithium battery aluminum-plastic film packaging apparatus and an aluminum-plastic film automatic packaging process, the apparatus comprises a support bottom plate,a placing frame, a suction device and a leveling device, wherein the upper end surface of the middle part of the support bottom plate is provided with a placing frame, the right end rear side of theplacing frame is provided with a square groove, the suction device is installed on the top of the outer end of the support bottom plate, and the leveling device is installed on the top of the left endof the placing frame. The suction device comprises a suction top plate, a suction pillar, a suction electric slide block, a suction linkage plate, a suction rotating plate, a suction adjusting push rod, a suction mechanism and a pressure-resisting branch chain. The invention can solve the problems that the aluminum plastic film of the external packaging of the soft-clad lithium battery in the prior art needs to be folded manually when the aluminum plastic film is folded, the rotational point of the aluminum plastic film can be displaced when the aluminum plastic film is folded, the raised part of the aluminum plastic film cannot be straightened when the aluminum plastic film is folded, and the position deviation of the left and right ends of the aluminum plastic film exists when the aluminum plastic film is packed.

Owner:至信搏远新材料科技有限公司

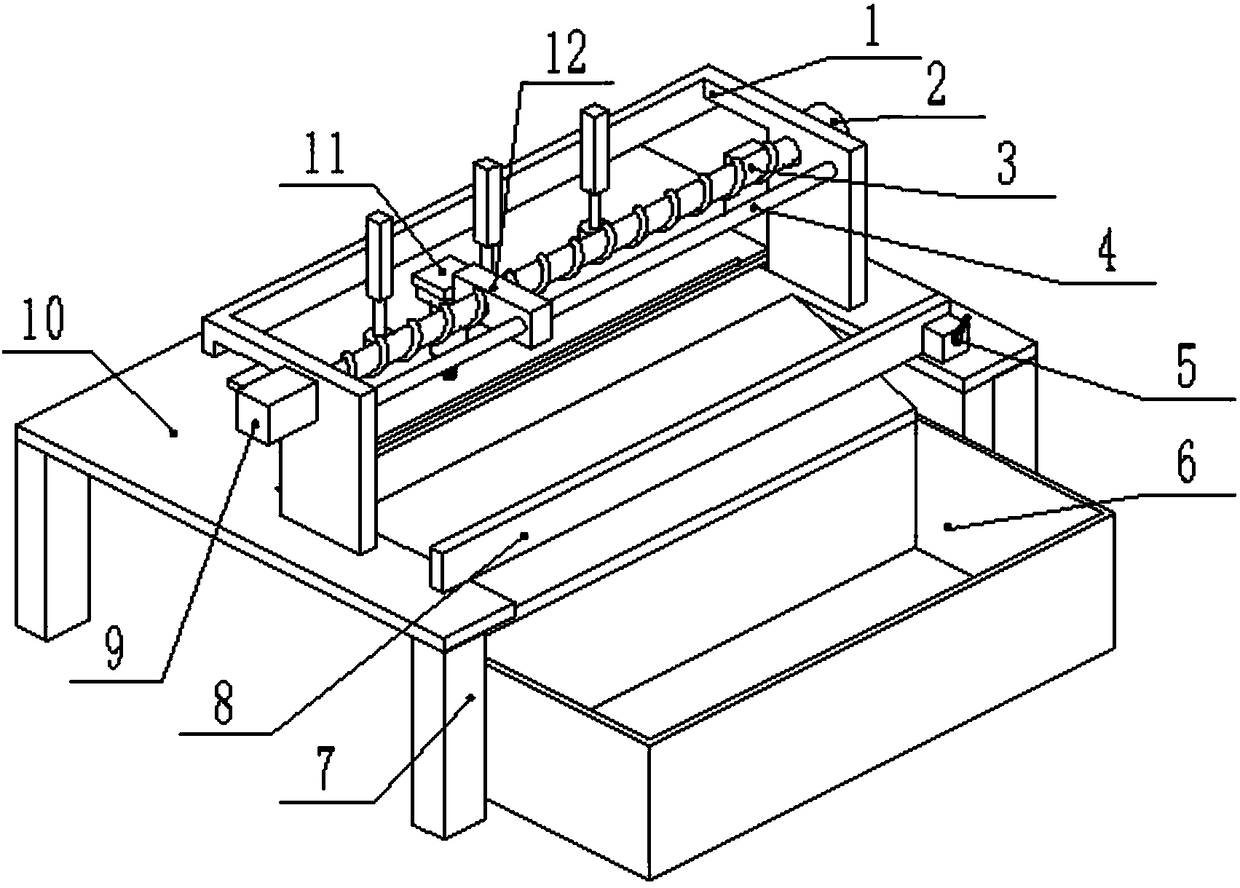

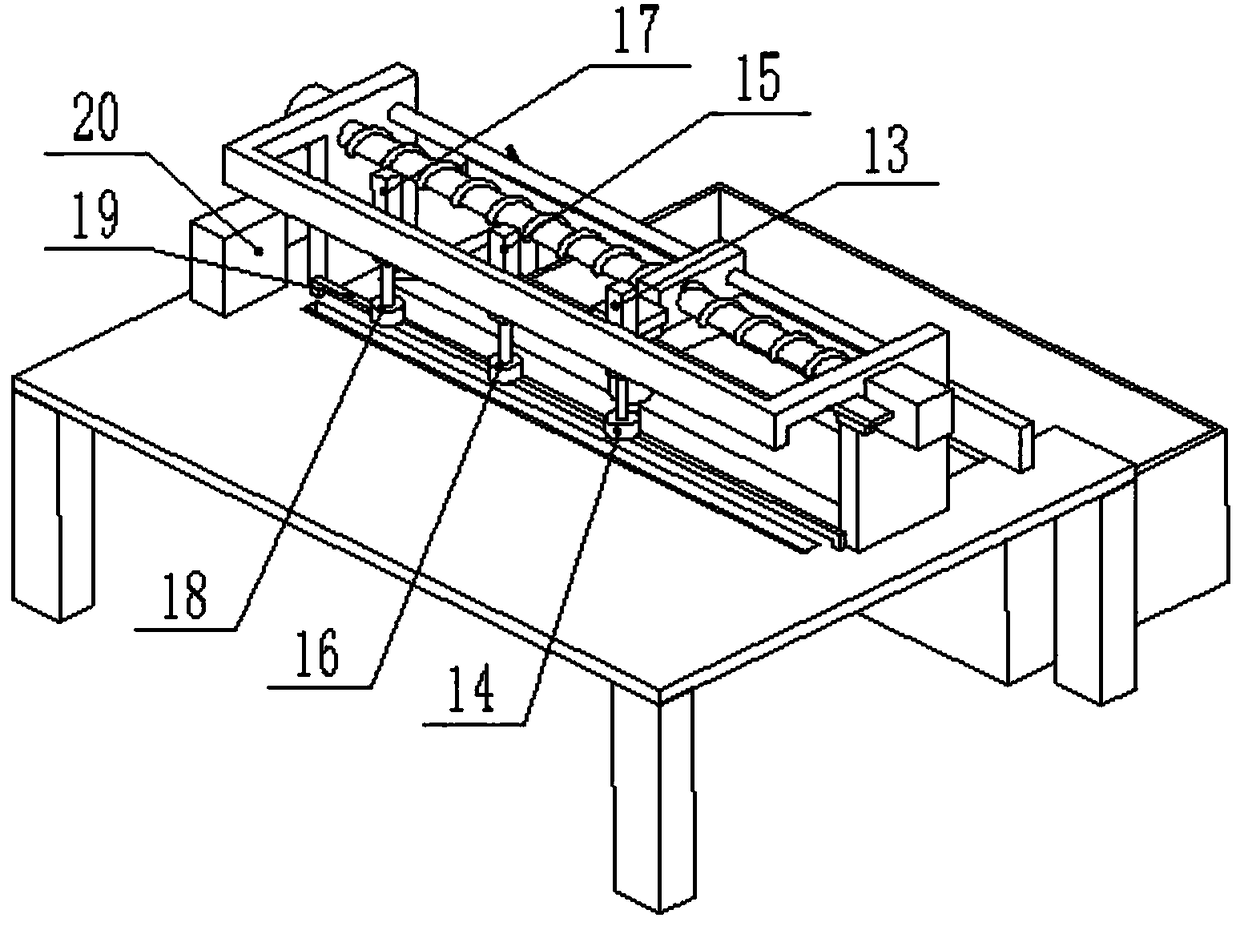

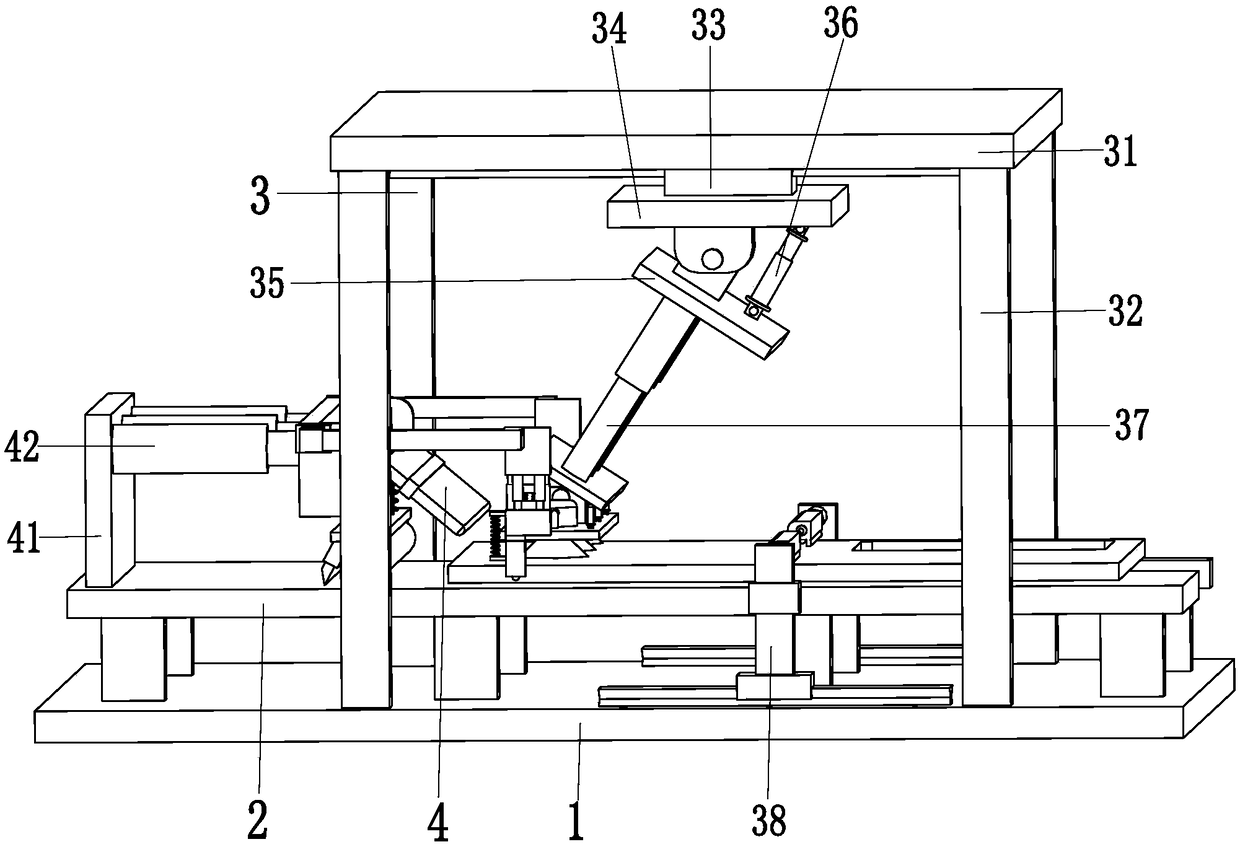

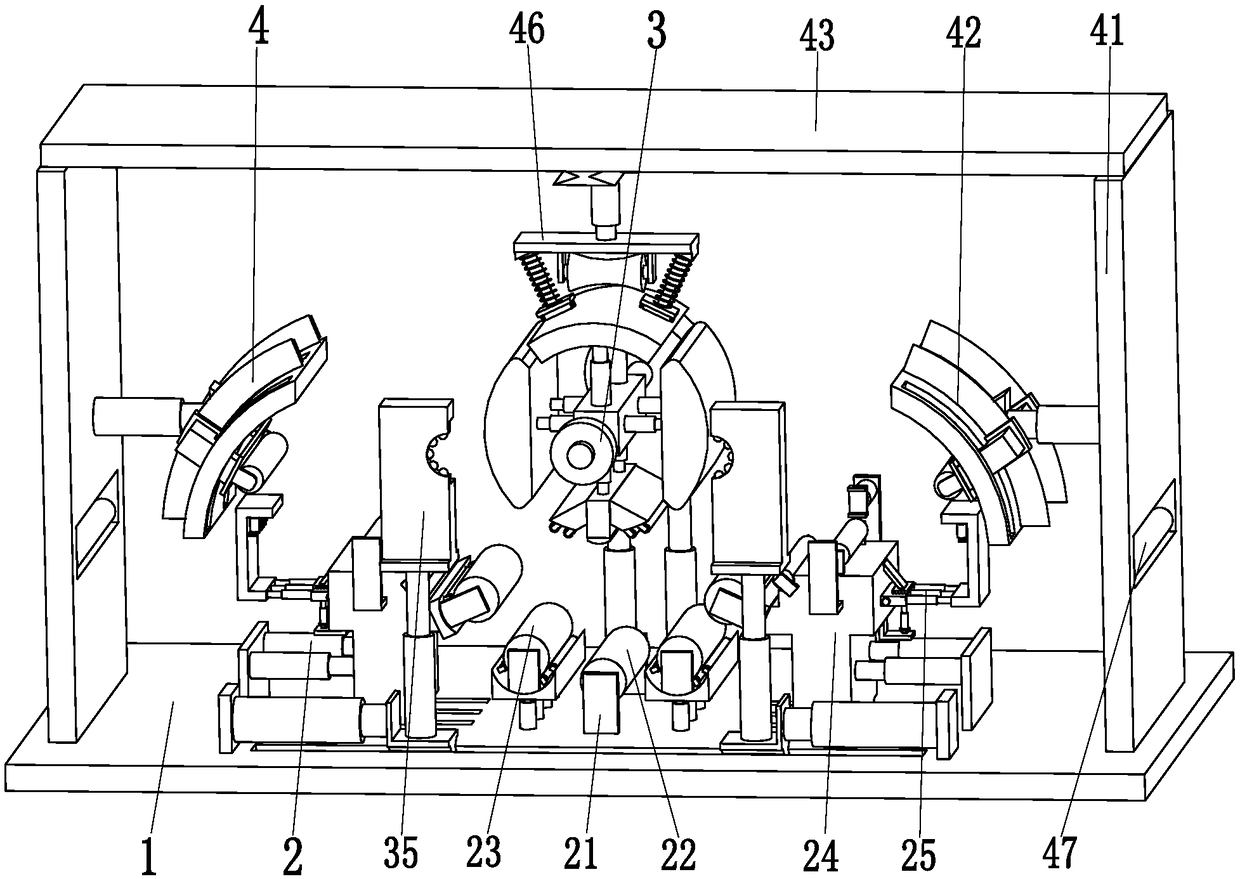

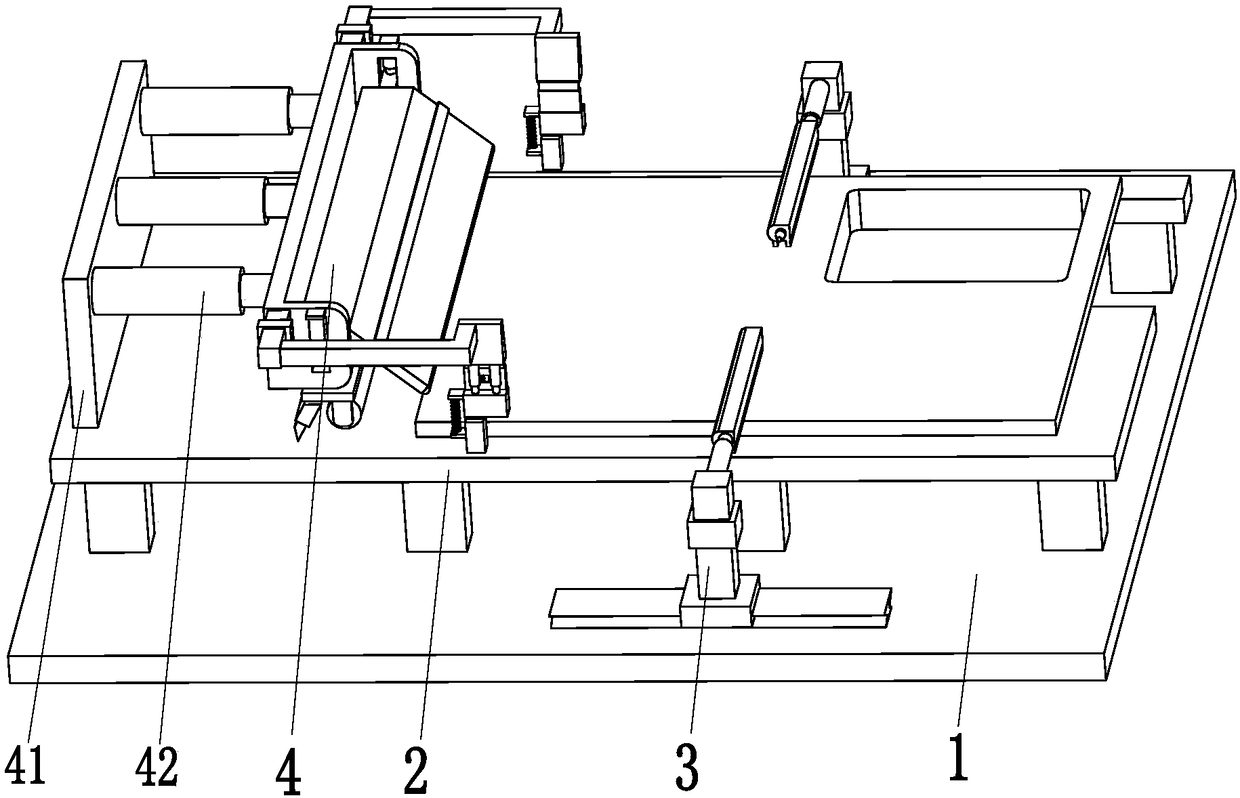

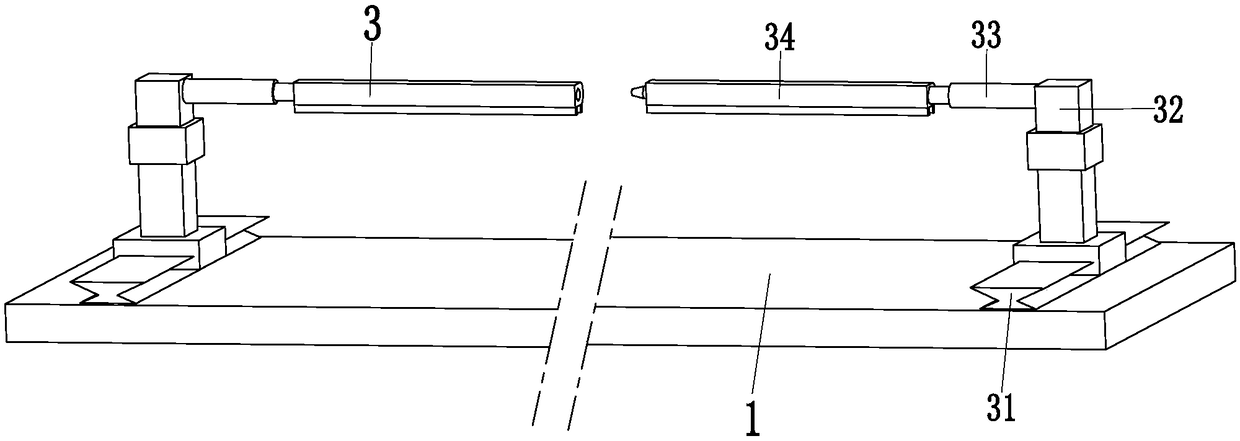

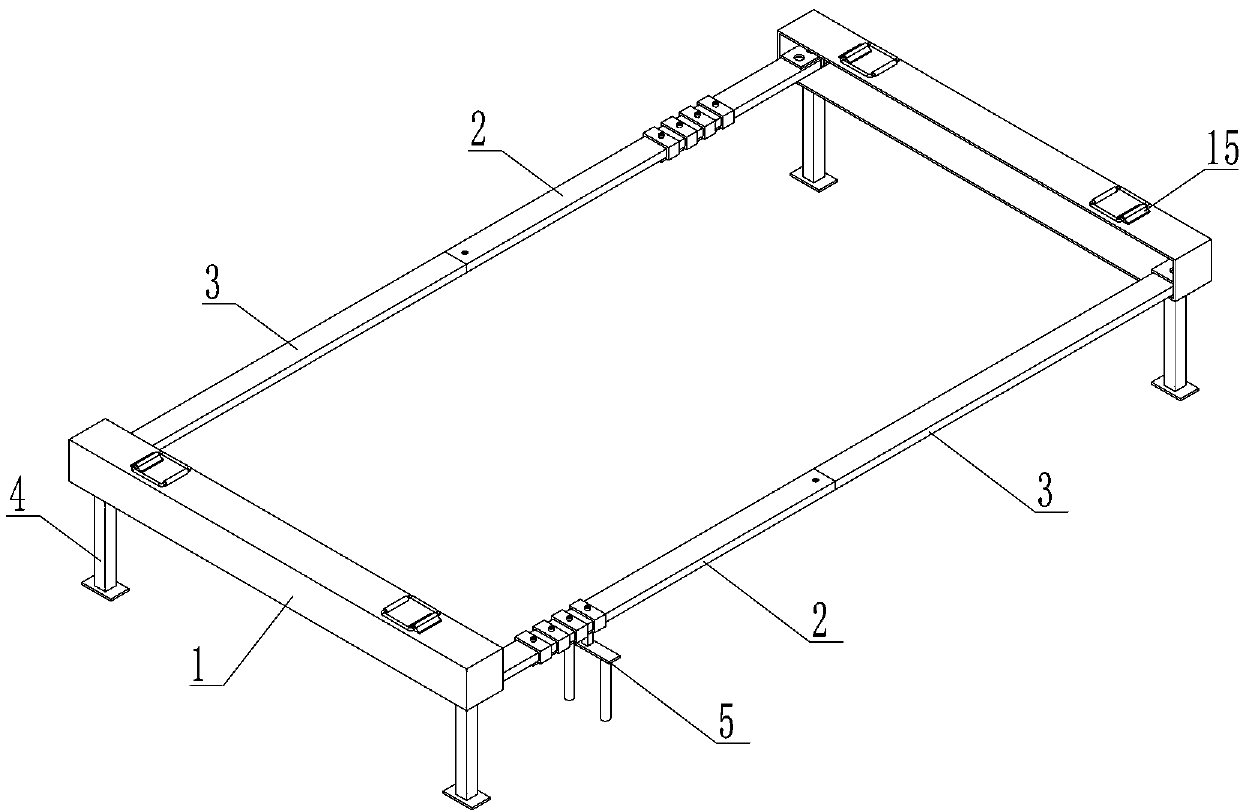

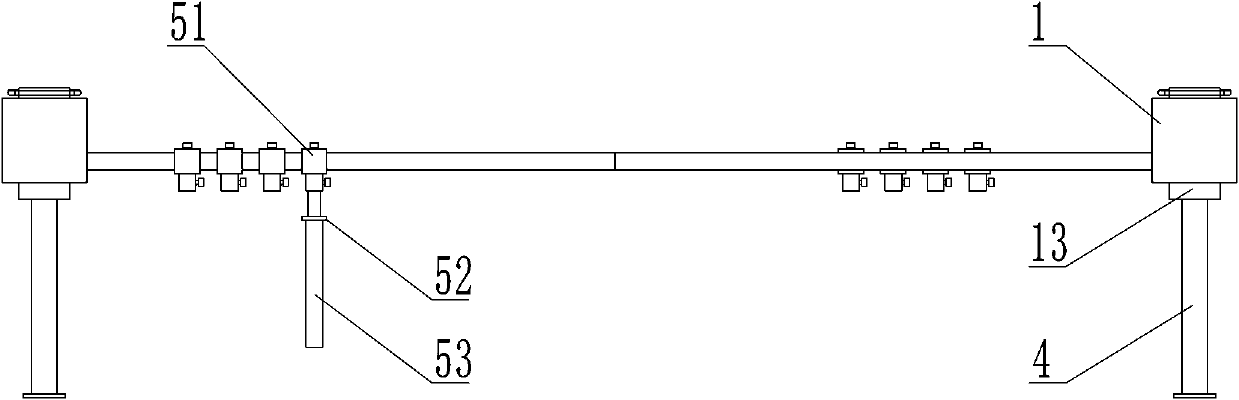

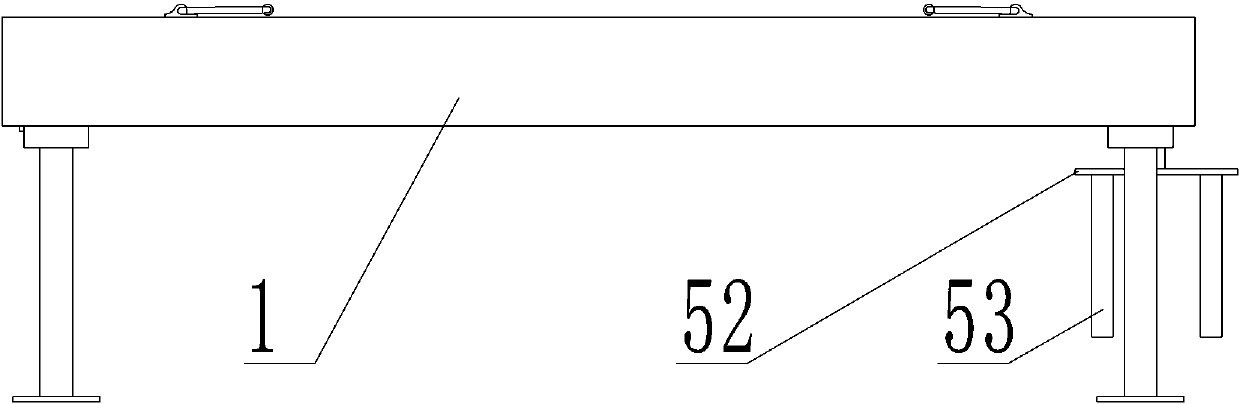

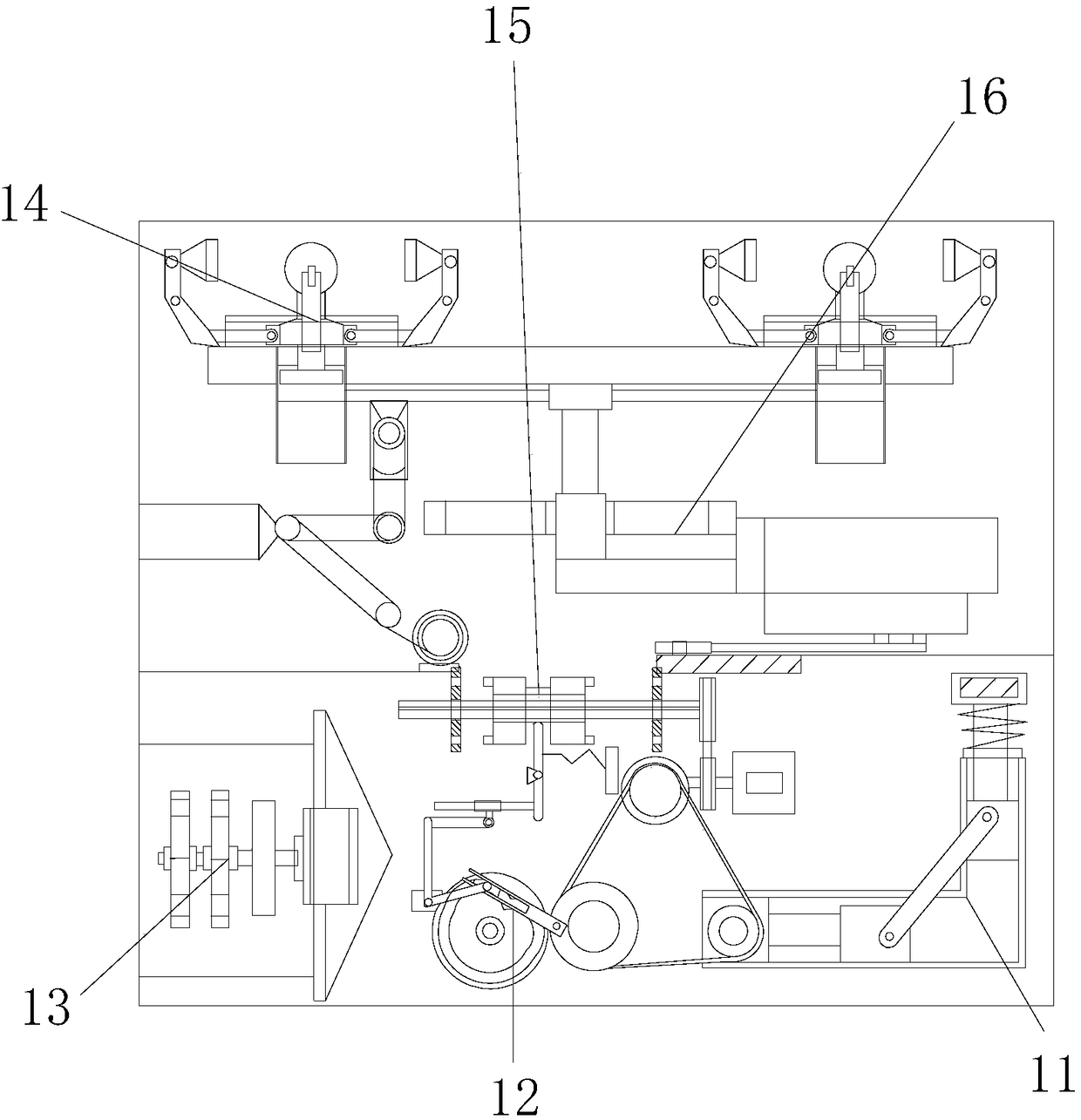

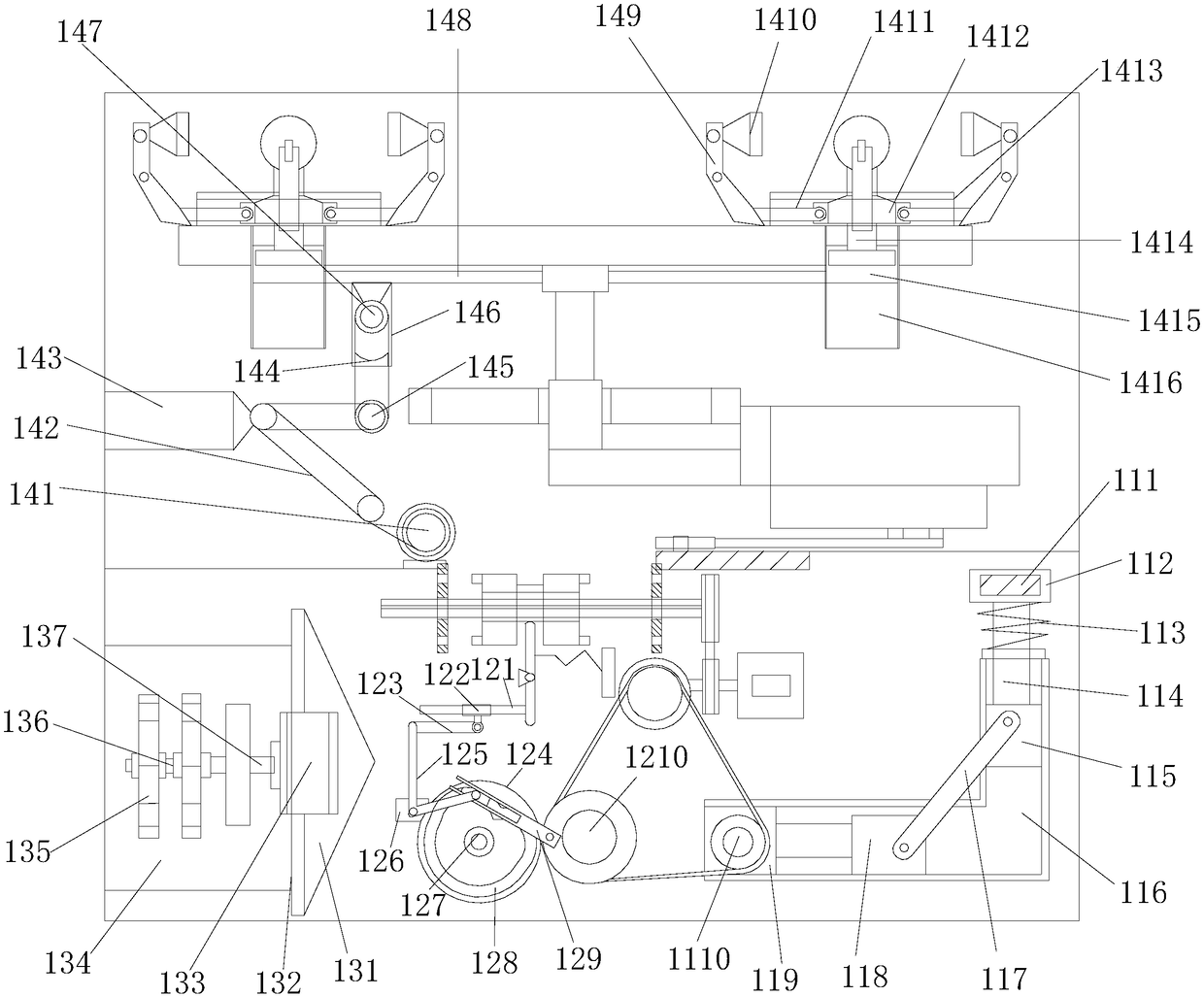

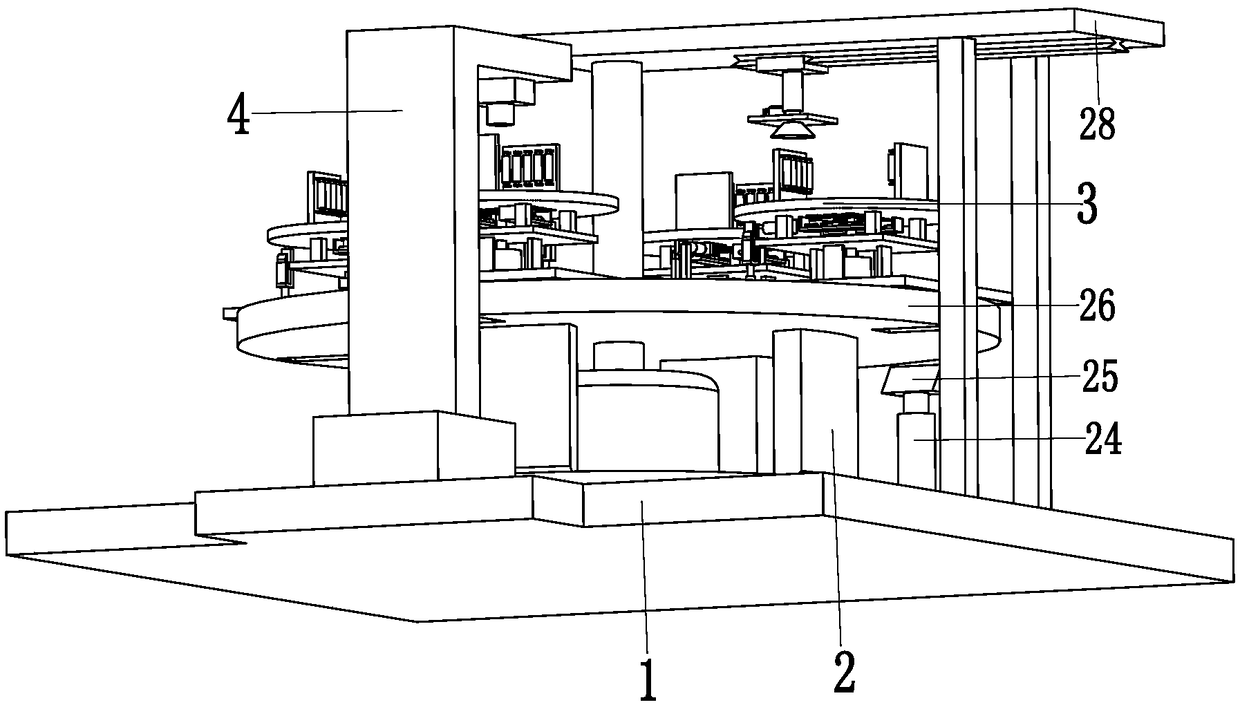

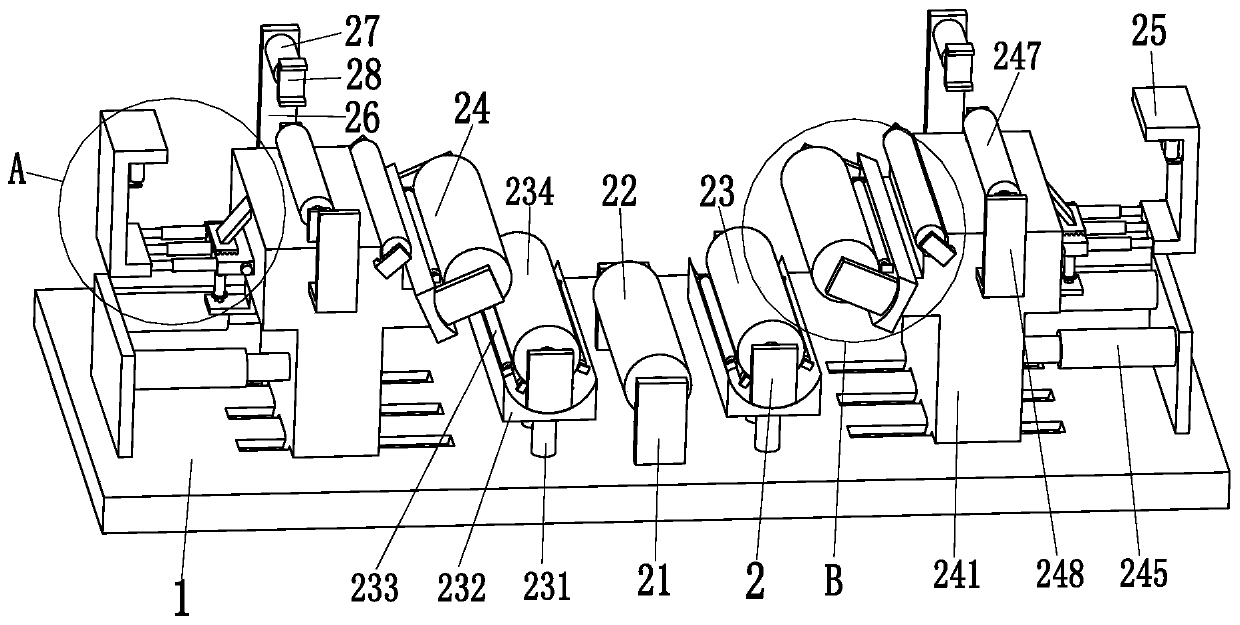

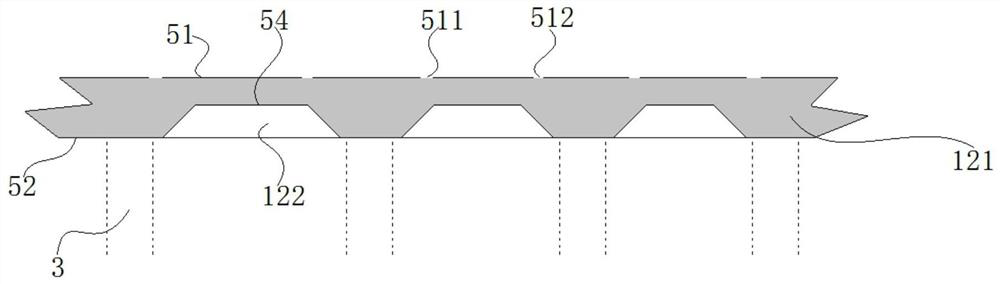

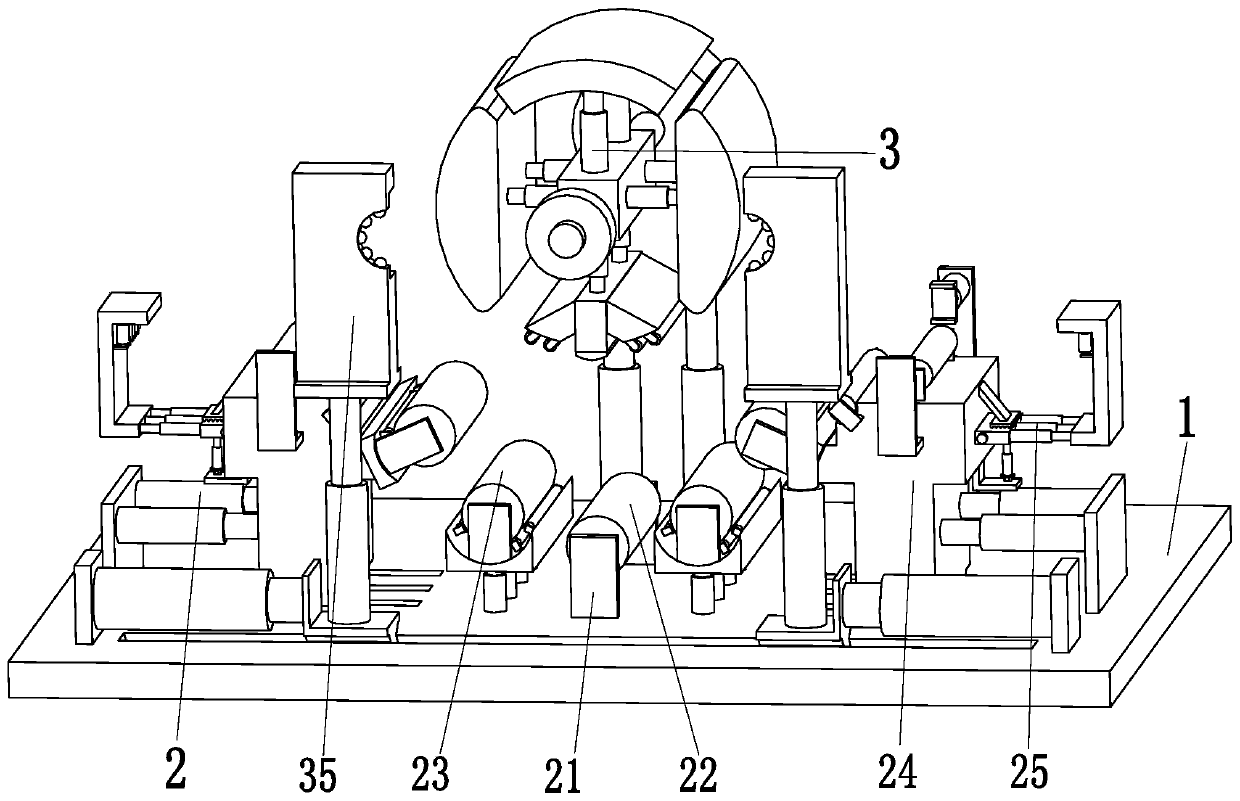

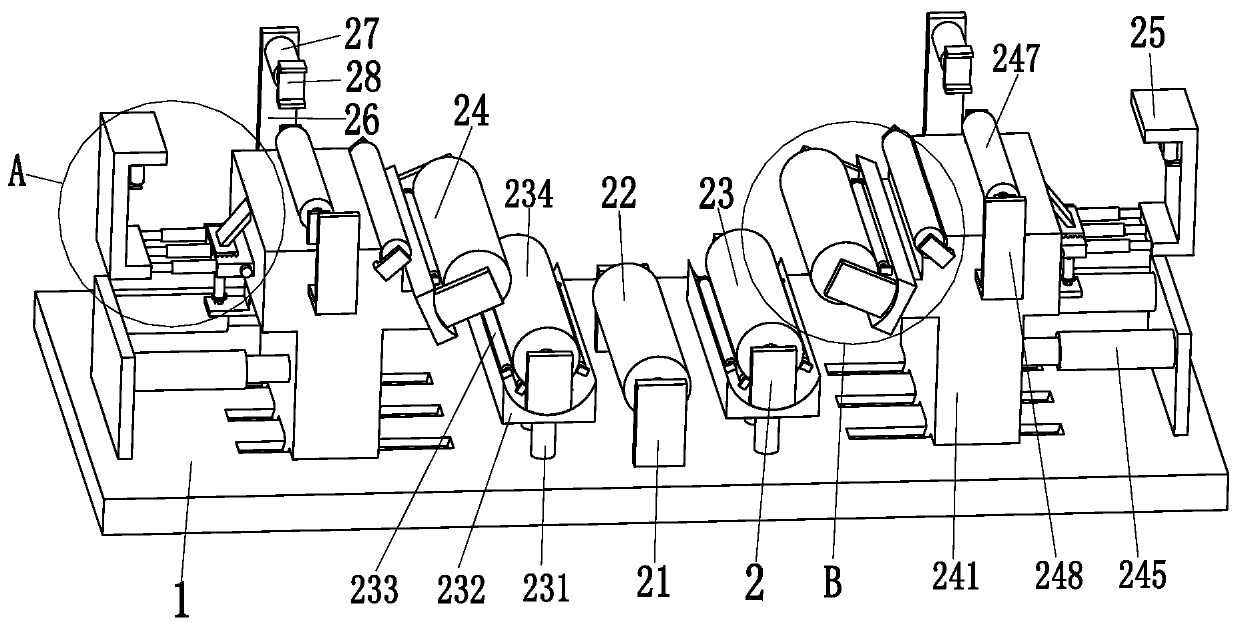

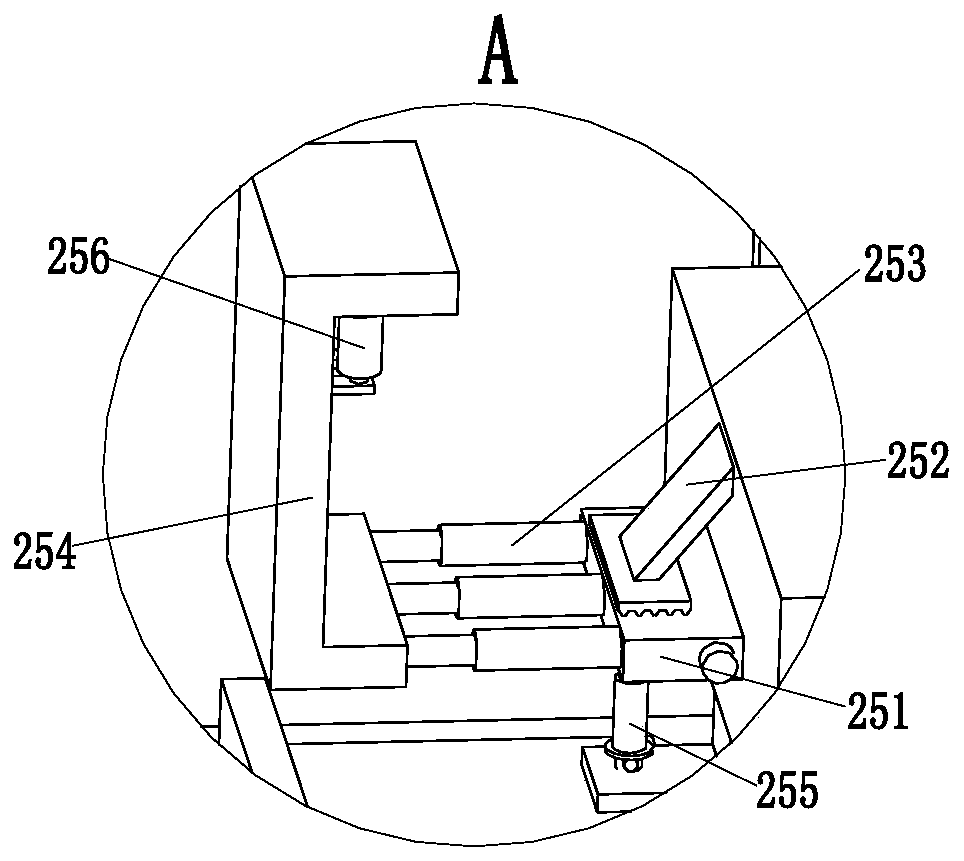

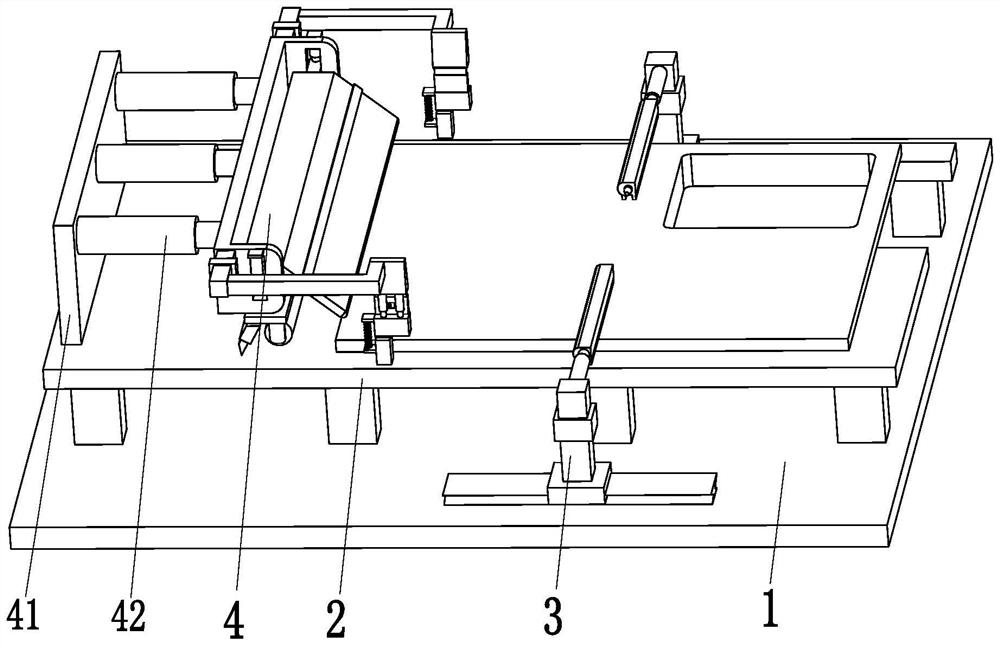

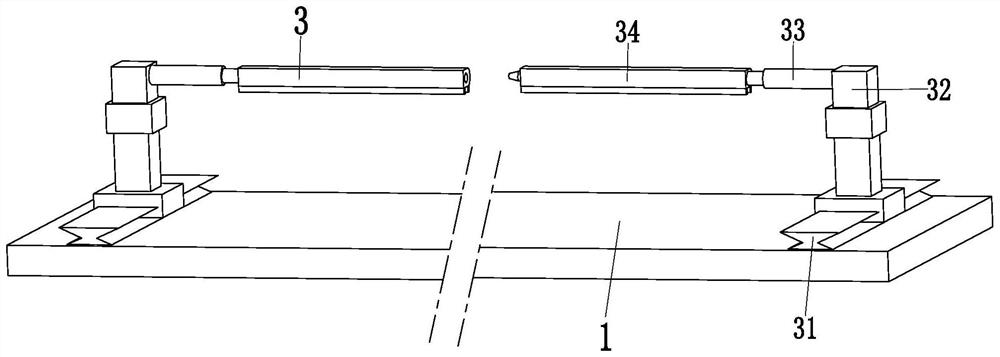

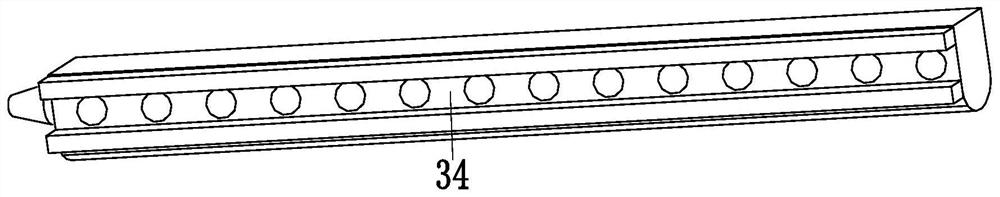

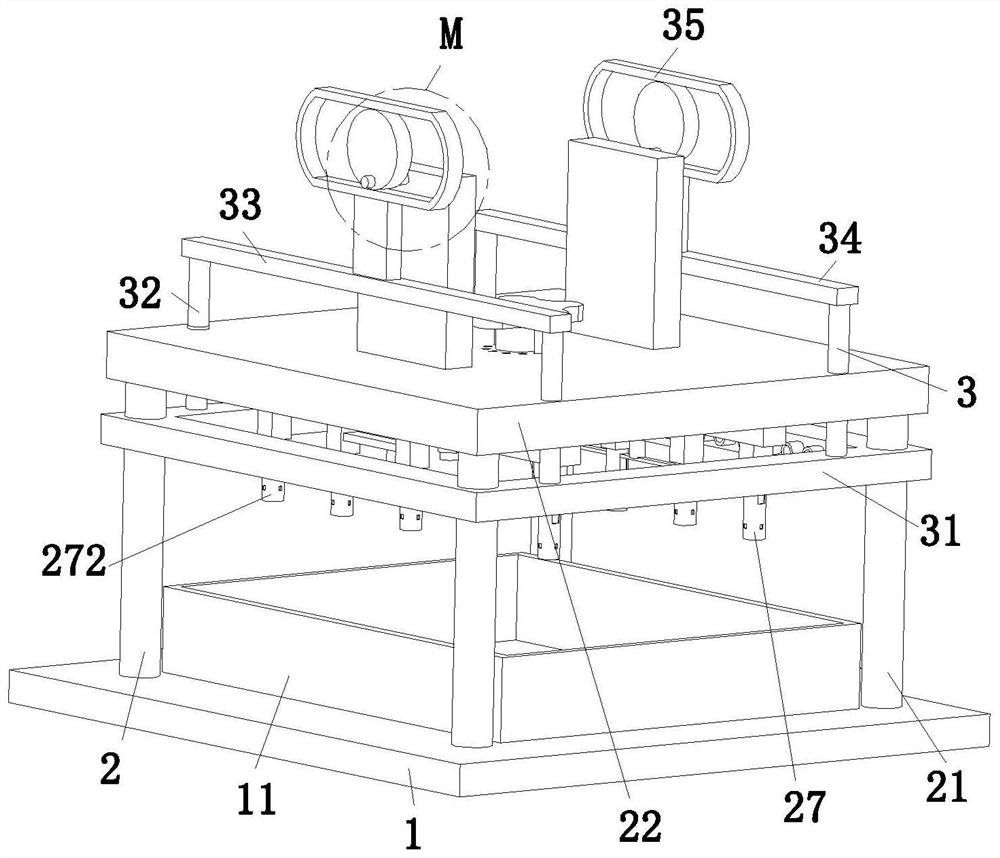

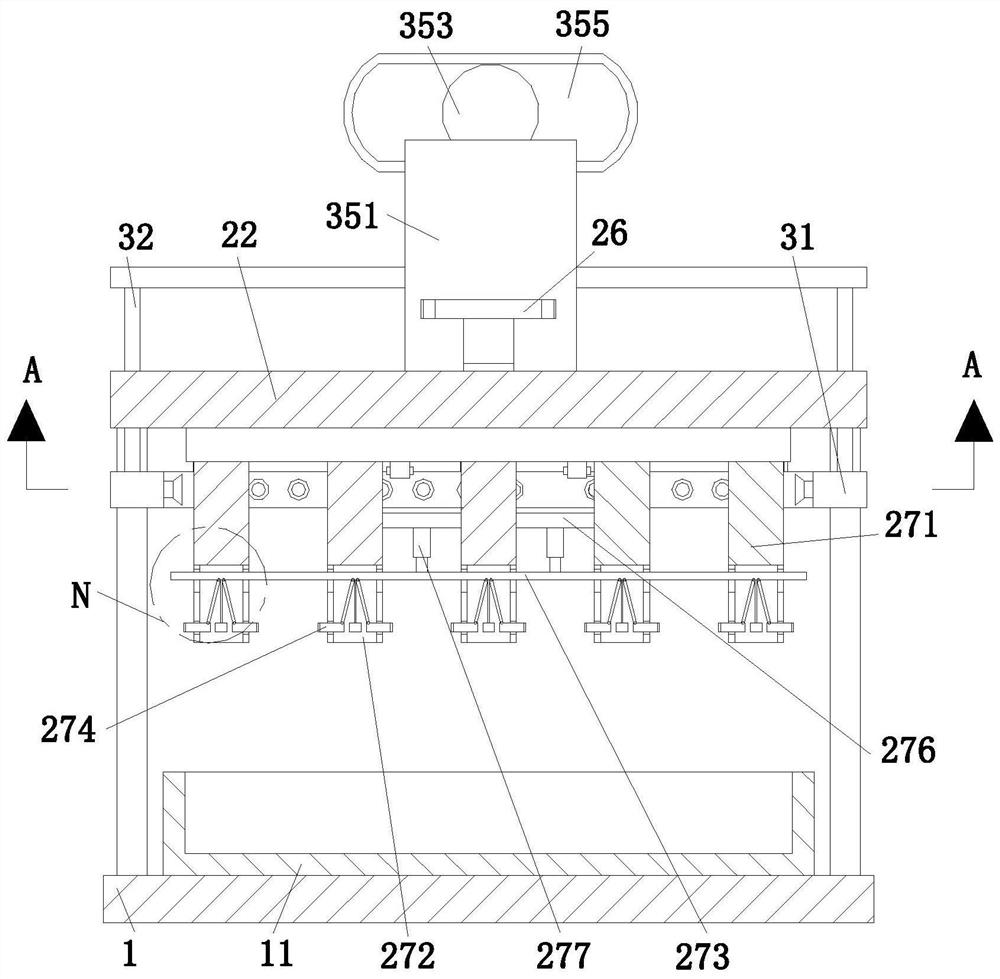

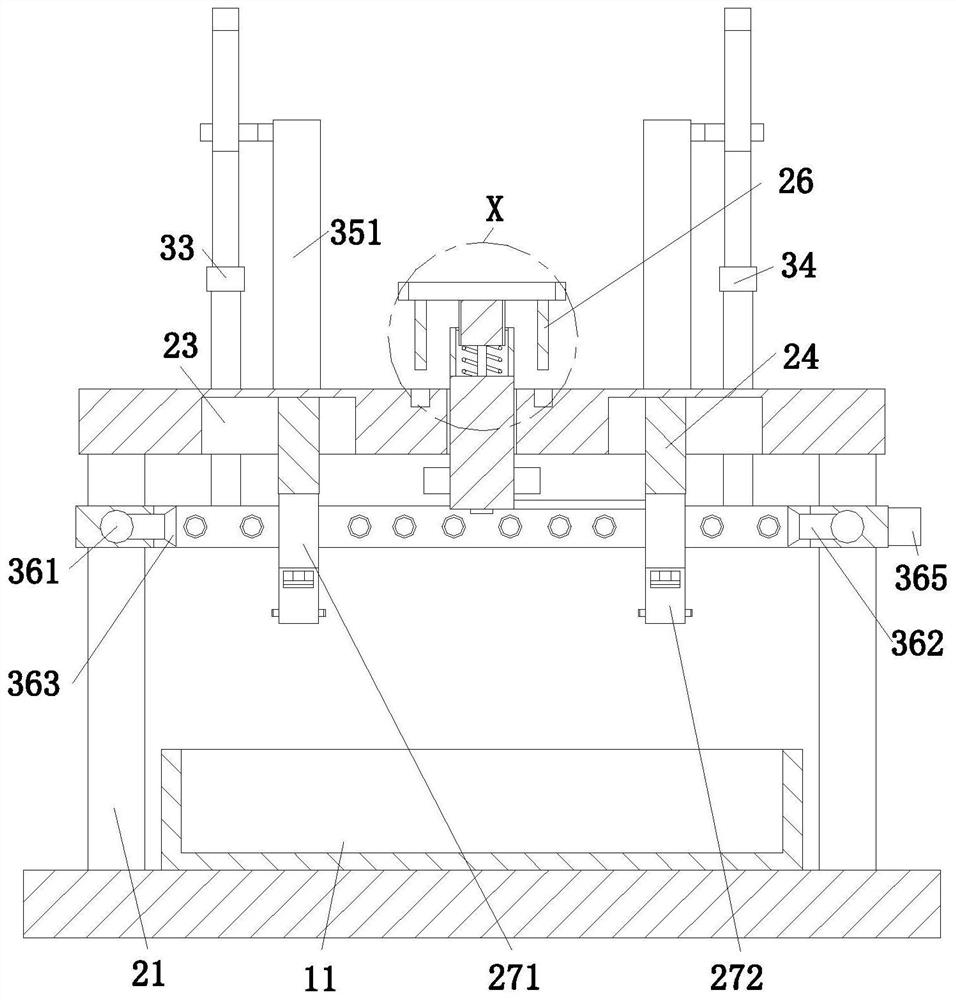

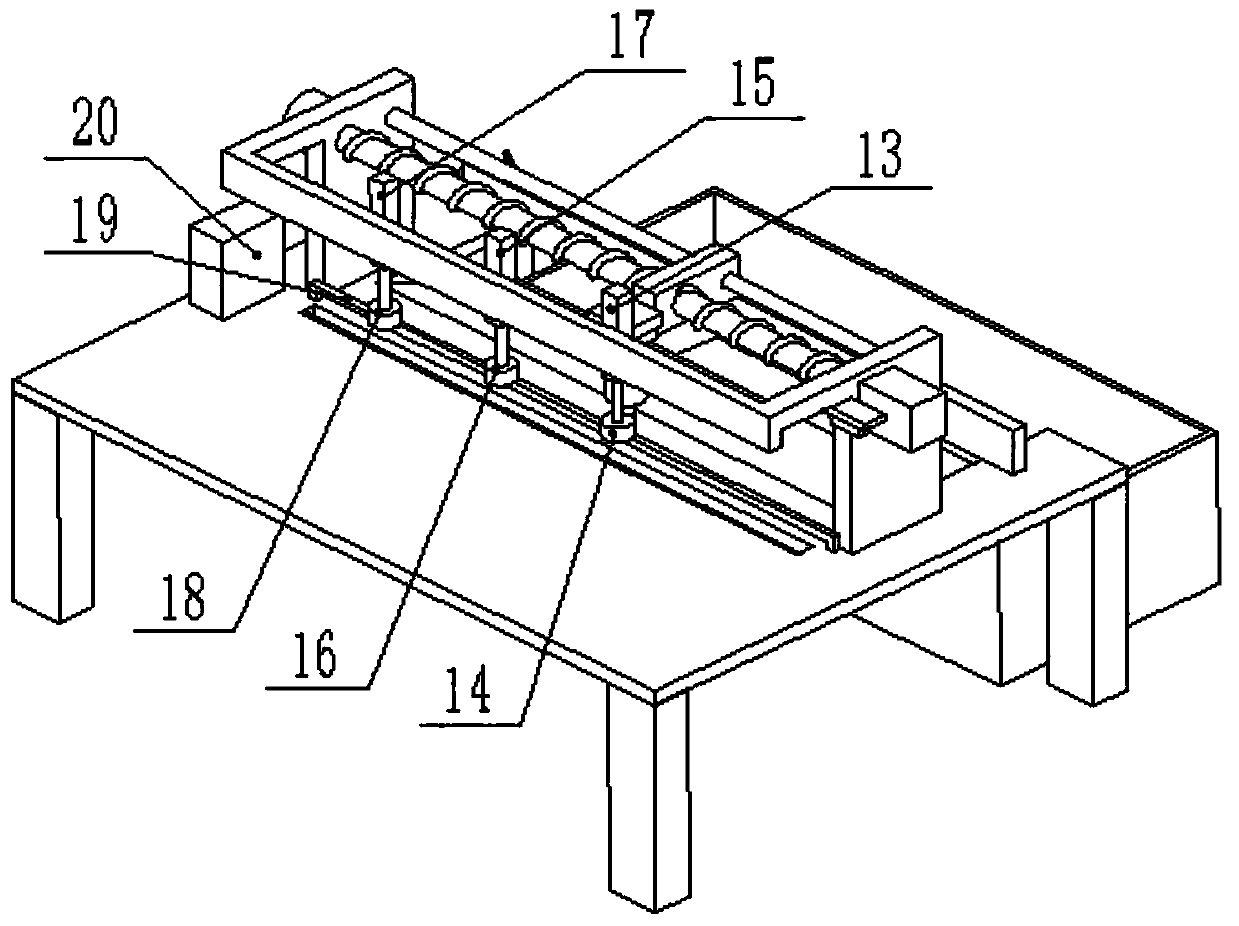

Oil tank automatic machining production line system and production machining process thereof

ActiveCN108856484APrecise positioningDisplacement does not occurMetal-working feeding devicesPositioning devicesProduction lineArchitectural engineering

The invention relates to an oil tank automatic machining production line system and a production machining process thereof. A fixed bottom plate, a supporting device, a forming device and an extrudingdevice are included; a supporting slide groove is arranged on the top of the front end of the fixed bottom plate; an adjusting slide groove is arranged on the middle portion of the fixed bottom plate; the supporting device is installed on the upper end face of the middle portion of the fixed bottom plate; the forming device is located on the outer side of the supporting device, and is installed on the top of the fixed bottom plate; and the bottom of the extruding device is connected with the outer side of the upper end face of the fixed bottom plate. The oil tank automatic machining production line system can solve the problems that accurate positioning cannot be performed on a steel plate when extruding machining is performed on an oil tank bucket body steel ring in the prior art, displacement can happen during steel plate extruding, the steel plate cannot be extruded into different diameters, the hidden danger that the bottom of the steel plate is clamped exists when the steel plateis extruded, rolling cannot be performed on the side face of the steel plate, rolling at the seam position of the steel plate is difficult, and the rolling effect of the top of the steel plate is poor.

Owner:铭宸(唐山)航天电子装备科技有限公司

Squaring method for silicon ingot

ActiveCN103802224ADisplacement does not occurEasy to removeWorking accessoriesFine working devicesPolystyreneIngot

The invention provides a squaring method for a silicon ingot, which comprises the following steps: laying an isolating membrane on one surface of a crystal support, which is provided with gaps, wherein the isolating membrane is used for isolating the crystal support from the silicon ingot to be squared; spraying polystyrene foam on the isolating membrane and filling the polystyrene foam into the gaps in the foaming process; placing the silicon ingot on the crystal support and enabling the polystyrene foam to be adhered to the silicon ingot; placing the crystal support supporting the silicon ingot in a cutting chamber of a squarer to carry out squaring on the silicon ingot. In the squaring method for the silicon ingot, which is provided by the invention, when the silicon ingot is to move, the hardened polystyrene foam filled into the gaps can keep the silicon ingot not moving by a relative acting force with the side walls of the gaps so as to achieve an effect of fixing the silicon ingot. The silicon ingot is isolated from the crystal support by the isolating membrane, and thus, after squaring on the silicon ingot is completed, an operator can very easily take down the silicon ingot from the crystal support, so that the operation difficulty in the process of taking down the silicon ingot from the crystal support after squaring is greatly reduced and production efficiency is improved.

Owner:TIANJIN YINGLI NEW ENERGY RESOURCES

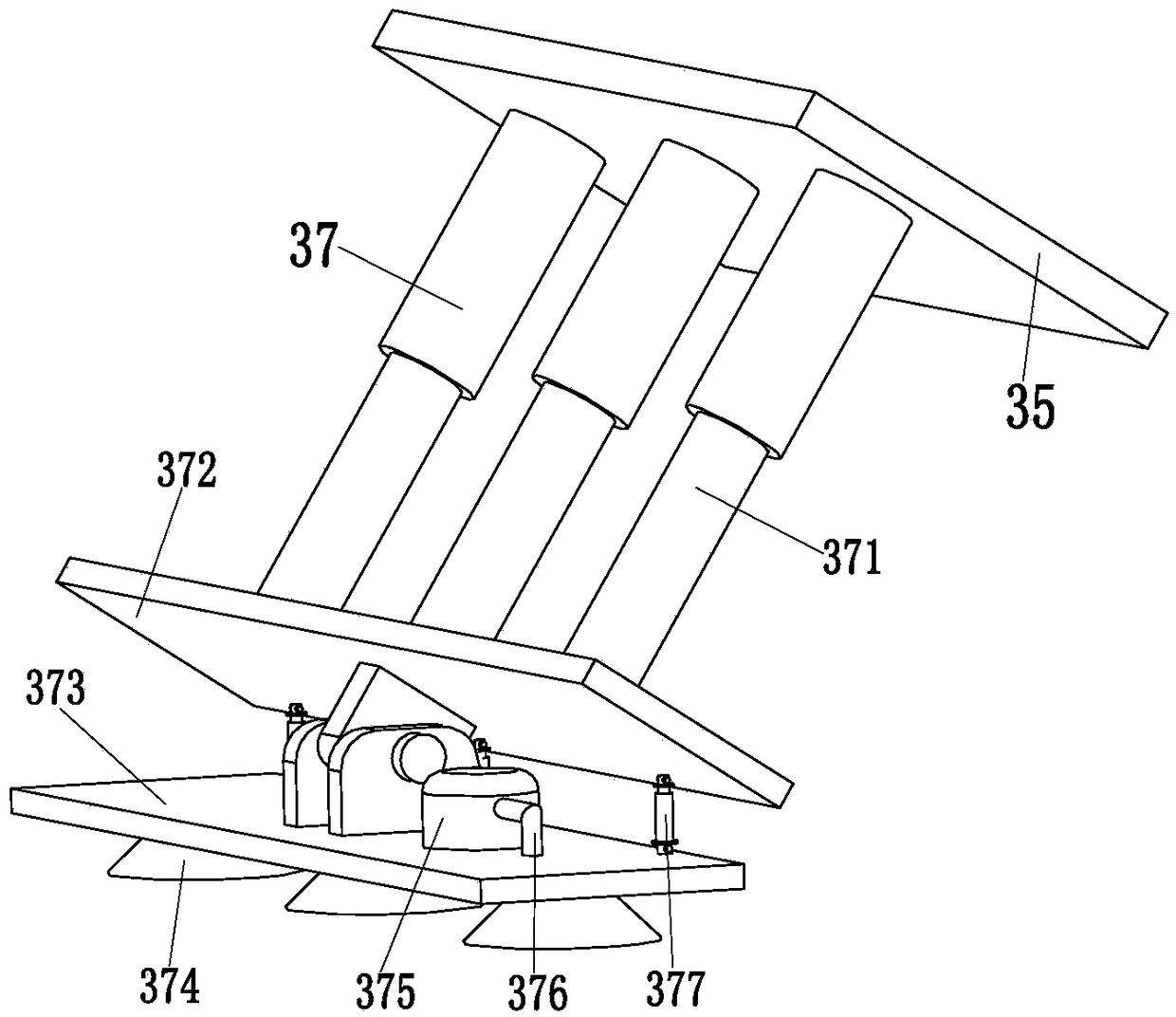

An aluminum-plastic film packaging rolling machine and an aluminum-plastic film packaging rolling method for soft-clad lithium battery

ActiveCN109216593ADisplacement does not occurAvoid misalignmentFinal product manufactureSmall-sized cells cases/jacketsPlastic filmLithium battery

The invention relates to an aluminum-plastic film packaging and rolling machine and an aluminum-plastic film packaging and rolling method for soft-clad lithium battery, comprises a support bottom plate, a placing bracket, a pressure-resisting branch chain and a leveling device, wherein the upper end surface of the middle part of the support bottom plate is provided with a placing bracket, a squaregroove is arranged at the rear side of the right end of the placing bracket, a pressure-resisting branch chain is arranged at the front and rear ends of the support bottom plate, and the pressure-resisting branch chain is arranged on the outside of the placing bracket, and the leveling device is arranged on the top of the left end of the placing bracket; The flattening device comprises a flattening support plate, a flattening position pushing rod, a flattening support, a flattening adjustment plate, a flattening sliding column, a height pushing rod, a flattening plate, a positioning mechanismand a rolling mechanism. The flattening device comprises a flattening support plate, a flattening position pushing rod, a flattening bracket, a flattening adjustment plate, a flattening slide column,a height pushing rod, a flattening plate, a positioning mechanism and a rolling mechanism. The invention can solve the problem that the rotational point of the aluminum plastic film is displaced whenthe aluminum plastic film of the outer package of the existing soft-clad lithium battery is folded, the positions of the left and right ends of the aluminum plastic film are deviated when the aluminum plastic film is packed, and the aluminum plastic film can not be rolled and scraped automatically after the aluminum plastic film is folded.

Owner:上海凯矜新材料科技有限公司

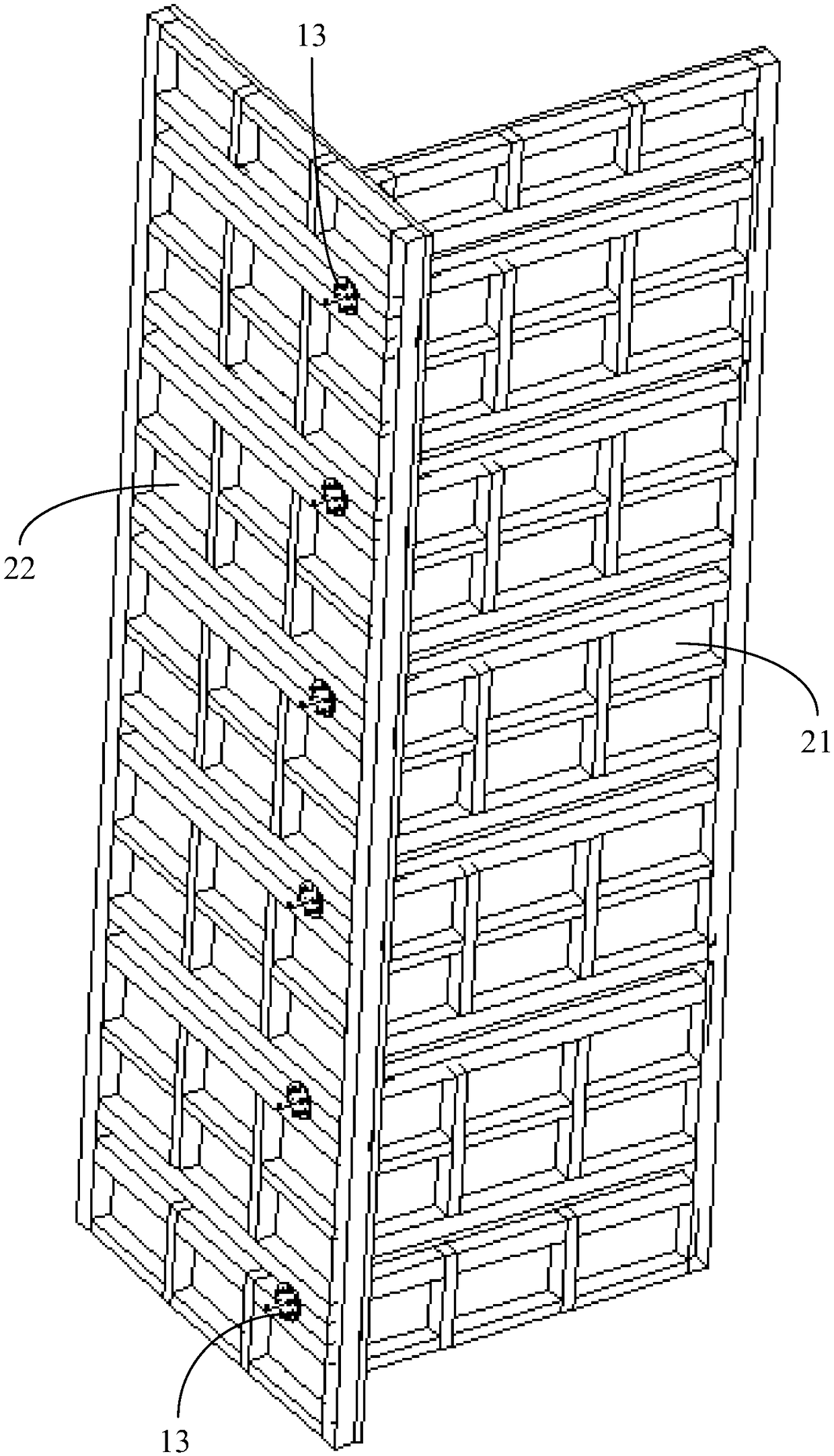

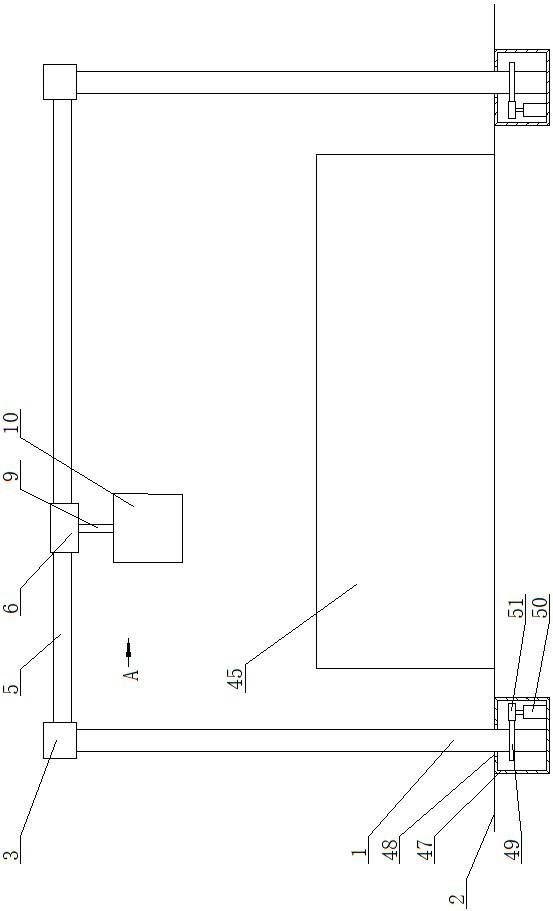

Prefabricated assembled type wall pouring forming positioning device and using method

InactiveCN110053155ADisplacement does not occurSimple structureCeramic shaping apparatusStructural engineeringForming processes

Owner:湖北广盛建筑产业化科技有限公司

Storage battery thermostat

ActiveCN108258163ADisplacement does not occurEasy to replaceElectric heatingCell component detailsThermostatToughened glass

The invention discloses a storage battery thermostat. The storage battery thermostat structurally comprises an intelligent regulating and controlling fixing device, a device shell, a controller, a fixing handle, a mounting frame, toughened glass, a protective door and a fixing base, wherein the fixing base is positioned on the lower surface of the device shell, and is fixed to the device shell ina welding manner to form an integral structure; the intelligent regulating and controlling fixing device is arranged inside the device shell, and the intelligent regulating and controlling fixing device and the device shell are fixedly connected together; the protective door is movably mounted on the front surface of the device shell, and the protective door and the device shell are movably matched together; the fixing handle is fixedly mounted on the left side of the protective door in a welding manner, and is parallel to the mounting frame. The storage battery thermostat achieves the purposes as follows: when the thermostat works, storage batteries placed therein can be fixed more conveniently; meanwhile, more storage batteries can be mounted through a rotating function of the thermostat; in addition, damaged storage batteries can be taken out more conveniently; therefore, the thermostat is more perfect.

Owner:泉州市东艾机械制造有限公司

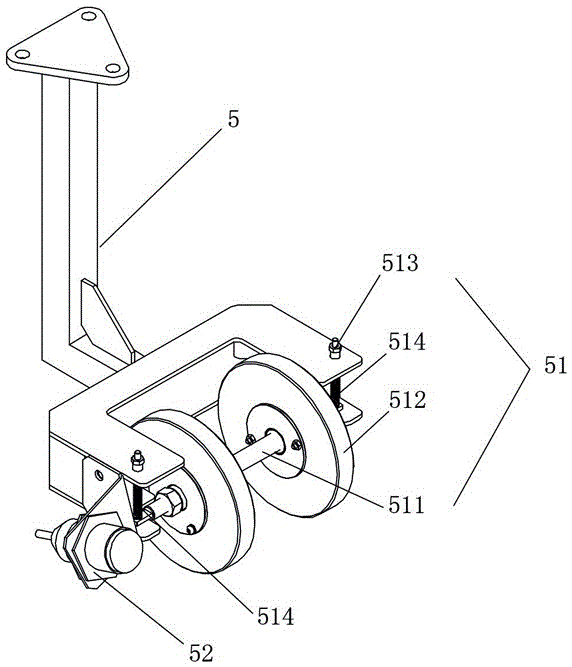

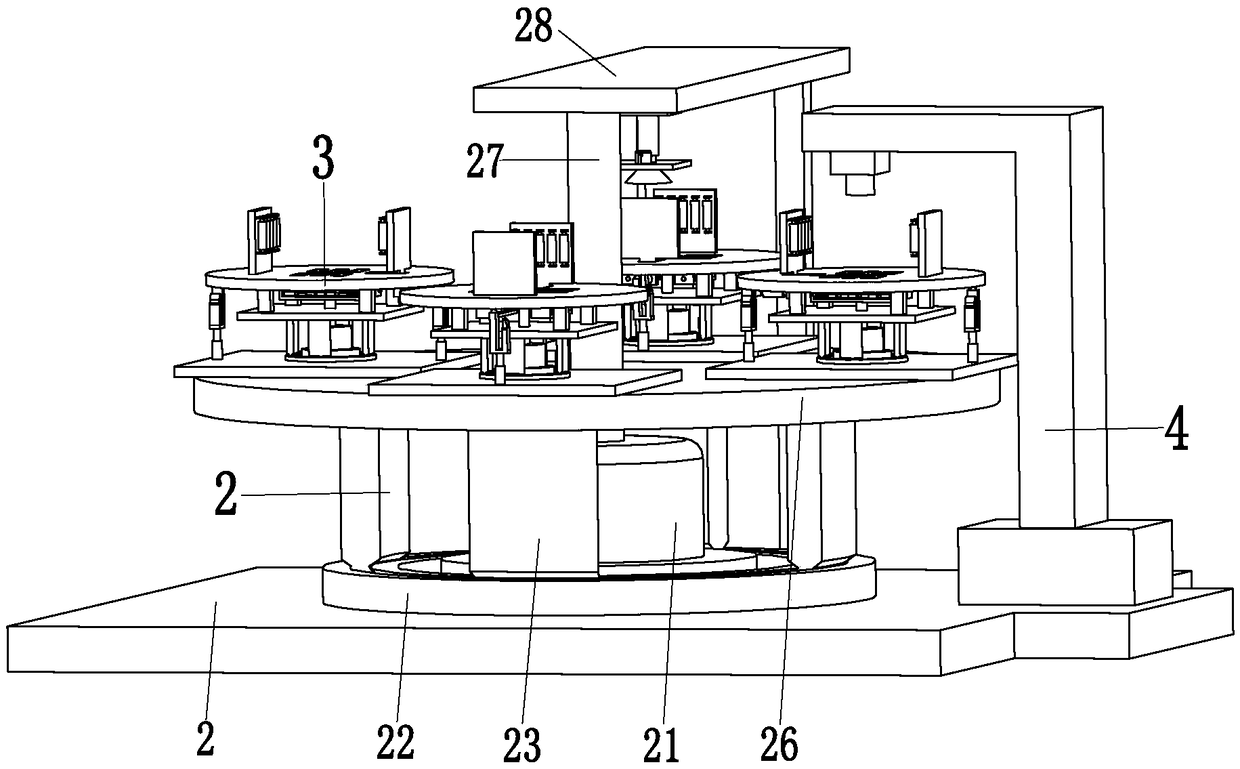

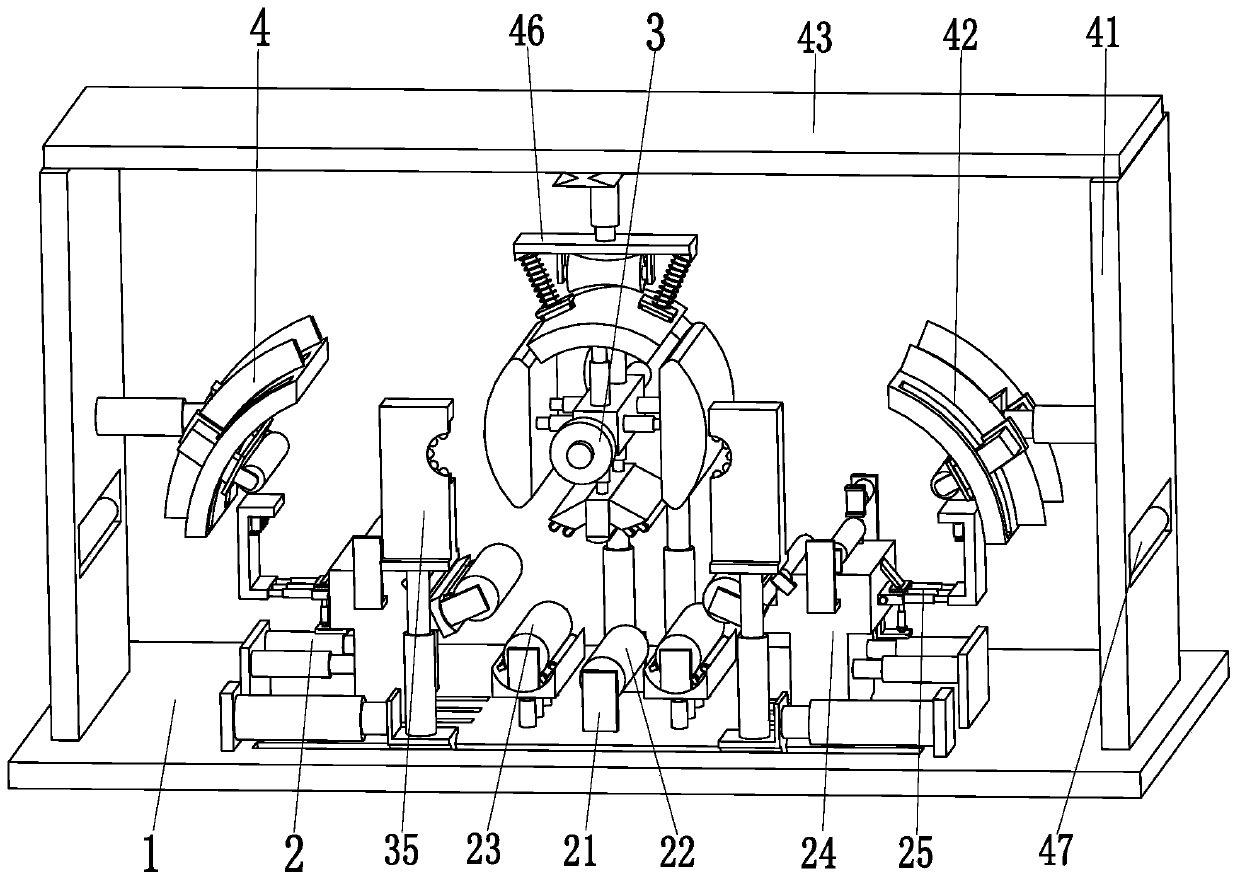

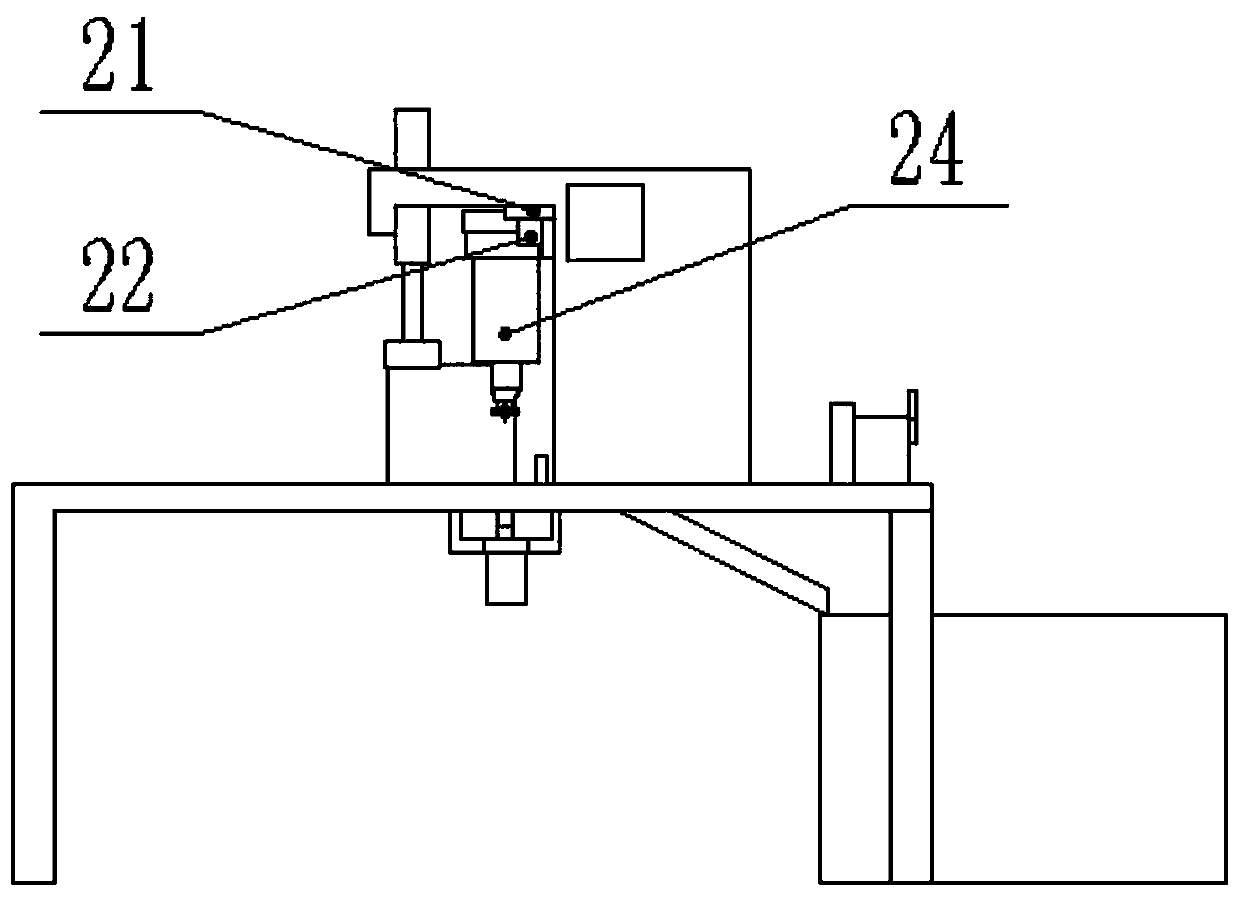

Fixed rotation robot for integrated electric power chip laser printing

ActiveCN109300812AEasy to fixDisplacement does not occurSemiconductor/solid-state device manufacturingLaser beam welding apparatusAutomatic transmissionEngineering

The present invention relates to a fixed rotation robot for integrated electric power chip laser printing. The robot comprises a support bottom plate, a transposition device, fixed devices and a laserprinter. The top portion of the right end of the support bottom plate is provided with the laser printer, the transposition device is installed at the upper end face of the middle portion of the support bottom plate, and fixed devices are symmetrically installed at the upper end of the transposition device; and the transposition device comprises a transposition motor, a transposition chute, a transposition slide rack, a transposition pull rod, a location block, a support disc, a transposition shaft and a transmission mechanism. The problems can be solved that a current IC chip cannot continuously perform printing of the IC chip when laser printing, the IC chip is poor in fixing effect, the IC chip is replaced when being transmitted, the polarity of the IC chip is difficult to regulate, the printed IC chip cannot perform automatic transmission, and the fixed rotation robot for integrated electric power chip laser printing can achieve functions of fixing and printing of different typesof IC chips and transmitting the printed IC chips.

Owner:老玩童(重庆)科技发展有限公司

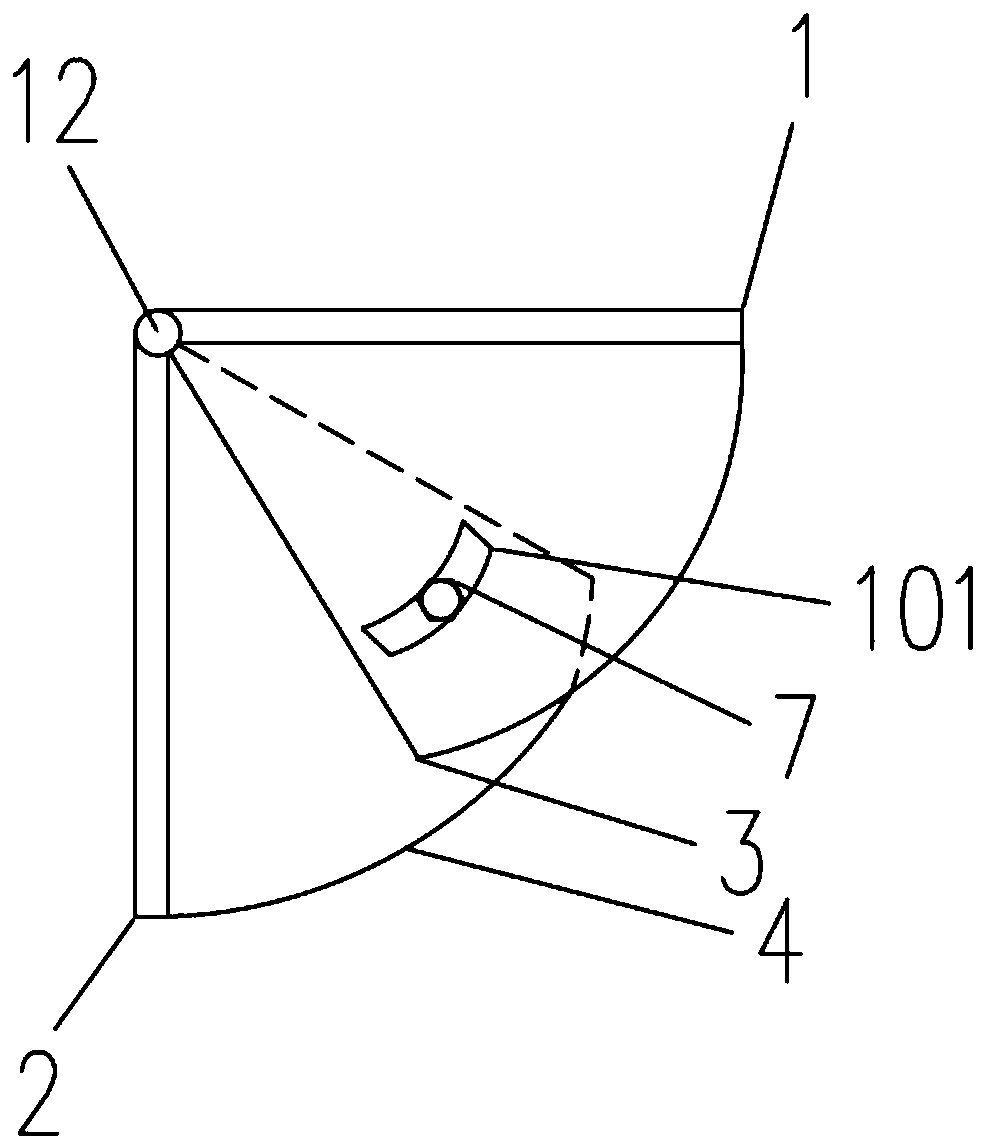

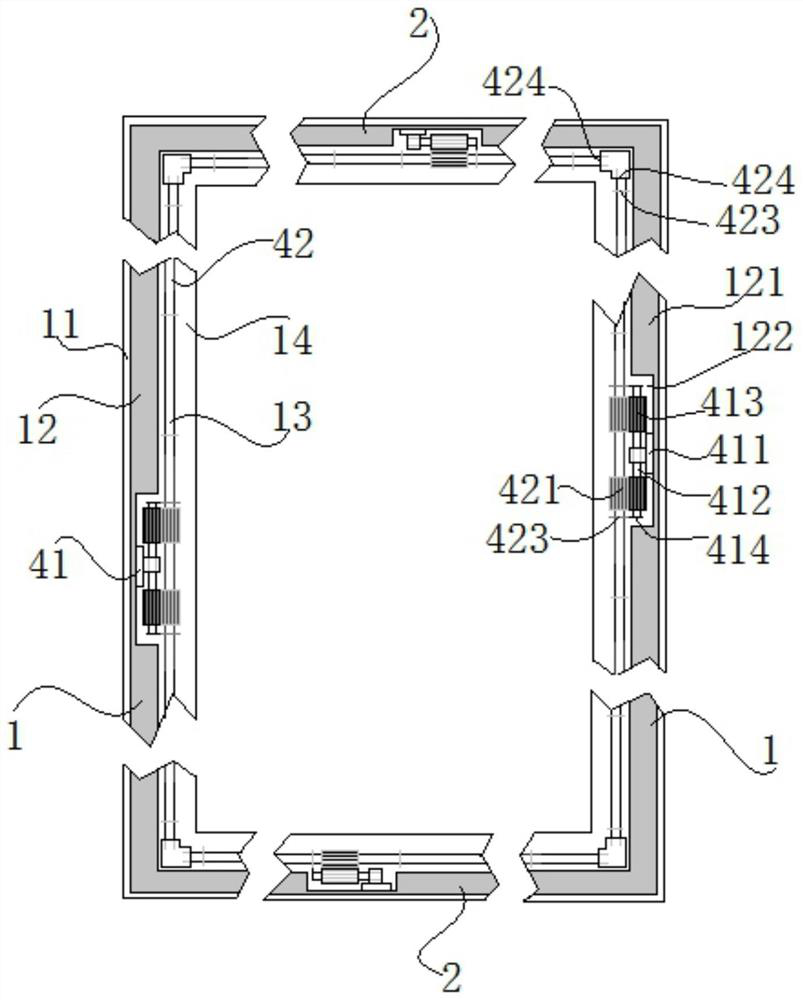

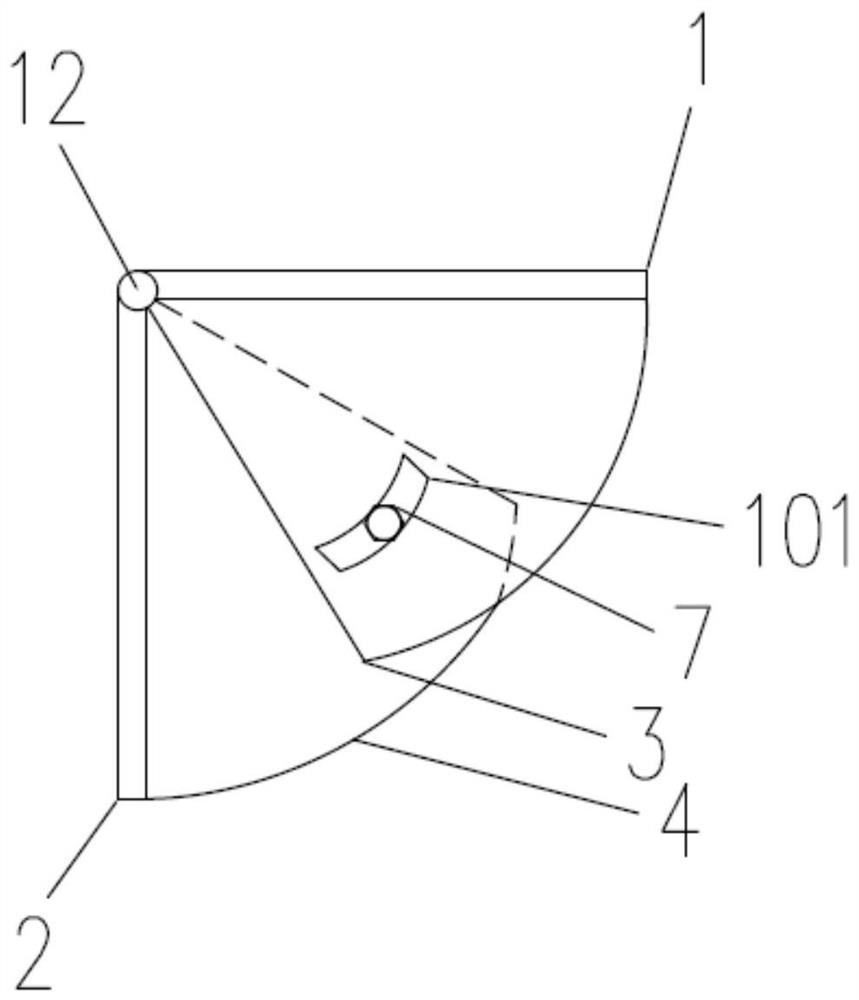

Assembly type frame intelligent damping structure

ActiveCN111236424APrevent rotationChange static friction in real timeBuilding constructionsMechanical engineeringCeramic

The invention discloses an assembly type frame intelligent damping structure. The intelligent damping structure comprises a prefabricated beam and prefabricated columns, wherein the prefabricated beamand the prefabricated columns are connected through hinge structures, beam column joint intelligent damping devices are installed below the hinge structures, the beam column joint intelligent dampingdevices comprise first embedded bodies and second embedded bodies, one ends of the first embedded bodies are hinged to one ends of the second embedded bodies, two first fan-shaped steel plates are arranged on the inner side of each first embedded body, a second fan-shaped steel plate is arranged on the inner side of each second embedded body, each second fan-shaped steel plate is arranged betweenthe two first fan-shaped steel plates, a first high-strength bolt is arranged on each second fan-shaped steel plate, a piezoelectric ceramic is arranged on one side of each first high-strength bolt,and the piezoelectric ceramics are connected with a controller. According to the intelligent damping structure, the controller adjusts the voltage of the piezoelectric ceramics under the action of different earthquake loads, so that the rotating friction force and the sliding friction force of the core area are adjusted, the purpose that the overall structure is self-adaptive to earthquake response is achieved, and real-time variable-friction shear resistance under the action of medium and small earthquakes is achieved.

Owner:CHANGAN UNIV

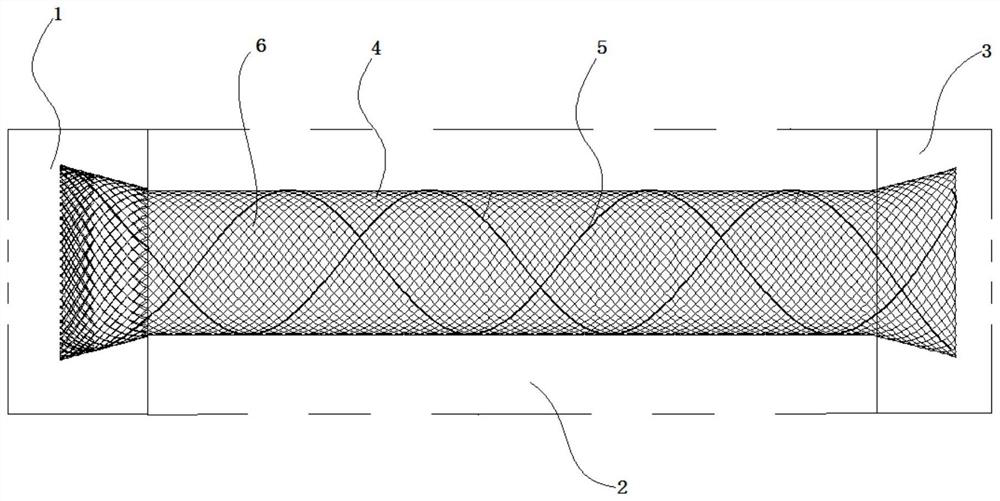

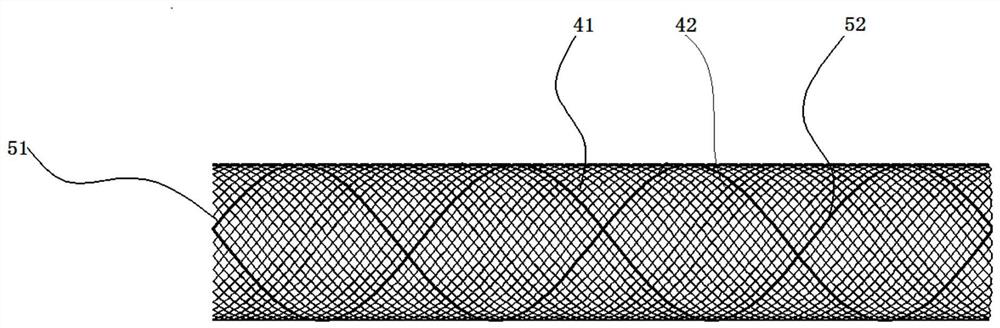

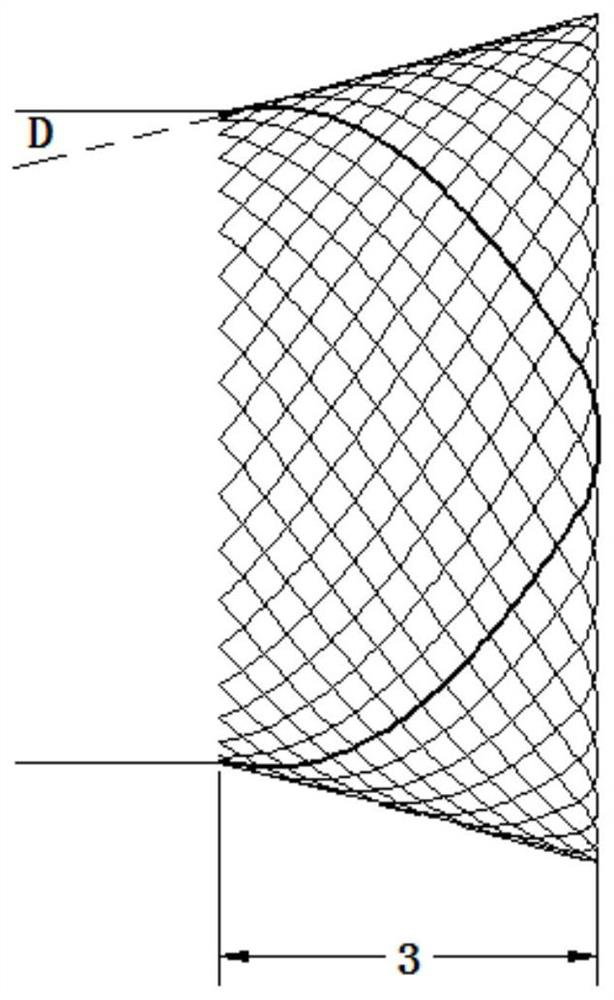

Intracranial vascular stent

PendingCN113288535ASolve the displacementDisplacement does not occurStentsProsthesisIntracranial vascular stentBiomedical engineering

The invention discloses an intracranial vascular stent, and the stent is formed by weaving a developing wire and a plurality of skeleton wires; and the vascular stent is sequentially provided with a near-end area, a working area and a far-end area in the axial direction of the vascular stent. The skeleton wires spirally extend to the tail end of the far-end area from the end part of the near-end area, then are folded back and spirally extend to the tail end of the near-end area, and are woven in an up-and-down staggered manner to form rhombic meshes; the near-end area and the far-end area are horn-shaped, and the tail end of the near-end area is folded inwards to form a folded area; and the developing wires are inserted into the skeleton formed by weaving the skeleton wires in the same way as the skeleton wires, so that the intracranial vascular stent is formed together. The radial supporting force of the two ends of the intracranial vascular stent is improved, and the problem that the stent is impacted by blood flow in a blood vessel to generate displacement is solved. In addition, the two ends of the stent are of a closed-loop structure, and the problem that the blood vessel wall is punctured due to necking and separation of weaving wires can be avoided.

Owner:成都百瑞恒通医疗科技有限公司

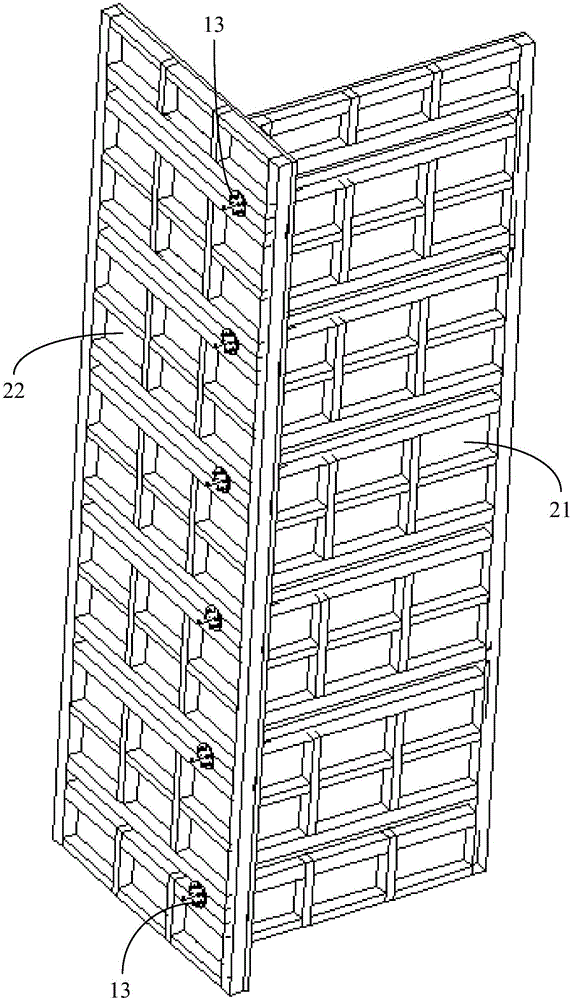

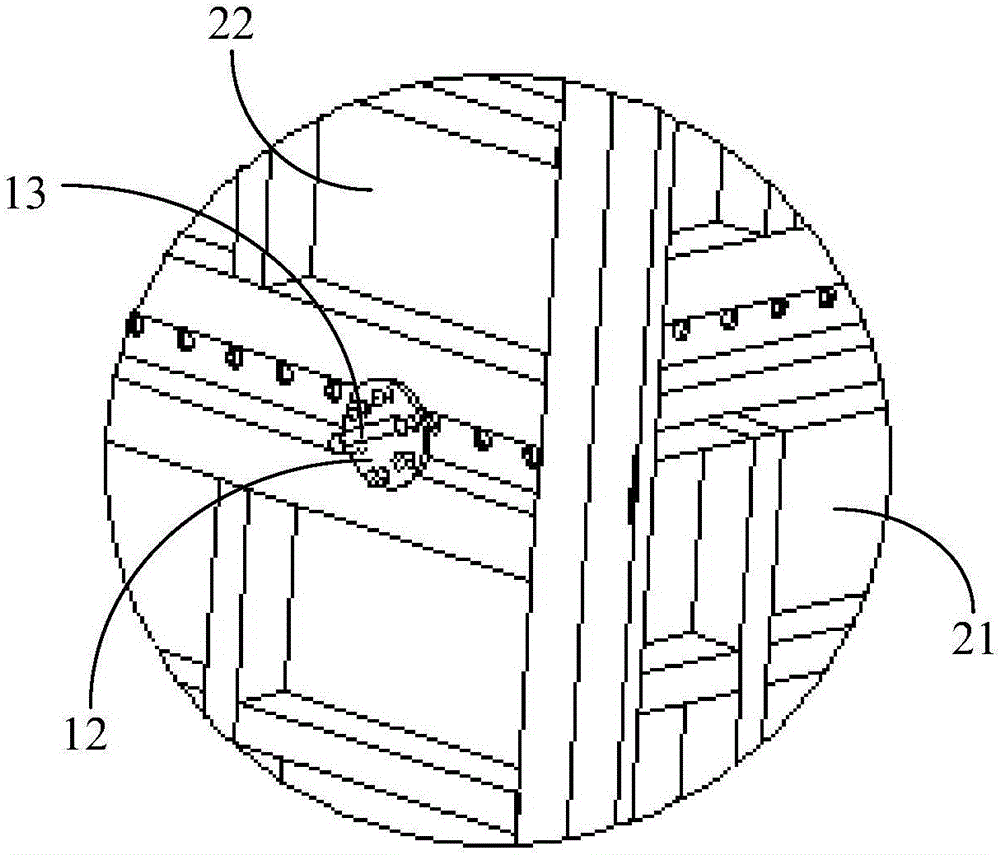

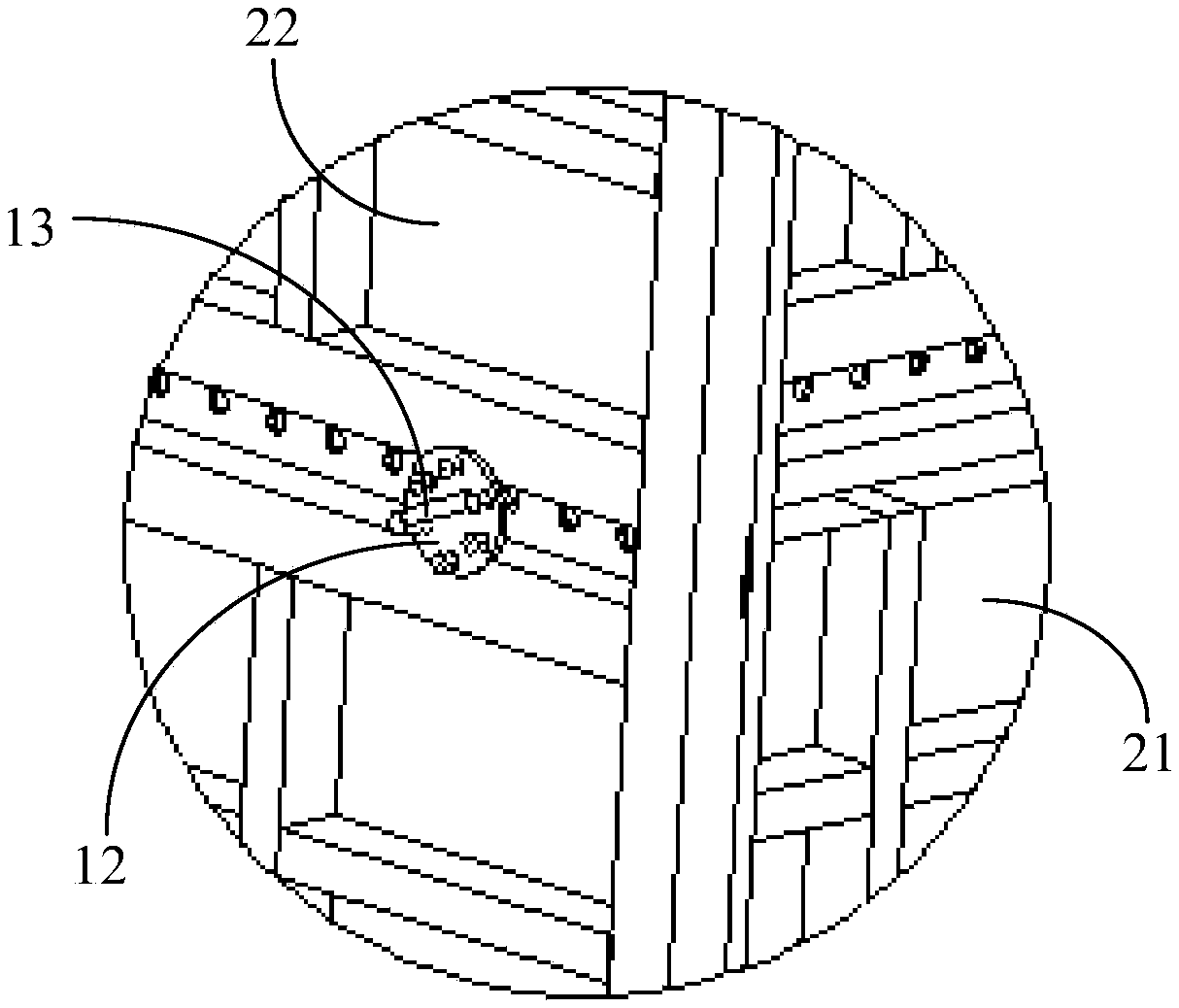

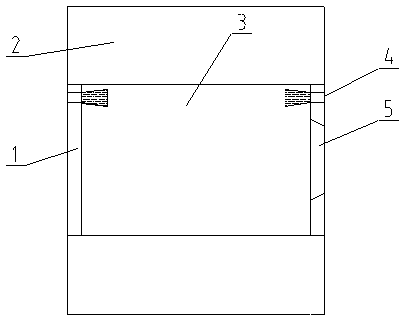

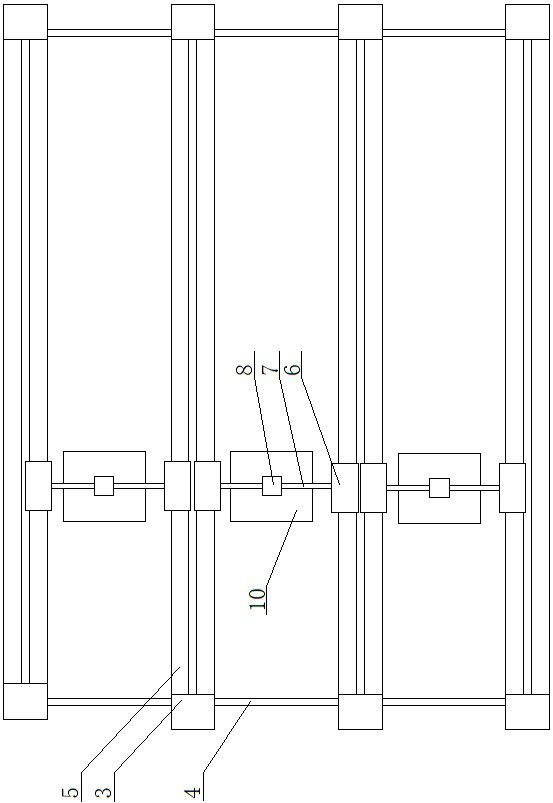

Steel frame template anti-displacement apparatus

ActiveCN106049861AQuality improvementPrevent left and right shiftForms/shuttering/falseworksHigh turnoverEngineering

The invention discloses a steel frame template anti-displacement apparatus which is intended for positioning of a steel frame between a first side mold and a second side mold which constitute an included angle. The apparatus includes a positioning clamp which includes a clamping part of a frame back ridge which is clamped to the first side mold and an abut against part which abuts against the second side mold, and the abut against part and the clamping part are in fixed connection; a drawing rod body which is fixed to the abut against part; a fixing part which is movably installed on the drawing rod body and is fixed to the drawing rod body through a fixing structure; the fixing part and the abut against part constitute a positioning space which is intended for fixing the second side mold. According to the invention, the apparatus uses the positioning clamp to clamp and fix the frame back ridge of the first side mold, and uses the drawing rod body and the fixing body to connect and fix the second side mold of the steel frame template, so that the first side mold and the second side mold of the steel frame template which constitute an included angle are fixed. The apparatus has simple structure, is easy to use, and has high turnover rate.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A fixed rotating robot for integrated circuit chip laser printing

ActiveCN109300812BEasy to fixDisplacement does not occurSemiconductor/solid-state device manufacturingLaser beam welding apparatusElectric machineryEmbedded system

The invention relates to a fixed rotating robot for laser printing of integrated circuit chips, comprising a supporting base plate, a transposition device, a fixing device and a laser printer, a laser printer is installed on the top right end of the support base plate, and the transposition device is installed on the support base plate On the upper end face of the middle part, a fixing device is symmetrically installed on the upper end of the indexing device; the indexing device includes an indexing motor, an indexing chute, an indexing carriage, an indexing push rod, a positioning block, a support plate, Indexing shaft and transfer mechanism. The present invention can solve the problems of the existing IC chips in laser printing, such as the inability to continuously print the IC chips, the poor fixing effect of the IC chips, the displacement of the IC chips during transmission, the difficulty in adjusting the polarity of the IC chips, and the difficulty of printing the IC chips. Chips cannot be automatically transferred and other problems; it can realize the fixed printing of different types of IC chips and the function of transferring the printed IC chips.

Owner:老玩童(重庆)科技发展有限公司

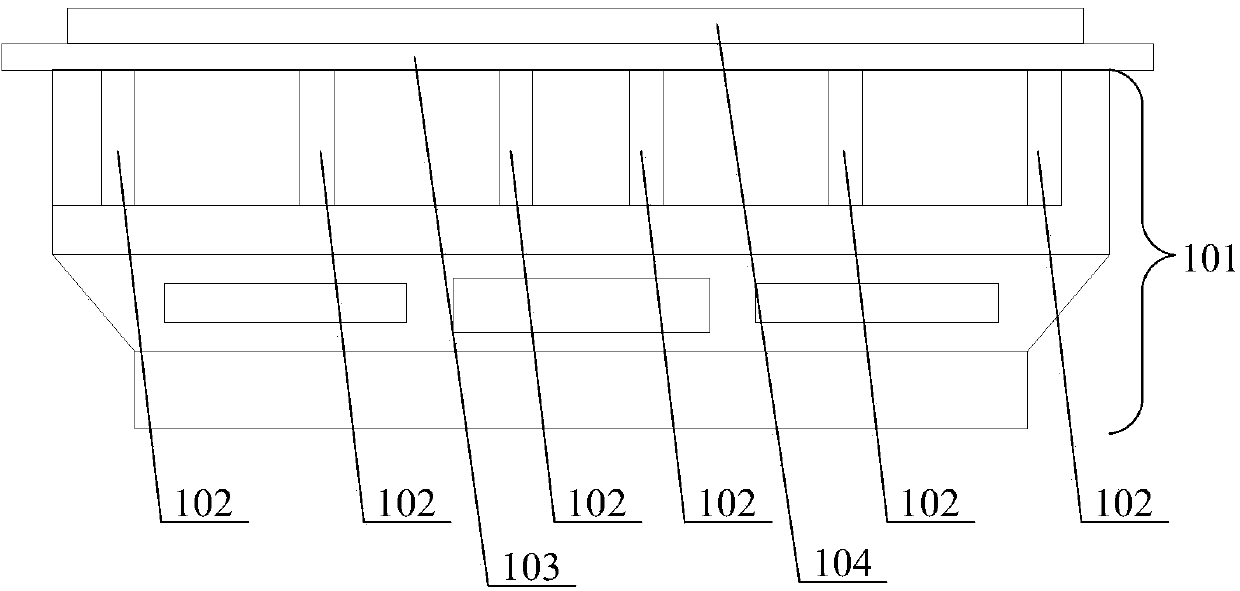

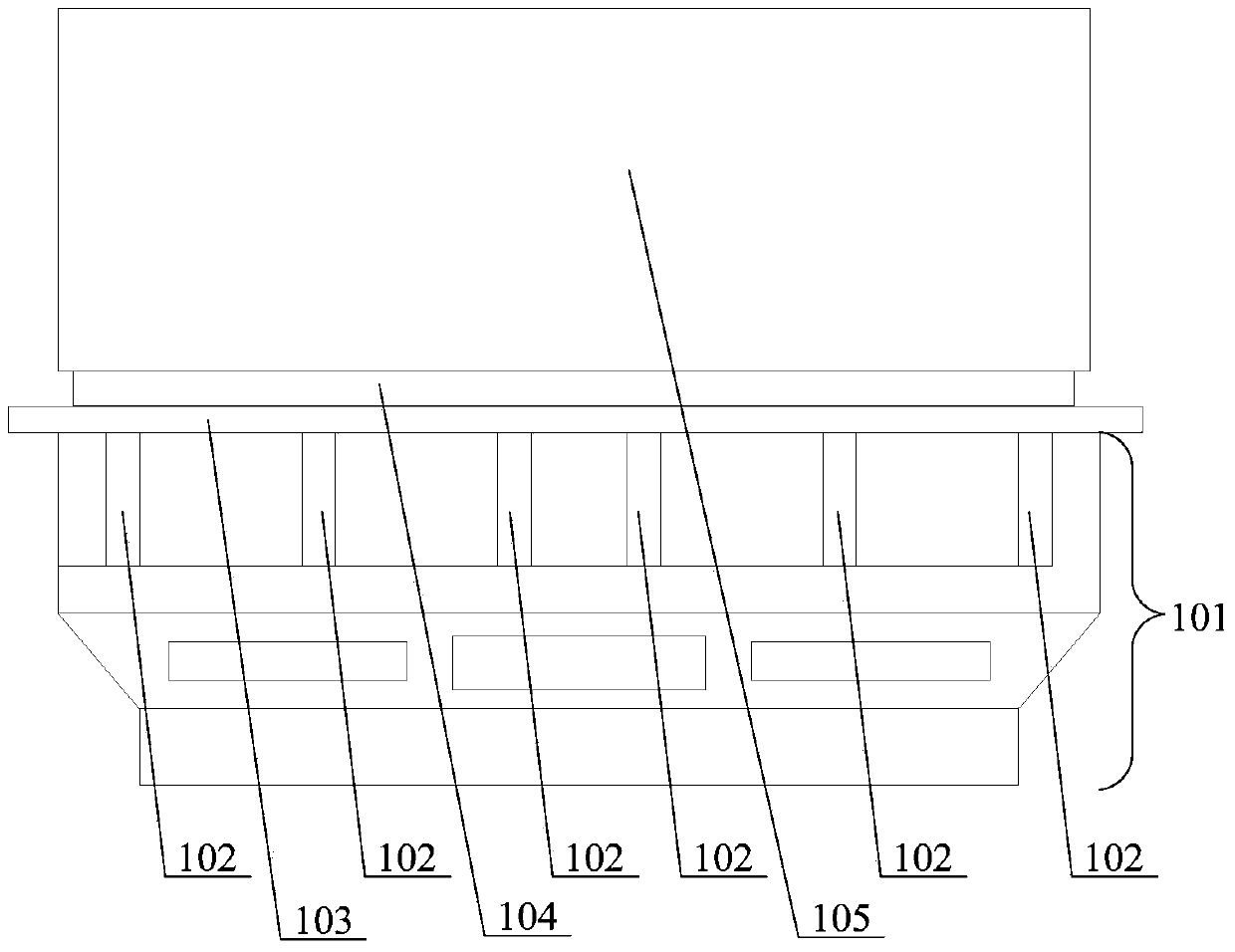

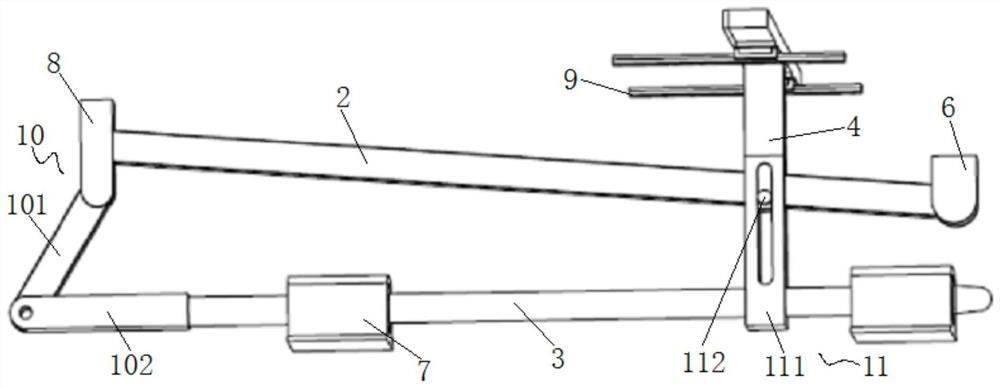

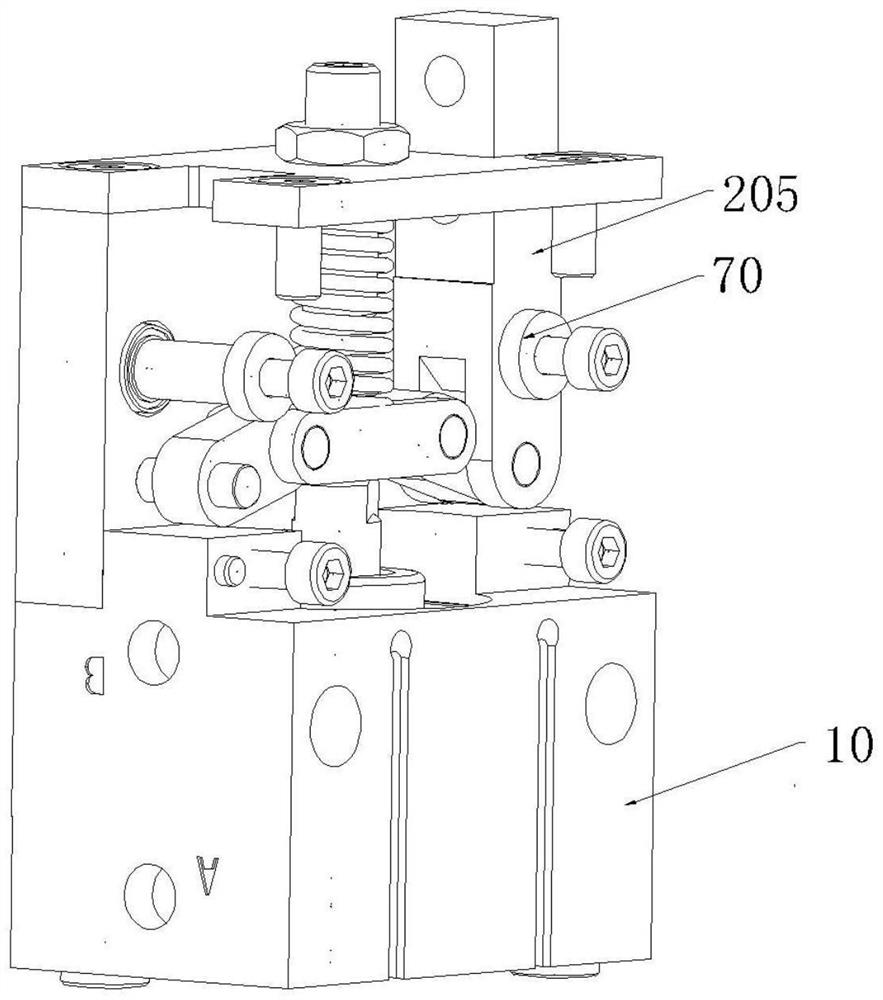

A motherboard positioning and clamping device and motherboard detection equipment

ActiveCN112649434BObvious displacementDisplacement does not occurWork holdersOptically investigating flaws/contaminationControl engineeringTest equipment

The invention provides a main board positioning and clamping device and main board detection equipment, belonging to the technical field of main board detection related test equipment, and solves the problem that the main board is placed without positioning and clamping, and the main board is skewed in place due to unstable movement process and movement inertia. The problem. It includes a base, a first connecting rod, a guide column, a clamping rib and a liftable mainboard carrier. The base is fixedly provided with a first support and a linear bearing seat, and the lower surface of the mainboard carrier is fixedly provided with The second support, the first end of the first connecting rod is connected with the first support through the rotating shaft, the second end of the first connecting rod is connected with the second support through the rotating shaft, the guide column is The first end is movably connected with the linear bearing seat. The invention optimizes the placement process of the main board, avoids the occurrence of inaccurate detection results caused by the incorrect position of the main board, and adopts a pure mechanical structure, which can basically achieve maintenance-free, long service life and reliable performance.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Steel frame formwork anti-displacement device

ActiveCN106049861BQuality improvementPrevent left and right shiftForms/shuttering/falseworksHigh turnoverSteel frame

The invention discloses a steel frame template anti-displacement apparatus which is intended for positioning of a steel frame between a first side mold and a second side mold which constitute an included angle. The apparatus includes a positioning clamp which includes a clamping part of a frame back ridge which is clamped to the first side mold and an abut against part which abuts against the second side mold, and the abut against part and the clamping part are in fixed connection; a drawing rod body which is fixed to the abut against part; a fixing part which is movably installed on the drawing rod body and is fixed to the drawing rod body through a fixing structure; the fixing part and the abut against part constitute a positioning space which is intended for fixing the second side mold. According to the invention, the apparatus uses the positioning clamp to clamp and fix the frame back ridge of the first side mold, and uses the drawing rod body and the fixing body to connect and fix the second side mold of the steel frame template, so that the first side mold and the second side mold of the steel frame template which constitute an included angle are fixed. The apparatus has simple structure, is easy to use, and has high turnover rate.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

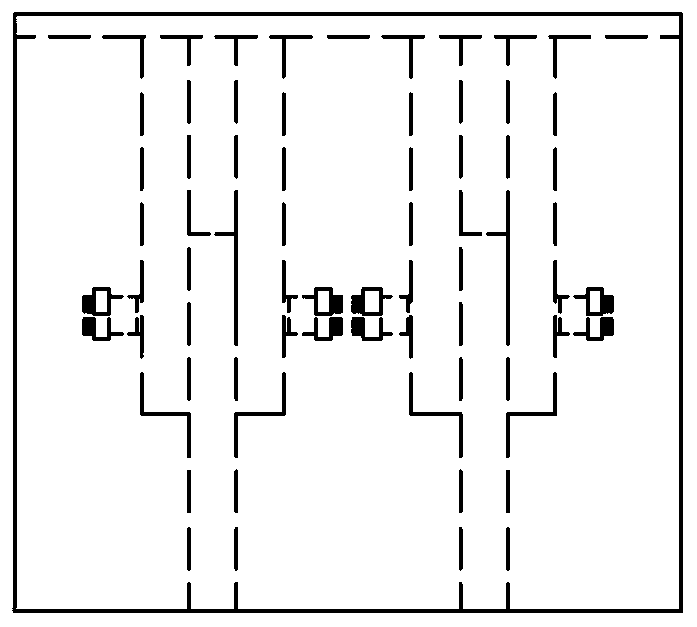

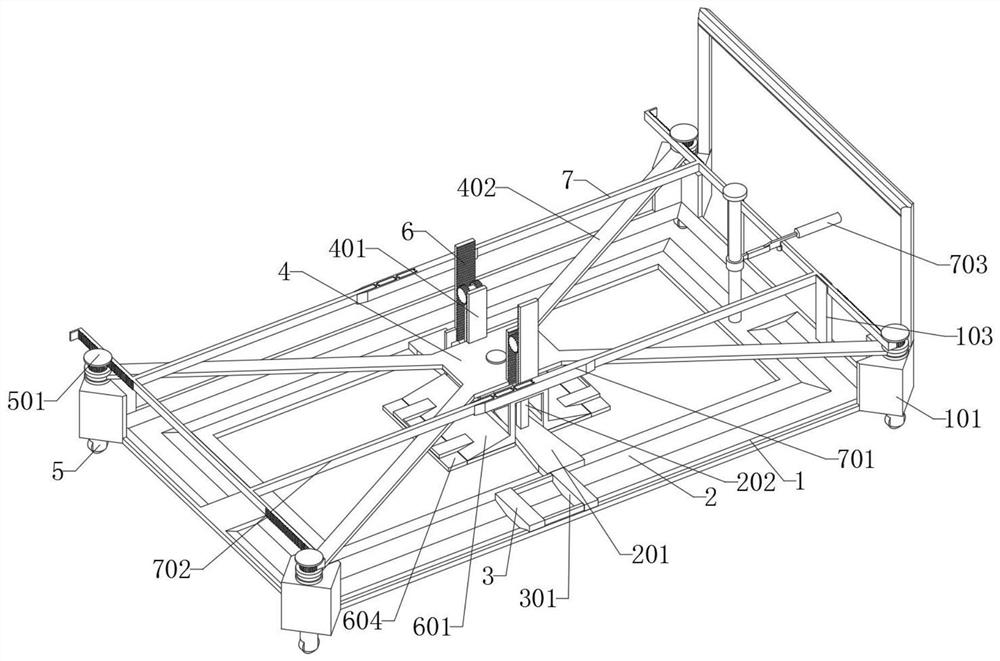

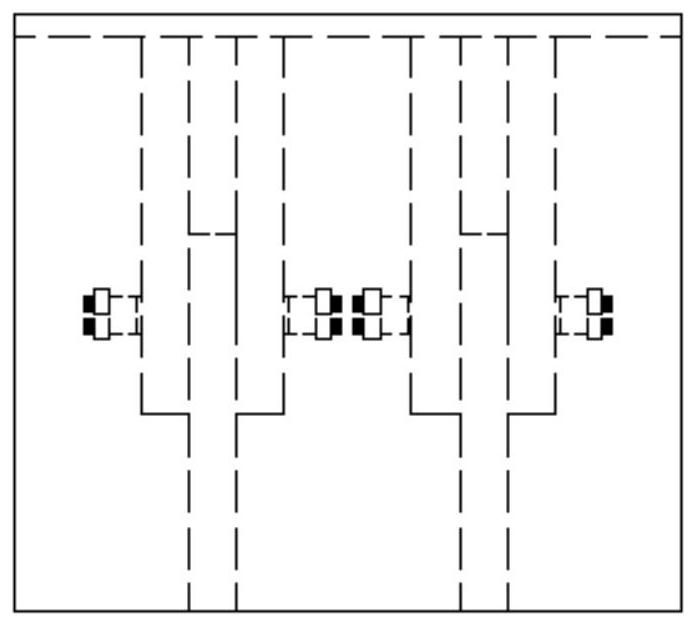

Parking space line control equipment based on convenient and intelligent control adjustment

ActiveCN112962414APlay the role of receiving gear powerNo displacementRoads maintainenceGear wheelControl engineering

The invention provides parking space line control equipment based on convenient and intelligent control adjustment, relates to the technical field of parking space line drawing, and aims to solve problems that when an existing parking space line drawing control device is used, the parking space line drawing control device cannot be automatically contacted and fixed with the ground, displacement cannot be avoided during line drawing, and the edge position of a parking space line cannot be neat. The equipment comprises a main body; the main body is a rectangular frame structure, and the edge of the inner side of the main body is an inclined structure; and the inner part is mounted in the main body. When the equipment needs to be used, an electric cylinder extends to drive a guide rod to retract inwards so that the main body can move downwards, an auxiliary plate can control a gear at the top end of a transmission part to rotate, the gear can be meshed with a gear groove of a limiting part through clamping teeth, and the limiting part can automatically move downwards; and a pressing piece can be in contact with the ground through the contact piece and the bottom of the adjusting plate so that the device does not displace, and the parking space line can be tidier.

Owner:宋明

An automatic oil tank processing production line system and its production and processing technology

ActiveCN108856484BPrecise positioningDisplacement does not occurMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention relates to an oil tank automatic machining production line system and a production machining process thereof. A fixed bottom plate, a supporting device, a forming device and an extrudingdevice are included; a supporting slide groove is arranged on the top of the front end of the fixed bottom plate; an adjusting slide groove is arranged on the middle portion of the fixed bottom plate; the supporting device is installed on the upper end face of the middle portion of the fixed bottom plate; the forming device is located on the outer side of the supporting device, and is installed on the top of the fixed bottom plate; and the bottom of the extruding device is connected with the outer side of the upper end face of the fixed bottom plate. The oil tank automatic machining production line system can solve the problems that accurate positioning cannot be performed on a steel plate when extruding machining is performed on an oil tank bucket body steel ring in the prior art, displacement can happen during steel plate extruding, the steel plate cannot be extruded into different diameters, the hidden danger that the bottom of the steel plate is clamped exists when the steel plateis extruded, rolling cannot be performed on the side face of the steel plate, rolling at the seam position of the steel plate is difficult, and the rolling effect of the top of the steel plate is poor.

Owner:铭宸(唐山)航天电子装备科技有限公司

A kind of manufacturing method of bamboo fiber non-iron shirt

ActiveCN106820277BStrong damageGuaranteed strongDry-cleaning apparatus for textilesShaping/stretching tubular fabricsFiberOxygen

The invention discloses a method for making a bamboo fiber no-ironing shirt. The method comprises the steps that first bamboo fiber fabric is placed into souring and bleaching liquid and is soured and bleached for 30-60min, wherein souring and bleaching temperature is 90-100 DEG C, a liquor ratio is 1: 30-35, the souring and bleaching liquid contains 30% of hydrogen peroxide with concentration being 6-10g / L, sodium silicate with the concentration being 5-10g / L, penetrating agents with the concentration being 5-8g / L, scouring agents with the concentration being 3-5g / L and oxygen bleaching stabilizer with the concentration being 5-8g / L; the bamboo fiber fabric is cleaned and dried after the scouring and bleaching, then the processed bamboo fiber fabric is tailored and sewed and a ready-made garment is obtained; then a no-ironing treatment is carried out on the manufactured garment, wherein according to the no-ironing treatment, bidirectional stereoscopic type atomization resin absorption, pre-drying, medium or high temperature micro-pressure stereoscopic shaping and finishing, washing, drying, cooling and re-shaping are conducted on the garment. The method for making the bamboo fiber no-ironing shirt can effectively improve the crease-resistant property of bamboo fiber and have a better shrink-proof and no-ironing effect, a manufactured shirt has the advantages of being not deformed easily, and not easy to shrink and the shirt is not easily deformed, not easy to shrink and yellowing, stable in size, soft in handle, uniform in color and lustre, and cool and comfortable to wear.

Owner:YUNNAN HAOXIANG CLOTHING CO LTD

A corrugated paper conveyor for flexible sheet packaging

ActiveCN109292165BDisplacement does not occurPositioning doesn't happenWrapper folding/bending apparatusMechanical engineeringEngineering

Owner:ZHEJIANG GUANGYUE ENVIRONMENTAL POLYTRON TECH INC

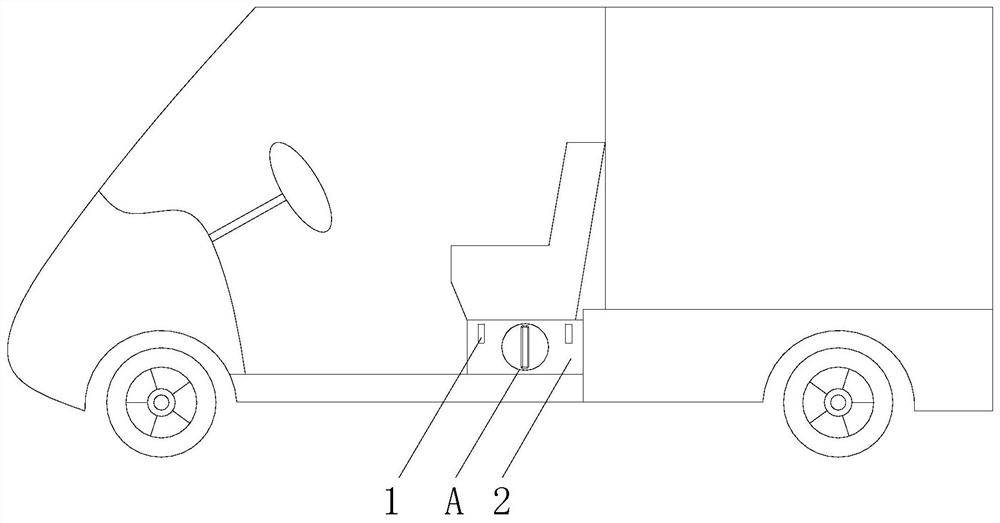

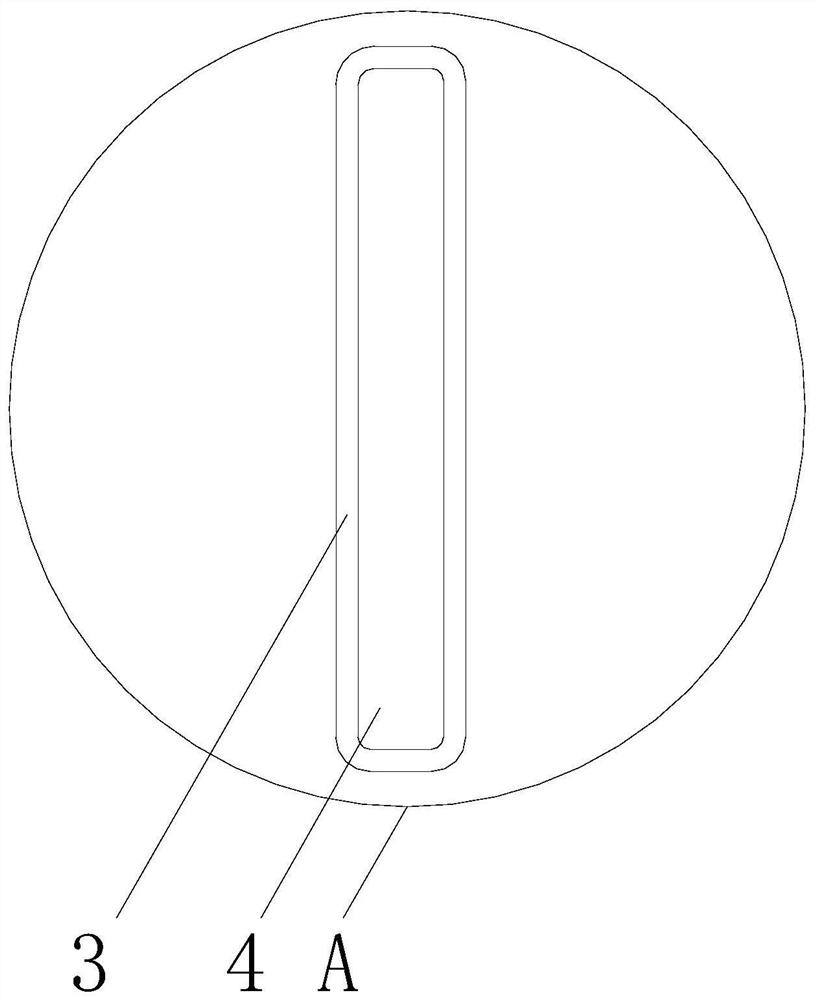

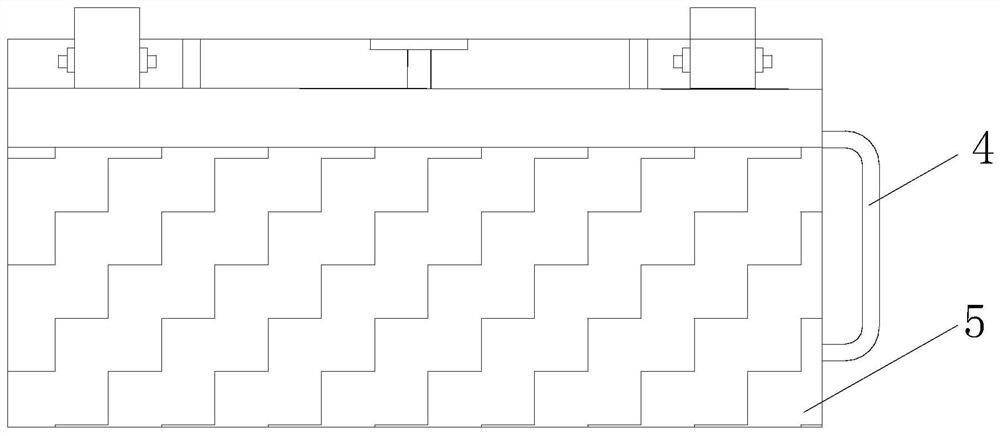

Battery pack quickly replaceable electric fire-fighting truck

The invention discloses a battery pack quickly replaceable electric fire-fighting truck and relates to the technical field of fire-fighting equipment. The battery pack quickly replaceable electric fire-fighting truck comprises a storage box. A first sliding rail and a second sliding rail. Two first sliding blocks spaced by a distance and two second sliding blocks spaced by a distance are slidablyconnected to the inner surfaces of the first sliding rail and the second sliding rail. The first sliding blocks are fixedly connected through a first connecting rod. The second sliding blocks are fixedly connected through a second connecting rod. The first sliding blocks are in threaded connection with the corresponding second sliding blocks are through third connecting rods. The middle portion ofthe surface of one end of the storage box is provided with a fourth screw hole. A second fastener is in threaded connection with the interior of the fourth screw hole. A battery pack body is placed on the tops of the first sliding blocks and the second sliding blocks. The battery pack quickly replaceable electric fire-fighting truck is provided with the first sliding rail, the first sliding blocks, the second sliding rail, the second sliding blocks and the second fastener, the problems that a battery pack cannot be replaced quickly and is prone to displacement are solved.

Owner:泰州市佳洁环保科技有限公司

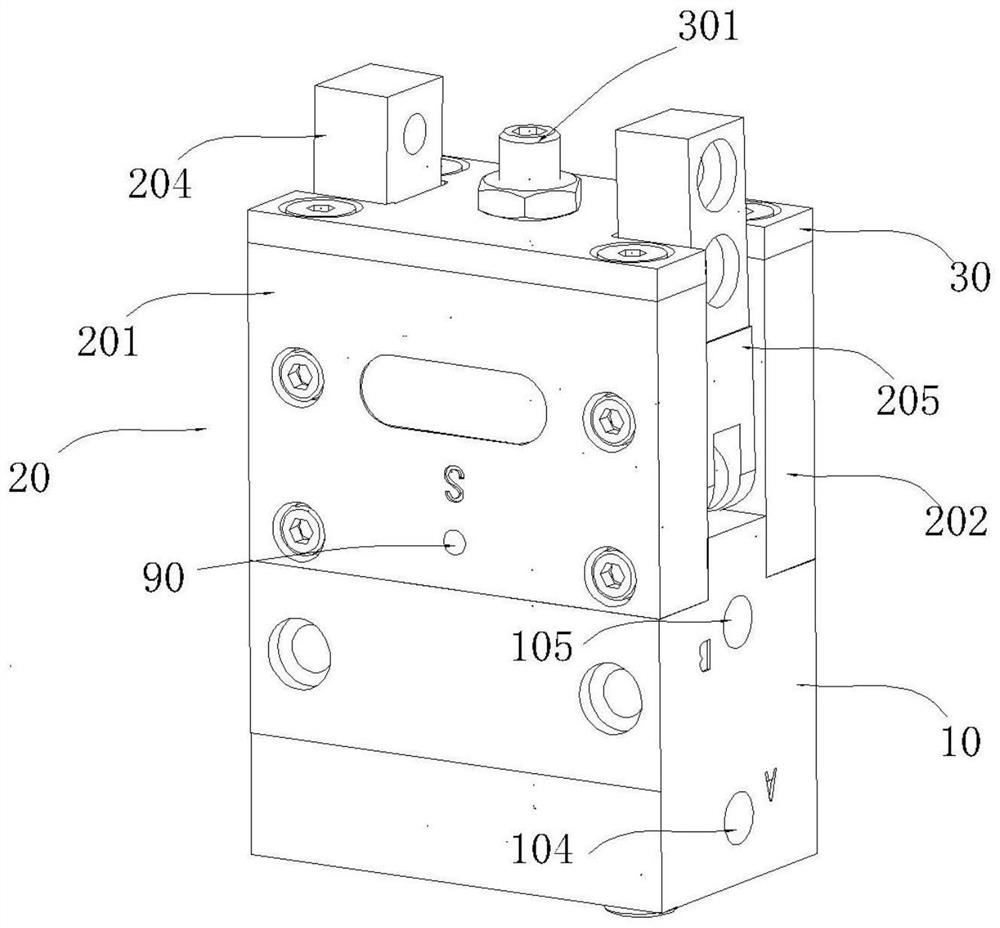

Field angle type manipulator and gas path system thereof

PendingCN114770576AHold tight to achieveNo displacementMetal-working feeding devicesGripping headsSpring forceEngineering

The opening angle type mechanical arm comprises a cylinder body and a finger assembly, a piston and a piston rod are arranged in a movable cavity, an air hole A and an air hole B are formed in the two sides of the cylinder body, the air hole B is formed close to one side of the finger assembly, and the air hole A and the air hole B communicate with the movable cavity; the first mounting plate and the second mounting plate are fixed to the cylinder body and are arranged at a certain distance, a first finger and a second finger are arranged on the two sides of the mounting cavity, connecting rods are hinged to the bottoms of the first finger and the second finger, and a piston rod connector is arranged between the connecting rods; a sealing plate is further arranged between the first mounting plate and the second mounting plate, and a spring is arranged between the sealing plate and the piston rod connector. The device solves the problem of grabbing a workpiece in the hot punching process, simulates the flexible clamping of the continuously deformed workpiece in the punching process manually through spring force and gas circuit control, can avoid displacement in the punching process, and improves the punching efficiency through spring force and gas circuit control. And manual flexible clamping on the continuously-deformed workpiece in the stamping process is simulated, so that the workpiece can be prevented from displacement in the stamping process.

Owner:浙江森扬气动有限公司

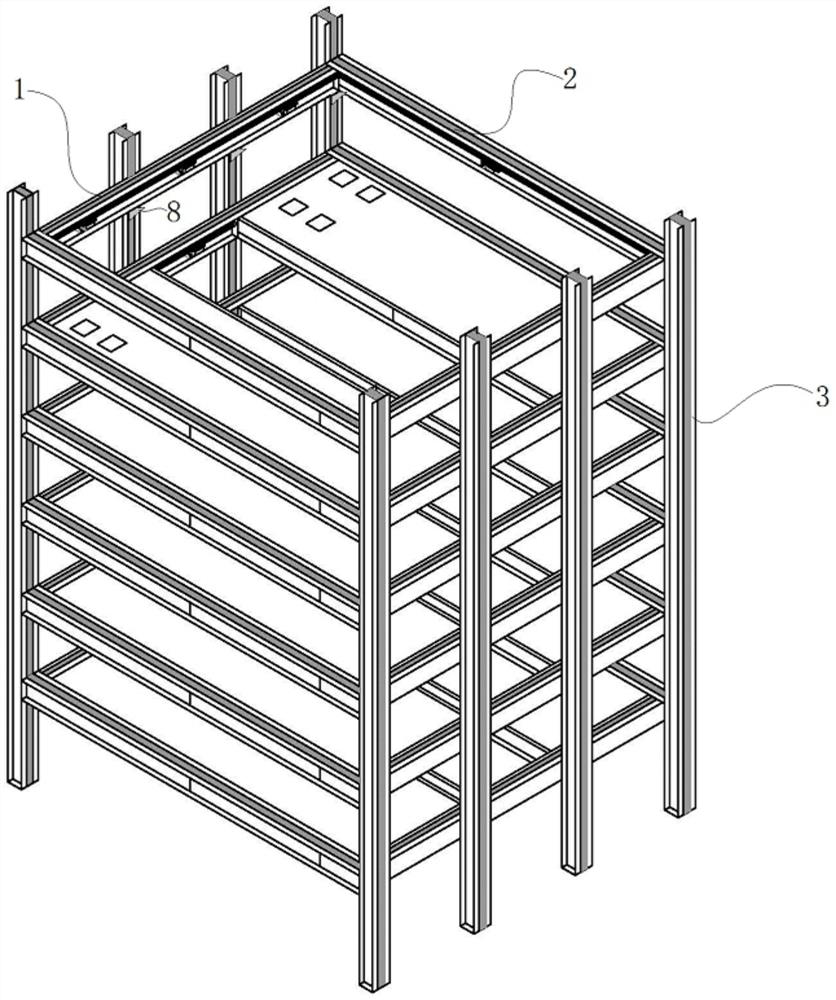

Three-dimensional intelligent garage with big data safety early warning and fire-fighting disposal

PendingCN113107244AImprove structural rigidityImprove structural stabilityFire rescueFire alarm electric actuationEarly warning systemArchitectural engineering

The invention discloses a three-dimensional intelligent garage with big data safety early warning and fire-fighting disposal. The three-dimensional intelligent garage comprises a longitudinal steel frame and a transverse steel frame with a variable cross-section rigid structure and further comprises a vertical steel frame with a uniform cross-section rigid structure, the longitudinal steel frame and the transverse steel frame are internally provided with fire-fighting disposal systems, the vertical steel frame is internally provided with a safety early warning system, the defects that in the prior art, the three-dimensional intelligent garage is high in land cost and limited in space are overcome, and the space utilization rate is increased; after the integral three-dimensional intelligent garage rigid frame structure is built, concrete is poured into the integral three-dimensional intelligent garage rigid frame structure, so that the mounting efficiency is improved, and the integral rigidity, stability and safety are improved; a top plate, a bottom plate, two webs and a middle plate form the variable cross-section rigid structure, the rigidity and the stability of the rigid frame structure are improved, the first open-web section, the variable cross-section section, the fire fighting section and the track section are sequentially defined by the top plate, the bottom plate, the two webs and the middle plate from left to right, and the overall space utilization rate is increased; and thick sections, thin sections and gradient gradually-changing sections are prefabricated through the spatially-intersected intersecting faces, and the overall frame is optimal in performance.

Owner:SHENZHEN BRIDGE DOCTOR DESIGN & RES INSTITUDE CO LTD +1

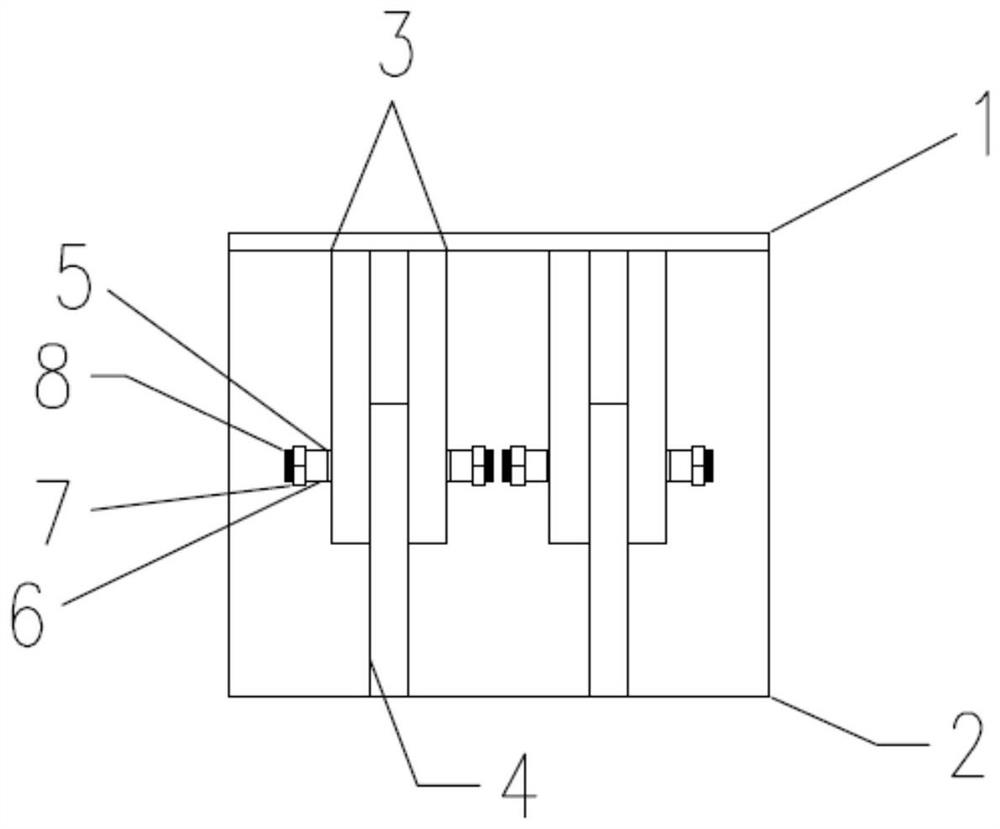

A steel plate positioning extrusion processing die and its processing technology

The invention relates to a steel plate positioning and extruding mold and a processing technology thereof. The steel plate positioning and extruding mold comprises a fixed bottom plate, a supporting device and a forming device, a supporting sliding groove is formed in the top of the front end of the fixed bottom plate, an adjusting sliding groove is formed in the middle of the fixed bottom plate,the supporting device is mounted on the upper end surface of the middle of the fixed bottom plate, the forming device is positioned on the outer side of the supporting device and mounted at the top ofthe fixed bottom plate, and the supporting device comprises a supporting lug seat, a bottom supporting wheel, a limit mechanism, a side supporting mechanism, a positioning mechanism, a return connecting spanner, a return pushing rod and a return pushing frame. The mold can solves the problems that when an existing oil tank cylinder steel ring is extruded, a steel plate cannot be accurately positioned and can displace when being extruded, the steel plate cannot be extruded into different diameters, the bottom of the steel plate is possibly clamped when the steel plate is extruded and the like.

Owner:烟台安信机电科技有限公司

Aluminum-plastic film packaging rolling machine for soft-pack lithium battery and rolling method for aluminum-plastic film packaging

ActiveCN109216593BDisplacement does not occurAvoid misalignmentFinal product manufactureSmall-sized cells cases/jacketsPlastic filmMaterials science

The invention relates to a rolling machine for aluminum-plastic film packaging of soft-pack lithium batteries and a rolling method for aluminum-plastic film packaging, including a supporting base plate, a placing frame, a pressing branch chain and a flattening device. The upper end surface of the middle part of the supporting base plate A placing frame is installed on the top, and a square groove is arranged on the right end and rear side of the placing frame. A pressing branch chain is installed on the front and rear ends of the supporting base plate, and the pressing branch chain is located outside the placing frame, and the leveling device is installed on the placing frame. on the top of the left end; the leveling device includes a leveling support plate, a leveling position push rod, a leveling bracket, a leveling adjustment plate, a leveling sliding column, a height pusher, a smoothing plate, a positive position mechanism and a rolling mechanism. The present invention can solve the problem that the existing aluminum-plastic film on the outer packaging of the soft-packed lithium battery is folded and packaged. After the aluminum-plastic film is folded, it is automatically rolled and scraped to equalize the problem.

Owner:上海凯矜新材料科技有限公司

A prefabricated frame intelligent shock-absorbing structure

ActiveCN111236424BPrevent rotationChange static friction in real timeBuilding constructionsCeramicShock absorber

A prefabricated frame intelligent damping structure, including prefabricated beams and prefabricated columns, the prefabricated beams and prefabricated columns are connected by a hinged structure, and an intelligent damping device for beam-column joints is installed under the hinged structure; the intelligent damping device for beam-column joints includes The first pre-embedded body and the second pre-embedded body, one end of the first pre-embedded body is hingedly connected with one end of the second pre-embedded body, two first fan-shaped steel plates are arranged inside the first pre-embedded body; the second pre-embedded body A second fan-shaped steel plate is arranged on the inner side, and the second fan-shaped steel plate is arranged between two first fan-shaped steel plates; first high-strength bolts are arranged on the second fan-shaped steel plate; piezoelectric ceramics are arranged on one side of the first high-strength bolts, The electroceramic is connected with a controller. In the present invention, the controller adjusts the applied voltage of piezoelectric ceramics under different earthquake loads, thereby adjusting the rotational friction force and sliding friction force in the core area, so as to achieve the purpose of self-adaptive response of the whole structure to the earthquake, and realize the real-time change under the action of small and medium earthquakes. Frictional shear.

Owner:CHANGAN UNIV

Cabinet hardware handle forming, manufacturing and machining machine

PendingCN113231237AImprove applicabilityImprove work efficiencyPretreated surfacesCoatingsEmbedded systemManufacturing engineering

The invention relates to a cabinet hardware handle forming, manufacturing and machining machine. The machine comprises a workbench, a fixing device and a moving device, wherein the top of the workbench is provided with the fixing device, and the top of the fixing device is provided with the moving device. According to the machine, the workbench, the fixing device and the moving device are matched, firstly, the fixing device is adjusted according to different intervals of holes of the cabinet hardware handles, so that the applicability of the machine is enhanced when the cabinet hardware handles are clamped and limited; the multiple sets of cabinet hardware handles are clamped and fixed at the same time through the arranged fixing device, so that the working efficiency of forming and manufacturing the cabinet hardware handles by the machine is greatly improved; and after the cabinet hardware handles are clamped and fixed through the fixing device, the formed and manufactured cabinet hardware handles are quickly air-dried through the arranged moving device, so that the working efficiency is improved when the cabinet hardware handles are formed and manufactured.

Owner:陈鑫

A fixture for laser printing of integrated circuit chips

InactiveCN109108480BEasy to fixAchieve displacementLaser beam welding apparatusElectric machineryEngineering

Owner:江苏清联光电技术研究院有限公司

A ceramic tile cutting device for construction engineering

ActiveCN108214946BDisplacement does not occurSo as not to damageWorking accessoriesStone-like material working toolsUltrasonic sensorArchitectural engineering

Owner:中国机械工业第五建设有限公司

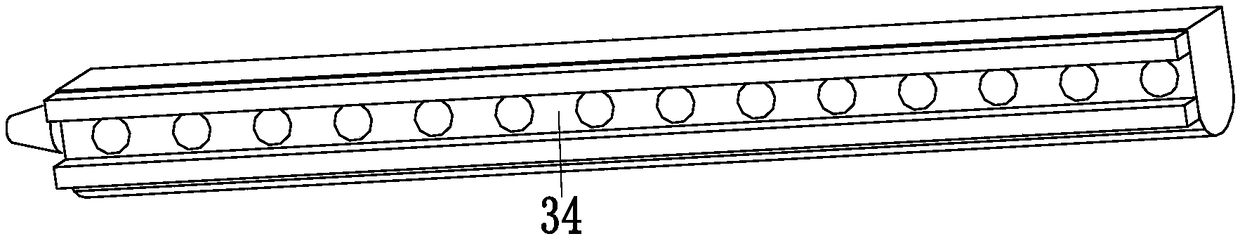

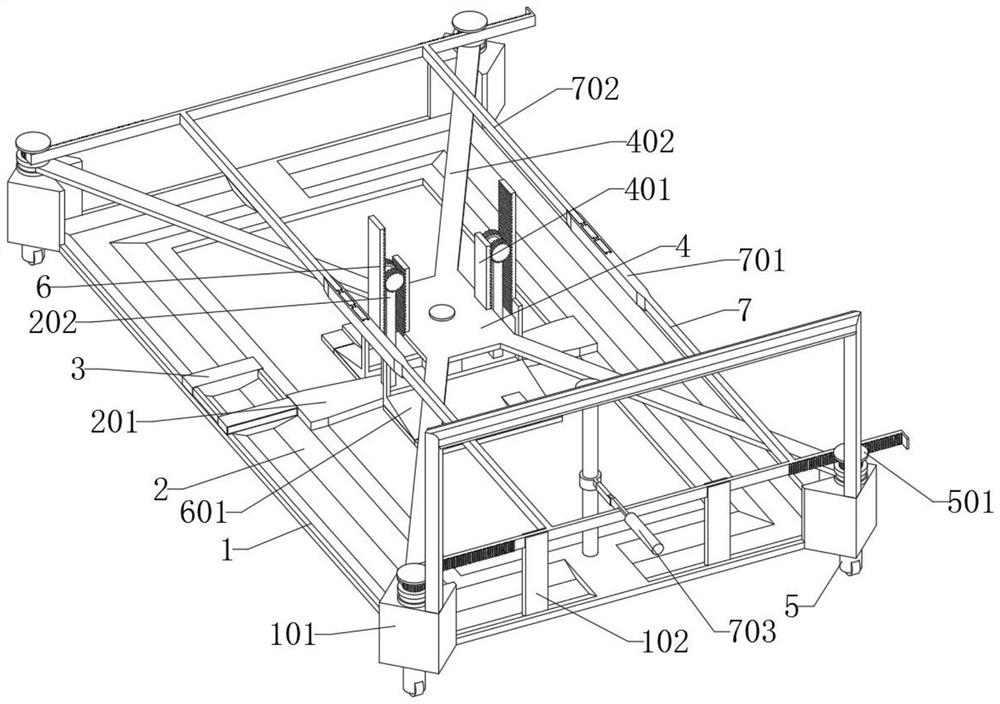

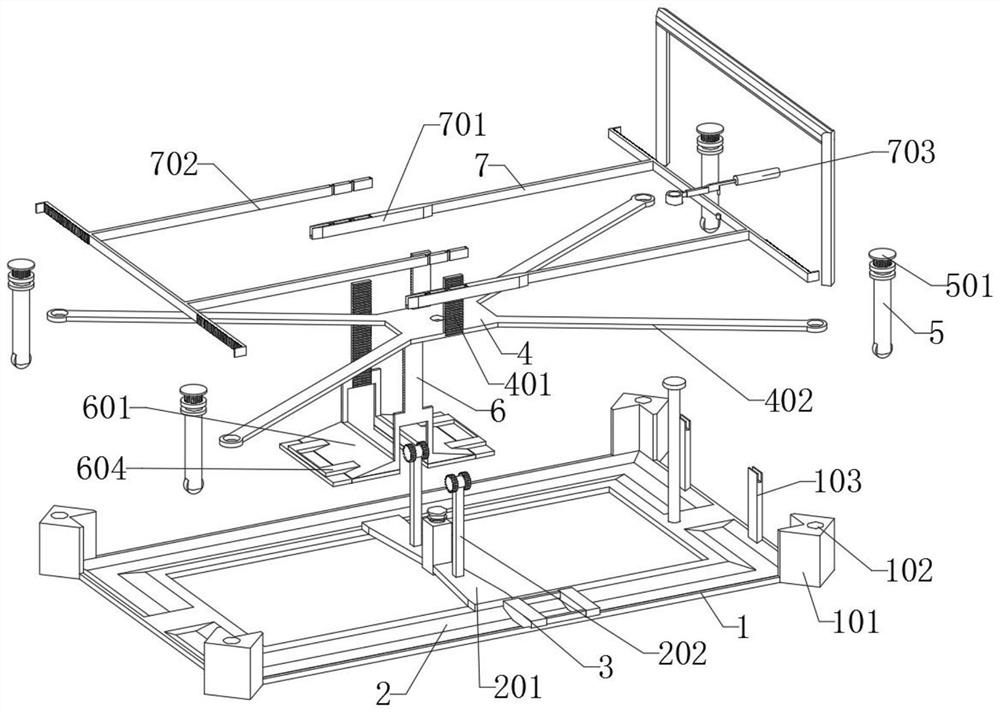

An automated multifunctional assembly platform in the field of prefabricated buildings

InactiveCN111962880BGuaranteed uptimeDisplacement does not occurBuilding material handlingAutomatic controlThreaded pipe

An automatic multi-functional assembly platform in the field of prefabricated construction, comprising a number of equidistantly spaced vertical external threaded pipes and a platform trolley. The top surface of the externally threaded pipe is rotatably connected with connecting blocks, the connecting blocks on the same side are fixedly connected by brackets, and the left-right symmetrical connecting blocks are fixedly connected by two horizontal first beams, and the first beams are all set The first electric car. Through automatic control, the present invention can improve the installation accuracy of the prefabricated building, make the installation more stable, and at the same time, it can adjust the angle of the prefabricated installation at different angles, making it more widely applicable. The threaded pipe can reduce the moving distance of the prefabricated parts on the building, and can be moved early on the ground, which greatly improves the work efficiency and is suitable for large-scale promotion.

Owner:广州中穗建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com